Are you aware of the critical factor that determines the performance of nylon materials at high temperatures in injection molding processes?

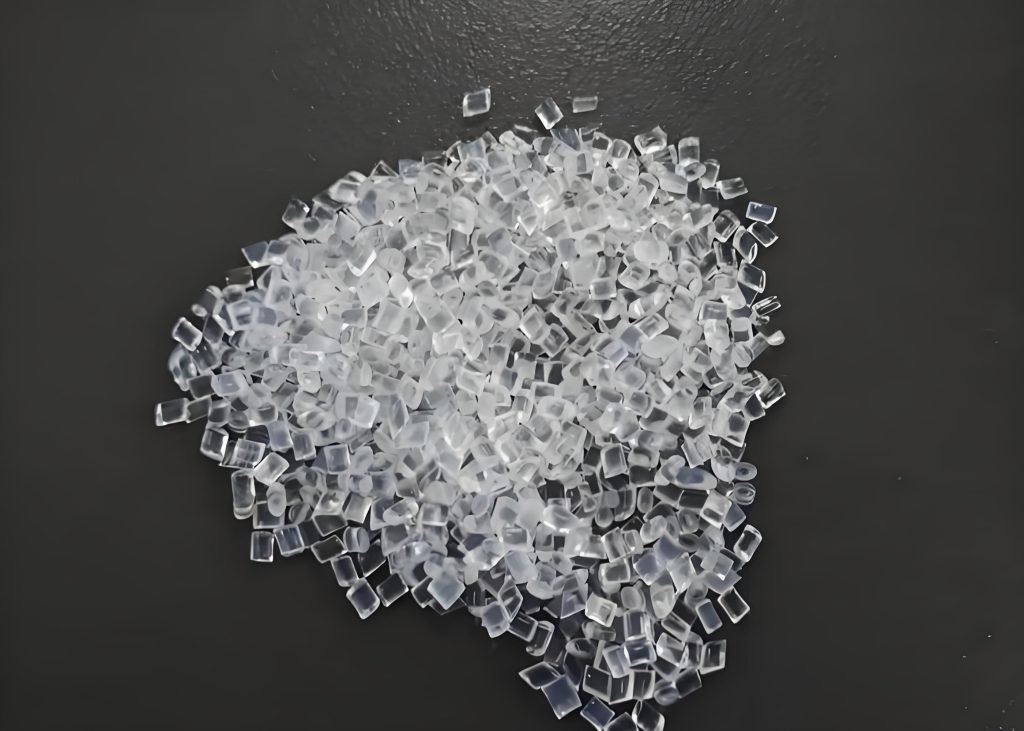

polymer used extensively in various industries, including automotive, electronics, and textiles, due to its excellent durability and mechanical properties.

The melting point of this material is crucial for successful manufacturing and directly impacts its suitability for specific applications. Different types of nylon have varying melting points, affecting their strength, durability, and chemical resistance.

Understanding these differences is key to selecting the right nylon material for your needs, whether you’re comparing nylon 6 vs. nylon 66 or considering high vs. low melting point nylons.

What Is Nylon? An Introduction to This Versatile Polymer

Nylon, a polyamide known for its strength and durability, has been a cornerstone in manufacturing for decades. You might be familiar with its use in various products, from clothing to industrial components. Nylon’s versatility stems from its unique combination of properties, making it an ideal material for a wide range of applications.

Chemical Structure and Classification of Nylon Types

Nylon is classified as a polyamide (PA), characterized by amide linkages that provide superior strength and durability. Different types of nylon, such as Nylon 6 and Nylon 66, are classified based on their chemical structure and the number of carbon atoms in their monomer units. Understanding these classifications is crucial for selecting the right type of nylon for specific applications.

Key Properties That Make Nylon Valuable for Manufacturing

Nylon’s exceptional mechanical properties, including high tensile strength, impact resistance, and abrasion resistance, make it a preferred choice for manufacturing. Additionally, nylon offers excellent thermal properties, such as heat resistance and dimensional stability at elevated temperatures. Its chemical resistance to oils, solvents, and many chemicals, along with self-lubricating properties and a low coefficient of friction, further enhance its suitability for demanding environments and moving parts.

