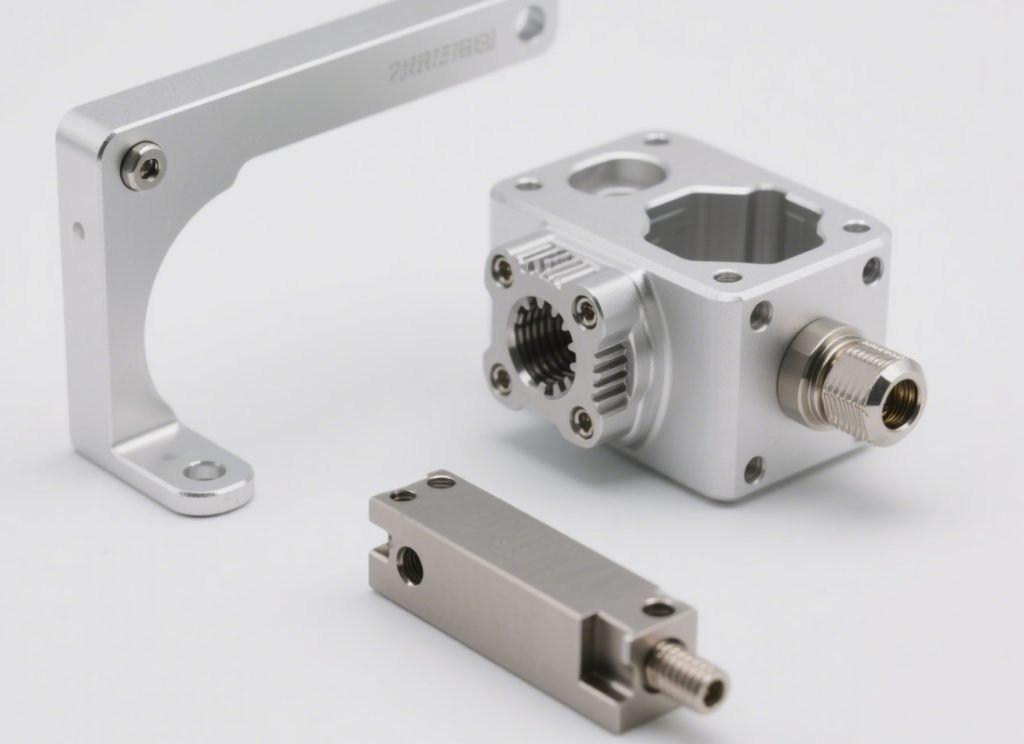

Aluminum Machining Services

Aluminum CNC machining is one of the most versatile and cost-effective manufacturing techniques available today. With its exceptional machinability, lightweight properties, and excellent strength-to-weight ratio, aluminum has become the material of choice for countless precision components across industries.

Various Options

Functionality

Cost-effectiveness

| Specification | Capability | Notes |

| Dimensional Tolerance | ±0.001 in (0.025 mm) | Tighter tolerances possible for specific applications |

| Surface Roughness | Ra 0.8–3.2 μm | Smoother finishes achievable with polishing |

| Maximum Part Size | 60″ x 40″ x 20″ | Varies by equipment capabilities |

| Minimum Wall Thickness | 0.020″ (0.5 mm) | Depends on part geometry and alloy |

