Premium Tool Steel Solutions

As a leading tool steel supplier, we offer a comprehensive range of high-quality tool steel grades designed for demanding industrial applications. Our expert team ensures each product meets rigorous standards for performance and reliability.

Our Tool Steel Types

Explore our comprehensive range of tool steel products designed for various industrial applications.

Cold Work Tool Steel

Ideal for applications requiring high hardness and wear resistance at low temperatures, such as blanking dies, cold forming tools, and thread rolling dies.

Hot Work Tool Steel

Designed for applications involving high temperatures and thermal cycling, such as die casting, hot forging, and extrusion tools.

High-Speed Steel

Offers excellent hardness, wear resistance, and cutting performance at high speeds, making it suitable for cutting tools, drills, and milling cutters.

Water-Hardening Tool Steel

Shock-Resistant Tool Steel

Engineered to withstand high impact and shock loads, making it ideal for tools such as punches, chisels, and impact extrusion dies.

Special Purpose Tool Steel

Custom alloys designed for specific applications requiring unique properties such as corrosion resistance or high-temperature strength.

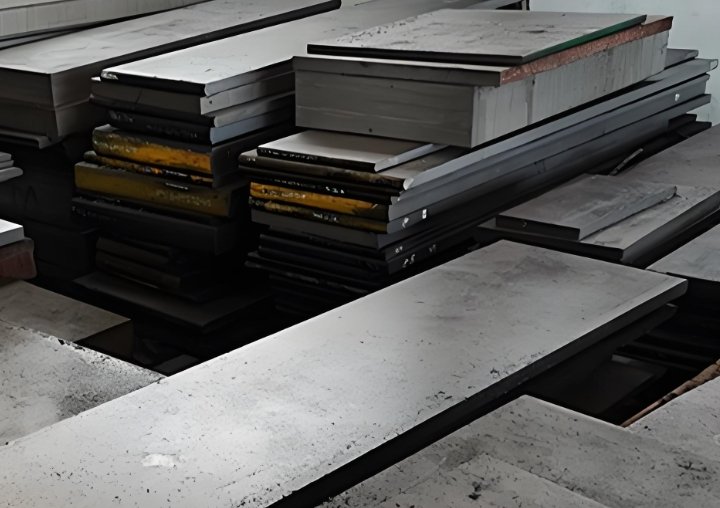

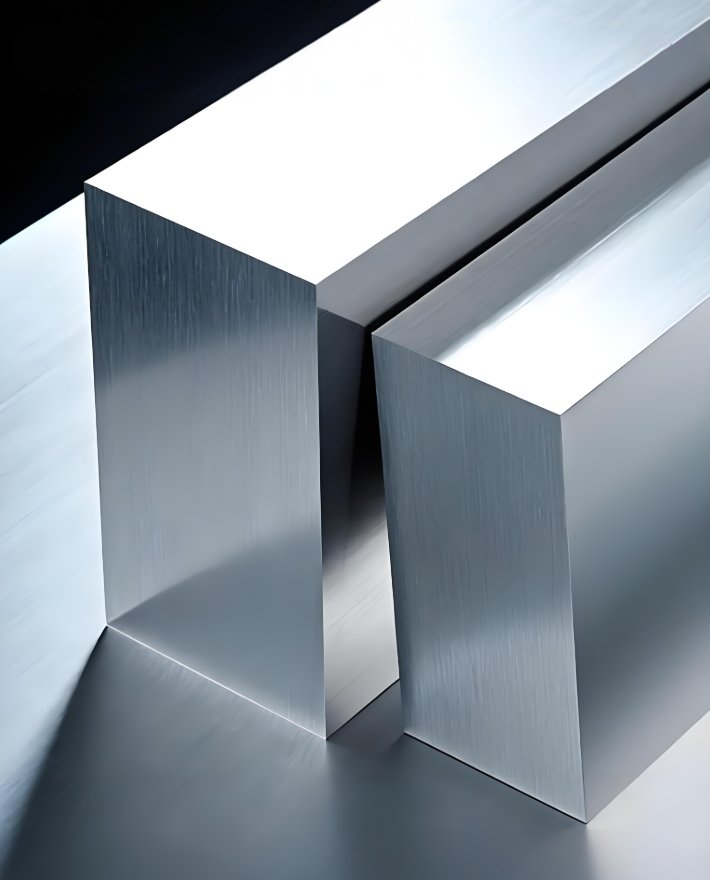

Available Shapes & Forms

Bars

Round, square, flat

Tubes

Seamless, welded

Sheets

Various thicknesses

Bars

Forged components

Key Properties of Tool Steel

Tool steel is renowned for its exceptional properties that make it ideal for demanding industrial applications.

High Hardness

Tool steel maintains its hardness even at elevated temperatures, ensuring wear resistance and dimensional stability in high-stress applications.

Wear Resistance

Exceptional resistance to abrasion and erosion, making it suitable for applications involving high-speed cutting, forming, and extrusion.

Heat Resistance

Retains mechanical properties at high temperatures, making it ideal for hot working processes such as forging, casting, and extrusion.

Toughness

Ability to withstand high impact loads without fracturing, critical for tools subjected to sudden shocks or dynamic forces.

Corrosion Resistance

Certain tool steel grades offer excellent resistance to corrosion, making them suitable for applications in harsh environments.

Common Tool Steel Grades

Explore our range of tool steel grades, each offering unique properties for specific applications.

Tool Steel Solutions for Precision-Driven Industries

Our premium tool steels are engineered to withstand extreme heat, pressure, and wear—making them the go-to material for high-performance tooling across modern manufacturing sectors.