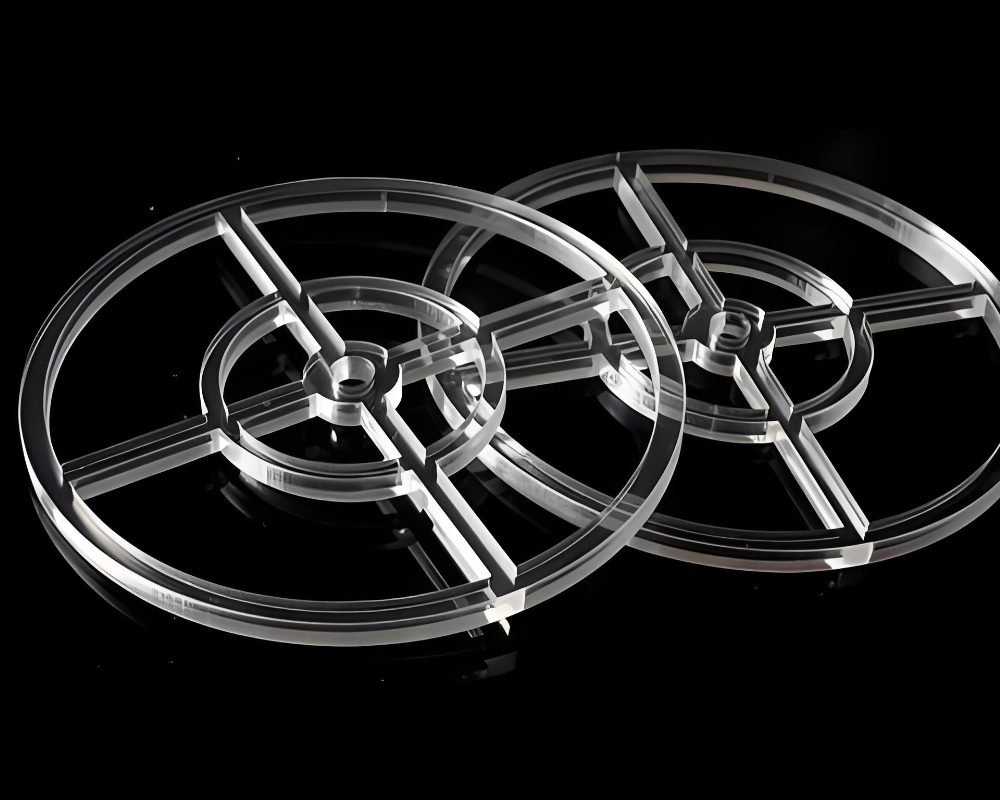

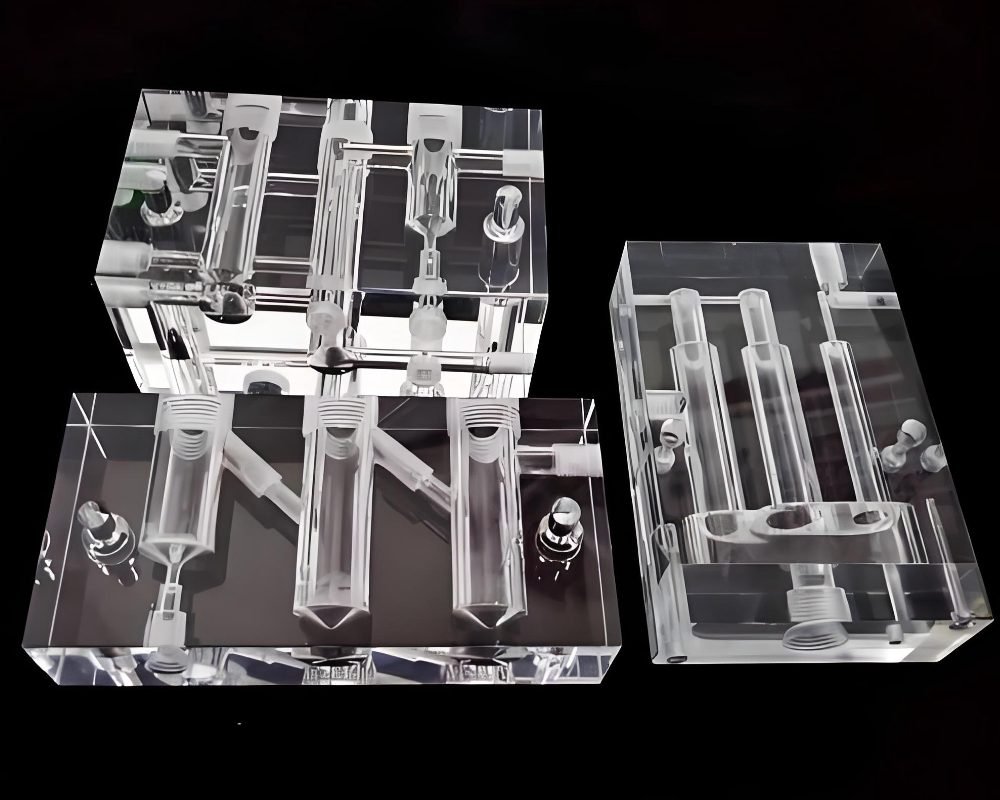

Acrylic Machining Services: PMMA Parts

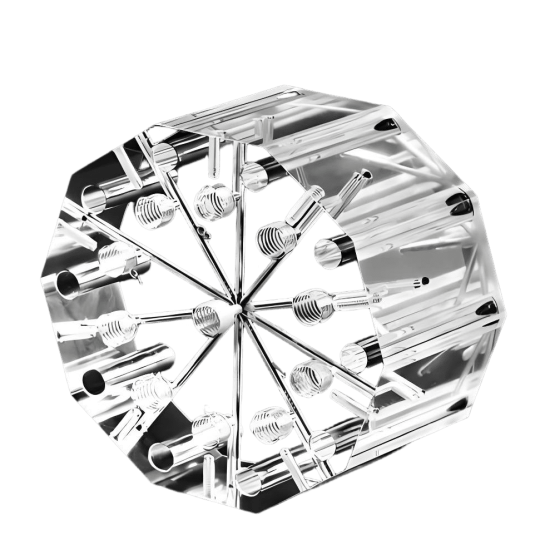

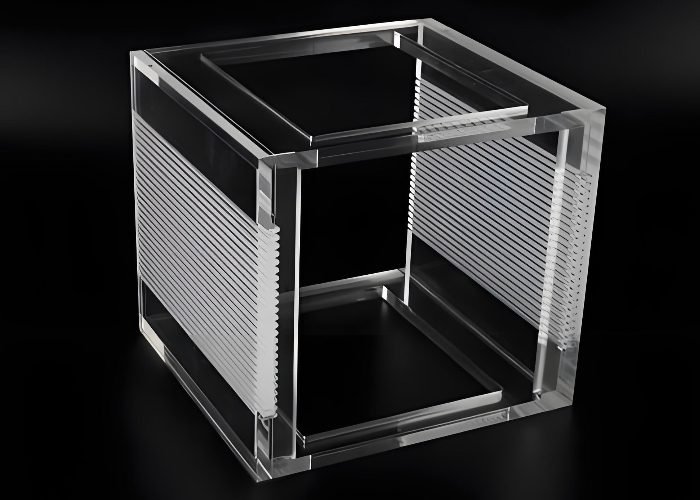

Acrylic CNC machining combines advanced computer-controlled precision with one of the most versatile transparent materials available today. This manufacturing process delivers exceptional clarity, dimensional accuracy, and surface finish for custom acrylic components across industries.

Our specialized approach to machining acrylic ensures consistent quality and precision for every component.

Various Options

Functionality

Cost-effectiveness

| Property | Value | Notes |

| Tensile Strength | 65-75 MPa | Higher than many other thermoplastics |

| Melting Point | 160°C (320°F) | Critical for machining parameters |

| Elongation at Break | 3-10% | Limited flexibility compared to other plastics |

| Hardness | 90-95 (Rockwell M) | Excellent surface hardness |

| Density | 1.18 g/cm³ | Approximately half the weight of glass |

| Light Transmission | 92% | Exceptional clarity for transparent grades |

| UV Resistance | Excellent | Minimal yellowing over time |

About Acrylic (PMMA) Material

Acrylic, technically known as Polymethyl Methacrylate (PMMA), is a transparent thermoplastic polymer often referred to as plexiglass in commercial applications.

This versatile material offers exceptional optical clarity while being significantly lighter and more impact-resistant than traditional glass. Its molecular structure provides a unique combination of transparency, weather resistance, and machinability that makes it ideal for precision manufacturing.

