Have you ever wondered how complex parts with precise specifications are manufactured across various industries? The answer lies in the advanced technology of CNC milling machines.

CNC milling machines have revolutionized precision manufacturing by automating the cutting and shaping of materials with exceptional accuracy. These sophisticated computerized systems have evolved significantly from their manual predecessors, enabling the creation of complex parts with consistent quality.

Understanding CNC Milling Machines

Understanding the basics of CNC milling machines is crucial for appreciating their role in modern manufacturing. You might be wondering what makes these machines so significant in today’s production processes.

Definition and Basic Concept

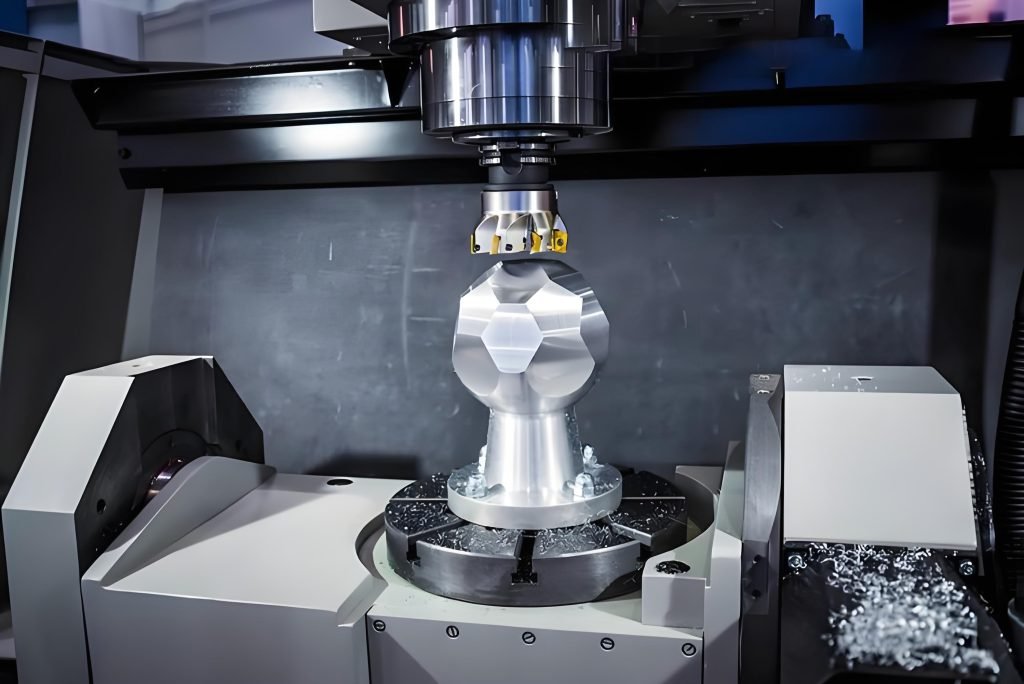

CNC milling machines are computer-controlled cutting tools that remove material from a workpiece to create precise parts and components. Unlike traditional manual milling, CNC milling machines interpret digital instructions to control cutting tools along multiple axes, offering automation and precision. This fundamental difference enables the production of complex parts with high accuracy and repeatability.

Evolution of CNC Milling Technology

The evolution of CNC milling technology has been remarkable, transforming from manual machines to NC (numerical control) and eventually to modern CNC systems. Key technological milestones include the integration of computer systems and advanced control software, making CNC milling machines more accessible, user-friendly, and capable over the decades. Today, these machines combine mechanical precision with sophisticated digital control systems, revolutionizing the machining process.

Key Components of a CNC Milling Machine

Understanding the key components of a CNC milling machine is crucial for optimizing its performance. A CNC milling machine is made up of several critical parts that work together to achieve precise material removal.

Machine Base and Frame

The machine base and frame serve as the foundation, providing stability and absorbing vibrations during milling operations.

Spindle System

The spindle system is the heart of the CNC milling machine, holding and rotating cutting tools at various speeds. A high-quality spindle is essential for accurate and efficient milling.

