Precision Hydraulic Fixtures: Power, Accuracy & Customization

ISO 9001:2015

Quality Management

AS9100D Certification

Aerospace Industry

ISO 13485: 2016

Medical Device

Custom Hydraulic Solutions

Engineered for precision and efficiency

Custom Manufacturing Expertise

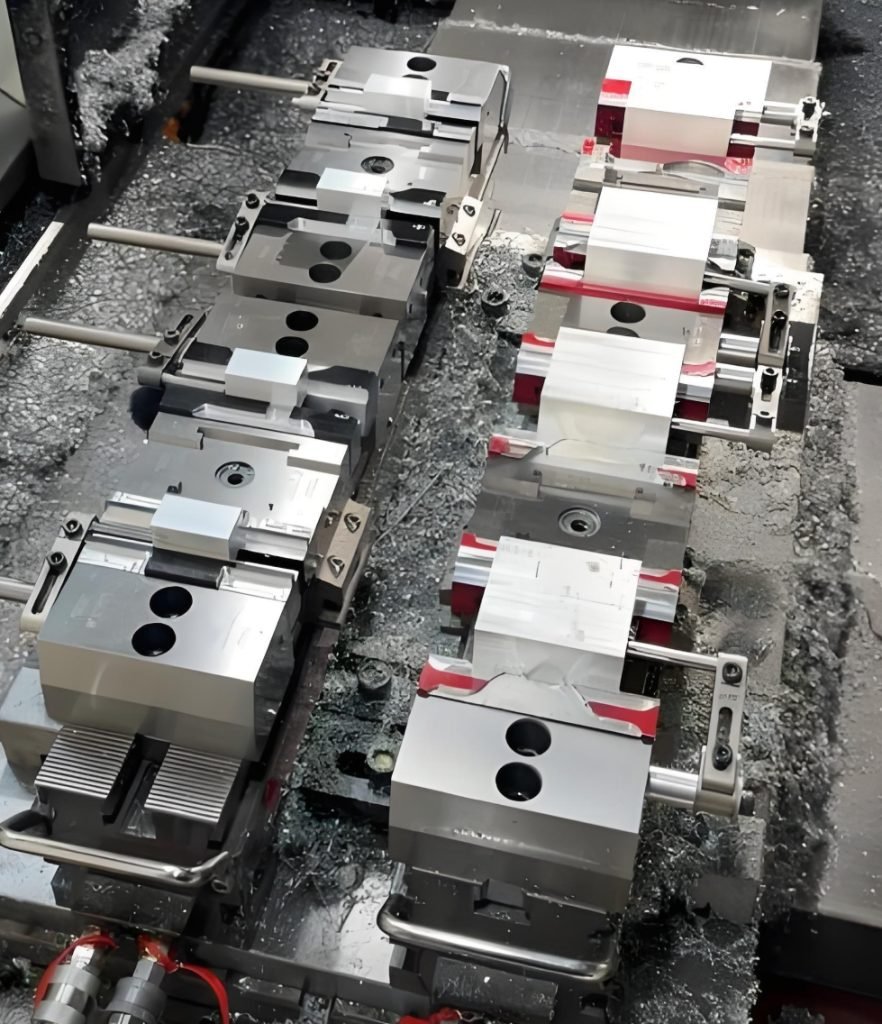

Hydraulic Workholding Fixture

Hydraulic fixtures are advanced workholding devices that utilize hydraulic power to secure workpieces during machining operations. As part of our Fixtures and Jigs services, these precision-engineered components deliver consistent clamping force, enhancing accuracy and efficiency in manufacturing processes.

Precision Engineering

Advanced 5-axis machining equipment for high-precision

Fast Turnaround

Efficient production processes for shorter delivery times

Competitive Pricing

Cost-effective solutions without compromising on quality

Our Hydraulic Fixture Products

Discover our comprehensive range of hydraulic fixtures designed for precision, durability, and efficiency in industrial applications.

