CNC machining is one of the most powerful manufacturing processes. It is used to make extremely accurate components found in many different industries. You might be asking, “How much does CNC machining cost?” The answer is somewhat complex, as costs can vary greatly depending on a number of aspects.

Understanding these factors is really important. It helps you make smart choices. You can also find ways to reduce CNC machining costs. This knowledge helps you get the best value for your money. So, let’s get right into understanding the points associated with CNC machining. We will cover all of the important aspects impacting pricing.

What Is CNC Machining?

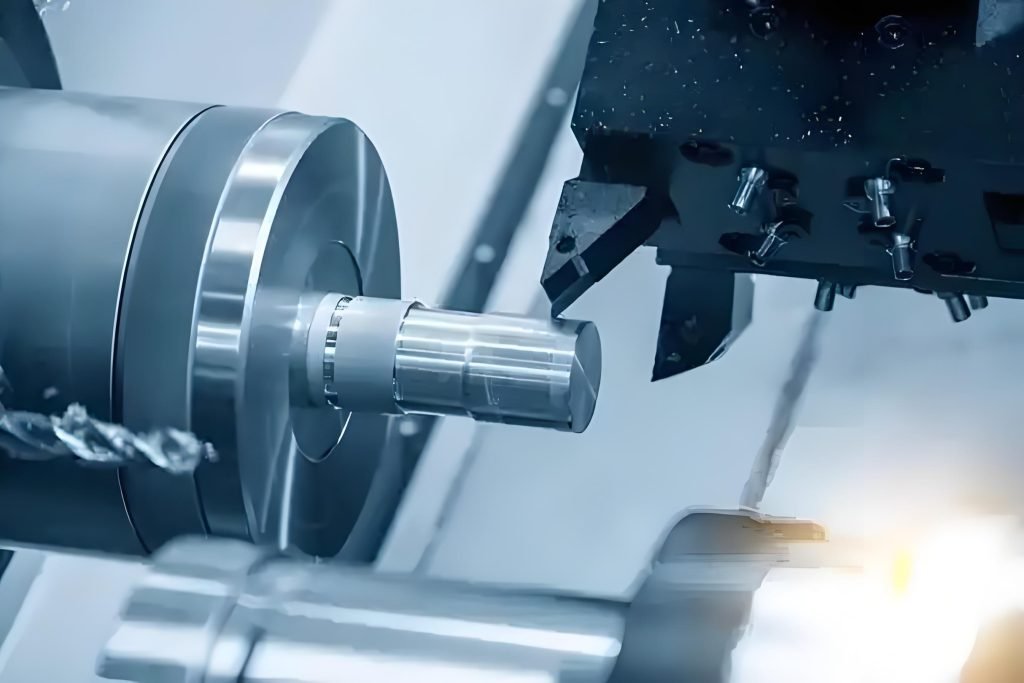

CNC machining, also known as Computer Numerical Control machining, is an advanced manufacturing process. It relies on the computer to precisely drive tools like drills and mills to create parts from raw materials with very high accuracy and repeatability. It is sort of a robotic craftsmanship project with a digital drawing and plan for reference.

This technology is important in all the high-tech industries. The aerospace industry uses it for parts of their aircraft that require a strong but lightweight material. The automotive industry uses it for engine and chassis parts of vehicles. It is equally important for precise medical devices and complicated components of consumer electronics.

It isn’t easy to calculate the total CNC machining cost accurately. There are many aspects to take into consideration, but the overall variables are the precision requirement, material type, and part volume. All matters have to be taken into account to realize your total investment in your CNC machined components.

Factors That Affect CNC Machining Cost

There are plenty of variables that contribute to the cost of CNC machining. Knowing these variables is important in your decision-making process, which will affect your budget.

Material Selection

The material you choose is one of the most significant cost drivers. Each material has different machinability scores. For instance, working with aluminum is cheaper, as it is a softer material that can be quickly cut through; therefore, the machining time can be reduced drastically. Stainless steel is much harder and abrasive; therefore, the cutting speeds will have to be slower and can wear tools faster. This directly increases machine operating time and tool replacement costs.

In addition to machinability, the market price of the raw material varies quite a bit as well. While a small block of specialized aerospace-grade titanium may set you back hundreds of dollars, the same small block of commodity aluminum is likely only a few dollars. Think of both the raw material cost of your selected material and the ease (or difficulty) of machining when agreeing on your materials.

