Did you know that the melting point of stainless steel ranges from 1,370 to 1,530 degrees Celsius? This critical property affects its performance in various industries.

Understanding the temperature at which steel melts is essential for manufacturing processes and material selection. Different grades of stainless steel have varying melting points, influenced by their composition.

This guide will explore the melting point of stainless steel, its importance, and how it impacts practical applications. Whether you’re in manufacturing or engineering, this information will provide valuable insights into this critical characteristic of materials.

Understanding Melting Points: Basic Concepts

Understanding the concept of melting points is crucial for working with various materials, including stainless steel. You need to grasp this fundamental property to appreciate how materials behave under different conditions.

What Is a Melting Point?

A melting point is the temperature at which a solid substance transitions to a liquid state under normal atmospheric pressure. It’s a physical property that helps characterize materials and determine their suitability for various applications.

Physical Changes During the Melting Process

When a solid is heated, its internal energy increases, causing particle vibration. At the melting temperature, these vibrations overcome the forces holding the particles together in a solid structure, allowing them to move freely as a liquid. During this process, the material absorbs heat energy (latent heat of fusion) while maintaining a constant temperature until the phase change is complete.

Difference Between Pure Metals and Alloys

Pure metals have precise, single-temperature melting points because their uniform molecular structure changes phase at exactly the same temperature. In contrast, alloys like stainless steel exhibit melting ranges rather than single points because different components melt at different temperatures, creating a gradual transition from solid to liquid.

Understanding the difference between melting points of pure metals versus alloys is crucial for predicting material behavior in high-temperature applications. The melting point serves as an important reference point for material processing, helping determine appropriate temperatures for welding, casting, and other manufacturing processes.

The Importance of Melting Points in Stainless Steel Applications

Stainless steel’s melting point is a critical factor in its application across various industries, including aerospace and construction. Understanding this property is essential for ensuring the material’s performance and safety in different environments.

Manufacturing and Processing Considerations

Knowing the melting points of stainless steel is crucial for manufacturing processes, including welding, casting, forging, and heat treatment. This knowledge determines the maximum operating temperatures and helps prevent damage to the material.

For instance, during welding, understanding the melting point helps in selecting the right techniques and temperatures to avoid deforming or damaging the stainless steel. Similarly, in casting and forging, knowing the melting point ensures that the material is processed correctly, maintaining its structural integrity.

Safety and Structural Integrity

The structural integrity of stainless steel components can be compromised when exposed to temperatures approaching their melting points. Mechanical properties begin to degrade well before actual melting occurs, which can lead to catastrophic failures in critical applications.

Material Selection for High-Temperature Applications

Material selection for high-temperature applications must consider not just the melting point but also how the stainless steel’s properties change as temperatures increase. This includes potential phase transformations and oxidation resistance.

| Industry | Application | Importance of Melting Point |

| Aerospace | Engine Components | High melting point ensures durability at high temperatures |

| Automotive | Exhaust Systems | Resistance to corrosion and heat deformation |

| Construction | Structural Components | Maintains strength and integrity under various conditions |

By understanding the melting point of stainless steel, engineers can establish safety margins and determine appropriate temperature limits for components in critical applications, ensuring operational safety and preventing failures.

The Melting Point of Stainless Steel: Temperature Ranges

The temperature range at which stainless steel melts is essential knowledge for anyone working with this versatile material. Stainless steel exhibits a melting range rather than a single melting point, typically falling between 1,370°C to 1,530°C (2,500°F to 2,790°F) depending on the specific grade and composition.

General Melting Range of Stainless Steel

The melting temperature of stainless steel falls between 1,400 and 1,530 degrees Celsius (2,550 to 2,790 degrees Fahrenheit). This range is influenced by the proportions of iron, chromium, nickel, and other elements in the alloy.

