Fixtures are absolutely critical in the manufacturing world. They hold your workpieces steady so that machining can be done precisely to great effect. You may not be able to get the accuracy and rapidity you may be searching for without the right fixture. This leads to the question: Which hydraulic or pneumatic fixtures are best for you?

The pneumatics vs hydraulics debate is a common one. Each comes with its pros and cons. Choosing the wrong system will unnecessarily increase costs, slow down production and even risk parts becoming damaged. This guide will help you understand some of the differences, enhance your knowledge and assist you in making a decision regarding your manufacturing operation. Understanding the core of hydraulic vs pneumatic applications is vital.

What Are Hydraulic Fixtures?

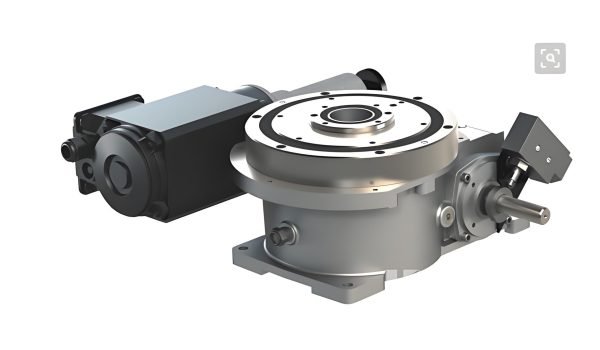

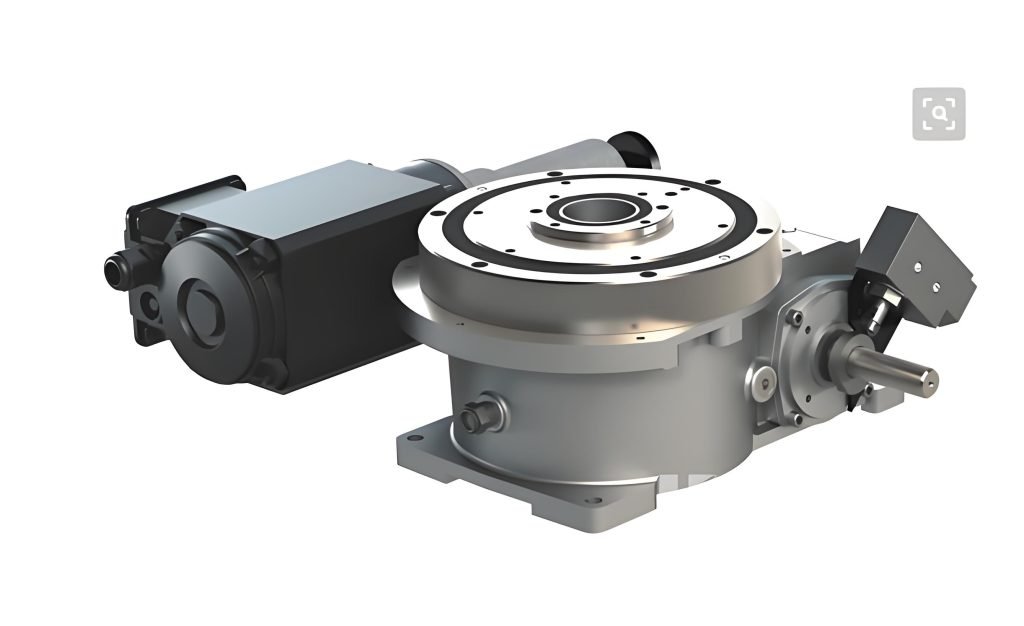

Hydraulic fixtures utilize a fluid, typically oil, to produce the significant clamping force necessary to hold workpieces securely. When we say hydraulic fixtures, we mean the actual part that securely holds your material. However, it does help to know that hydraulic fixtures are attached to systems of hydraulically controlled pumps, hydraulic reservoirs, and valves to control the flow and pressure of the oil.

Advantages

High Force Output

They are capable of producing a very high amount of force. This makes them exceptional for holding heavy or irregular parts, and especially for jobs with high cutting force, which require a large gripping surface. If you need a really powerful grip, then a hydraulic system is the right choice.

