Are you choosing between Inconel 718 and Inconel X-750 for your next high-temperature project, but unsure which alloy is best suited for your needs?

Inconel 718 and Inconel X-750 are renowned for their exceptional high-temperature strength and corrosion resistance, making them staples in the aerospace industry.

This comparison aims to explore the key differences between these two premier nickel-based superalloys, helping you understand which one best fits your specific industrial requirements.

Understanding Inconel Superalloys

The world of high-temperature alloys is dominated by Inconel superalloys, known for their outstanding performance in extreme environments. As you explore the properties and applications of these alloys, it’s essential to understand what sets them apart.

What Are Inconel Alloys?

Inconel alloys belong to a family of austenitic nickel-chromium-based superalloys. They are known for their exceptional resistance to oxidation and corrosion, even at extreme temperatures. This makes them ideal for use in demanding industries such as aerospace, power generation, and chemical processing.

History and Development

The history of Inconel alloys dates back to the 1940s when they were first developed for use in aircraft engines. Inconel X-750 was one of the earlier formulations, with Inconel 718 following as an improved version in the 1960s. This development was crucial for meeting the demanding requirements of high-stress, high-temperature applications.

General Properties and Characteristics

All Inconel alloys share certain characteristics, including excellent resistance to oxidation and carburization, high mechanical strength, and remarkable stability in extreme environments. The precipitation hardening mechanism in these alloys creates a microstructure that provides exceptional strength and stability at elevated temperatures.

| Alloy | Corrosion Resistance | High-Temperature Strength |

| Inconel 718 | Excellent | High |

| Inconel X-750 | Excellent | High |

As you can see, both Inconel 718 and Inconel X-750 offer unique properties that make them suitable for demanding applications. Understanding these properties is crucial for selecting the right alloy for your specific needs.

Inconel 718 vs Inconel X-750: An Overview

The development of Inconel 718 was influenced by its predecessor, Inconel X-750. Understanding the origins and evolution of these alloys is crucial for appreciating their differences.

Origins and Development History

Inconel X-750 was one of the first precipitation-hardened superalloys, designed for high-temperature applications in aerospace engines. Later, Inconel 718 emerged as an evolution of X-750, with more controlled trace elements and a modified composition to address some of the limitations of its predecessor.

Basic Classification and Standards

Both Inconel 718 and Inconel X-750 are classified as precipitation-hardened nickel-chromium superalloys. They fall under different standard specifications, such as ASTM B637 and various SAE AMS specifications, reflecting their unique properties and applications.

Market Position and Popularity

Inconel 718 has gained significant market popularity and become the industry standard for many high-performance applications, particularly in aerospace turbines and oil and gas equipment. Inconel X-750 maintains a presence in specific applications where its higher temperature capability is beneficial.

In summary, while Inconel X-750 is the ancestor of Inconel 718, the latter has become more widely used due to its improved properties. The choice between the two alloys depends on the specific requirements of the application.

Chemical Composition Comparison

A comparison of the chemical composition of Inconel 718 and Inconel X-750 reveals key differences that impact their performance and application. Both alloys are nickel-chromium based, but they vary significantly in their specific elemental makeup.

Primary Elements in Both Alloys

Inconel 718 and X-750 share a common base of nickel and chromium, but the proportions differ. Inconel 718 contains 50-55% nickel, whereas X-750 has a minimum of 70% nickel, making X-750 more nickel-rich. The presence of chromium in both alloys contributes to their resistance to corrosion.

Key Compositional Differences

The presence of molybdenum in Inconel 718 (2.8-3.3%) and its absence in X-750 is a critical difference, enhancing solid solution strengthening and corrosion resistance in reducing environments for Inconel 718. Additionally, Inconel 718 has a significantly higher niobium content (4.75-5.5%) compared to X-750, which is crucial for its strength through the formation of gamma double prime precipitates.

Impact of Trace Elements on Performance

Inconel 718 has stricter control over trace elements like silicon, manganese, and phosphorus, improving its durability at high temperatures. The reduction of aluminum and titanium in Inconel 718 compared to X-750 affects the formation of strengthening precipitates. Furthermore, Inconel 718 contains more iron than X-750, reducing alloy cost while maintaining performance.

These compositional differences significantly influence the alloys’ properties, making Inconel 718 and X-750 suitable for different applications based on their unique chemical makeup.

