You encounter steel daily, from kitchen appliances to medical instruments and building construction. But have you ever wondered about its magnetic properties? The notion that stainless steel is non-magnetic is a common misconception. In reality, its magnetic behavior varies based on its composition and microstructure.

The quality and properties of stainless steel, such as its corrosion resistance, are influenced by its chromium content, with a minimum of 10.5% chromium defining the material as stainless. Different types of stainless steel exhibit different characteristics, making it crucial to understand its magnetic behavior for various applications.

Understanding Stainless Steel

To grasp the concept of stainless steel, you need to understand its composition and properties. Stainless steel is not just a single material but a family of alloys that contain a minimum of 10.5% chromium content, which is the key to its corrosion resistance and other beneficial properties.

What Defines Stainless Steel

Stainless steel is defined by its chromium content, which is the primary element that distinguishes it from other types of steel. The presence of chromium leads to the formation of a thin, invisible layer of chromium oxide on the surface, protecting the underlying metal from oxygen and moisture. This characteristic is what gives stainless steel its rust-resistant status.

The chromium content not only provides corrosion resistance but also contributes to the mechanical properties of stainless steel, such as its strength, hardness, and heat resistance. The interaction between chromium and other alloying elements determines the microstructure of stainless steel, influencing its magnetic properties.

The Role of Chromium in Stainless Steel

Chromium plays a pivotal role in stainless steel, creating a self-healing protective layer that prevents corrosion. When scratched or damaged, the exposed chromium reacts with oxygen to reform the protective barrier, ensuring ongoing corrosion resistance. Higher chromium content generally results in better corrosion resistance, with some grades containing up to 30% chromium for extreme environments.

Understanding the role of chromium is essential for selecting the right stainless steel grade for specific applications, especially when magnetic properties are a consideration. The chromium content, along with other alloying elements, affects the overall properties of stainless steel, making it suitable for a wide range of uses.

Is Stainless Steel Magnetic?

The question of whether stainless steel is magnetic depends on several factors. You need to understand the underlying composition and processing of the steel to determine its magnetic properties.

The Science Behind Magnetism in Metals

Magnetism in metals is primarily influenced by their atomic structure and the presence of ferromagnetic elements like iron, nickel, and cobalt. In the case of stainless steel, the addition of elements such as nickel can significantly impact its magnetic behavior.

The science behind magnetism involves understanding how the electrons in a material respond to magnetic fields. In stainless steel, the presence of chromium and other alloying elements can alter the magnetic properties.

Factors Affecting Magnetism in Stainless Steel

Several factors can influence the magnetic properties of stainless steel. The chemical composition is a primary factor, with elements like nickel, manganese, and nitrogen promoting non-magnetic austenitic structures.

The manufacturing process also plays a significant role. Cold working, such as bending or drawing, can transform non-magnetic austenitic stainless steel into a magnetic material. Heat treatment and welding can also alter the magnetic properties by changing the crystal structure or creating localized magnetic zones.

Additionally, environmental factors like exposure to certain chemicals or mechanical stress can affect the surface structure of stainless steel, potentially altering its magnetic response.

Understanding these factors is crucial for selecting the right type of stainless steel for your application, whether you need magnetic or non-magnetic properties.

Types of Stainless Steel and Their Magnetic Properties

Understanding the different types of stainless steel is crucial for determining their magnetic properties. Stainless steel is broadly classified into several categories based on its microstructure and composition, which in turn influence its magnetic behavior.

Ferritic Stainless Steels

Ferritic stainless steels are known for their magnetic properties due to their ferrite content. They contain between 10.5% and 18% chromium, with minimal nickel content. These steels are used in applications requiring high corrosion resistance and are often used in automotive trim and appliances.

Martensitic Stainless Steels

Martensitic stainless steels are also magnetic, owing to their martensitic microstructure. They contain a higher carbon content compared to other stainless steels, which allows them to be hardened through heat treatment. Their applications include cutlery, surgical instruments, and turbine blades.

Austenitic Stainless Steels

Austenitic stainless steels, such as the popular 304 grade, are generally non-magnetic due to their austenitic microstructure. However, some grades may exhibit slight magnetism after cold working. These steels are widely used in kitchen utensils, chemical processing equipment, and construction materials due to their excellent corrosion resistance and formability.

