Have you ever wondered how materials behave under different types of loading conditions? Understanding the difference between stress and strain is crucial in materials science and engineering.

When a force is applied to a material, it experiences internal forces, known as stress, which can cause it to deform. The resulting deformation, measured as a ratio of the change in length to the original length, is known as strain. Understanding the relationship between stress and strain is vital for predicting how materials will behave under various conditions.

This relationship defines important mechanical properties like elasticity, plasticity, and strength, which are essential for engineers and manufacturers when selecting materials for specific applications.

Understanding Material Stress in Engineering

Material stress is a fundamental concept in engineering that refers to the internal forces that arise within a material due to external loads. You need to understand stress to design and develop structures that can withstand various external forces without failing.

Definition of Stress in Materials

Stress in materials is defined as the internal resistance force per unit area within a material that responds to external forces. Mathematically, stress is represented as force divided by the cross-sectional area (σ = F/A), making it an intensity measurement rather than a total force measurement. This definition is crucial in understanding how materials behave under different loading conditions.

Types of Stress: Normal and Shear

There are two primary types of stress that a structure can experience: normal stress and shear stress. Normal stress occurs when a force acts perpendicular to the surface of an object, while shear stress occurs when a force acts parallel to the surface. Normal stress can be further categorized into tensile stress (pulling forces) and compressive stress (pushing forces).

Units of Measurement for Stress

The standard units of measurement for stress are Pascal (Pa) in SI units and pounds per square inch (psi) in imperial units. Understanding these units is essential for stress analysis, which helps engineers predict material behavior and prevent failure. Stress is a point property that can vary throughout a material depending on its geometry and loading conditions.

By grasping the concept of material stress, including its definition, types, and units of measurement, you can better appreciate the complexities involved in designing and engineering structures that are safe and durable.

How Stress in Materials is Measured

Stress measurement in materials is critical for evaluating their performance under different loading conditions. You need to understand how various testing methods are used to measure stress to ensure the safe and efficient design of structures and components.

Tensile Testing Methods

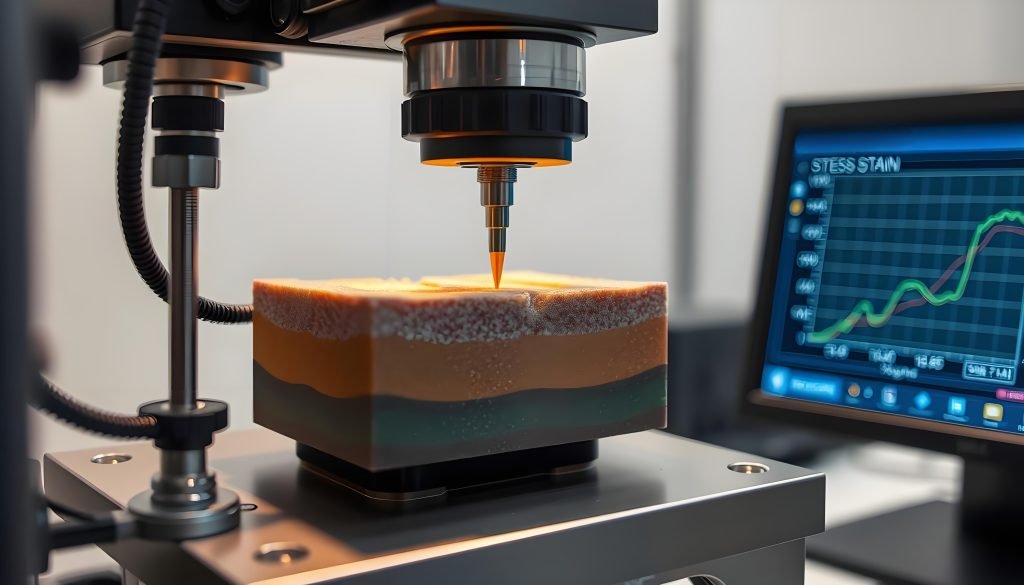

Tensile testing is a common method used to measure the stress in materials by applying a controlled tensile force to a standardized specimen until it fails. You can determine the material’s tensile strength, yield point, and other critical properties through this test. The test involves measuring the deformation of the specimen as the load is increased, resulting in a stress-strain curve that provides valuable information about the material’s behavior under tension.

Compression and Shear Stress Testing

In addition to tensile testing, compression and shear stress testing are also essential for understanding material behavior under different types of loading. Compression testing involves subjecting a specimen to a compressive force, while shear testing measures the material’s response to shear forces. These tests provide critical data on the material’s compressive strength and shear resistance, which are vital for designing structures that withstand various loads. Modern techniques, such as digital image correlation and strain gauges, enhance the precision of these measurements.