Complexity of the Design

Complex designs will directly lead to more machining costs. Complex geometries such as organic shapes or internal channels will require a lot of programming, specialized tools, and often go on more expensive multi-axis machines, which will result in hourly rate increases.

Also, tight tolerances will cost you more. Tight tolerances result in slower machining speeds, more passes, and more involved inspection. Moreover, very small holes, thin walls, or deep pockets will increase complexity, requiring fragile tooling and will contribute to the overall cost, as well as more potential lead time. So if you can learn how to simplify your features, you will usually save money.

Volume of Production

Production volume will greatly impact the CNC machining cost on a per-unit basis. The larger the quantity of parts you order, the lower the cost per unit. The largest impact on the per-unit-of-quantity quantity would be the economy of scale. With more parts ordered, the setup cost is shared more, driving down the cost per piece.

If you are only getting a handful of parts or a single prototype, you will find that the cost per part will be higher. This is due to the fact that the setup time and initial programming still need to be paid for, regardless of how few parts you are producing.

Machine Operating Time

Machine operating time directly reflects how long the CNC machine actively processes your part, encompassing two key elements. Cycle time is the actual duration the machine spends cutting and shaping, influenced by material, design, and tool parameters. Longer cycle times directly increase cost with more machine time and energy consumption.

Setup time occurs when preparing the machine for a job: programming, tooling, and fixture for the material. If the production run is small, this setup time impacts the overall cost significantly. Streamlining the setup procedures and designing effective fixtures is critically important to reducing this cost. This is often a key part of how much does CNC machining cost per hour.

Labor Costs

There is skilled human labor behind every CNC machine, which consists of the wages of engineers, machinists, and quality control technicians. CNC machining requires specialization when programming the machine, monitoring the operation, and maintaining the machinery to produce high-quality products effectively.

The common principles of CNC machining often relate to efficiency. Experienced CNC machine operators will have a clear understanding of the parameters surrounding CNC machining processes and be able to define the parameters, modify them, troubleshoot them, and manage work in process to minimize material waste. Improving the operator efficiency on the machine will not only improve production efficiency, but also lower your overall production costs by minimizing mistakes and remaining at peak production rates.

CNC Machine Types

The type of CNC machine used for your project also affects the hourly rate. This is a key part of answering “how much does CNC machining cost per hour”.

Machine Types:

- 3-axis CNC machines are the most common and generally the most affordable, ideal for basic CNC milling and drilling on flat surfaces.

- 4-axis CNC machines add a rotational axis, allowing for more complex geometries and machining on multiple sides without re-fixturing.

- 5-axis CNC machines offer two additional rotational axes, enabling the creation of extremely complex shapes and machining on all sides of a part in a single setup. These are the most expensive but offer unparalleled capabilities.

The hourly rates for these machines vary significantly. A 3-axis machine might cost $75 – $150 an hour, but an expensive 5-axis machine can easily be $150 – $300+ an hour. The machine is determined by the complexity of your part, so make sure to choose the correct machine because this will aid in controlling your costs. If you are looking for a quick CNC machining cost calculator, knowing these hourly rates is a good start.

Finishing Operations

After a part is machined, it often requires additional operations in order to look good and perform better. These finishing operations increase the overall cost for you. They include, but are not limited to, deburring, bead blasting, anodizing, powder coating, painting, heat treatment, and polishing. Each of these operations will either change the surface or the mechanical properties of the part.

These processes include additional time or specialized equipment. For example, polishing a complex part can require a lot of labor and increase overall cost if you are not careful. If you are doing a part, really consider how many of the finishes are actually required for specific applications.

CNC Machining Cost Factors at a Glance

| Factor | Impact on Cost |

| Material Selection | Harder materials (e.g., titanium) cost more due to slower machining and tool wear. |

| Design Complexity | Complex geometries, tight tolerances, and thin walls increase machining time. |

| Production Volume | Higher quantities reduce per-unit costs (economies of scale). |

| Machine Operating Time | Longer cycle/setup times equal higher costs. |

| Labor Costs | Skilled operators and QC add expenses; efficiency reduces costs. |

| CNC Machine Type | 5-axis > 4-axis > 3-axis in cost; complex parts may require pricier machines. |

| Finishing Operations | Additional processes (anodizing, polishing) increase total cost. |

10 Tips to Reduce CNC Machining Cost

Now that you know what drives the cost, here are some tips to help you reduce it.