Duplex Stainless Steels

Duplex stainless steels feature a mixed microstructure of ferrite and austenite, resulting in moderate magnetic properties. They offer superior strength and excellent resistance to stress corrosion cracking, making them ideal for chemical processing, oil and gas, and desalination industries. The most common duplex grade is 2205, containing 22% chromium and 5% nickel.

Duplex stainless steels are increasingly popular due to their enhanced strength, corrosion resistance, and improved weldability compared to earlier generations. Their magnetic properties are generally stronger than austenitic grades but weaker than ferritic or martensitic grades, making them identifiable with a magnet test.

How Processing Affects the Magnetic Properties of Stainless Steel

Processing stainless steel can alter its magnetic properties in ways that are crucial for specific applications. The type of processing technique used can significantly impact the material’s magnetic behavior, making it either more or less magnetic.

Cold Working and Its Effects

Cold working is a process that involves deforming stainless steel under room temperature, causing strain hardening. This process can induce magnetism in non-magnetic austenitic stainless steels by transforming some of the austenite into martensite, a magnetic form of steel. The extent of magnetism induced depends on the degree of cold working and the specific grade of stainless steel.

Heat Treatment and Welding Impacts

Heat treatment and welding are other critical processes that can affect the magnetic properties of stainless steel. Heat treatment, such as annealing, can restore non-magnetic properties to cold-worked austenitic stainless steel by reverting martensite back to austenite. Welding austenitic stainless steel can create magnetic zones in the heat-affected area due to the formation of delta ferrite, which introduces magnetic properties. The cooling rate after welding or heat treatment plays a crucial role in determining the final microstructure and, consequently, the magnetic properties of the steel.

For instance, solution annealing (heating to 1050-1100°C followed by rapid cooling) is commonly used to restore the original non-magnetic properties of austenitic stainless steels after fabrication. In contrast, martensitic stainless steels remain magnetic regardless of heat treatment, which is used to control hardness and strength rather than magnetic properties.

Testing and Identifying Magnetic Stainless Steel

Testing the magnetic properties of stainless steel is essential for ensuring it meets your project’s requirements. Whether you’re working on a construction project or designing a product, understanding the magnetic properties of the stainless steel you’re using can be crucial.

Simple Methods to Test Magnetism

You can use a few straightforward methods to determine if your stainless steel material is magnetic. The most common method is the “magnet test.” If a magnet sticks to the stainless steel, it’s likely to be magnetic. The appearance of the steel can also give clues; bright, highly polished stainless steel that doesn’t attract a magnet is likely austenitic and non-magnetic.

For more definitive identification, you can use portable X-ray fluorescence (XRF) analyzers to determine the exact grade of stainless steel and predict its magnetic properties.

Understanding Stainless Steel Grades and Markings

Stainless steel grades are typically marked using the American Iron and Steel Institute (AISI) numbering system. The 300 series (like 304, 316) are generally austenitic and non-magnetic, while the 400 series (like 410, 430) are ferritic or martensitic and magnetic. Many stainless steel products include markings that indicate their grade. Look for numbers like “304” or “316” stamped or etched on the material, which can give you immediate information about its likely magnetic properties.

Understanding that duplex stainless steels (often marked with numbers like “2205”) will show moderate magnetic properties can help distinguish them from both fully magnetic and non-magnetic grades. When purchasing stainless steel for applications where magnetic properties are critical, always request material certification that specifies the exact grade and its expected magnetic permeability.

Practical Applications Based on Magnetic Properties

The magnetic properties of stainless steel play a crucial role in determining its suitability for various industries. You need to consider these properties when selecting materials for your projects.

Industries Requiring Magnetic Stainless Steel

Magnetic stainless steel is used in industries where its magnetic properties are beneficial. For example, it is used in applications requiring high strength and moderate corrosion resistance. You can find magnetic stainless steel in certain kitchen appliances and magnetic clutches.