Mechanical Properties and Strength

Understanding the mechanical properties of Inconel 718 and Inconel X-750 is essential for selecting the right alloy for your specific needs. The mechanical properties of these alloys significantly influence their performance in various applications.

Tensile and Yield Strength Comparison

Inconel 718 and Inconel X-750 have different tensile and yield strengths, which are crucial for determining their load-bearing capacity. Inconel 718 has a tensile strength of 1370 MPa and a yield strength of 1030 MPa, whereas Inconel X-750 has a tensile strength of 1100 MPa and a yield strength of 780 MPa.

| Alloy | Tensile Strength (MPa) | Yield Strength (MPa) |

| Inconel 718 | 1370 | 1030 |

| Inconel X-750 | 1100 | 780 |

Hardness and Ductility

The hardness of Inconel 718 is B95-C36 Rockwell, making it harder than Inconel X-750, which has a hardness of B88-C32 Rockwell. While Inconel 718 offers greater strength, Inconel X-750 provides slightly better elongation (15-20% vs. 12-15% for Inconel 718), indicating somewhat improved ductility.

Performance Under Stress

Inconel 718 demonstrates superior fatigue resistance under cyclic loading conditions, making it particularly valuable for components subjected to repeated stress cycles. The addition of molybdenum and higher niobium content in Inconel 718 creates a more effective solid solution strengthening mechanism, contributing to its enhanced mechanical properties.

When choosing between Inconel 718 and Inconel X-750, consider the specific mechanical properties required for your application. Inconel X-750 exhibits slightly higher stiffness (Young’s Modulus) at all operating temperatures, which can be beneficial in applications where dimensional stability under load is critical.

Temperature Resistance and Performance

When it comes to high-temperature applications, understanding the temperature resistance of Inconel 718 and Inconel X-750 is crucial. Both alloys are renowned for their ability to perform under extreme thermal conditions, but their temperature resistance properties differ.

Operating Temperature Ranges

Inconel 718 demonstrates excellent performance across a wide temperature range from cryogenic (-250°C) to elevated temperatures (700°C), making it versatile for various operating environments. In contrast, Inconel X-750 can withstand higher maximum operating temperatures up to 980°C, giving it an advantage in extremely high-temperature applications.

High-Temperature Strength Retention

At temperatures below 700°C, Inconel 718 generally maintains better strength properties than X-750, making it the preferred choice for applications operating in this range. However, for applications operating above 700°C, Inconel X-750 begins to show advantages in terms of long-term strength retention.

Creep Resistance Comparison

Inconel X-750 demonstrates superior stress rupture strength at temperatures between 760-870°C (1400-1600°F), making it particularly valuable for components that must withstand sustained loads at very high temperatures. The different precipitation strengthening mechanisms in these alloys explain their temperature performance differences.

The melting range of Inconel 718 (1260-1336°C) is lower than that of X-750 (1390-1430°C), which correlates with their respective maximum service temperatures. Understanding these differences is key to selecting the right alloy for your high-temperature application.

Corrosion Resistance Properties

When comparing Inconel 718 and Inconel X-750, their corrosion resistance properties play a crucial role in determining their suitability for various applications. Both alloys are known for their high-performance characteristics, but they exhibit different corrosion resistance behaviors.

Oxidation Resistance

Inconel 718 demonstrates superior oxidation resistance compared to Inconel X-750 due to its higher chromium content (17-21% vs. 14-17%). This provides better protection in high-temperature oxidizing environments.

Chemical Corrosion Behavior

The presence of 2.8-3.3% molybdenum in Inconel 718, which is absent in X-750, significantly enhances its resistance to reducing environments and pitting corrosion, particularly in chloride-containing media. Inconel 718 shows exceptional resistance to stress corrosion cracking in various environments.

Performance in Harsh Environments

In marine and offshore applications, Inconel 718’s superior resistance to pitting and crevice corrosion makes it the preferred choice over X-750 for components exposed to seawater. For applications involving exposure to strong acids, Inconel 718 generally outperforms X-750.

| Alloy | Oxidation Resistance | Corrosion Resistance in Reducing Environments |

| Inconel 718 | Excellent (Higher Cr content) | Excellent (Presence of Mo) |

| Inconel X-750 | Good | Fair (No Mo) |

Machinability and Fabrication Considerations

When working with Inconel 718 and Inconel X-750, understanding their machinability and fabrication characteristics is crucial. Both alloys are known for their high-performance properties, but they present different challenges during processing.

