Mold lifespan isn’t a fixed number stamped on steel—it’s the culmination of every mold life cycle squeezed from its first pristine run through its final repair. Imagine a rookie mold fresh off CNC machining: it fires flawless parts until wear emerges—fine scratches on core pins or a sticking slide block.

Each repair life becomes a high-stakes gamble: engineering quality buys the chips, but maintenance skill dictates how long you stay at the table. Play smart, and that mold pays for itself tenfold; neglect it, and failure arrives unannounced.

Operators debating mold longevity are really arguing survival economics. Surface scratches mark the beginning; deep fatigue triggers structural collapse. The difference between a shop legend and scrap metal hinges on five pillars: material resilience, stress-optimized design, operational discipline, meticulous maintenance, and failure analysis. Master these, and molds transform from consumable tools to enduring assets.

What Is the Lifespan of Mold?

Walk into any factory floor, and you’ll hear operators debating mold lifespan like chefs arguing over knife sharpness. Here’s the truth: lifespan isn’t a number stamped on a mold. It’s the total parts squeezed out before that mold gives up – through its first life, a few repair lives, and finally the last clunk in its total lifespan. The first life cycle of a mold? That’s the mold’s rookie run. Fresh from the CNC machine, firing out perfect parts until wear signs show – maybe fine scratches on core pins or a sticking slide block. Exactly when this happens? Depends. Maybe simple box molds run 300,000 cycles untouched, while thin-wall electronics molds start fading at 20,000.

After repairs begin, things get interesting. Each repair life is a gamble. How these repairs hold up decides if the mold life cycle dies young or becomes a shop legend. Mold lifespan is a high-stakes poker game. Engineering quality buys your chips, but maintenance skills decide how long you stay at the table. Play smart – that mold will pay for itself ten times over.

The Factors That Affect Mold Durability

Durability measures the total functional life cycle of mold until failure occurs. Failure specifically means deformation-altering part quality. Surface scratches typically develop first. Deep fatigue subsequently causes structural collapse. Four verified factors control this degradation process. Their combined interactions define a mold’s actual service span.

Material Compatibility Dictates Wear Resistance

Material compatibility determines wear resistance. Hardened steels outperform soft metals against abrasive plastics. Glass-filled resins act like sandpaper, scraping mold walls and deepening microscopic grooves with each cycle—insufficient hardness accelerates dimensional erosion.

Corrosive plastics release reactive chemicals during injection, pitting steel surfaces and impairing ejection reliability. Protective coatings (e.g., chrome plating) isolate base metals from chemical attack. Material selection must precisely match the processed plastic type.

Design Intelligence Influences Stress Distribution

Effective design ensures uniform stress distribution by eliminating stress concentrators. Sharp internal corners intensify operational forces, creating localized pressure points where micro-cracks initiate. These cracks propagate steadily through the structure, often leading to sudden, catastrophic failure. To mitigate these risks, generous radii disperse stress, while strategic sliding inserts absorb impact in critical zones.

Consistent wall thickness is critical for maintaining structural integrity. Variations in thickness cause uneven cooling, leading to warped parts that strain ejector mechanisms. Similarly, bent cores degrade molding precision over time. By prioritizing simplicity and balanced geometry, designs achieve longer functional lifespans and more reliable performance.

Operational Control Manages Production Damage

Operational control prevents production-related damage by maintaining optimal processing conditions. Excessive injection pressure strains components, gradually bending ejector pins and deforming overheated steel. Insufficient lubrication leads to metal-on-metal grinding, causing microscopic welding and subsequent jamming in precision mechanisms. By controlling parameters like pressure and temperature, fatigue accumulation is significantly reduced.

A clean production environment is equally critical for longevity. Airborne dust infiltrates sliding parts, accelerating wear through abrasion, while humidity promotes microscopic rust formation. Over time, pitted surfaces degrade functionality. Proactive measures—such as controlled environments and proper lubrication—preserve component performance and reliability.

Maintenance Rigor Counters Early Failure

Rigorous maintenance prevents premature failure by addressing key wear mechanisms. Heating cycles carbonize plastic residues on cavity surfaces, while unremoved debris causes continuous grinding during operation. Proper lubrication prevents metal-to-metal contact and avoids galling scars in ejection systems.

Cooling channel maintenance is critical – mineral deposits reduce flow efficiency, leading to uneven cooling that warps core inserts. Chemical flushes effectively dissolve these blockages. Early scratch detection enables timely repairs, while professional polishing eliminates micro-defects before they propagate.

