Reamer bits are machinist cutting tools for thinning and finishing holes with accuracy. These precision hole-making tools produce precise holes and are used in the production of high-accuracy holes. Suppose you’re manufacturing parts deep within precision industries like aerospace or automotive. In that case, a reamer delivers precision and quality in the end product. But why are reamers so essential, and how do they work?

Reamers are rotating cutting tools that cut small chips off a pre-drilled hole to enhance the hole’s surface finish and achieve a higher degree of accuracy to size. Drills make holes, but reamers perfect them, correcting misaligned holes and creating them to be uniform. Their fluted cutting edges support efficient cutting and feeding with precision.

Reamers come in a wide variety of types, catering for everything from manual reaming through to ultrahigh-speed CNC machining. In this post, we will take a deep dive into the various types of reamer tools, their applications and how to select the right one for your machining requirements.

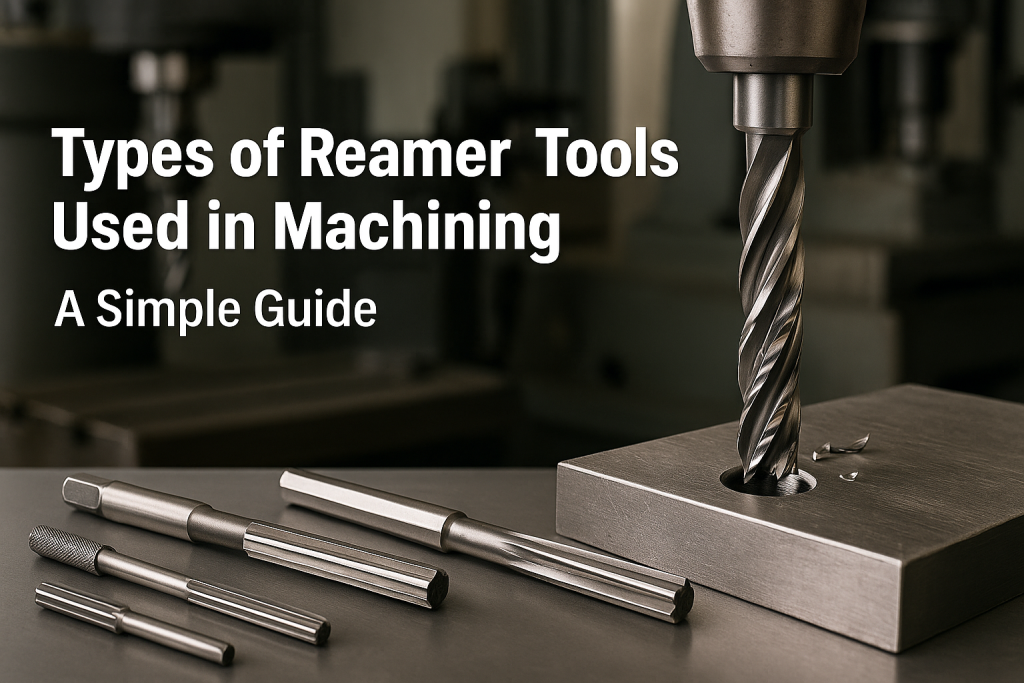

Types of Reamer Tools

Reamer tools come in a variety of designs, each tailored to specific machining tasks. Below, we dive into the main types, their subtypes, and their unique applications.

Hand Reamers

Hand reamers are held on a taper shank that is inserted into the spindle of a drill press or a lathe tailstock. These reamers have a long shank with a straight flute and square drive end that can be turned by hand with a wrench or T-handle. They’re great for finishing holes in soft materials, such as aluminium or brass, requiring precision but not high-speed machining.

Hand reamers are usually straight-fluted and are intended for manual use. They are also a favourite when it comes to workshops and general DIYs, including drilling through holes in metalworking or fixing worn-out machine parts. But they are difficult to get the hand of how to use precisely; off-centre pressure can easily make them inaccurate. Hand reaming is most appropriate in low-tolerance applications and is rarely used in high-production environments, for it is slow and lacks support against reactionary forces.

Hand reamer adjustments are as follows: a small amount of material is removed from the hole by the reamer, and a small amount can be taken from the shank, depending on the setup of the machine and the application.

Machine Reamers

Machine reamers are intended to be used in power-driven equipment, such as drill presses, lathes or CNC machines. These reamers are designed for speed, accuracy and performance and are ideal for high-volume production and machine “difficult to work” materials such as steel or titanium. There are several subcategories in machine reamers.

Chucking Reamers

Chucking reamers are the most widely used type of machine reamer and are generally used in drill presses or turret lathes. Being of the short and thick shank, it is fit for use in the chuck for the high hardness of the material; the chuck’s chucking clamping action is good, high precision and very stable during machining. With straight or spiral flute styles, chucking reamers are excellent for close-tolerance finishing work. They are commonly employed in the automotive and manufacturing industries to accurately bore clean holes in components such as engine blocks or gear housings.