Comparison with Other Metals and Alloys

This temperature range is significantly higher than many common metals like aluminum (660°C), copper (1,085°C), and brass (900-940°C), making stainless steel suitable for high-temperature applications where these metals would fail.

Temperature Behavior Near Melting Point

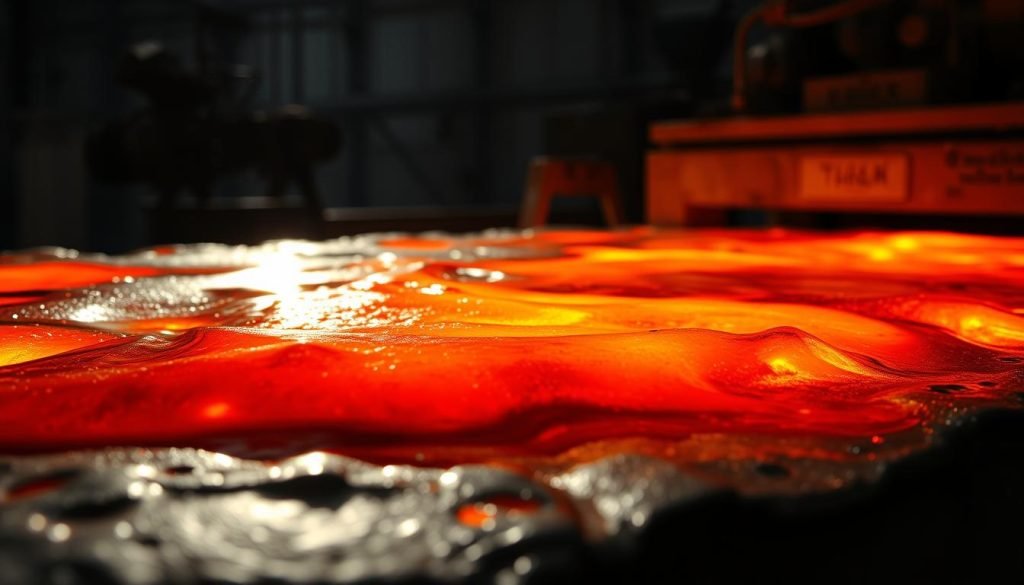

As stainless steel approaches its melting point, it undergoes several behavioral changes, including color shifts (from red to orange to yellow-white), decreased tensile strength, and increased malleability. The solidus temperature (where melting begins) and liquidus temperature (where melting completes) define the melting range, with the material existing as a semi-solid slurry between these temperatures.

Understanding this temperature range is crucial for processes like investment casting, continuous casting, and precision welding, where controlling the material’s phase state is essential. The relatively high melting point of stainless steel contributes to its excellent fire resistance and structural stability in high-temperature environments compared to other construction materials.

Melting Points Across Different Stainless Steel Grades

Understanding the melting points of different stainless steel grades is crucial for selecting the right material for your high-temperature applications. Stainless steel’s melting points can vary significantly across different grades, making it essential to choose the correct grade for your specific needs.

Austenitic Stainless Steel Melting Points

Austenitic stainless steels, such as grades 304 and 316, generally have lower melting points compared to other types. Grade 316 stainless steel, for instance, has a melting range of 1,375-1,400°C (2,507-2,552°F) due to its higher nickel and molybdenum content.

The popular grade 304 stainless steel has a melting range of 1,400-1,450°C (2,552-2,642°F), making it versatile for many applications while still offering good high-temperature performance.

Ferritic Stainless Steel Melting Points

Ferritic stainless steels like grade 430 have higher melting points, ranging from 1,425-1,510°C (2,597-2,750°F), due to their higher chromium content and lower nickel content.

Martensitic Stainless Steel Melting Points

Martensitic stainless steels typically melt between 1,420-1,460°C (2,588-2,660°F) and are known for their hardness and strength rather than their heat resistance.