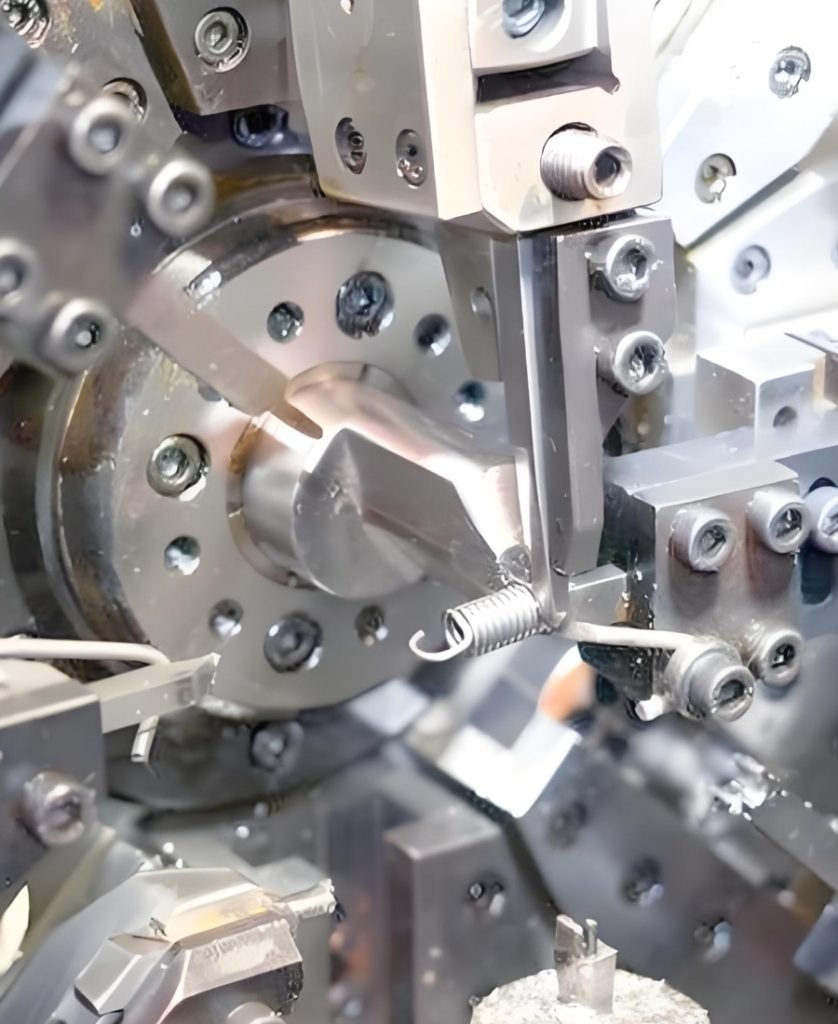

Power Chucks

Heavy-duty power chucks designed for high-speed machining and demanding industrial applications.