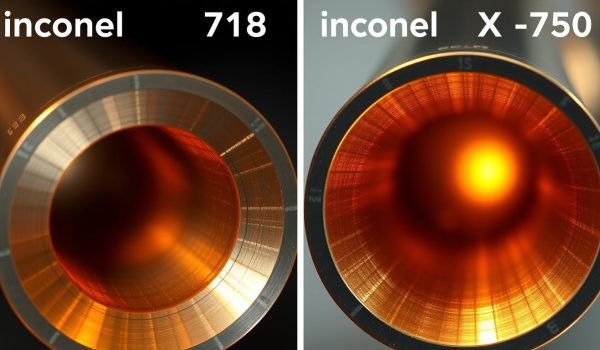

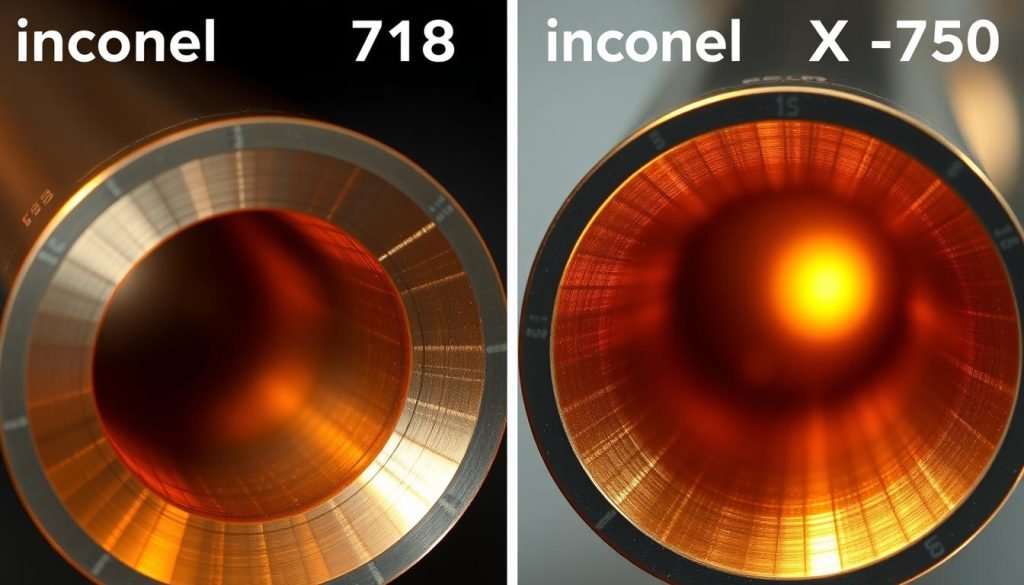

Machining Challenges and Solutions

Machining Inconel 718 is generally easier than Inconel X-750 due to its lower work-hardening rate. Specialized tooling and cooling strategies are essential for managing heat during cutting operations.

Weldability Comparison

Inconel 718 demonstrates excellent weldability without immediate post-weld heat treatment, whereas Inconel X-750 requires careful welding procedures and often necessitates post-weld heat treatment.

Heat Treatment Requirements

The heat treatment cycles for Inconel 718 and X-750 differ significantly. Inconel 718 undergoes a solution treatment at around 980°C followed by a two-step aging process, while X-750 requires a higher solution treatment temperature and aging at 845°C.

Applications Across Industries

You can find Inconel 718 and Inconel X-750 in various critical applications across different sectors. Their unique properties make them ideal for use in harsh environments and high-temperature applications.

Aerospace and Aviation Applications

Both alloys are heavily used in aerospace engine applications. Inconel 718 is widely used for turbine discs, compressor blades, and high-temperature structural components in jet engines. In contrast, Inconel X-750 is often selected for specialized components like springs, fasteners, and retaining rings that must withstand extreme temperatures.

Oil and Gas Industry Uses

The oil and gas industry relies heavily on Inconel 718 for downhole tools, wellhead components, and subsea equipment due to its exceptional combination of strength and corrosion resistance in harsh environments containing hydrogen sulfide and chlorides.