| Minimum Hole Diameter | 0.020″ (0.5 mm) | Aspect ratio considerations apply |

| Thread Size Range | M1.6 to M36 | Standard and custom threading available |

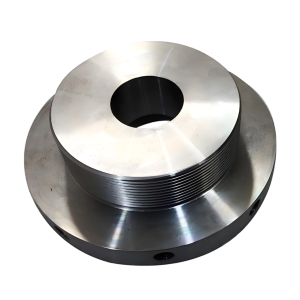

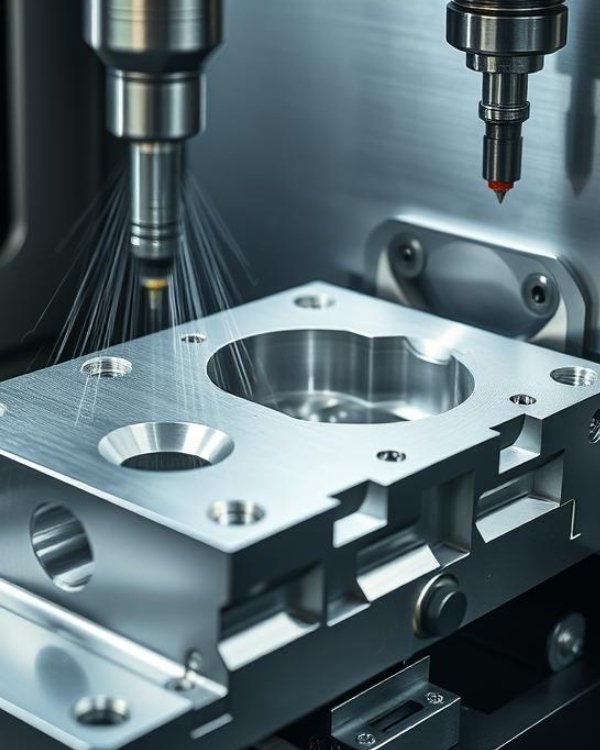

CNC Machining of Aluminum

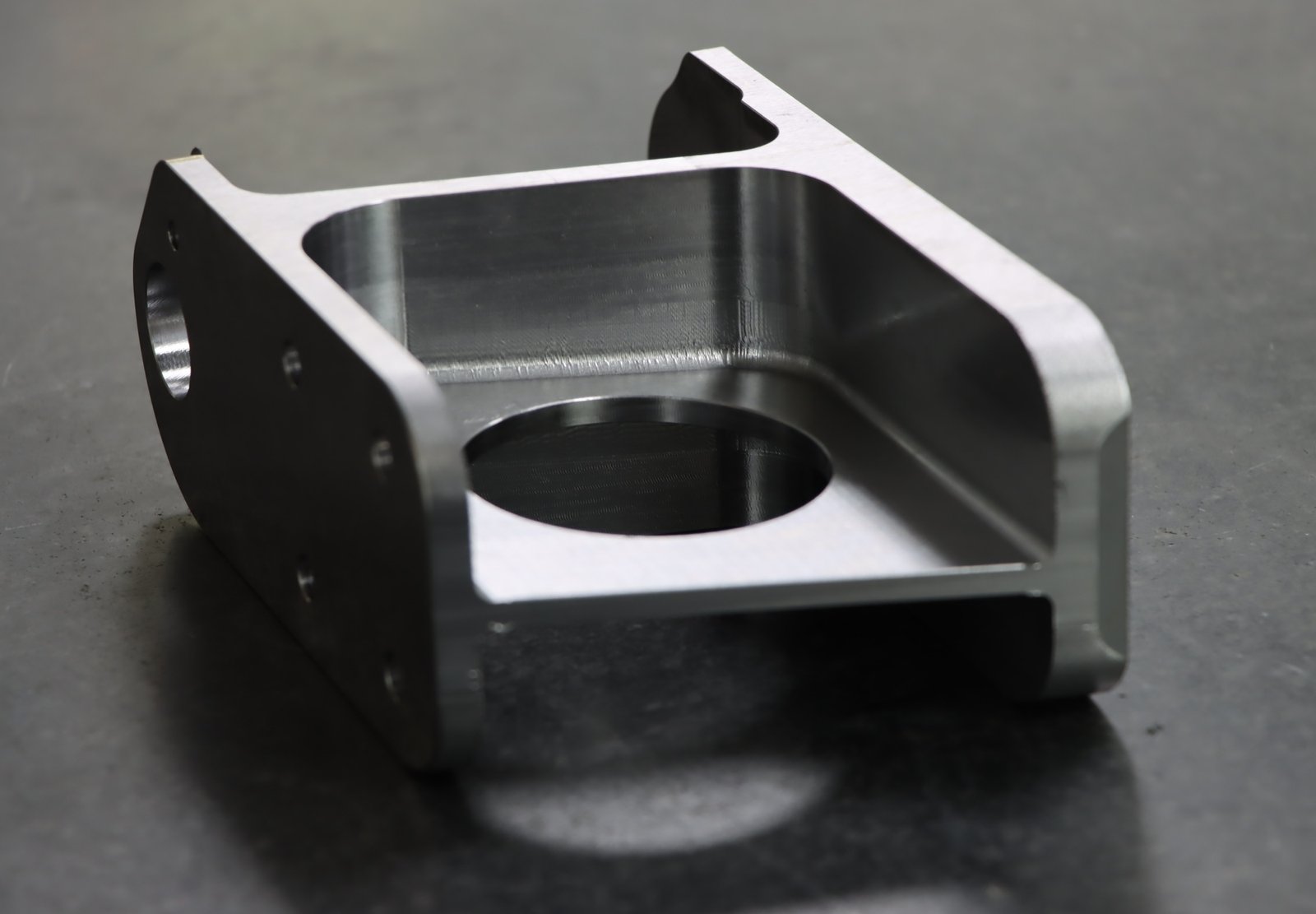

Aluminum is highly machinable and can be processed three to four times faster than steel or titanium. This efficiency, combined with aluminum's natural properties, makes it ideal for applications requiring lightweight yet durable components with complex geometries.

