Assembly fixtures are the unsung brawlers of production floors. Forget precision robots—these are steel-framed anchors that muscle warped composites into submission, lock trembling engine blocks during violent drilling, and save human hands from razor-sharp edges. They don’t guide tools; they wage war against vibration, springback, and human error. Picture aircraft skins pinned under hydraulic plates or car doors snapped into pneumatic claws—fixtures are the brutal, vital hands that hold chaos at bay so rivets and welds land true.

What Are Assembly Fixtures?

Imagine workers assembling airplane bodies with big curved aluminum plates pushing composite skins against metal frames. Those plates are assembly fixtures – not fancy robots, but simple assembly fixtures tooling physically holding parts in exact positions. Their job is crude yet vital: to correct gaps when materials warp, and to lock components so that every rivet or weld hits precisely where the blueprint says unlike drilling jigs that guide tools, fixtures only battle movement. Picture car factory workers battling wobbling sheet metal; fixtures become invisible hands gripping panels until robots finish welding seams straight.

Why Every Workshop Needs Them

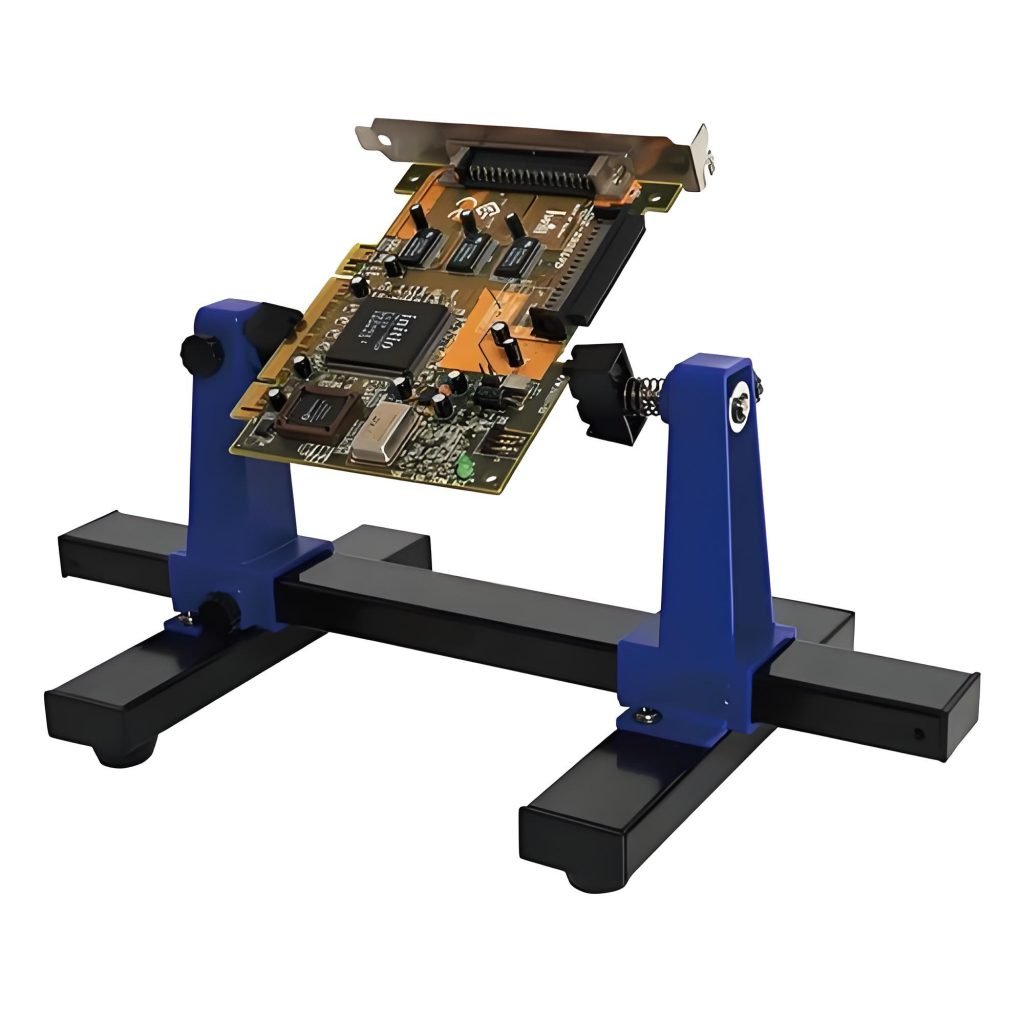

Fixtures solve four headaches every production chief hates: First, they stop parts from walking away during violent operations. Vibration from a drill could shift an engine bracket just 2mm, causing later bolt failures. Second, they forgive material flaws. Aircraft composites shrink unpredictably after molding; contoured fixtures muscle them back into shape before assembly. Third, they let regular workers act like experts. Instead of measuring angles for hours, a plumbing fixture holds pipes at 45° while the beginner just solders joints. Fourth, they prevent expensive scratches. Electronics test rigs hold fragile circuit boards with plastic claws – human fingers leave fingerprints that damage circuits later.