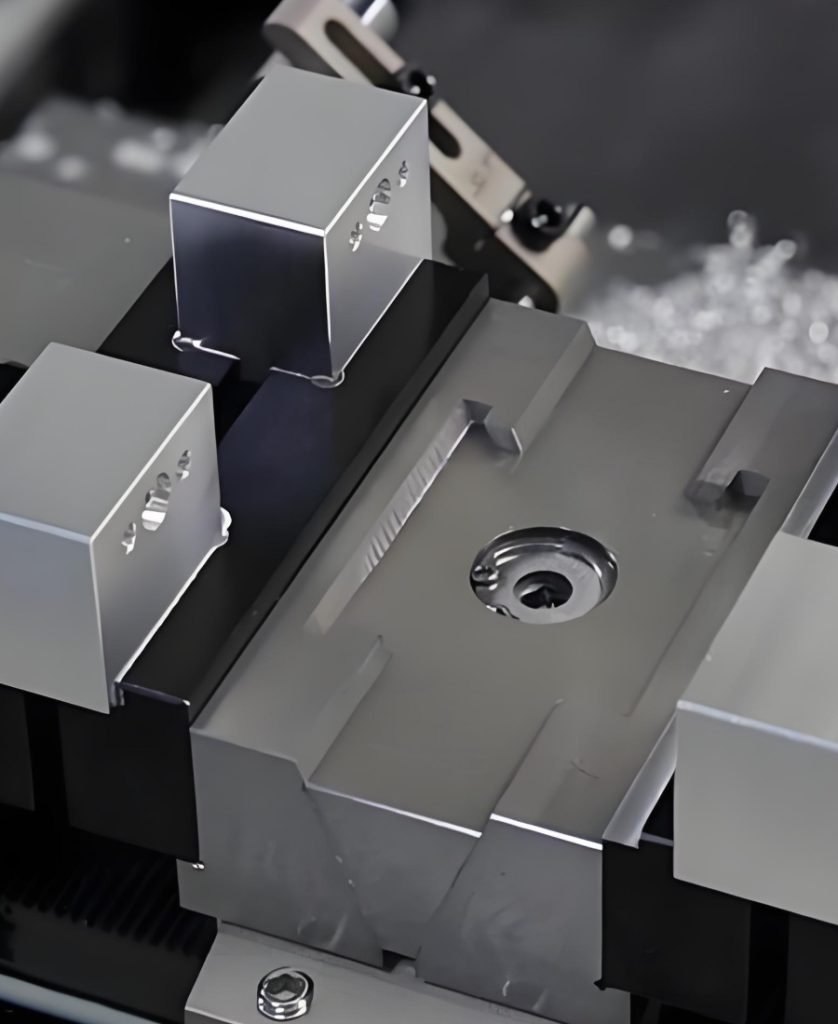

Hydraulic Clamps

High-performance hydraulic clamps for secure workpiece holding during machining operations.

Hydraulic Vises

Heavy-duty hydraulic vises providing exceptional clamping force for milling and turning applications.

Hydraulic Chucks

Precision hydraulic chucks for CNC lathes and turning centers, ensuring accurate workpiece gripping.

Hydraulic Cylinders

Precision-engineered hydraulic cylinders for reliable linear motion control in automation systems.

Custom Hydraulic Fixtures

Tailor-made hydraulic fixture solutions designed to meet your specific manufacturing requirements.

Our Custom Manufacturing Services

We provide comprehensive hydraulic fixture solutions from design to production, ensuring precision and efficiency for your manufacturing processes.

Design Analysis

- Application-specific engineering calculations

- Finite Element Analysis (FEA) for stress optimization

- Flow analysis for optimal hydraulic circuit design

- 3D modeling and simulation validation

Material Selection

- High-grade steel alloys (4140, 4340, tool steels)

- Stainless steel options for corrosive environments

- Specialized coatings and surface treatments

- Heat treatment to achieve optimal hardness (58-62 HRC)

Precision Manufacturing

- CNC machining centers with ±0.0002″ tolerance capability

- Wire EDM for complex geometries

- Surface grinding for critical contact surfaces

- Assembly and testing in controlled environments

Quality Control

- Rigorous inspection processes

- CMM Inspection

- Dimensional Verification

- Material Certification

Fast Delivery

- Streamlined Production

- Expedited Shipping Option

- On-Time Delivery Guarantee

- Efficient production planning and logistics management

After-Sales Support

- Comprehensive post-purchase support

- Installation Guidance

- Maintenance Training

- 24/7 Technical Support

Selection Guidance

Choose the right hydraulic fixture with these considerations:

✅ Workpiece Size: Select Power Chucks for cylindrical parts or Hydraulic Vises for irregular shapes.

✅ Clamping Force: Ensure Hydraulic Clamps match your machining load requirements.

✅ Production Volume: Opt for durable materials for high-cycle operations.

✅ Application Needs: Customize fixtures for specific industries like aerospace or automotive.

Our team is available to provide expert guidance for your project.

Our team is available to provide expert guidance for your project.

Applications Across Industries

Our hydraulic fixtures are trusted in a variety of sectors.

- Engine block and cylinder head machining

- Transmission case precision boring operations

- Crankshaft and camshaft grinding fixtures

- Brake component manufacturing workholding

- Critical tolerance maintenance for aircraft components

- Reliable clamping for turbine blade machining

- High-precision workholding for landing gear components

- Contamination-free operation in clean room environments

- Surgical instrument precision machining

- Orthopedic implant manufacturing fixtures

- Dental equipment component workholding

- Clean room compatible hydraulic systems

- Large component machining fixtures

- Heavy-duty clamping for mining equipment parts

- Construction equipment component manufacturing

- Marine industry precision workholding

Why Choose Fecision

We are your trusted partner for high-quality hydraulic fixtures, offering expertise, precision, and reliability.

Industry Certifications

ISO 9001:2015, IATF 16949 certified for automotive applications, ensuring the highest quality standards.

Precision Engineering

Utilizing advanced 5-axis machining and German/Japanese equipment for micron-level precision.

Modular Fixture

Efficient production processes ensure we meet or exceed industry-standard delivery times.

Competitive Pricing

Cost-effective solutions without compromising on quality or performance.

Contact Us for Custom Hydraulic Fixtures

Ready to enhance your machining operations with custom hydraulic fixtures?

Contact us today to request a quote or discuss your needs.