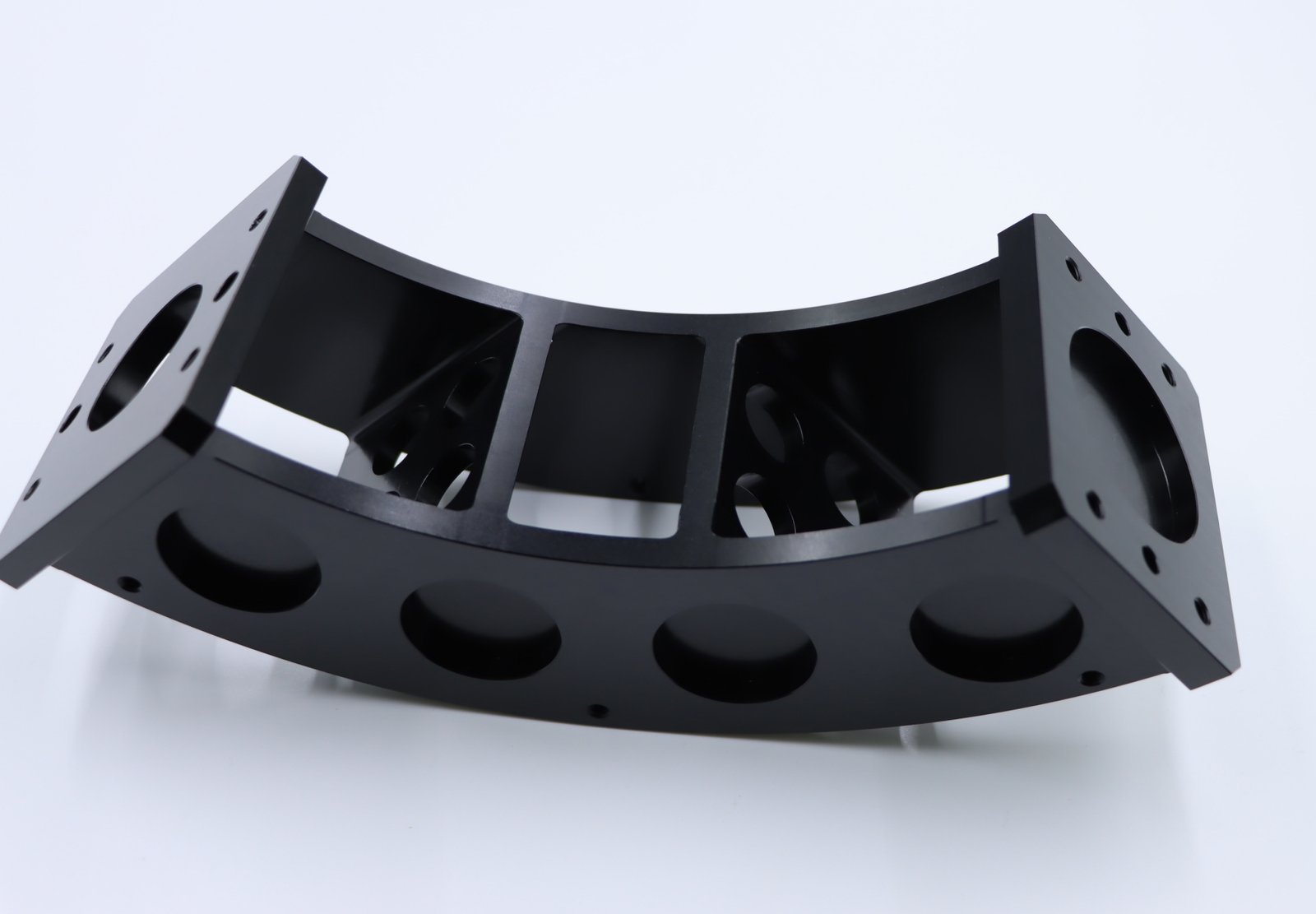

CNC machining centers used for aluminum processing range from 3-axis to 5-axis configurations, with the latter enabling complex geometries and undercuts in a single setup. This multi-axis capability is particularly valuable for aerospace and automotive components where intricate features and weight reduction are critical.

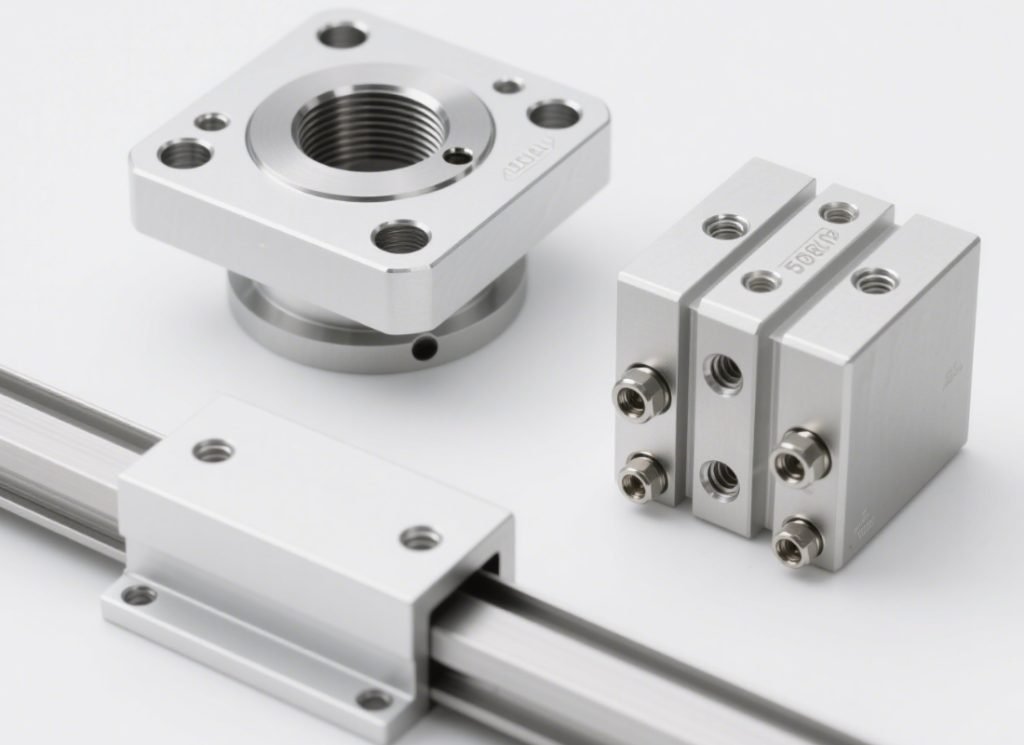

Machining Capabilities

- CNC milling – using rotating cutting tools to remove material

- CNC turning – rotating the workpiece against stationary cutting tools

- Drilling – creating precise holes in aluminum components

- Tapping – cutting threads into holes for fasteners

- Surface finishing – achieving desired texture and appearance

Speak With Our Engineering Team

Discuss your specific application needs with our CNC machining specialists.

