Rivets are permanent mechanical fasteners that have been used for centuries in construction and manufacturing. Today, they remain essential for creating strong, reliable connections between materials.

When choosing a rivet, you’ll encounter various types and materials, such as steel and specialized alloys, each serving specific purposes. By the end of this article, you’ll have a thorough understanding of rivets and be able to make informed decisions about which types to use for your specific applications.

Understanding Rivets

Understanding rivets is key to appreciating their significance in modern construction and manufacturing. Today, rivets remain one of the most reliable fastening methods for applications where welding or other techniques aren’t suitable or practical.

Definition and Basic Principles

Rivets are permanent mechanical fasteners consisting of a head and a tail that, when installed, create a secondary head that secures materials together. This basic principle is fundamental to their operation, providing a strong and durable bond.

Materials Used for Rivets

The materials used for rivets vary widely, with aluminum rivets being popular for lightweight applications and stainless steel rivets used where corrosion resistance is crucial. Other materials include copper, brass, titanium, and specialized alloys designed for specific environmental conditions or load requirements.

The Riveting Process Explained

The riveting process involves placing the rivet through pre-drilled holes in the materials to be joined, then deforming the tail end using specialized tools to create a secondary head. Modern riveting tools range from simple hand-operated devices to sophisticated pneumatic and hydraulic systems that help increase efficiency and consistency in industrial applications.

Types of Rivets

You can choose from a range of rivet types, depending on your project’s requirements. Today, rivets are available in various forms, each designed for specific applications and materials.

Solid Rivets

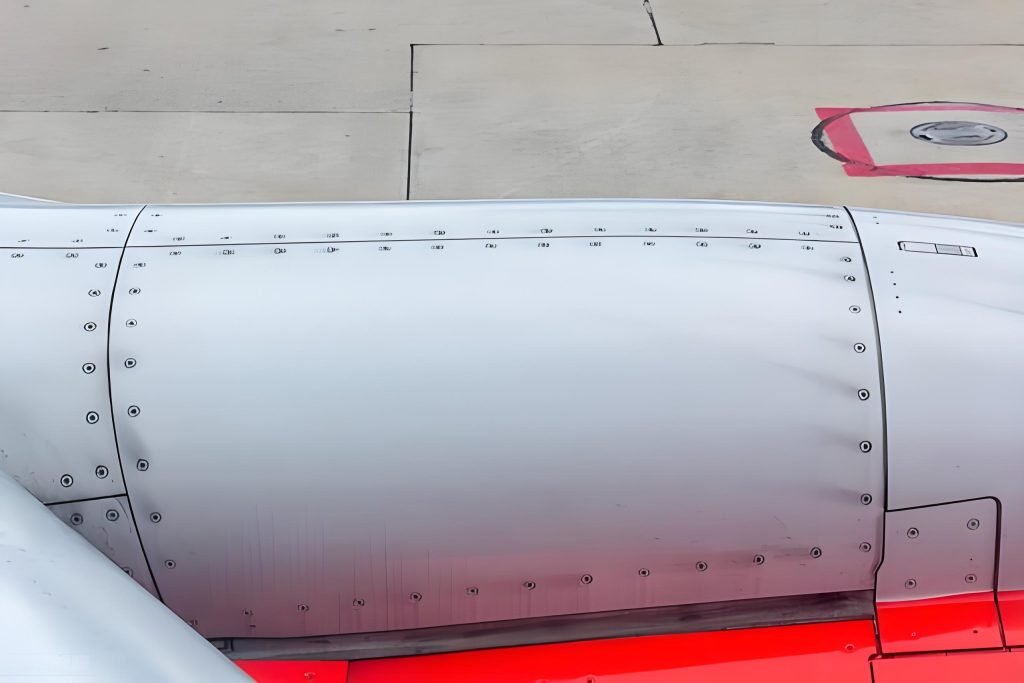

Solid rivets are the oldest and simplest type, requiring access to both sides of the workpiece. They’re ideal for high-stress applications like aircraft construction.

Blind Rivets

Blind rivets, also known as pop rivets, allow installation from one side. Aluminum blind rivets are popular for lightweight applications.

Other Rivet Types

Drive rivets feature a grooved pin that spreads when hammered, creating a secure fastening. Structural rivets are designed for high-strength construction applications, often used with washers. Specialty rivets, including tri-fold and multi-grip rivets, address unique fastening challenges.

When selecting rivets, consider the specific needs of your project, including the material and required strength. Today, various brand options and complementary items like back-up washers are available to enhance rivet performance.

Applications and Advantages of Rivets

The versatility of rivets makes them a preferred choice in multiple applications. Rivets are widely used today in various industries, including aerospace, automotive, construction, electronics, and furniture manufacturing, due to their reliability and strength-to-weight ratio.

Common Industrial Applications

Aluminum rivets are commonly used in aerospace and automotive applications where weight reduction is crucial. In contrast, stainless steel rivets are preferred in marine environments and food processing equipment due to their corrosion resistance.

Riveting vs. Other Fastening Methods

Riveting offers distinct advantages over other fastening methods, including vibration resistance and the ability to join dissimilar materials effectively. Unlike welding, riveting doesn’t alter the material properties of the joined components, making it ideal for heat-sensitive materials.

How to Choose the Right Rivet

Choosing the right rivet involves considering factors like material compatibility, load requirements, and environmental conditions. You should also consider the thickness of the materials being joined and the anticipated stress on the joint to determine the appropriate rivet diameter and material.

Conclusion

You now know a lot about rivets. This includes what they are, their types, and how they’re used. Rivets are key in many fields, helping to join materials securely and reliably.

It’s important to pick the right rivet for your project. Think about the material, size, and type you need. This ensures a strong and lasting bond.

With this knowledge, you’re ready to tackle your projects with confidence. Rivets are great for making strong connections. They’re perfect for construction or crafting furniture, providing the fastening solution you need.

FAQ

How do I choose the right rivet for my project?

Pick a rivet based on the materials, their thickness, and the joint’s strength. Also, think about the environment it will be in.

What are the advantages of using rivets over other fastening methods?

Rivets are strong, resist vibration, and work well with materials hard to weld or bolt. They’re a good choice for many projects.

Can rivets be removed and reused?

Usually, rivets can’t be removed and reused. The deformation process makes them hard to take out without damage.