How Stress Works in Different Materials

When forces are applied to materials, the resulting stress can vary significantly depending on the material’s properties. This variation is crucial in understanding how different materials respond to external loads.

Stress Distribution in Homogeneous Materials

In homogeneous materials, stress distribution is typically uniform when the applied force is evenly distributed. This uniformity is due to the consistent properties throughout the material.

For instance, metals like aluminum and steel often exhibit homogeneous behavior under certain conditions. The uniform stress distribution allows engineers to predict the material’s response to applied forces more accurately.

Stress Concentration in Complex Structures

In contrast, complex structures or materials with varying geometries can experience stress concentration at specific points.

Geometric features such as holes, notches, and sharp corners can amplify local stress levels, potentially leading to material failure.

Engineers must consider these stress concentrations when designing components to prevent unexpected failures.

Material Response to Applied Forces

The response of a material to applied forces depends on its properties, including its atomic and molecular structure.

Different materials, such as metals, polymers, ceramics, and composites, respond uniquely to applied stresses.

For example, some materials may undergo elastic deformation, returning to their original shape once the force is removed, while others may experience plastic deformation or eventual failure.

Material Stress vs Strain: Key Differences

When analyzing materials under load, it’s essential to differentiate between stress and strain to predict their behavior accurately. Understanding the distinction between these two concepts is vital for engineers and researchers working with various materials.

Fundamental Distinctions Between Stress and Strain

Stress refers to the internal resistance force per unit area within a material when subjected to an external load. On the other hand, strain is the resulting deformation or change in dimension relative to the original length. Essentially, stress is about the forces acting within a material, while strain is about the material’s response to those forces.

The distinction between stress and strain is not just semantic; it reflects fundamentally different physical quantities. Stress is measured in units of force per area (like Pascals or psi), indicating the internal forces at play. Strain, being a ratio of change in length to original length, is dimensionless.

Cause and Effect Relationship

The relationship between stress and strain is causal: stress causes strain. When a material is subjected to stress, it deforms, resulting in strain. This cause-and-effect relationship is foundational to understanding material behavior under various loading conditions.

For linear, elastic materials, the relationship between stress and strain is linear, governed by Hooke’s Law. The proportionality constant in this relationship is known as the material’s elastic modulus, a critical property that indicates the material’s stiffness.

Dimensional Analysis: Units and Measurements

Stress is quantified in units of force per unit area, such as Pascals (Pa) or pounds per square inch (psi). In contrast, strain is dimensionless, as it represents a ratio of lengths (change in length divided by original length). This difference in units highlights the distinct nature of these two properties.

The stress-strain curve, a graphical representation of how stress and strain relate, serves as a material’s “fingerprint.” It provides crucial information about a material’s stiffness, elasticity, and ductility. Understanding these differences and the stress-strain relationship is pivotal for material selection and engineering design decisions.

Understanding Material Strain in Engineering

Material strain is a fundamental concept in engineering that refers to the deformation of materials under applied loads. As an engineer, understanding strain is crucial for designing and analyzing structures that can withstand various types of forces. Strain is a measure of how much an object deforms when subjected to stress.

Definition of Strain in Materials

Strain in materials is defined as the measure of deformation representing the displacement of particles in a material relative to their original positions. It is calculated as the change in dimension divided by the original dimension (ε = ΔL/L), making it a dimensionless ratio or percentage. This calculation provides a clear indication of how much a material has deformed under stress.

Types of Strain: Normal and Shear

There are two primary types of strain: normal strain and shear strain. Normal strain occurs when the elongation of an object is in response to a normal stress, resulting in either tensile or compressive strain. Shear strain, on the other hand, occurs when the deformation is in response to a shear stress, causing angular distortion. Understanding these types is essential for analyzing material behavior.

Elastic vs. Plastic Strain

Strain can be either elastic or plastic. Elastic strain is temporary and reversible, meaning the material returns to its original shape once the stress is removed. Plastic strain, however, is permanent, indicating that the material has undergone plastic deformation and will not return to its original shape. The distinction between these two types of strain is critical in material selection and design.

How Strain in Materials is Measured and Analyzed

Understanding how strain in materials is measured is crucial for engineers and researchers to assess material behavior under various loads. Strain measurement is a fundamental aspect of material testing, providing insights into how materials deform under stress.