Strengths and Limitations of Aluminum for CNC Machining

Advantages of Aluminum Machining

- Excellent machinability – Cuts 3-4 times faster than steel

- Lightweight – 2.7 g/cm³ (about 1/3 the weight of steel)

- High strength-to-weight ratio – Ideal for aerospace and automotive

- Corrosion resistance – Natural oxide layer provides protection

- Thermal conductivity – Excellent heat dissipation properties

- Electrical conductivity – Good for electrical components

- 100% recyclable – Environmentally friendly material

- Cost-effective – Lower machining costs than many metals

Aluminum vs. Steel

When comparing aluminum to steel for machining applications, aluminum offers significant advantages in terms of processing speed and tool life. While steel provides greater strength and durability, aluminum's lightweight properties and excellent machinability make it the preferred choice for many applications where weight reduction is critical.

Limitations of Aluminum Machining

- Lower hardness – Less wear-resistant than steel

- Heat sensitivity – Can melt and stick to cutting tools

- Chip management – Long chips can tangle and cause issues

- Galling tendency – Can stick to cutting tools without proper lubrication

- Lower fatigue strength – Compared to steel and titanium

- Welding challenges – Some alloys are difficult to weld

- Thermal expansion – Higher than steel, affecting precision

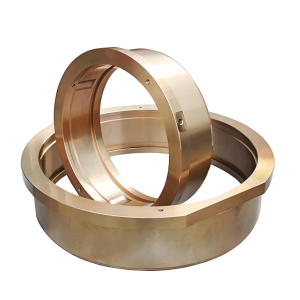

Popular Aluminum Alloys for CNC Machining

The selection of the right aluminum alloy is crucial for ensuring optimal performance in specific applications.

Each alloy offers unique properties in terms of strength, machinability, corrosion resistance, and cost-effectiveness.

Aluminum

1000 Series

(Pure Aluminum)

- Core Characteristics: ≥99% aluminum content; excellent corrosion resistance, high thermal/electrical conductivity, good ductility; low strength (no heat treatability).

- Common Applications: Electrical conductors, heat exchangers, chemical tanks, food packaging (foils), decorative trim.

Grade

Tensile Strength (MPa)

Yield Strength (MPa)

Fatigue Strength (MPa)

Hardness (Brinell)

Elongation at Break (%)

Density (g/cm³)

Maximum Temp (°C)

1050

70–90

30–50

~35

15–20

20–30

2.71

120

1060

70–95

30–55

~35

15–22

20–35

2.71

120

1100

75–100

35–60

~40

18–23

15–30

2.71

120

Aluminum

2000 Series

(Al-Cu Alloys)

- Core Characteristics: Copper as main alloying element; high strength (heat-treatable, peak strength in T6 temper); poor corrosion resistance (needs surface treatment like anodizing).

- Common Applications: Aerospace components (fuselages, wings), high-strength structural parts, truck frames.

Grade

Tensile Strength (MPa)

Yield Strength (MPa)

Fatigue Strength (MPa)

Hardness (Brinell)

Elongation at Break (%)

Density (g/cm³)

Maximum Temp (°C)

2011

290–370 (T6)

170–260 (T6)

~100 (T6)

80–100 (T6)

20–30

2.80

150

2024

470–520 (T6)

325–380 (T6)

~145 (T6)

120–140 (T6)

20–35

2.78

150

2017

380–420 (T6)

275–310 (T6)

~120 (T6)

100–115 (T6)

15–30

2.79

150

Aluminum

3000 Series

(Al-Mn Alloys)

- Core Characteristics: Manganese as main alloying element; moderate strength (non-heat-treatable, strengthened by cold working); good corrosion resistance and formability.

- Common Applications: Cookware, beverage cans (sidewalls), heat sinks, architectural trim.

Grade

Tensile Strength (MPa)

Yield Strength (MPa)

Fatigue Strength (MPa)

Hardness (Brinell)

Elongation at Break (%)

Density (g/cm³)

Maximum Temp (°C)

3003

110–160 (H14)

40–110 (H14)

~50 (H14)

30–45 (H14)

12–20 (H14)

2.73

120

3004

140–210 (H16)

65–140 (H16)

~65 (H16)

40–60 (H16)

8–15 (H16)

2.73

120

3105

120–170 (H14)

50–120 (H14)

~55 (H14)

35–50 (H14)

15–25 (H14)

2.73

120

Aluminum

4000 Series

(Al-Si Alloys)

- Core Characteristics: Low melting point (ideal for brazing/welding); medium strength (non-heat-treatable); good fluidity in molten state; moderate corrosion resistance; primarily used as filler metals (welding rods/wires).

- Common Applications: Welding consumables (for joining aluminum alloys), heat exchangers, automotive cylinder heads.