Precision Control

Hydraulic fixtures have great precision control over movement and positioning. This is important for jobs where precision matters, especially when operating with tight tolerances. You can control the pressure and movement to get precise results.

Consistent Performance

After the hydraulic system has been properly set, it will be dependable for the entire lifetime of the usage. Hydraulic systems have a very small fluctuation, so there is consistent mechanical force exerted on each part, and the same product quality can be obtained.

Disadvantages

Complexity

Hydraulic systems are complex. They require pumps to move fluid, valves to control flow, and reservoirs to store fluid. It means more device setups and additional management.

Maintenance

These systems require regular attention. You need to check for leaks, top up fluids, and ensure all parts are working correctly. Neglecting maintenance can lead to breakdowns and costly repairs.

Cost

As there are complex components, the initial cost to set up hydraulic fixtures is higher. Maintenance costs can also accumulate due to the need for specialized fluids and parts.

Applications

You will see hydraulic fixtures in industries where power and precision are key. A great example is the automotive industry, which manufactures extremely heavy parts like engine blocks. You’ll also see hydraulic fixtures in aerospace, as they are extremely effective in holding parts during the entire manufacturing process of critical aerospace parts.

Hydraulic fixtures are also key to the manufacturing of heavy machinery. They clamp huge components for construction or agricultural equipment, and in the case of milling, welding, and drilling operations, they provide critical and proper clamping.

What Are Pneumatic Fixtures?

Definition

Pneumatic fixtures employ compressed air for holding and positioning workpieces. A pneumatic fixture is one part of a pneumatic system. It relies on the changes in air pressure to do the work. Instead of fluid, air is pushed through hoses to activate clamps and other holding mechanisms.

Advantages

Simplicity

Pneumatic systems are less complex. Normally, they are an air compressor, some valves, and air cylinders. That makes pneumatic systems easier to set up and maintain.

Speed

Pneumatic fixtures can typically act very quickly. Air can be compressed and released at far faster rates than fluid to facilitate a fast environment to clamp and unclamp. This represents a meaningful contribution to improving the production efficiency of your operations, particularly in an environment where you handle high volumes.

Cost-Effective

Pneumatic systems are often much cheaper to buy and install. Usually, because the system is simpler and more basic, pneumatic systems require much less ongoing maintenance.

Disadvantages

Lower Force Output

They are not capable of exerting as much force as hydraulic systems, which means that they are less suitable for very high force or heavy-duty applications.

Precision Limitations

Although good, they typically do not provide the same level of super-fine precision control as hydraulic fixtures do. Because air is compressible, this typically leads to variability in positioning the workpiece.

Noise

Pneumatic systems can be very noisy. Air compressors or compressed air release are capable of producing significant noise that could be concerning within some work environments.

Applications

You will often see pneumatic fixtures in industries where speed and lighter loads are their primary purposes. The manufacturing of electronics, for example, will use pneumatic fixtures for the assembly of circuit boards, or when handling small electronic components that need delicate but fast clamping.

They are also frequently utilized in packaging, clamping boxes quickly into place or when positioning items on a conveyor. In light manufacturing, think about their use in assembling small plastic parts, or performing quick drilling operations on aluminum sheets.

Hydraulic vs Pneumatic Fixtures: Key Differences

Let’s look at some of the key differences to help illustrate which option may be better for your particular operational tasks.

Force Output

Hydraulic fixtures are force monsters. They can exert great clamping force and are perfect for holding heavy difficult-to-machine parts. Think about operations that create a lot of vibration or require a very rigid setup.

Pneumatic fixtures are not going to have a lot of force capabilities compared to hydraulics. They are perfectly fine for lighter workpieces or where less clamping force is needed. If you are holding plastics, thin metals, or a small assembly, pneumatics could be all right.

Precision

In terms of accuracy, hydraulic fixtures provide a higher precision level. Since hydraulic fluid is incompressible, you can consistently control movement and positioning very well to a fine degree. If your parts require extremely tight tolerances, the hydraulic solution will often produce better outcomes.

Pneumatic fixtures can be just as precise, but they aren’t usually an ultra-fine control process. The compressibility of air might cause some slight, unpredictable differences in performance, and while often acceptable for many applications, they are not ideal for your highest level of positional accuracy application.