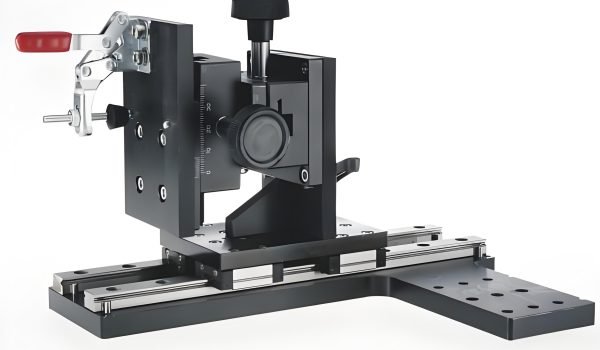

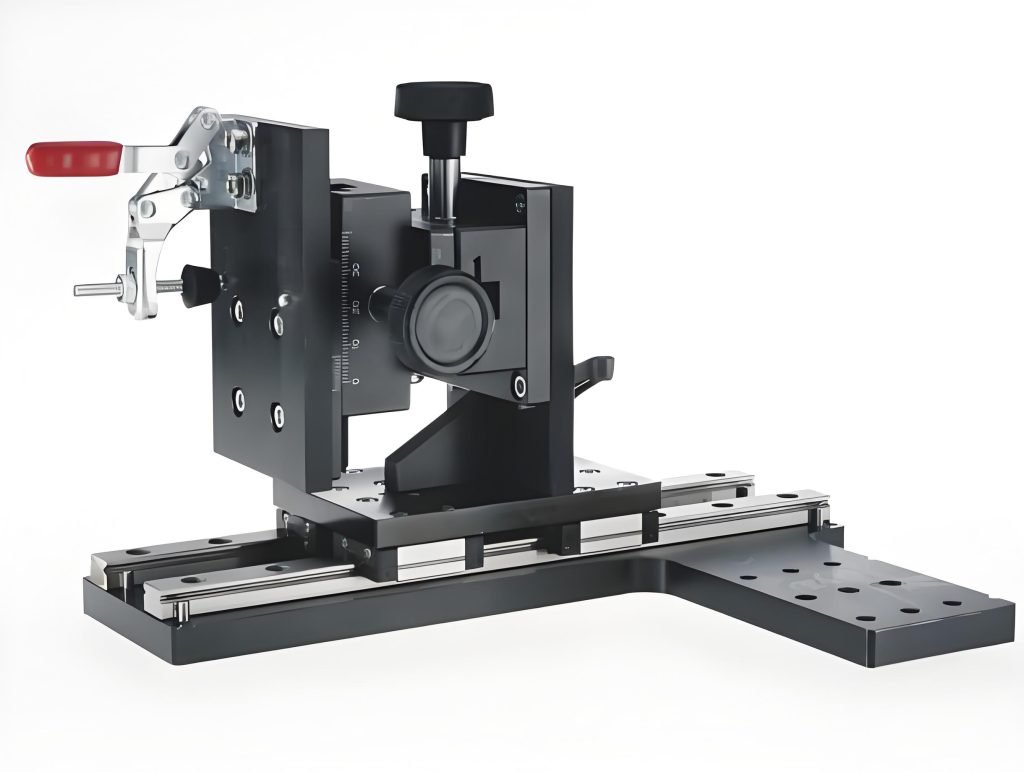

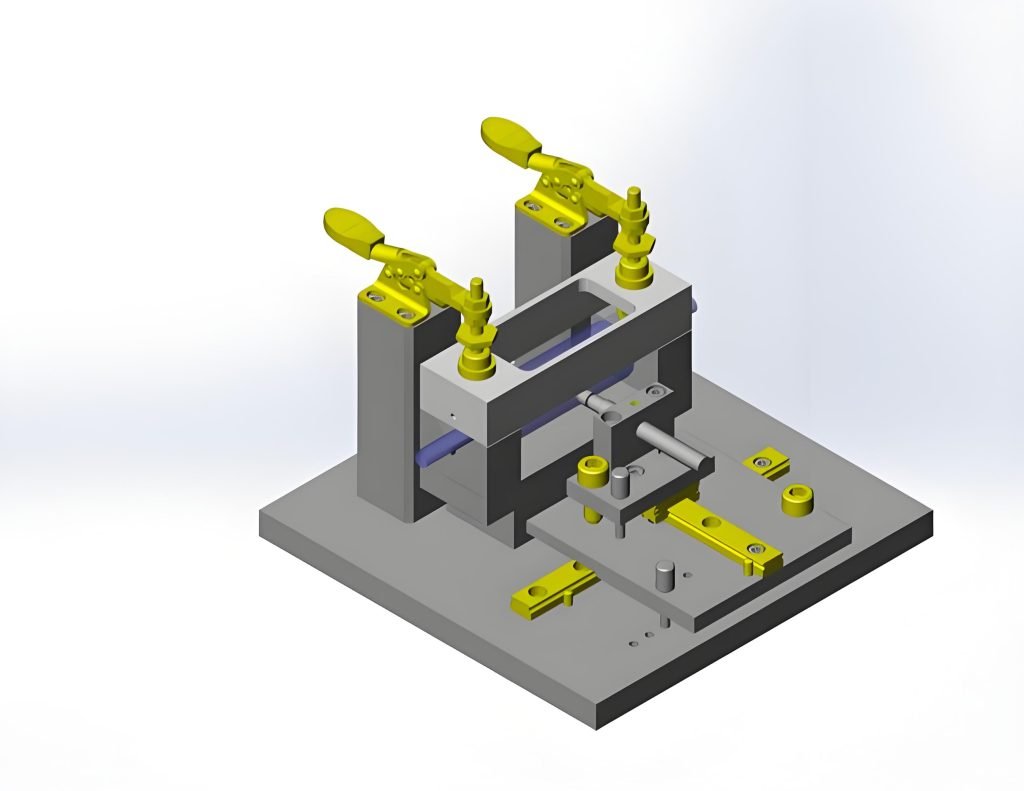

Four Fixture Types We Use

Block-and-pin fixtures rule repair shops. Mechanics bolt adjustable steel blocks onto tables to secure irregular tractor engine parts. Air-powered clamps dominate car factories: an operator presses a button, and piston rods shoot out to grab door frames in one second flat. For ultra-delicate tasks like carbon fiber jet wings, we carve custom foam beds that hug the part’s exact shape. And for quality checks, spring-loaded test rigs poke electronic devices without leaving marks – anything touched by workers risks static electricity burns.

Four Parts That Matter

Every working fixture needs these: A welded steel base, often bolted to concrete floors to stay put during wrenching. Locator pins – not smart sensors, just stainless steel rods shoved into predrilled holes to position parts by feel. Clamping arms, either hand-turned screws for cheap jobs or air-driven pistons for tire plants moving sixty parts per hour. Finally, soft jaws: copper pads on welding clamps that conduct current while not scratching chrome bumpers. Without these, fixtures become part crushers.

Truths Owners Won’t Tell You

Fixtures cost time but save lives. Aircraft skin plate fixtures take three weeks to make – yet they prevent hand-clamping accidents with composite edges sharp as scalpels. They slow first-time setups but crush rework costs: electronics makers see 80% fewer solder errors using testing rigs. Even garage shops profit. My uncle’s key duplication store upgraded from hand vices to simple toggle clamps – copies now fit locks first time. But caution! Poorly aligned fixtures chew through materials. One bicycle frame jig wore out, causing fifty crooked handlebars before anyone noticed the bent locator pin.

Assembly Fixture Design Principles

Fixture designers wage war against hidden forces – thermal expansion twisting metal frames overnight, vibration loosening bolts during grinding, even human muscle fatigue causing millimeter drifts in hand-clamped parts. Their weapon? Deliberate over-engineering. Aircraft assembly fixtures teams shape aluminum molds intentionally tighter than the final part dimensions, knowing carbon fiber panels will slowly relax into perfect curves after release. Car welding jigs clamp sheet metal past theoretical positions to counter spring-back during spot welding. This controlled distortion seems illogical on CAD screens but saves entire production batches from scrap heaps.