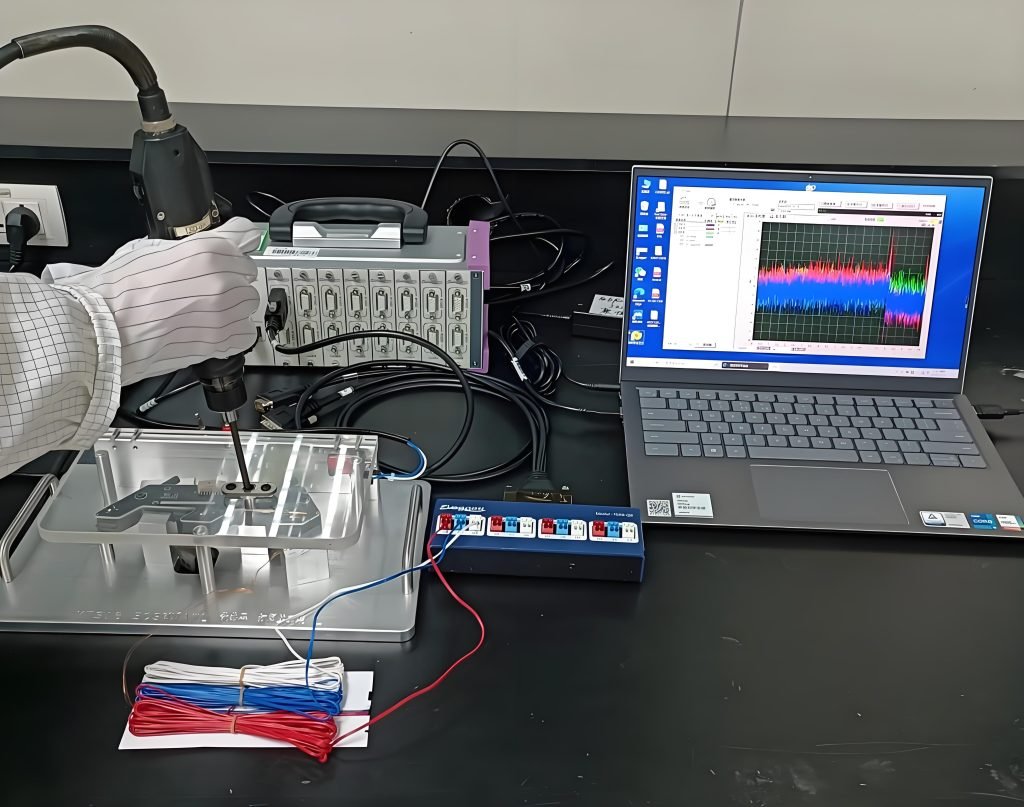

Strain Gauges and Measurement Techniques

Strain gauges are commonly used to measure strain in materials. These devices detect changes in electrical resistance as the material deforms, allowing for precise strain measurement. Modern techniques like digital image correlation (DIC) and fiber optic sensors are also revolutionizing material testing by providing high-resolution strain data.

Strain measurements can be conducted in both laboratory settings and field applications on existing structures. In laboratory settings, strain gauges and other instruments are used to test material samples under controlled conditions. In field applications, strain measurement techniques help monitor the health of structures and detect potential issues before they become critical.

True Strain vs. Engineering Strain

There are two primary ways to calculate strain: engineering strain and true strain. Engineering strain is calculated as the change in length divided by the original length (ε = ΔL/L0). True strain, on the other hand, accounts for the instantaneous length during deformation and is calculated as the natural logarithm of the ratio of final length to original length.

Understanding the difference between true strain and engineering strain is crucial for accurate material characterization, especially when dealing with large deformations. True strain provides a more accurate representation of material behavior under significant deformation.

Conclusion: The Importance of Understanding Stress and Strain in Material Selection

To ensure the longevity and performance of your product, it’s essential to grasp the concepts of stress and strain in materials. The stress-strain curve serves as a material’s performance signature, revealing key properties like Young’s modulus, yield strength, and ultimate tensile strength.

By understanding yield points, engineers can design components that avoid permanent deformation during normal operation. This knowledge is crucial for balancing competing requirements like strength, weight, cost, and manufacturability when selecting materials.

Practical applications of stress-strain knowledge vary across industries, with different sectors prioritizing different aspects of the stress-strain relationship based on their specific needs. As advanced materials science continues to evolve, new possibilities emerge through engineered stress-strain properties.

Proper material selection based on stress-strain characteristics can lead to improved product performance, longer service life, and reduced manufacturing costs. By considering these factors, you can make informed decisions that drive success in your manufacturing projects.