Complexity and Maintenance

Hydraulic systems are more complex because they have more components, including pumps, reservoirs, and filters. This means the initial setup is more involved. The maintenance demands are also higher, with scheduled fluid checks, filter changes, and leak checks – all very regular parts of ongoing care, which are important to ensure that there are no system failures.

Pneumatics are simpler systems that only require a few components, and are generally easier to set up. The maintenance of a pneumatic fixture is also less involved; it often only requires basic checks of airlines, seals, and compressor filters. The simplistic nature of pneumatic systems could translate to reduced downtime.

Cost

The outset cost of hydraulic fixtures is higher because of their more complex machine components and more specialized fluids. The lifecycle costs for hydraulic fixtures can also be higher because of fluid replacement, filter changes, and repair work that are often more specialized.

Pneumatic fixtures are typically less expensive from the outset. A pneumatic fixture’s simple design and available components typically reduce the cost of purchase and installation positively. Their ongoing maintenance costs are also cheaper because generating and managing compressed air costs less than hydraulic fluid.

Speed

Pneumatic fixtures have a faster operation speed. Generating and compressing air takes less time than hydraulic fluid, which allows for various clamping and unclamping cycles. For example, if your manufacturing sequence is dependent on high-speed, pneumatic power could very well increase your throughput.

Hydraulic fixtures, however, are generally slower in their operations. Because fluids move more slowly, this could be a consideration when dealing with different processes that rely on high volumes, where every second of production is critical.

| Feature | Hydraulic Fixtures | Pneumatic Fixtures |

| Force Output | High force, ideal for heavy parts | Lower force, suited for lighter materials |

| Precision | High (fluid is incompressible) | Good, but air compressibility may reduce accuracy |

| Complexity | More complex (pumps, fluid, filters) | Simple (air compressor, valves) |

| Maintenance | Higher (fluid leaks, filter changes) | Lower (basic airline checks) |

| Cost | Higher upfront & maintenance | Lower initial & operational costs |

| Speed | Slower (fluid movement delays clamping) | Faster (quick air compression/release) |

How to Choose Between Hydraulic and Pneumatic Fixtures

The decision regarding what fixture you choose, hydraulics vs pneumatics, is application-dependent. Here is a quick assessment of your decision:

Assess Your Application Requirements

Force Needs

First of all, ask yourself, “How much force do I really need to hold my workpiece in position?” If you’re working with heavy materials, aggressive cutting, or deep drilling, hydraulic fixtures that create high clamping force are usually the ideal fixtures. If you are working with lightweight materials, assembly work, or less demanding actions, you will most likely be fine with pneumatic fixtures.

Precision Needs

How accurate does your positioning need to be? If your product has super tight tolerances and even a tiny bit of movement can ruin a part, then the superior precision of hydraulic fixtures will be crucial. If some slight variation is acceptable, pneumatic fixtures can still offer good enough accuracy for many tasks.

Production Speed

Is production speed a key consideration for your manufacturing process? If you need to clamp and unclamp parts very quickly to attain your production outputs, then you will surely benefit from the rapid cycling of pneumatic fixtures. If, on the other hand, your cycle times are longer and you are more interested in precision than in speed, hydraulic fixtures will certainly meet your needs.

Consider Cost and Maintenance

Initial Investment

Look at the initial investment cost as part of your budget. Typically, pneumatic fixtures have lower initial investment requirements, which work well for less complex operations or smaller budgets. Hydraulic fixtures will require a more substantial initial investment.

Ongoing Maintenance

Consider the long-term. Are you prepared for the more involved maintenance of a hydraulic system (fluid changes, leak checks)? Or do you prefer the simpler, less frequent maintenance of a pneumatic system? Think about labor time, while the cost of parts and fluids needs to be considered. This comparison of a hydraulic system vs pneumatic system is vital for long-term planning.

Seek Expert Advice

Choosing the right fixture can be complex, especially for specialized applications. Don’t hesitate to consult with experts. Engineers and manufacturers who specialize in fixturing can provide tailored advice based on your specific materials, processes, and production goals. They can help you weigh the pros and cons in detail for your unique situation.