Advantages of Acrylic

- Exceptional optical clarity (92% light transmission)

- Lightweight (50% lighter than glass)

- Excellent weather and UV resistance

- Superior machinability compared to glass

- High dimensional stability

- Good electrical insulation properties

- Available in transparent, translucent, and opaque variants

- Biocompatible for medical applications

Restrictions of Acrylic

- Prone to stress cracking during machining

- Susceptible to scratching without protective coatings

- Limited temperature resistance (softens at 160°C)

- Lower impact resistance than polycarbonate

- Can develop crazing under improper machining

- Not suitable for high-stress mechanical applications

- Vulnerable to certain solvents and chemicals

Acrylic (PMMA) CNC Machining at a Glance

CNC Machining Processes for Acrylic

CNC Milling

Ideal for creating complex geometries, pockets, and surface features in acrylic sheets and blocks. Our multi-axis CNC mills achieve tolerances of ±0.1mm with exceptional surface finish.

CNC Turning

Perfect for cylindrical acrylic components with precise diameters and profiles. CNC lathes produce smooth surfaces on acrylic rods with minimal post-processing requirements.

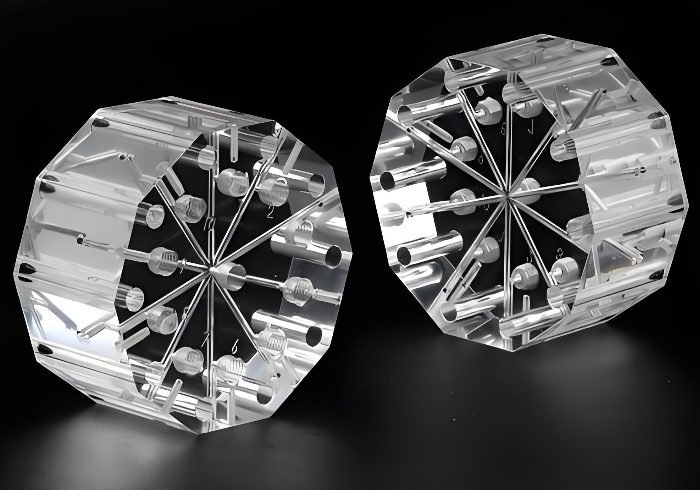

CNC Drilling

Specialized drilling operations with controlled feed rates prevent cracking and chipping around hole edges, ensuring clean through-holes and threaded features.

Technical Specifications

| Specification | Capability | Notes |

| Standard Tolerance | ±0.1 mm (±0.004″) | Tighter tolerances available upon request |

| Precision Tolerance | ±0.05 mm (±0.002″) | For critical dimensions |

| Minimum Wall Thickness | 1.0 mm (0.039″) | Depends on part geometry and height |

| Maximum Part Size | 600×400×300 mm | Larger parts possible with multiple setups |

| Surface Roughness | Ra 0.8 μm | Before finishing operations |

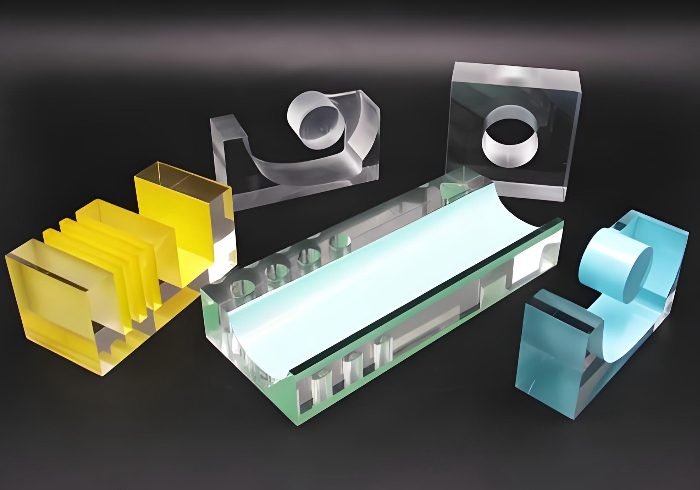

| Available Colors | Clear, Black, White, Custom | Transparent, translucent, and opaque options |

| Thread Sizes | M2 to M8 | Self-tapping or machine threads |

Key Considerations for CNC Machining Acrylic

Successful acrylic CNC machining requires attention to specific parameters and techniques.

Our manufacturing experts follow these best practices to ensure optimal results:

Cutting Tool Selection

Cooling and Chip Evacuation

Feed Rate and Speed Control

Proper feed rate settings are critical when machining acrylic. We maintain higher feed rates with moderate spindle speeds to prevent material melting while ensuring clean cuts.

Workholding Techniques

Expert Tip

When machining acrylic, maintaining sharp tools is critical. Dull cutting edges generate excessive heat that can cause melting, poor surface finish, and stress cracking. We regularly replace and maintain our tooling to ensure optimal cutting performance.