Power Generation and Nuclear Applications

Both alloys find extensive use in power generation. Inconel 718 is commonly employed in land-based gas turbines for combustion chambers and turbine blades, while Inconel X-750 is often used for bolting applications and valve components. In nuclear applications, Inconel X-750 is frequently used for springs and fasteners in reactor internals, while Inconel 718 is preferred for structural components and pressure boundary applications.

Other Industrial Applications

Other industries also benefit from these alloys. The chemical processing industry uses Inconel 718 for pressure vessels and piping systems handling corrosive chemicals, while Inconel X-750 is used for high-temperature heat exchanger components. Marine applications favor Inconel 718 due to its superior resistance to seawater corrosion.

| Industry | Inconel 718 Applications | Inconel X-750 Applications |

| Aerospace | Turbine discs, compressor blades | Springs, fasteners, retaining rings |

| Oil and Gas | Downhole tools, wellhead components | Limited use due to corrosion concerns |

| Power Generation | Combustion chambers, turbine blades | Bolting applications, valve components |

Cost Considerations and Availability

Cost considerations play a vital role in deciding between Inconel 718 and Inconel X-750 for your projects. The cost difference between these two alloys is influenced by their composition and production processes.

Raw Material Costs

The raw material costs for Inconel 718 and Inconel X-750 vary due to differences in their nickel and iron content. Inconel X-750 contains more nickel (minimum 70%) than Inconel 718 (50-55%), but Inconel 718 has a higher iron content, which reduces its overall cost.

Processing and Manufacturing Expenses

Processing costs for both materials are significant due to their difficult machinability. However, Inconel 718 offers advantages in fabrication efficiency due to its better weldability and easier machining characteristics.

Long-term Value Analysis

When considering long-term value, Inconel 718’s superior corrosion resistance and mechanical properties often justify its potentially higher initial cost through extended service life and reduced maintenance requirements.

Selection Criteria: Choosing Between Inconel 718 and X-750

When deciding between Inconel 718 and Inconel X-750 for your application, several key factors come into play. The decision hinges on understanding the specific requirements of your project, including the operating environment, mechanical demands, and budget constraints.

Application-Specific Considerations

The primary consideration in choosing between Inconel 718 and Inconel X-750 is the specific application. For instance, if your project involves high-strength, corrosion-resistant components operating at moderate temperatures, Inconel 718 might be the preferred choice. On the other hand, if your application requires sustained performance at extremely high temperatures, Inconel X-750 could be more suitable.

| Alloy | Temperature Range | Corrosion Resistance | Mechanical Strength |

| Inconel 718 | Below 700°C | Superior | High |

| Inconel X-750 | 700-980°C | Good | High at high temperatures |

Environmental Factors

Environmental factors, such as exposure to corrosive media or high temperatures, play a crucial role in the selection process. For environments involving corrosive media, particularly in reducing conditions or those containing chlorides, Inconel 718’s superior corrosion resistance makes it the preferred choice.

Budget and Performance Balance

Balancing budget constraints against performance requirements is essential. While the price difference between these alloys can be significant, their performance differences in specific applications often outweigh the cost considerations. You should consider not only the raw material costs but also the long-term value and potential cost savings from improved performance and durability.

Ultimately, the choice between Inconel 718 and Inconel X-750 depends on a careful evaluation of your application’s specific needs, including temperature requirements, mechanical strength, corrosion resistance, and budget constraints. By considering these factors, you can make an informed decision that balances performance and cost.

Conclusion

The selection between Inconel 718 and Inconel X-750 depends on various factors, including temperature range and corrosion environment. Inconel 718 generally offers superior mechanical strength, better overall corrosion resistance, and excellent fabricability, making it the preferred choice for most applications operating below 700°C.

In contrast, Inconel X-750 provides advantages in very high-temperature applications (700-980°C) where its better microstructural stability and creep resistance become critical performance factors. The chemical composition differences, particularly Inconel 718’s higher chromium and molybdenum content, give it better overall performance in corrosive environments.

When choosing between these alloys, consider your specific application requirements. For aerospace applications, Inconel 718 excels in turbine discs, while X-750 is preferred for high-temperature fasteners. In oil and gas applications, Inconel 718’s strength and corrosion resistance make it the predominant choice. Ultimately, matching the alloy to your specific needs ensures optimal performance and reliability.