Duplex Stainless Steel Melting Points

Duplex stainless steels, with their mixed austenitic-ferritic structure, generally have melting points between 1,410-1,470°C (2,570-2,678°F), offering a balance of corrosion resistance and strength.

Comprehensive Melting Point Chart by Grade

| Grade | Melting Point (°C) | Melting Point (°F) |

| 301 | 1400-1420 | 2552-2588 |

| 304 | 1400-1450 | 2552-2642 |

| 316 | 1375-1400 | 2507-2552 |

| 430 | 1425-1510 | 2597-2750 |

The comprehensive melting point chart reveals that grade 430 ferritic stainless steel has the highest melting point among common grades, while grade 316 austenitic stainless steel has the lowest. Understanding these grade-specific melting points is essential for applications where materials will be exposed to extreme temperatures or thermal cycling.

Determining the Melting Point of Stainless Steel

To accurately determine the melting point of stainless steel, you need to understand the various methods and equipment used. The process involves precise measurements and specialized equipment due to the high temperatures involved.

Laboratory Methods for Measuring Melting Points

Laboratory methods are crucial for accurately determining the melting point of stainless steel. Two primary techniques used are Differential Scanning Calorimetry (DSC) and Thermocouples with Pyrometry.

Differential Scanning Calorimetry (DSC)

DSC measures the heat flow into or out of a sample as it is heated. When the sample melts, a distinct peak appears on the DSC graph, indicating the melting point.

Thermocouples and Pyrometry

Thermocouples and pyrometry use temperature sensors or non-contact infrared devices to measure temperature changes. This method observes the material’s transition from solid to liquid state.

Industrial Testing Procedures

Industrial testing procedures often employ standardized methods established by organizations like ASTM International. These methods ensure consistency and reliability in melting point determination.

Challenges in Accurate Measurement

One significant challenge is preventing contamination of the sample, as even small impurities can alter the observed melting point. Controlling the heating rate is also crucial to avoid temperature gradients within the sample.

Factors Affecting the Melting Point of Stainless Steel

The melting point of stainless steel is influenced by several key factors that you need to consider for optimal performance. These factors can be broadly categorized into the chemical composition of the alloy, its crystal structure, and external conditions.

Chemical Composition and Alloying Elements

The chemical makeup of stainless steel plays a significant role in determining its melting point. Key elements include chromium, nickel, and carbon, among others.

Effect of Chromium Content

Chromium is essential for stainless steel’s corrosion resistance and generally increases its melting point. A higher chromium content typically results in a higher melting temperature.

Effect of Nickel Content

Nickel, commonly added to austenitic stainless steels, tends to lower the melting point. However, it enhances ductility, formability, and corrosion resistance in acidic environments.

Effect of Carbon and Other Elements

Carbon content, though typically less than 0.08% in most stainless steels, can significantly impact the melting point. Higher carbon levels generally raise the melting temperature but may reduce corrosion resistance.

Crystal Structure Influence

The crystal structure of stainless steel, whether face-centered cubic (FCC) for austenitic or body-centered cubic (BCC) for ferritic, influences its melting characteristics. Generally, FCC structures have lower melting points than BCC structures.

External Factors: Pressure and Atmosphere

External factors such as pressure and the surrounding atmosphere during heating can also affect the melting point of stainless steel. Increased pressure typically raises the melting temperature.

Conclusion: Practical Implications of Stainless Steel Melting Points

As we explore the properties of stainless steel, its melting point emerges as a critical factor in material selection. The melting point of stainless steel, ranging from 1,370 to 1,530 degrees Celsius, is influenced by its alloy composition, including chromium, nickel, and iron. This variability affects the suitability of different grades for specific applications in manufacturing, construction, and aerospace.

When designing components, consider not just the absolute melting point but also how the material’s properties change as temperatures increase. The ongoing development of new stainless steel alloys continues to push the boundaries of what’s possible in high-temperature applications, offering optimized combinations of melting point, strength, and corrosion resistance.