Grade

Tensile Strength (MPa)

Yield Strength (MPa)

Fatigue Strength (MPa)

Hardness (Brinell)

Elongation at Break (%)

Density (g/cm³)

Maximum Temp (°C)

4043

170–210 (T6)

100–130 (T6)

~65 (T6)

45–55 (T6)

12–20 (T6)

2.69

160

4047

150–190 (T6)

90–120 (T6)

~60 (T6)

40–50 (T6)

10–18 (T6)

2.68

160

4A01

180–220 (T6)

110–140 (T6)

~70 (T6)

50–60 (T6)

10–15 (T6)

2.70

160

Aluminum

5000 Series

(Al-Mg Alloys)

- Core Characteristics: Magnesium as main alloying element; high strength-to-weight ratio (non-heat-treatable); excellent corrosion resistance (especially in marine environments) and weldability.

- Common Applications: Marine structures (hulls, decks), automotive body panels, pressure vessels, offshore components.

Grade

Tensile Strength (MPa)

Yield Strength (MPa)

Fatigue Strength (MPa)

Hardness (Brinell)

Elongation at Break (%)

Density (g/cm³)

Maximum Temp (°C)

5052

210–290 (H34)

100–210 (H34)

~90 (H34)

60–80 (H34)

10–18 (H34)

2.68

150

5083

310–380 (H116)

190–270 (H116)

~125 (H116)

85–105 (H116)

15–25 (H116)

2.66

120

5754

180–250 (H24)

80–160 (H24)

~80 (H24)

50–70 (H24)

15–25 (H24)

2.68

150

Aluminum

6000 Series

(Al-Mg-Si Alloys)

- Core Characteristics: Mg-Si as main alloying elements; balanced strength/formability (heat-treatable); good corrosion resistance and weldability.

- Common Applications: Architectural extrusions (window frames, doors), automotive parts (wheels, bumpers), structural frames.

Grade

Tensile Strength (MPa)

Yield Strength (MPa)

Fatigue Strength (MPa)

Hardness (Brinell)

Elongation at Break (%)

Density (g/cm³)

Maximum Temp (°C)

6061

310–380 (T6)

275–310 (T6)

~110 (T6)

95–110 (T6)

10–15 (T6)

2.7

150

6063

170–240 (T5)

110–200 (T5)

~70 (T5)

50–70 (T5)

15–25 (T5)

2.7

150

6082

180–250 (H24)

250–300 (T6)

~120 (T6)

90–110 (T6)

8–12 (T6)

2.7

150

Aluminum

7000 Series

(Al-Zn-Mg Alloys)

- Core Characteristics: Zinc as main alloying element (often with Mg/Cu); highest strength among aluminum alloys (heat-treatable); good fatigue resistance; moderate corrosion resistance (needs surface protection).

- Common Applications: Aerospace (landing gear, aircraft spars), high-performance sports equipment (bike frames, ski poles), military components.

Grade

Tensile Strength (MPa)

Yield Strength (MPa)

Fatigue Strength (MPa)

Hardness (Brinell)

Elongation at Break (%)

Density (g/cm³)

Maximum Temp (°C)

7075

570–650 (T6)

500–570 (T6)

~160 (T6)

150–170 (T6)

5–8 (T6)

2.81

120

7050

510–580 (T7451)

450–530 (T7451)

~150 (T7451)

135–155 (T7451)

7–11 (T7451)

2.80

150

7005

350–400 (T6)

290–340 (T6)

~130 (T6)

100–120 (T6)

10–15 (T6)

2.79

120

Aluminum

8000 Series

(Specialty Alloys)

- Core Characteristics: Specialized properties (varies by alloying elementl like lithium, iron, tin, etc.): e.g., lithium reduces density; iron improves wear resistance; customized for niche industries; limited commercial availability.

- Common Applications: High-performance aerospace parts (lithium-containing alloys), food packaging foils, battery tabs.

Grade

Tensile Strength (MPa)

Yield Strength (MPa)

Fatigue Strength (MPa)

Hardness (Brinell)

Elongation at Break (%)

Density (g/cm³)

Maximum Temp (°C)

8011

190–220 (H18)

150–180 (H18)

~160 (T6)

55–65 (H18)

3–8 (H18)

2.71

130

8090

450–510 (T6)

380–450 (T6)

~140 (T6)

120–140 (T6)

5–9 (T6)

2.55

150

8176

280–330 (T6)

200–250 (T6)

~95 (T6)

75–90 (T6)

8–12 (T6)