Tool Changer Mechanism

The tool changer mechanism, including automatic tool changer, increases efficiency by swapping cutting tools without manual intervention.

CNC Controller and Software

The CNC controller and software interpret CAD/CAM programs, converting them into precise machine movements.

Axis Systems and Motors

The axis systems and motors enable multi-dimensional movement of either the tool or the workpiece, working together as an integrated system within the machine.

These components work together to achieve precise material removal, and their quality directly impacts the machine’s accuracy, speed, and overall performance.

How CNC Milling Machines Work

CNC milling machines operate through a sophisticated interplay of hardware and software. You will gain a deeper understanding of their functionality by exploring the programming process and the sequence of operations involved in their work.

The CNC Programming Process

The CNC programming process is a critical step in the operation of CNC milling machines. You can generate G-code from CAD/CAM

software or use conversational programming interfaces. The CNC controller interprets the program and converts it into precise movements of the machine’s components, allowing for accurate material removal according to the programmed specifications.

Machine Operation Sequence

The machine operation sequence involves several key steps, from setup and workpiece mounting to tool path execution and final inspection. You should understand how the machine coordinates tool movements across multiple axes to achieve the desired outcome. Feedback systems play a crucial role in maintaining accuracy during the milling process. Modern CNC machines can simulate operations before actual cutting to prevent errors and optimize the process. Parameters like feed rate, spindle speed, and cutting depth significantly affect the milling process, and adjusting them appropriately is essential for achieving the desired results.

Types of CNC Milling Machines

CNC milling machines come in various configurations to suit different manufacturing needs. You can choose from a range of machines, each designed for specific applications and workpiece characteristics.

Vertical Milling Machines

Vertical milling machines feature vertically oriented spindles, making them ideal for drilling, face milling, and profile milling operations. They are versatile and suitable for a variety of tasks.

Horizontal Milling Machines

Horizontal milling machines have horizontally oriented spindles, which are advantageous for heavy cutting and machining long workpieces. They are particularly useful for removing large amounts of material.

Universal Milling Machines

Universal milling machines combine the features of both vertical and horizontal configurations, offering maximum versatility for complex machining tasks. They are suitable for a wide range of operations.

Bed-Type Milling Machines

Bed-type milling machines are characterized by their fixed beds and moving cutting heads, making them ideal for large, heavy workpieces that require precise machining.

Gantry-Type Milling Machines

Gantry-type milling machines, such as the MR-1 CNC Gantry Mill, feature overhead bridge structures that enable the machining of large flat surfaces and panels with high precision.

The choice between different CNC milling machine types depends on factors like workpiece size, material, complexity, and production volume. Understanding these factors helps you select the most appropriate machine for your manufacturing needs.

Axis Classifications in CNC Milling

Understanding the different axis configurations in CNC milling machines is essential for selecting the right machine for your manufacturing needs. CNC milling machines are classified based on the number of axes they have, which affects their capability and complexity.

3-Axis Milling Machines

3-axis milling machines move in the three linear directions (X, Y, Z), enabling the creation of most standard parts. They are suitable for a wide range of applications and are the most common type of CNC milling machine.

4-Axis Milling Machines

4-axis milling machines add a rotational axis (typically the A-axis) to the three linear axes, allowing for machining around cylindrical workpieces. This additional axis enhances the machine’s capability to produce complex parts.

5-Axis Milling Machines

5-axis milling machines incorporate two rotational axes in addition to the three linear axes, providing complete access to complex geometries. This configuration enables the production of highly intricate parts with reduced setup times.

The Benefits of 5-Axis CNC Milling Machines

The advent of 5-axis CNC milling machines has revolutionized the manufacturing industry by providing unparalleled precision and complexity in machining. These advanced machines enable the production of complex geometries that would be impossible to achieve with fewer axes.

Enhanced Precision and Complexity

5-axis CNC milling machines allow for enhanced precision by accessing difficult-to-reach areas of a workpiece from multiple angles in a single setup. This capability enables the creation of complex parts with high accuracy, reducing the need for multiple setups and improving overall part quality.