Nylon’s balance of properties makes it uniquely valuable for manufacturing applications compared to other polymers. You can leverage these benefits to create high-performance products that meet specific requirements.

The Science Behind Nylon Melting Point

Nylon’s melting behavior is a complex phenomenon that is essential to comprehend for effective material processing. The melting point of a polymer like nylon is not just a simple physical property; it’s a critical factor that influences its processing, performance, and application.

What Determines a Polymer’s Melting Point

A polymer’s melting point is determined by the strength of the intermolecular forces between its molecular chains. In the case of nylon, the presence of amide linkages and hydrogen bonding between chains significantly affects its melting behavior. The molecular weight, crystalline structure, and presence of impurities or additives also play crucial roles in determining nylon’s melting point.

How Crystallinity Affects Nylon’s Melting Behavior

The crystallinity of nylon has a profound impact on its melting behavior. Nylon is a semi-crystalline polymer, meaning it has both crystalline and amorphous regions. The crystalline regions have a more ordered structure, which requires more energy to melt, thus affecting the overall melting point. The degree of crystallinity can vary depending on the processing conditions, such as cooling rate and annealing treatments.

Measuring and Testing Nylon Melting Points

Measuring the melting point of nylon is crucial for understanding its processing and performance characteristics. Differential Scanning Calorimetry (DSC) is a widely used technique for determining the melting point. DSC measures the heat flow associated with the melting transition, providing valuable information on the peak melting temperature and enthalpy changes. Other testing methods, such as Thermomechanical Analysis (TMA) and Thermogravimetric Analysis (TGA), can also provide complementary information on nylon’s thermal behavior.

Comparing Nylon 6 vs. Nylon 66 Melting Points

The melting points of Nylon6 and Nylon66 differ significantly, influencing their performance in various industrial applications. Understanding these differences is crucial for selecting the right material for your specific needs.

Nylon6: Structure and Melting Characteristics

Nylon6 is produced from caprolactam, which consists of 6 carbon atoms. It has a melting point of around 220°C. This relatively lower melting point compared to Nylon66 affects its heat deflection temperature and continuous use temperature, making it less suitable for extremely high-temperature environments.

Nylon66: Structure and Melting Characteristics

Nylon66 is synthesized from adipic acid and hexamethylene diamine, both of which have 6 carbon atoms. It boasts a higher melting point near 260°C, making it more thermally tolerant than Nylon6. This characteristic makes Nylon66 ideal for demanding applications where exposure to high temperatures is common.

Key Performance Differences Due to Melting Point Variations

The 40°C difference in melting points between Nylon6 and Nylon66 translates into distinct performance characteristics. Nylon66 retains its mechanical properties better at elevated temperatures, making it preferable for under-hood automotive applications. Additionally, the higher melting point of Nylon66 results in lower moisture absorption and better dimensional stability compared to Nylon6.

When choosing between Nylon6 and Nylon66, consider the temperature requirements of your application. For projects that demand higher thermal tolerance and better property retention at elevated temperatures, Nylon66 is the preferred choice. Conversely, for applications where the temperature is not a critical factor, Nylon6 may offer a more cost-effective solution without compromising on the necessary material properties.

Nylon Melting Point Compared to Other Engineering Polymers

Understanding how nylon’s melting point compares to other polymers is crucial for selecting the right material for your application. Nylon is a versatile polymer used in various engineering applications, but its melting point is just one factor to consider when choosing a material.

Comparison with Polyethylene and Polypropylene

Nylon’s melting point is significantly higher than that of polyethylene and polypropylene. For instance, nylon6 has a melting point around 220°C, while polyethylene’s melting point is typically between 105°C to 130°C. Polypropylene’s melting point ranges from 160°C to 170°C. This makes nylon more suitable for high-temperature applications.

Comparing Nylon with High-Temperature Polymers

When compared to high-temperature polymers like polyetheretherketone (PEEK) or polyimide, nylon’s melting point is relatively lower. PEEK, for example, has a melting point around 343°C. However, nylon offers a better balance of properties, including cost, mechanical strength, and chemical resistance, making it a preferred choice for many applications.