2.7

140

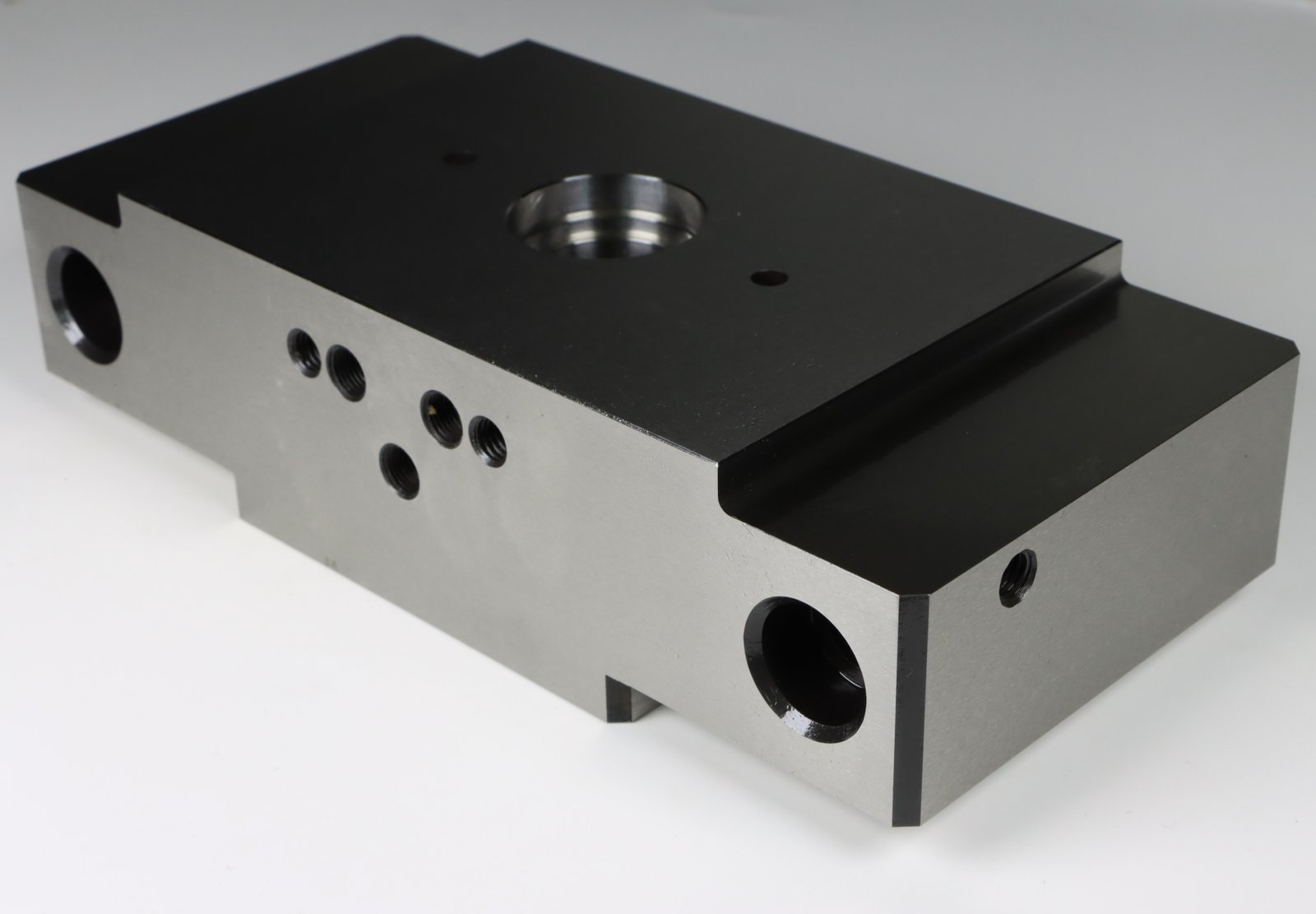

Surface Finish Options for Aluminum Machining

The surface finish of aluminum machined parts significantly impacts both aesthetics and functionality.

Various finishing options can enhance corrosion resistance, wear properties, electrical conductivity, and visual appeal.

Mechanical Finishes

These processes alter the surface texture through physical means:

- Polishing – Creates a mirror-like reflective surface

- Bead Blasting – Produces a uniform matte finish

- Brushing – Creates a directional, lined appearance

- Tumbling – Smooths edges and creates a consistent finish

Mechanical finishes can be applied before other treatments like anodizing for enhanced results.

Chemical Finishes

Chemical processes that modify the aluminum surface:

- Chemical Film (Alodine/Chromate) – Thin conversion coating for corrosion protection

- Passivation – Removes free iron from the surface

- Etching – Creates a matte finish by controlled chemical attack

Chemical finishes are often used as pre-treatments before painting or as standalone protective layers.

Applied Coatings

Additional materials applied to the aluminum surface:

- Powder Coating – Durable, thick coating available in many colors

- Wet Painting – Versatile finish with unlimited color options

- Clear Coating – Transparent protection that preserves appearance

- PTFE/Teflon Coating – Low friction surface for moving parts

Applied coatings offer the widest range of appearance options and specialized properties.

Anodizing

Create a durable, corrosion-resistant oxide layer on the aluminum surface:

- Type I (Chromic Acid) – Thin coating (0.00005″-0.0001″), excellent corrosion resistance

- Type II (Sulfuric Acid) – Medium coating (0.0002″-0.001″), decorative and functional

- Type III (Hard Anodizing) – Thick coating (0.001″-0.004″), excellent wear resistance

It can be done in various colors, popular for both functional and aesthetic applications.