Reduced Setup Time and Handling

By machining multiple faces of a part without repositioning, 5-axis CNC milling machines significantly reduce setup time and handling. This reduction in handling not only saves time but also minimizes the risk of errors associated with repositioning the workpiece.

Improved Surface Finish and Tool Life

The optimized tool orientation relative to the workpiece surface in 5-axis machining results in an improved surface finish. Additionally, 5-axis capabilities extend tool life by maintaining optimal cutting conditions and enabling the use of shorter, more rigid tooling. High-speed machining combined with 5-axis movement further creates opportunities for more efficient material removal.

The competitive advantages provided by 5-axis machining include improved part quality and production efficiency. Manufacturers can produce complex parts with high precision, reducing the need for manual finishing and improving overall productivity.

Materials Compatible with CNC Milling

With CNC milling machines, you can work with a broad spectrum of materials, each with its unique properties. The choice of material depends on the intended application, required precision, and desired surface finish.

Metals

Metals such as aluminum, steel, and titanium are commonly used in CNC milling. Aluminum is known for its excellent machinability, making it a popular choice for many applications. Steel, including stainless steel, offers high strength and corrosion resistance, while titanium provides exceptional strength-to-weight ratio and corrosion resistance, although it can be challenging to machine.

Plastics and Composites

CNC milling is also used to process various plastics and composites, including engineering plastics and fiber-reinforced composites. These materials offer a range of properties such as lightweight, corrosion resistance, and electrical insulation. However, they require specific cutting tools and techniques to achieve optimal results.

Wood and Other Materials

Wood, including hardwoods, softwoods, and engineered wood products, can be machined using CNC milling machines. Additionally, other materials like graphite, ceramics, and wax are used for specific applications such as prototyping or pattern making. The properties of these materials significantly influence the choice of cutting tools, machining parameters, and surface finish quality.

Modern CNC milling machines can be optimized for specific materials by adjusting spindle speed, feed rate, and tooling. This flexibility allows for efficient processing of a wide range of materials, making CNC milling a versatile manufacturing method.

CNC Milling Machine Specifications to Consider

To find the ideal CNC milling machine for your operations, you need to examine several important machine specifications. These specifications will determine the machine’s capability to handle your workload efficiently.

Spindle Speed and Power

The spindle speed, measured in RPM, and power are critical in determining the materials that can be machined and at what rates. Different materials and operations require specific RPM ranges, from low-speed heavy cutting to high-speed finishing. For instance, a higher RPM is often necessary for detailed work or when machining harder materials.

Table Size and Weight Capacity

The table size and weight capacity are vital in determining the dimensions and mass of workpieces that can be accommodated. The distance between the spindle nose and table also affects the maximum workpiece height that can be machined. Machines like DATRON CNC offer compact designs with surprisingly large machining areas, optimizing shop floor space.

Accuracy and Repeatability

Accuracy and repeatability specifications significantly impact part quality and consistency. Machine rigidity, control system precision, and feedback mechanisms all contribute to overall accuracy. Ensuring these specifications align with your production requirements is crucial for achieving desired outcomes.

When evaluating a CNC milling machine, it’s essential to consider how its specifications align with your specific production needs and workpiece characteristics. This includes assessing the machine footprint relative to available shop space.

Modern Technological Advancements in CNC Milling

Technological innovations in CNC milling have revolutionized manufacturing processes, enabling the production of intricate components with unprecedented accuracy. Modern CNC milling machines, such as those from DATRON, are designed for speed, precision, and ease of use, featuring compact footprints with surprisingly large machining areas.

High-Speed Machining Capabilities

High-speed machining has evolved to enable faster material removal while maintaining or improving surface finish quality. Modern control software and advanced algorithms optimize tool paths for speed machining, preventing tool damage.

Automation and Smart Features

Automation advancements include pallet changers, robotic loading/unloading, and lights-out manufacturing capabilities. Smart features such as in-process monitoring, adaptive feed control, and predictive maintenance systems further enhance productivity.