Practical Strategies to Extend Mold Service Life

Mold longevity fundamentally depends on total functional cycles preceding failure occurrence. Failure specifically implies deformation negatively affecting part quality standards. Initial surface wear typically manifests as fine microscopic scratches. Progressive deep fatigue eventually causes irreversible structural collapse. Maximizing actual service life necessitates systematic control implementation. This spans five interconnected operational domains comprehensively. Each domain critically influences wear accumulation speed.

Material Compatibility Foundation Building

Material compatibility establishes the fundamental performance base. Hardened tool steels endure abrasive plastic compounds better than soft metal alternatives. Glass-filled engineering resins actively scrape cavity walls during injection processes. These embedded particles function similarly to industrial sandpaper applications. Microscopic grooves deepen incrementally with each production cycle repetition. Without sufficiently hardened substrates, critical dimensions experience progressive erosion.

Corrosive polymer types release reactive chemicals under heating conditions. These substances chemically react with unprotected steel surfaces. Microscopic pits subsequently form across functional interfaces. Such damage disrupts consistent part ejection reliability. Protective coating systems effectively block chemical corrosion attacks. Chrome plating technology isolates base metal from harmful agents permanently. Strategic material choices must precisely match processed plastic specifications.

Stress Distribution Design Philosophy

Intelligent design engineering spreads operational stress evenly. Internal sharp corners naturally gather mechanical force intensity. Destructive pressure concentrates at these geometric focal points. Microscopic cracks typically initiate precisely at such locations. They gradually propagate silently through steel structures internally. Unexpected functional failure often occurs consequently.

Generous curvature radii diffuse structural stress widely. Purpose-designed sliding inserts absorb high-impact energy selectively. Strategic placement occurs specifically at critical fatigue zones. Consistent uniform wall thickness prevents uneven cooling occurrences. Thermally warped plastic components strain ejector pins excessively. Permanently bent cores progressively reduce dimensional precision. Overall design simplicity consistently extends functional service life.

Operational Discipline Maintenance Protocols

Consistent operational discipline controls daily damage accumulation. Excessively high injection pressure mechanically strains components systematically. Ejector pins gradually bend under sustained excessive loading conditions. Chronically overheated tool steel loses hardness properties. This softening leads to permanent plastic deformation development.

Insufficient lubrication causes direct metal grinding phenomena. Moving surfaces occasionally weld together microscopically during operation cycles. Precision mechanisms then jam without operational warning signs. Controlled processing parameters significantly reduce accumulated fatigue damage. Production environment cleanliness provides substantial operational benefits. Airborne dust particles enter sliding interfaces during routine function. Particulate-induced abrasion accelerates component wear exponentially. Ambient humidity exposure eventually causes surface rust formation. Micro-pitted functional surfaces rapidly lose performance capabilities.

Preventive Maintenance Regimen Implementation

Rigorous maintenance practices prevent premature collapse incidents. Residual plastic compounds carbonize on cavity surfaces thermally. Unremoved carbonized debris acts as grinding media during production. Systematic greasing procedures prevent metal contact completely. Galling damage scars ejector systems permanently without intervention.

Cooling channel maintenance requires disciplined scheduled attention. Accumulated mineral deposits internally restrict water flow volume. Such flow restriction enables uneven cooling patterns significantly. This thermal inconsistency warps core inserts irreversibly over time. Specialized chemical flushes dissolve persistent deposits effectively. Early-stage scratch detection permits timely repair implementation. Precision polishing techniques remove micro-defects during scheduled stops. This prevents microscopic damage propagation comprehensively.

Failure Analysis Cycle Breaking Methodology

Comprehensive failure analysis breaks degradation mold cycles proactively. Detailed examination studies physical wear pattern characteristics. Crack origin analysis points to stress concentration areas accurately. Corrosion site identification indicates chemical exposure histories.

Thorough lubrication records track application compliance chronologically. Production parameter data shows operational impacts quantitatively. Result adjustments specifically target identified system weaknesses. Structured training programs improve operator process awareness. Technical knowledge transfer prevents mistake repetition consistently.