Selecting the Right Polymer Based on Melting Point Requirements

To select the right polymer, you must balance melting point with other critical properties. Consider the application’s temperature requirements, mechanical stress, and environmental factors. For high-temperature applications, nylon66 might be preferred over nylon6 due to its higher melting point. For applications requiring flexibility and chemical resistance, lower melting point nylons like nylon11 or nylon12 could be more suitable.

High vs. Low Melting Point Nylons: Applications and Benefits

The melting point of nylon is a crucial characteristic that influences its performance in diverse environmental conditions. Nylons are available with a range of melting points, making some more suitable for high-temperature applications, while others are better suited for lower temperature or chemically limiting environments.

High Melting Point Nylons: Ideal Applications

Nylons with high melting points, such as Nylon46 and Nylon66, are known for their thermal stability and ability to withstand high heat loading. These characteristics make them ideal for applications in automotive parts and industrial environments where exposure to high temperatures is common. Their ability to maintain performance under heat stress is a significant benefit in such applications.

Low Melting Point Nylons: Ideal Applications

On the other hand, Nylons with lower melting points, like Nylon11 and Nylon12, are more suited for applications in low-temperature environments or where chemical resistance is critical, such as in chemical pipelining and fuel lines in automobiles. Their flexibility and resistance to damage under these conditions make them valuable in specific industrial applications.

Environmental Factors Affecting Nylon Performance Near Melting Point

Environmental factors such as humidity, chemical exposure, and UV radiation can significantly affect nylon’s performance as it approaches its melting point. Moisture absorption can lower the effective melting point and impact dimensional stability. Prolonged exposure to temperatures near the melting point can cause thermal aging and degrade nylon’s properties. Strategies to enhance nylon’s performance include using additives, coatings, and thoughtful design considerations. When selecting nylon types, it’s crucial to account for these environmental factors to ensure optimal performance.

Practical Injection Molding Tips for Different Nylon Types

When working with different nylon types in injection molding, understanding their unique characteristics is crucial for achieving optimal results. The melting point of nylon significantly affects the injection molding process, particularly in terms of cooling requirements.

Temperature Control Strategies for Various Nylon Grades

Different nylon types have distinct melting points, which necessitate tailored temperature control strategies. For instance, Nylon 6 has a lower melting point compared to Nylon 66, affecting the cooling time and mold temperature settings.

Nylon is hygroscopic, meaning it absorbs moisture from the environment. Effective moisture management is critical to prevent defects such as splay or bubbles in the molded parts. Drying nylon before processing is essential.

Optimizing Cooling Parameters Based on Melting Point

The cooling time in injection molding is directly influenced by the nylon type’s melting point. Parts made from nylon with a higher melting point may require longer cooling times to ensure proper crystallization and dimensional stability.

Uniform cooling is vital to prevent warpage and ensure the dimensional stability of nylon parts. Mold design considerations, including cooling channel layout and conformal cooling, play a significant role in achieving effective cooling.

Conclusion

As you’ve learned, the melting point of nylon is essential for achieving optimal results in injection molding. Understanding the relationship between nylon’s melting point and its performance in various environmental conditions is crucial for selecting the right material for your applications. Different types of nylon, such as high and low melting point nylons, offer unique benefits and are suited for different industries. By considering factors like temperature control, moisture management, and cooling optimization, you can ensure successful injection molding. Proper material selection based on melting point and other properties is vital for part reliability and performance.

FAQ

Nylon’s moisture absorption can impact its mechanical properties, such as strength and elasticity. When Nylon absorbs moisture, it can become more prone to warping or dimensional changes. However, some Nylon types are more resistant to moisture absorption than others.

High melting point Nylons, such as Nylon66, offer improved thermal stability, chemical resistance, and mechanical strength, making them suitable for demanding applications, including automotive and industrial parts.

While Nylon has a relatively high melting point, its performance can be affected by prolonged exposure to high temperatures. However, some Nylon types, such as Nylon46 and Nylon66, are more suitable for high-temperature applications due to their improved thermal stability.

The crystallinity of Nylon influences its melting behavior, with higher crystallinity typically resulting in a higher melting point. The crystalline structure of Nylon can be affected by factors such as processing conditions and the presence of additives.

When choosing a Nylon type, consider factors such as melting point, moisture absorption, chemical resistance, and mechanical properties to ensure the selected material meets the requirements of your application.