Finishing Options for CNC Machined Acrylic

After CNC machining, acrylic parts often require finishing operations to achieve the desired aesthetic and functional properties.

Edge Polishing

Mechanical or flame polishing techniques restore optical clarity to machined edges, creating glass-like transparency. This process removes tool marks and produces a smooth, reflective surface finish.

Surface Treatments

Options include matte finishing, frost effects, and anti-glare treatments. These processes modify light reflection and transmission properties while maintaining dimensional accuracy.

Protective Coatings

Application of scratch-resistant or UV-protective coatings enhances durability and extends product lifespan, particularly for outdoor applications or high-traffic environments.

Painting & Printing

Custom color application and graphic printing for branding, information display, or decorative purposes. Our specialized acrylic paints ensure excellent adhesion and durability.

Bonding & Assembly

Precision bonding of multiple acrylic components using solvent cements or UV-curable adhesives. Creates seamless joints with strength approaching that of the base material.

Laser Engraving

High-precision marking and engraving for text, logos, scales, or decorative patterns. Creates permanent markings with exceptional detail and contrast.

Common Applications for Acrylic CNC Parts

The exceptional properties of CNC machined acrylic make it ideal for numerous applications across diverse industries.

Our precision manufacturing capabilities deliver custom components for:

Medical

Surgical instruments and tools

Drug delivery devices

Medical device housings

Disposable medical products

Retail & Display

Product showcases

Illuminated signage

Museum exhibits

Trade show components

Industrial & Scientific

Optical components

Instrument panels

Protective guards

Inspection windows

Automotive & Transportation

Light covers and diffusers

Display screens

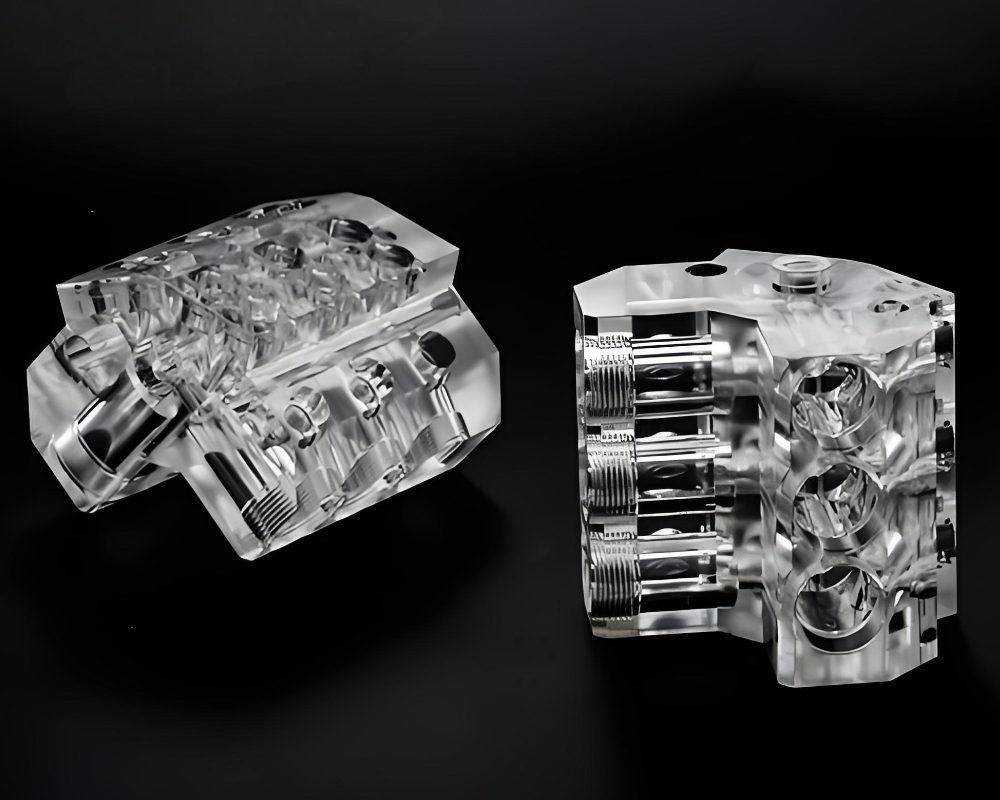

Prototype components

Custom interior elements

Architecture & Design

Decorative panels

Scale models

Furniture components

Artistic installations

Electronics & Lighting

Device enclosures

Control panel overlays

Display screens

Prototype housings

Ready to Start Your Acrylic CNC Project?

Upload your design files for a free quote or contact our engineering team for design assistance.