Materials: Choosing Survivors Over Princes

Walk any assembly line at midnight, and you’ll see fixture skeletons enduring torture: welding sparks eating soft alloys, hydraulic fluid degrading cheap polymers, and steel bases cracked by overloaded forklifts. Longevity demands hybrid material logic. Heavy clamping zones get hardened steel inserts that shrug off impact, while vibration-prone areas use aluminum dampers that quietly absorb shakes. Electronics test claws combine glass fibers for stiffness with rubber coatings guarding circuits against static discharge. The best designs mimic nature’s wisdom – hard teeth in soft gums. Detroit toolrooms weld scrap steel blocks beneath pristine aluminum guides, creating fixtures that age like oak rather than porcelain.

Ergonomics: When Fixtures Serve Humans

Fixtures forgetting human limits breed production mutinies. Imagine welding operators stretching over frames to toggle clamps daily – within months, shoulders fray like old ropes. Smart workshops enforce three rules: Natural movement paths (Toyota angles pneumatic valves toward hip pivots, not overhead reaches), intuitive indicators (green unlock handles glow against factory gloom), and fail-safe simplicity (Philips circuit testers click-lock with quarter turns – exhausted night-shifters can’t cross-thread them). Even gravity is harnessed; German axle stands tilt drivelines downward, letting oil drip into pans instead of sleeves. These silent adjustments keep Linda’s team productive without chronic painkillers.

Flexibility: Dancing with Design Changes

Rigid fixtures crumble when engineers tweak part dimensions. Survivors build in adjustability seams. Renault technicians slide locators along baseplate dovetail tracks for next year’s wider hatchbacks. Aircraft tooling allows bolt-on spacer kits to accommodate fuselage variations. Honda’s engine mount masters deploy layered brass shims – a stack thinner than business cards – to micro-adjust grip positions. For critical alignments, kinematic mounts work like ballet joints: three hardened balls gently guide parts into position without imposing strain. This foresight avoids rebuilding fixtures for trivial geometry shifts.

Endurance: Design for Inevitable Abuse

Blueprints never predict midnight chaos – pallet jacks ramming fixtures, hammers bouncing off clamps, coffee spills corroding sensors. Practicality demands forgiveness. GM plants weld reinforced skids under bases, lifting critical pins above debris-strewn floors. Electronics rigs shield components behind plexiglass screens blocking accidental probes. Even surface treatments matter: bead-blasted aluminum hides scratches better than polished chrome. And true artisans’ design for repairability – Boeing templates get refilled when worn, while Detroit jigs accept patch welds on cracked sections. Like good leather boots, they age with character.

| Principle | Shop Floor Payoff |

| Physics-driven distortion | Slashes composite rework – aircraft skins spring into true shape, not scrap bins |

| Hybrid materials | Outlasts single-metal builds – steel jaws absorb impacts while aluminum dampens shakes |

| Operator-centered ergonomics | Cuts shoulder injuries– hip-height clamps stop workers from stretching like over-tensioned cables |

| Adjustable platforms | Kills fixture replacement costs– slide locators adapt to next year’s hatchback redesign |

| Damage-resistant skeletons | Prevents 3 AM disasters– skid plates shrug off forklift hits, keeping lines running |

Tooling: The Silent Battle Against Chaos

Assembly fixtures are like rusty armor on production lines—weld spatters scar steel surfaces, hydraulic oil corrodes joints, and night-shift forklifts crash into edges. These unglamorous metal structures fight physical laws daily: crankshafts twisting under hydraulic pressure, aircraft composites springing back after molding.

Their value hides in disasters avoided. A slight misalignment in PCB test fixtures can destroy entire batches of sensitive components through static discharge; automotive welding jigs offset by millimeters cause door panels to grind against robotic arms. Practical solutions emerge from battlefield experience: hardened steel inserts in heavy clamping zones withstand impacts, while vibration areas use aluminum dampeners absorbing shakes—like nature’s wisdom where hard teeth meet soft gums.