Shell Reamers

Shell reamers are dimension hollow reamers mounted upon an arbour for finishing holes of larger diameter. They are designed for low-cost usage, as the reamer head can be replaced without changing the arbour. Examples are shell reamers, normally utilized in heavy work such as machining large pieces for engines or giant industrial equipment. Their versatility and consistent performance for applications with larger hole sizes have made them a workhorse in shops that demand a long-lasting tool.

Adjustable or Expanding Reamers

Adjustable and expanding reamers are flexible; they let you change the tool’s diameter within a range. Ideal for situations where there is a non-standard hole size or for reaming multiple holes with little variation. Machinists can vary the reamer size by changing cutting blades. They are also specifically designed to accommodate a range of sizes in a single tool and to work well in a production environment where speed is more important than finish.

Rotary (Spiral) Reamers

Rotary, or spiral, fluted reamers are more common as they have helical flutes that wrap around the tool’s body along its axis, smoothing the tool’s edge over straight-fluted reamers. The spiral point of this tap (the slight taper within the tap) causes the chips to spiral up and out of the hole to prevent clogging. These reamers are suitable for machining work-hardening materials, such as stainless steel and high-alloy steel.

In the case of deep and interrupted holes, spiral reamers are particularly efficient since the helical flutes improve chip evacuation, so there’s less of a chance the tool will clog. They’re popular in CNC machining applications where high precision is required, such as in aerospace components or medical devices. But on softer material, spiral reamers have less effect compared to straight-flute reamers.

Straight Flute Reamers

These reamers, as the title suggests, have straight and parallel cutting edges that run along the body of the tool. These reamers are of a more straightforward design and are for general-purpose reaming of softer materials such as aluminium, copper, or plastic. For simple applications and shallow holes, they are stable with minimum deflection and are the best choice.

Although straight flute reamers do not have the same chip-drawing capability as spiral reamers, they are cheaper and easier to produce. They are often used in manual or low-speed machining jobs, such as in small workshops or maintenance shops.

Specialty Reamers

Speciality reamers are intended for specific applications and usages that a regular reamer can’t do. These include:

- Taper Reamer: Drilling tapered holes for pins and fittings. They are found in applications as diverse as plumbing to aerospace, where tapered connections are needed.

- Bridge Reamers: Used in structural steel when aligning bolt or rivet holes. These reamers are strong and can be used with high-strength materials.

- Step Reamers: Have two or more cutter diameters on the same tool, allowing the operation to create a stepping or multi-diameter immediately without a second operation. They’re used in precision industries like electronics or car manufacturing.

- Carbide Reamers: Designed of carbide for durability, carbide reamers are recommended for high-wear materials such as titanium or hard steel. They’re costly but boast long tool life and good performance.

Specialized reamers are available for other industries or tasks, such as drilling overlong elliptical holes.

How to Pick the Right Reamer

Choosing the best reamer for your job means thinking about a few things. Here’s a quick guide to help you decide:

- What You’re Cutting: The material matters a lot. For soft stuff like aluminium or brass, straight flute or chucking reamers are fine. For harder stuff like steel or titanium, go for spiral or carbide reamers because they’re tougher and clear chips better.

- Hole Size and Accuracy: Think about the size of the hole and how precise it needs to be. Adjustable reamers are great for weird sizes while chucking reamers are best for super accurate holes. For big holes, use shell reamers.

- How Much Work You’re Doing: For just a few holes, hand reamers are okay. For big projects or factories, machine reamers like chucking or shell reamers work better with machines.

- Hole Depth: Deep or tricky holes need spiral reamers to clear chips. For shallow, simple holes, straight flute reamers are fine.

- Budget and Tool Life: Carbide reamers cost more but last longer, so they’re worth it for tough jobs. HSS reamers are cheaper for regular tasks.

- Special Jobs: If you need a tapered or stepped hole, pick a speciality reamer like a taper or step reamer to match the job.

- Your Equipment: Make sure the reamer works with your tools. Machine reamers need a solid setup like a CNC machine, while hand reamers just need your hands and some skill.

To get the best results, use cutting fluid to keep things cool and smooth. Keep the speed and pressure steady to avoid wearing out the tool. Check your reamer regularly for damage and sharpen or replace it to keep your holes perfect.

A Final Word

As an essential tool in machining, reamers provide precision by enlarging existing holes in materials to meet very specific requirements for use in many different applications and materials. Each has its intended purpose, from hand reamers for small-diameter tool work to machine reamers for large-scale production work. Variations such as chucking, shell, and interchangeable reamer types are available for versatility, and spiral, straight flute, and spiral/straight flute combined reaming styles enable reamers to-be changed to provide an optimum solution for specific applications.

Special-purpose reamers are designed for specialized tasks, so even your most complex project can be performed with precision.

Just by knowing the different kinds of reamers and their corresponding uses, machinists can choose the appropriate tool to achieve the proper balance between material, tolerance and production requirements.

Good reamer choice and good machining practices will get you to the workpiece you want in no time and help you salvage those all-too-common hand-me-downs. When you have the right reamer for your job in your toolkit, you’re likely to send it on its way with smooth, accurate and clean results.