Conclusion

In conclusion, both hydraulics and pneumatics fixtures have their requirements and usefulness in production. The decision between pneumatic vs hydraulic is critical.

Hydraulic fixtures have high force, superior precision and consistent performance – this is the best option for heavy-duty when dealing with manufacturing like automotive and aerospace. On the other hand, hydraulic fixtures come with more complexity, maintenance and cost.

Pneumatic fixtures give you ease of use, speed, and cost savings, which make them beneficial for lighter manufacturing, electronics, and packaging. However, pneumatic fixtures have low force output, low precision, and can be noisy.

Fecision: Your Best Partner for Fixture and CNC Machining Needs

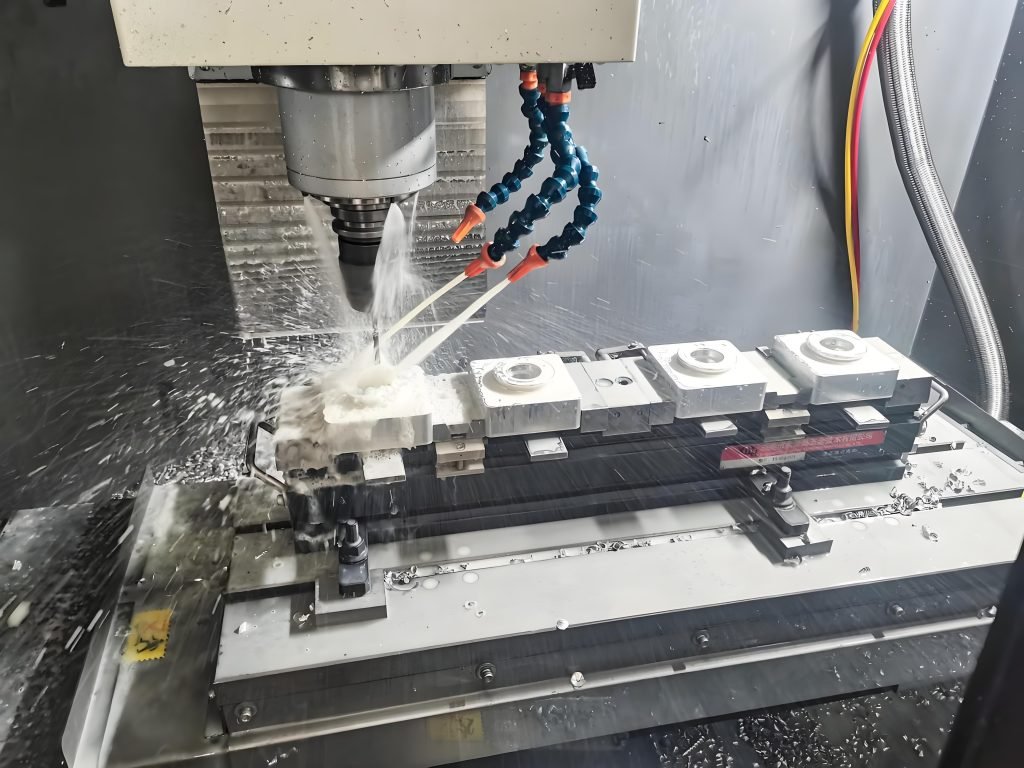

Fecision has expertise in high-precision CNC machining, and we manufacture custom hydraulic and pneumatic fixtures that will improve your manufacturing accuracy. Fixtures are an essential part of the process, which ensures vibration-free and stable clamping, directly improving CNC machined parts. Our CNC services also manufacture the fixtures themselves, ensuring they meet tight tolerances for optimal performance in your production line.

Fecision’s Key Advantages in Fixture & CNC Machining:

✔ ±0.005 inches Precision – 5-axis CNC ultra-precise fixtures

✔ Metal & Plastic Machining – Aluminum, steel, titanium, and more

✔Rapid Production – From prototype to final parts

✔ Custom Fixture Design – Optimized for your industry needs

✔ ISO 9001 Certified – Quality guaranteed with CMM inspection

Need reliable fixtures or CNC parts? Get a quote from Fecision today!