Integration with CAD/CAM Systems

Seamless integration with CAD/CAM systems allows for direct transfer of design data to machine instructions. Simulation capabilities within modern software reduce setup time and prevent costly errors, contributing to higher productivity and better part quality.

Industries Utilizing CNC Milling Machines

With their ability to produce complex geometries and precise dimensions, CNC milling machines are crucial in multiple industries. The aerospace and defense sectors, for instance, rely heavily on CNC milling for creating lightweight yet strong components with intricate designs and tight tolerances.

Aerospace and Defense

The aerospace industry benefits from CNC milling machines for producing parts that require high precision and complex geometries, such as engine mounts and satellite components.

Automotive Manufacturing

In automotive manufacturing, CNC machining plays a vital role in producing engine components, transmission parts, and custom aftermarket products. The precision offered by CNC milling machines ensures that these parts meet the stringent requirements of the automotive industry.

Medical Device Production

Medical device production also benefits significantly from CNC milling, which is used to create implants, surgical instruments, and diagnostic equipment with high precision and accuracy.

Electronics and Consumer Goods

The electronics industry utilizes CNC machines for creating housings, heat sinks, and precision components for both consumer and industrial electronics. The ability to produce complex designs with precision makes CNC milling an essential process in this sector.

Other industries that benefit from CNC milling include mold making, jewelry production, and general manufacturing. Each of these industries has specific requirements that influence the selection and configuration of CNC milling machines. Machines like DATRON’s are designed to help these industries make better parts faster, with their speed and precision capabilities. CNC milling enables these industries to maintain consistent quality while meeting increasing demands for customization.

Optimizing CNC Milling Operations

To maximize productivity and minimize costs, it’s essential to optimize your CNC milling operations. Optimizing these processes involves several key factors that can significantly impact your bottom line.

Tool Selection and Management

Proper tool selection is critical based on workpiece material, geometry, and desired surface finish. Effective tooling management strategies include monitoring tool life, using preset tooling, and implementing efficient tool change procedures.

Cutting Parameters and Strategies

Optimizing cutting parameters such as spindle speed, feed rate, and depth of cut can dramatically improve efficiency and extend spindle life. Strategies like high-speed machining, trochoidal milling, and adaptive clearing maximize material removal rates while minimizing tool wear.

Workholding and Fixturing

Workholding and fixturing options, including vises, clamps, vacuum tables, and custom fixtures, play a crucial role in reducing setup time, improving accuracy, and enabling higher cutting forces. Proper workholding is essential for optimizing CNC milling operations.

By optimizing these aspects, you can collectively reduce cycle times, extend tool life, and improve part quality, ultimately reducing per-part costs and increasing overall productivity.

Fecision’s CNC Milling Services

With advanced CNC milling capabilities, Fecision is your partner for precision manufacturing needs. Fecision’s CNC milling services are designed to deliver high-quality components with complex geometries and tight tolerances.

Precision Manufacturing Capabilities

Fecision excels in CNC machining complex components with exceptional surface finishes. Our state-of-the-art CNC milling equipment enables us to deliver superior quality products.

Competitive Pricing and Quality Assurance

Fecision is committed to competitive pricing while maintaining the highest quality standards. Our quality assurance processes include rigorous inspection protocols and certification standards to ensure customer satisfaction.

By partnering with Fecision for your CNC milling needs, you can achieve your precision manufacturing goals while controlling costs. For quotes, technical support, or custom project inquiries, please contact us.

Conclusion

As we conclude this comprehensive guide, it’s clear that CNC milling machines have revolutionized the manufacturing landscape. You’ve learned about the different types, key components, and capabilities of these machines, as well as the importance of understanding your manufacturing needs when making purchasing or outsourcing decisions.

Advances in CNC machining technology continue to expand manufacturing possibilities, making it crucial to select the right CNC machine or service provider. Fecision is a trusted partner for precision CNC milling requirements, especially for custom quick disconnect fittings. With the continued evolution of CNC milling machines, the future of manufacturing looks bright.