Automotive Assembly Fixtures: Speed Versus Human Limits

Automotive fixtures endure violent cycles: robotic welders hammer metal sixty times per minute, and pneumatic clamps must lock before workers turn around. Toyota’s breakthrough was angling levers toward operators’ hips—workers pivot naturally instead of stretching their arms, like turning a doorknob. A tougher challenge is tolerating human error: General Motors replaced steel jaws with chrome-plated brass claws after night-shift fatigue caused fixtures to scratch chrome bumpers, creating repair bills exceeding fixture costs.

Crankshaft Assembly Fixture: Taming Invisible Enemies

Crankshaft assembly battles unseen forces. As hydraulic presses force shafts into blocks, internal stresses twist metal like waking snakes. Veteran mechanics insist on tungsten locator pins—brutally shoved into pre-drilled holes, “feeling metal’s resisting tremor” remains more reliable than sensor numbers. Deadly traps hide in temperature shifts: workshop cooling overnight makes steel frames contract, gripping crankshafts tighter at dawn. The first product always needs readjustment or bearing clearance deviations to trigger engine whine. The fix? Milling “breathing slots” into fixture bodies, allowing steel to expand freely with heat—or dawn’s output becomes scrap metal.

PCB Assembly Fixtures: Precision Without Touch

PCB fixtures are surgeons, not butchers. Spring probes must contact circuit nodes without scratching copper traces—a static spark means thousands in losses. Philips’ answer was nylon claws with carbon-fiber fingertips: conducting current while isolating contamination, like surgeons in rubber gloves.

Aircraft Tooling: Rewriting Physics

Aircraft fixtures don’t assemble parts—they rewrite physical rules. Boeing’s composite wings warp like overcooked pizza edges after molding; aluminum inner mold plates muscle them into aerodynamic curves using hydraulic pressure exceeding flight stresses. The secret is controlled rebound: fixtures deliberately overbend by 5%, waiting for carbon fiber to relax overnight into perfection.

Tips on Choosing an Assembly Fixture Manufacturer

1. Demand Material Battle Scars

Seek manufacturers who show you steel samples with weld marks and oil stains—not shiny catalog pictures. Fixtures face real violence: hydraulic shocks bending metal, forklifts scraping edges during night shifts. Suppliers pretending fixtures never break are dangerous. Ask: “How will your steel claws survive when workers drop crankshafts?” Listen for words like “hardened inserts for impact zones” or “aluminum dampeners where vibration eats metal”. These prove they’ve seen workshop wars.

2. Obsess Over Human Weakness

Great fixtures forgive tired workers. At Toyota, lever angles follow hip rotation so operators clamp without stretching—like turning a door handle. Bad designs ignore human limits: sharp edges cut hands, heavy clamps strain shoulders. Demand evidence like General Motors’ switch to brass claws after steel jaws scratched chrome bumpers. “Show me how your fixture handles mistakes”—this question separates engineers from salesmen.

3. Hunt the Compromise

Perfection doesn’t exist in factories. Honda’s engine jigs use brass shims thinner than fingernails—when new parts warp slightly, technicians slide shims instead of halting production. Ask manufacturers: “Where did you sacrifice precision for reality?” Answers like “We bolt plastic claws to steel frames for flexible circuits” reveal practical thinking. Avoid those boasting “zero tolerance”—they’ve never smelled burnt metal at 3 AM.

4. Test Their Disaster Response

Fixtures fail. When laser guides failed at Airbus, technicians revived manual templates in hours. Grill suppliers: “What’s your backup when sensors die?” Watch their eyes. Do they describe quick-change locator pins? Can they sketch breathing slots for thermal expansion?

5. Demand Warehouse Truth

Beware factories hiding storage chaos. Good manufacturers plan for reverse logistics—recovering fixtures from closed stores to reuse elsewhere. Ask: “How will you label my 200 clamps for fast retrieval?” Listen for specifics: color-coded bolts, and modular frames that pack flat. Suppliers who can’t explain pallet breakdowns will drown you in unused steel.

Ø Why Fecision Embodies These Principles

Fecision builds CNC fixtures that fight on your workshop floor. We machine steel bases that shrug off forklift hits and carve aluminum dampeners swallowing vibrations. Forget perfect CAD models – our fixtures show grind marks and retrofit holes because they’ve survived real production chaos. When aircraft composites warp or crankshafts twist at dawn, our distortion-controlled jigs muscle parts into tolerance. Operators get hip-height clamps saving shoulders, tilted PCB claws defeating oil contamination, and breathing slots for thermal expansion. Bring us your violent processes; we deliver anchored, scarred metal that outlasts shifts.