1. Optimize Material Selection

Do not simply select the cheapest material, but select the material that provides you with a good balance of performance and cost. Also, consider how the material is processed. Softer metals and plastics may be easier to machine than very hard alloys, even though the raw material cost may be a bit more. You could end up saving on machining costs and time.

2. Simplify Design

Complex designs cost more. Try to avoid features like very sharp internal corners, deep, narrow pockets, or tiny intricate details. These require specialized CNC Machine tools and more machining time. Also, using standard sizes for holes and threads can save time, as the machinist won’t need to use custom tools.

3. Order in Bulk

This is a straightforward way to save money. The more parts you order, the lower the cost per part. The initial setup costs are spread across more units. Also, for larger orders, the machining setup often remains consistent, which further reduces costs compared to multiple small, individual runs.

4. Avoid Excessively Thin Walls

Designing parts with thin walls will increase costs. Thin walls vibrate, requiring multiple lighter passes, and running the risk of warping or breaking. Design for minimum thicknesses; approximately over 1.5mm for plastics and 0.8mm for metals, or check with your manufacturer.

5. Round Internal Edges

When designing your parts, please opt for rounded internal corners instead of sharp corners. Cutting your sharp internal corners requires smaller tools and often needs multiple passes to achieve the sharp angle, which increases time. The larger radius will allow you to use larger tools, which are much more efficient, and can also speed up the machining process, thus reducing costs.

6. Limit Deep Cavities

Deep and narrow cavities can be difficult to machine. The tools will need to extend further, and this may cause vibration, and they will run slower. Keep the depth-to-width ratio for cavities as low as possible, ideally staying around 4:1 or lower. If you are required to have a deep cavity, look at different manufacturing processes or modify your design.

7. Specify Tolerances Only When Necessary

Tight tolerances are very costly in machining. Achieving tight tolerances requires slower speeds, more passes, or can only be achieved using specialized tools. Use tight tolerances only on the necessary, critical features of the part. Use standard, looser tolerances for other less critical areas. Using GD&T can help clarify the areas of true precision requirement.

8. Use Standard Hole Sizes

Use standard drill bit sizes wherever possible. This allows the machinist to use efficient off-the-shelf tools. Custom hole sizes require custom tooling or additional machining steps, leading to higher cost. Try to keep the hole depth reasonable, as extra-long drill bits may tend to break more readily.

9. Avoid Lettering in Designs

Getting text or logos engraved directly on a part using CNC machining takes much more machine time and cost than you would expect. The machine must make complex cuts, way more than just a straight cut. Try to find other means of putting text on your parts, such as laser engraving, screen printing, or labels after machining. These are usually much more affordable options to add text or branding.

10. Leverage DFM Feedback

DFM stands for Design for Manufacturability. Well, before your parts go into full production, seek feedback from your machinist or manufacturing partner to fully review your design. They will be able to comment on the design and provide you with possible changes that could help make it easier or cheaper to machine without hurting its function. Finding and acting on potential issues early is always cheaper than later.

Outsourcing CNC Machining Services with Fecision

How much does CNC machining cost at the end of the day? It depends on a lot: the material you choose, how complex your design is, how many parts you want, and even how long it takes to run the machine. The good news is that there are a lot of ways to cut costs for CNC machining, while still getting quality and precision, just by considering the design, and picking the right partner.

If you are looking for a partner for your CNC machining requirements, Fecision should definitely be on your consideration list. We focus on a smart and cost-effective choice for you, by combining efficient processes and excellent precision. We are experts in CNC milling parts with complex shapes, CNC turning for cylindrical components, and high precision parts with tight tolerances.

Here’s why Fecision stands out:

- Cost Effective: We minimize waste and maximize process efficiency to realize competitive prices without sacrificing quality.

- Precision Manufacturing: You can get accurate parts, tight tolerances, and whatever specifications you require.

- Fast speed: We help meet tight deadlines, whether you are looking for rapid prototypes or high-volume production.

- Materials Expertise: We help you determine the best and most cost-effective materials for your project.

Looking for affordable, high-quality CNC machining services that you can trust? Get a quote from Fecision today! Visit our CNC Machining Services page to learn more and start your project with confidence.