Applications Needing Non-Magnetic Stainless Steel

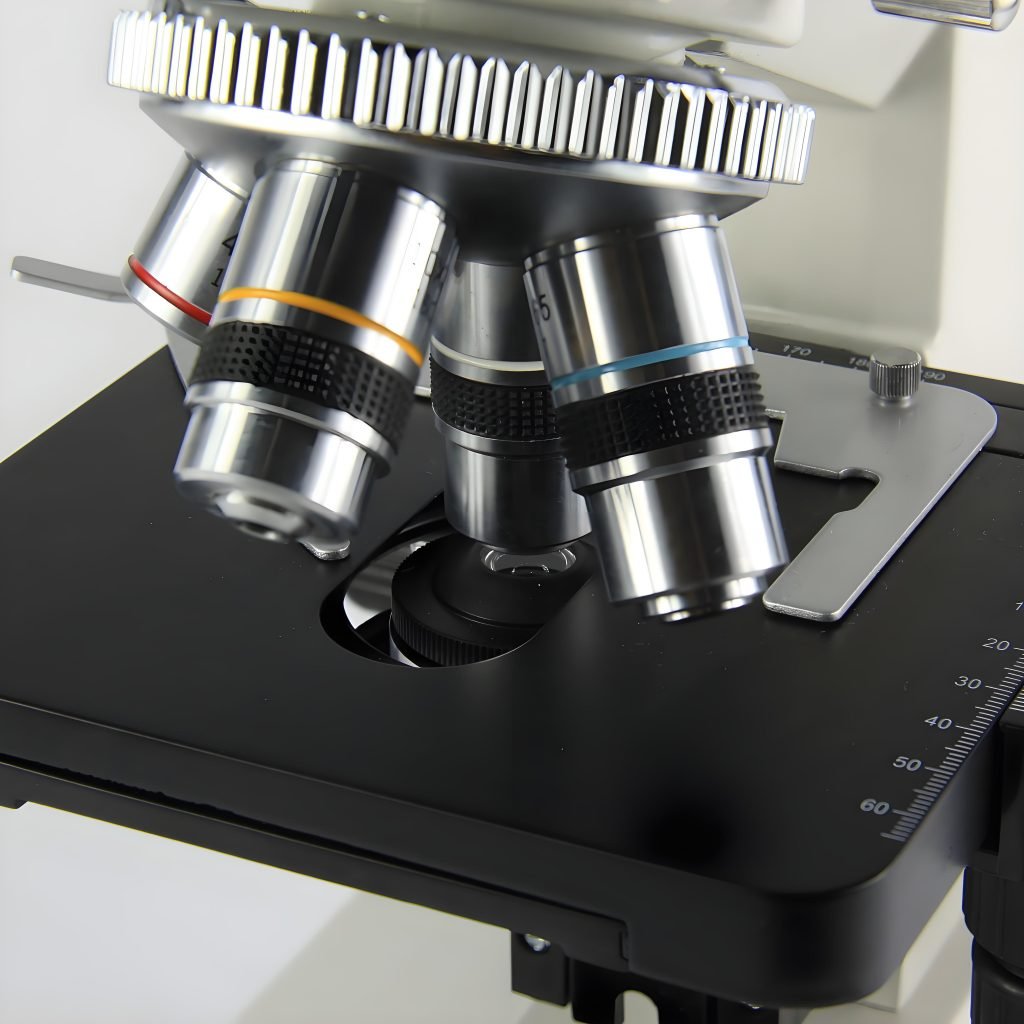

Non-magnetic stainless steel, particularly austenitic types, is essential in applications where magnetic interference must be minimized. You will find it in medical equipment like MRI machines, scientific instruments such as electron microscopes, and marine navigation equipment. Additionally, it is used in watchmaking, precision instruments, and cryogenic applications. For instance, austenitic stainless steels are used in MRI machines because they have low magnetic permeability, as low as 1.004, to prevent interference with the powerful magnetic fields used in diagnostic imaging.

Conclusion

As we’ve explored, stainless steel’s magnetic behavior varies based on its composition and processing. The magnetic properties of stainless steel are determined by its microstructure, influenced by its chemical composition and manufacturing processes. When selecting stainless steel, consider both its corrosion resistance and whether magnetic properties are beneficial or problematic for your application. Understanding the relationship between stainless steel types and their magnetic properties is essential for making informed decisions.