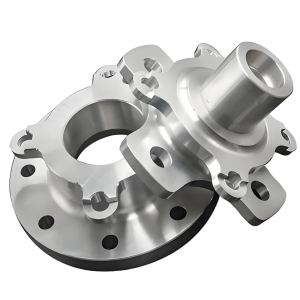

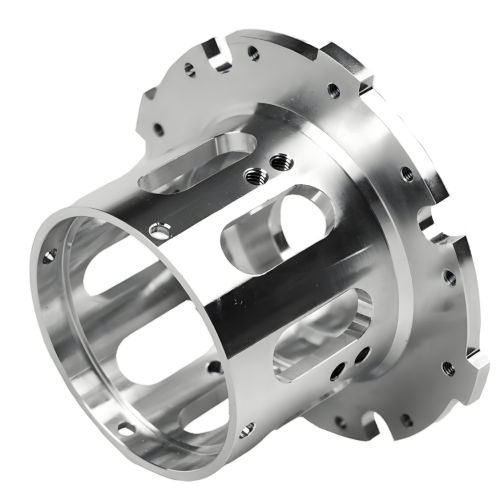

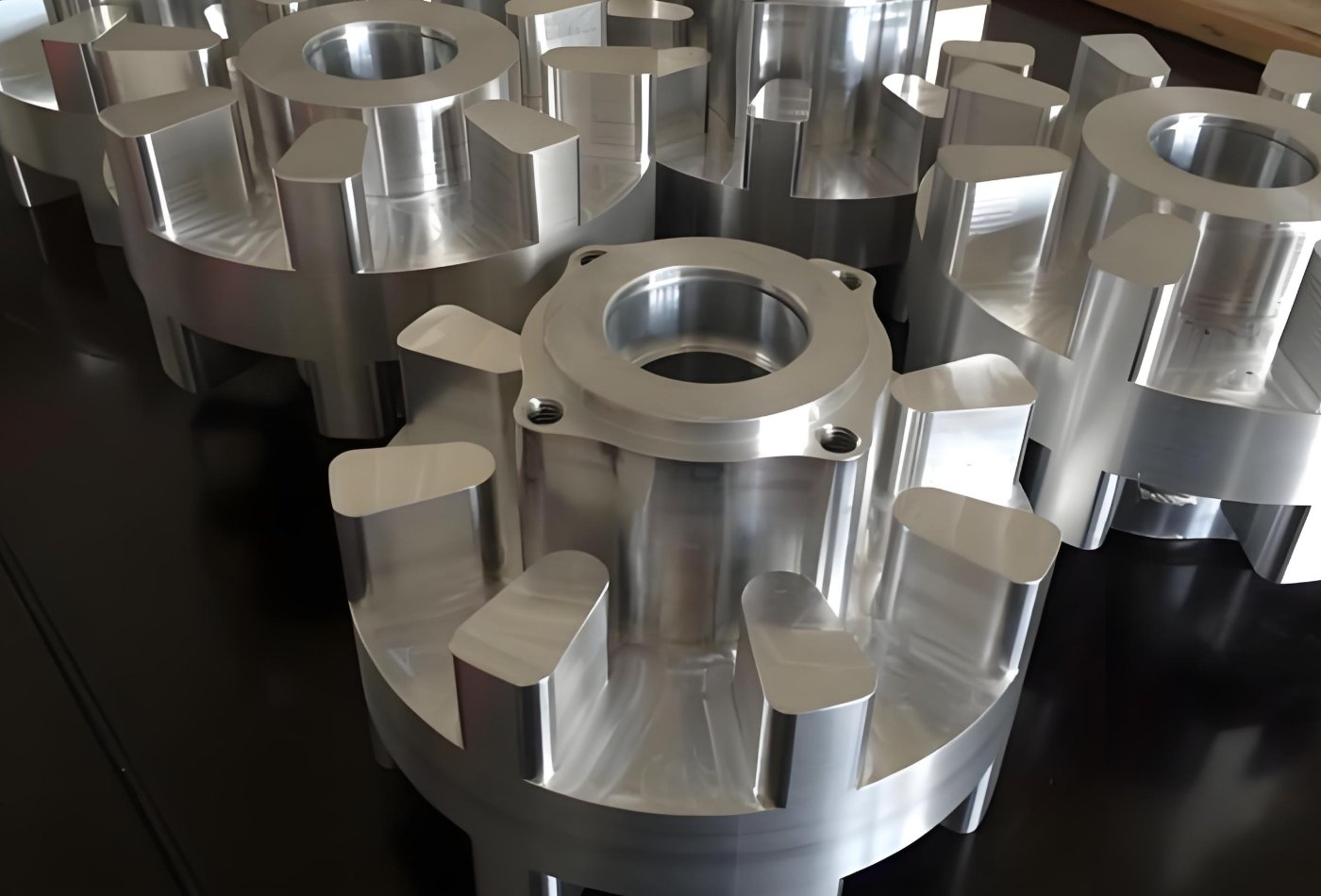

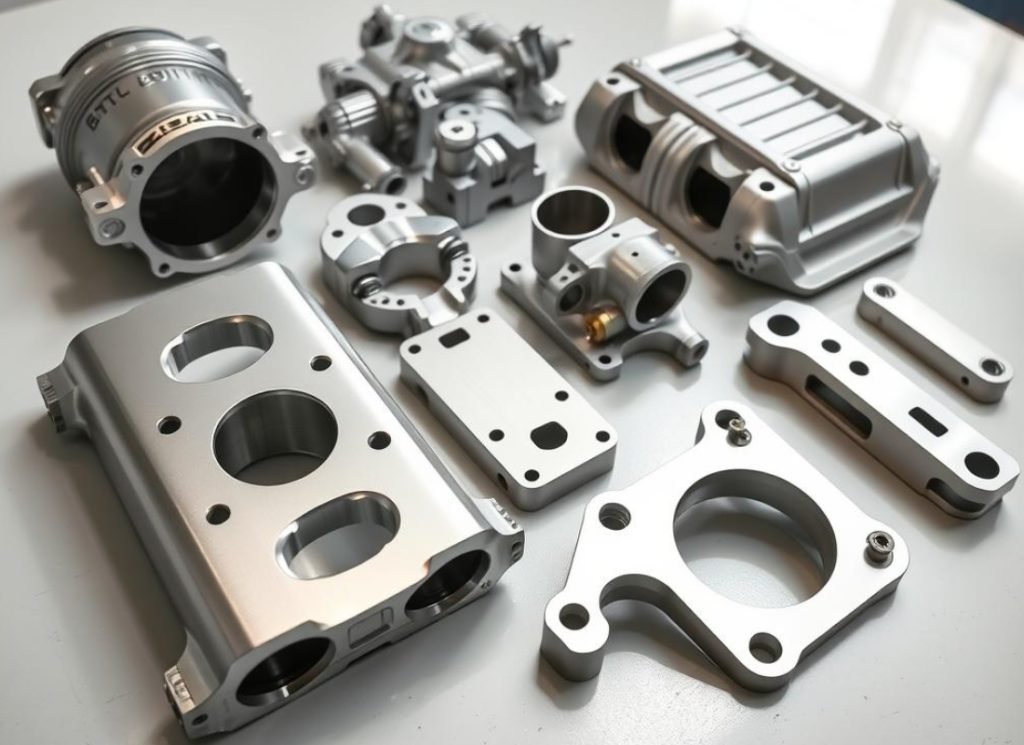

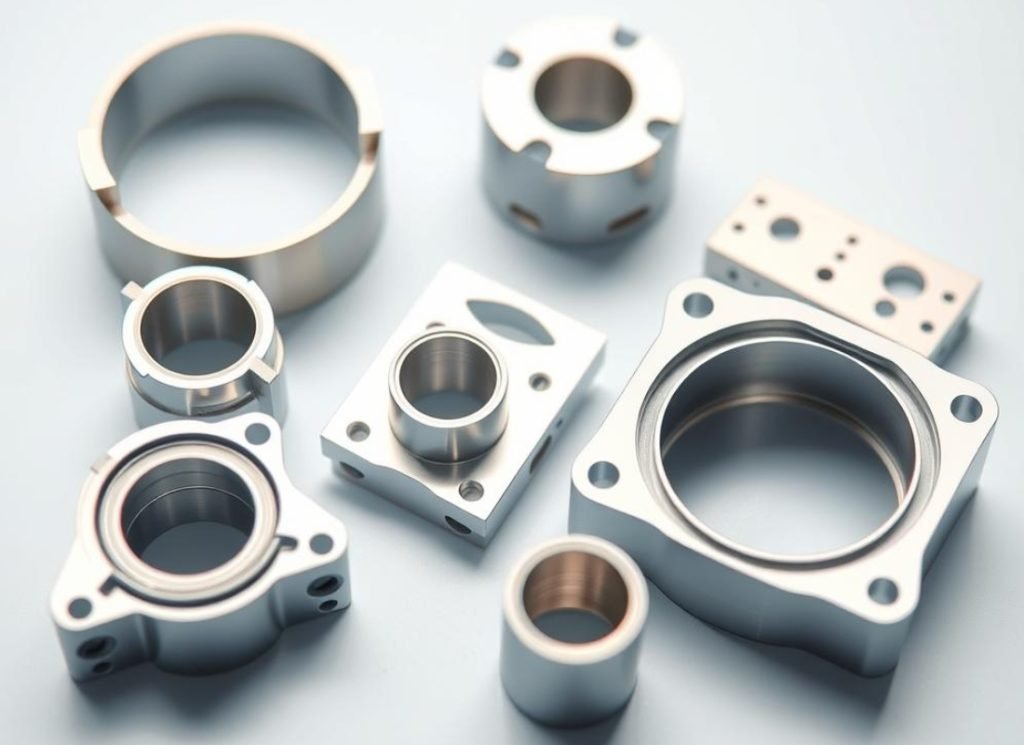

Applications of CNC Machined Aluminum Parts

The versatility of aluminum machining makes it suitable for a wide range of industries and applications.

Here are some of the most common uses for precision CNC machined aluminum components:

Aerospace

- Structural components and brackets

- Instrument housings and panels

- Fuel system components

- Wing and fuselage parts

- Satellite and space vehicle components

Automotive

- Engine components and blocks

- Transmission housings

- Suspension components

- Heat sinks and cooling systems

- Interior trim and structural elements

Medical

- Surgical instrument components

- Medical device housings

- Diagnostic equipment parts

- Laboratory equipment frames

- Prosthetic components

Electronics

- Heat sinks and thermal management

- Enclosures and housings

- Mounting brackets and frames

- LED lighting components

- Computer and server chassis parts

Robotics & Automation

- Actuator housings and mounts

- Robotic arm components

- Sensor mounts and enclosures

- Structural frames and joints

- End-effector tooling

Consumer Products

- Camera bodies and mounts

- Sporting equipment components

- High-end audio equipment

- Decorative hardware and fixtures

- Smartphone and laptop chassis

Aluminum Machining FAQs

Need to discuss aluminum machinig project?

Our expert engineers can analyze your application requirements and recommend the optimal solution.

Ready to Start Your Aluminum Machining Project?

Contact our team today for expert consultation and competitive quotes on your precision aluminum components.