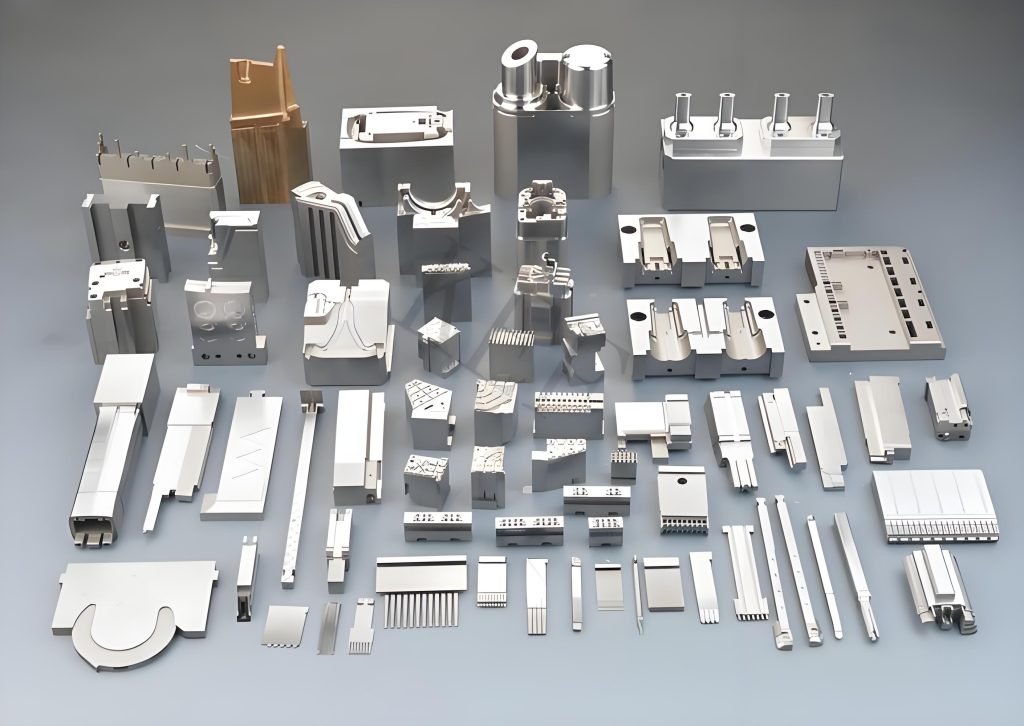

High-Quality Mold Components Tailored to Your Specifications

Durable molds result from mastering five critical factors:

- Superior Materials – Withstand abrasive/corrosive plastics through optimized metallurgy

- Intelligent Design – Distributes stress evenly to prevent crack formation

- Precision Operation – Maintains ideal production parameters to reduce fatigue

- Proactive Maintenance – Scheduled cleaning, lubrication, and defect prevention

- Continuous Improvement – Failure analysis drives iterative enhancements

This systematic approach transforms molds from consumable tools into high-value assets that deliver exceptional ROI through extended service life.

Fecision Mold Components: Engineering Resilience into Every Cycle

Component quality directly dictates how molds endure operational stresses. Fecision specializes in mission-critical parts engineered to overcome your specific production challenges, leveraging three core technological advantages:

1.Material Science Mastery

Tool Steel Selection: Components like core pins and ejector sleeves utilize hardened steels with certified hardness profiles. This ensures consistent resistance against abrasive glass or mineral-filled plastics that gradually erode softer metals.

Corrosion Defense: Cavity inserts facing aggressive resins (e.g., PVC, flame-retardant grades) receive tailored coatings. Options include hard chrome for chlorine resistance, DLC for low-friction sliding, or nickel-PTFE for improved release – each applied to precise thickness specifications.

2.Precision Manufacturing & Validation

Micron-Level Accuracy: Critical dimensions on guiding pillars and bushings are maintained greatly via CNC grinding and 3D scanning. This eliminates premature wear from misalignment-induced friction.

Stress-Optimized Geometry: Custom cavity inserts employ topology optimization and FEA simulation to eliminate stress concentrations at internal corners and thin walls – common failure origins in high-cycle applications.

Triple Verification Protocol:

Material Certification–Traceable mill reports with hardness testing

Geometry Assurance–Full 3D scan comparison against design intent

Durability Simulation–Virtual fatigue testing under client-specified parameters

3.Thermal Management Innovation

Conformal Cooling Cores: Utilizing deep-drilling and DMLS (Direct Metal Laser Sintering) technologies, cooling channels follow cavity contours precisely. This enables uniform heat extraction, preventing warpage from differential thermal expansion – a major cause of dimensional drift and early failure.