Precision Jigs And Fixtures for Every Industry

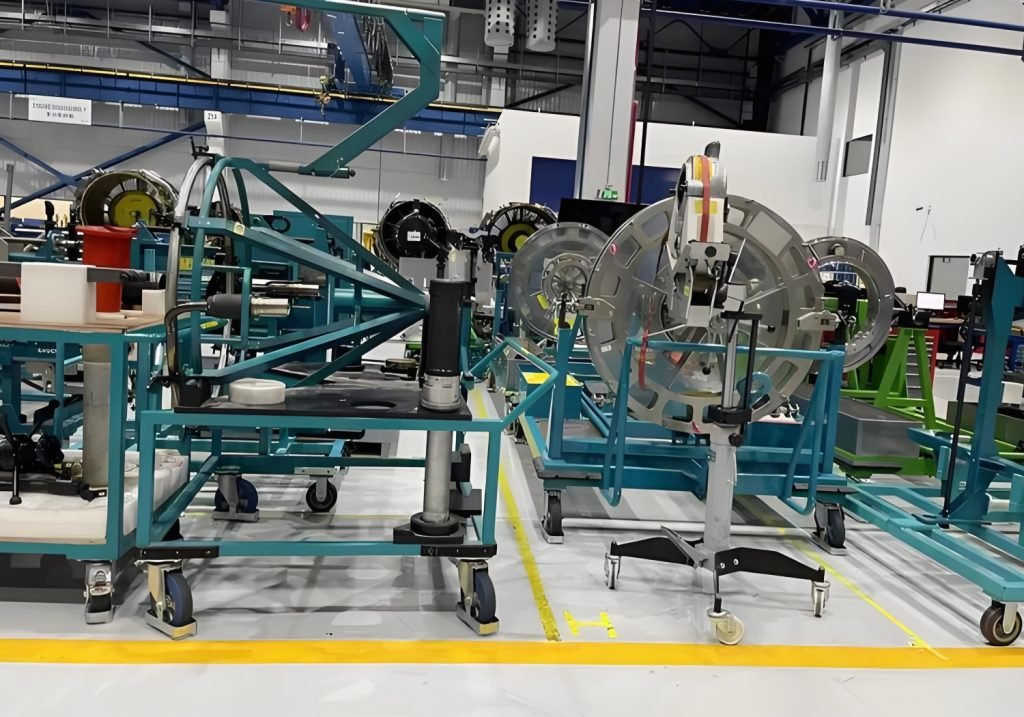

Fecision specializes in manufacturing high-precision fixturees and jigs for automotive, aerospace, medical, and industrial applications. Our solutions ensure accuracy, durability, and efficiency for your production needs.

Industry Ceifications

Faster Turnaround

5-Axis Machining Ablility

Custom Solutions for Your Needs

Engineered with precision and expertise

Service Capabilities

Our experienced team combines engineering expertise with advanced manufacturing capabilities to create jigs and fixtures that solve your most challenging production problems while enhancing quality, efficiency, and repeatability.

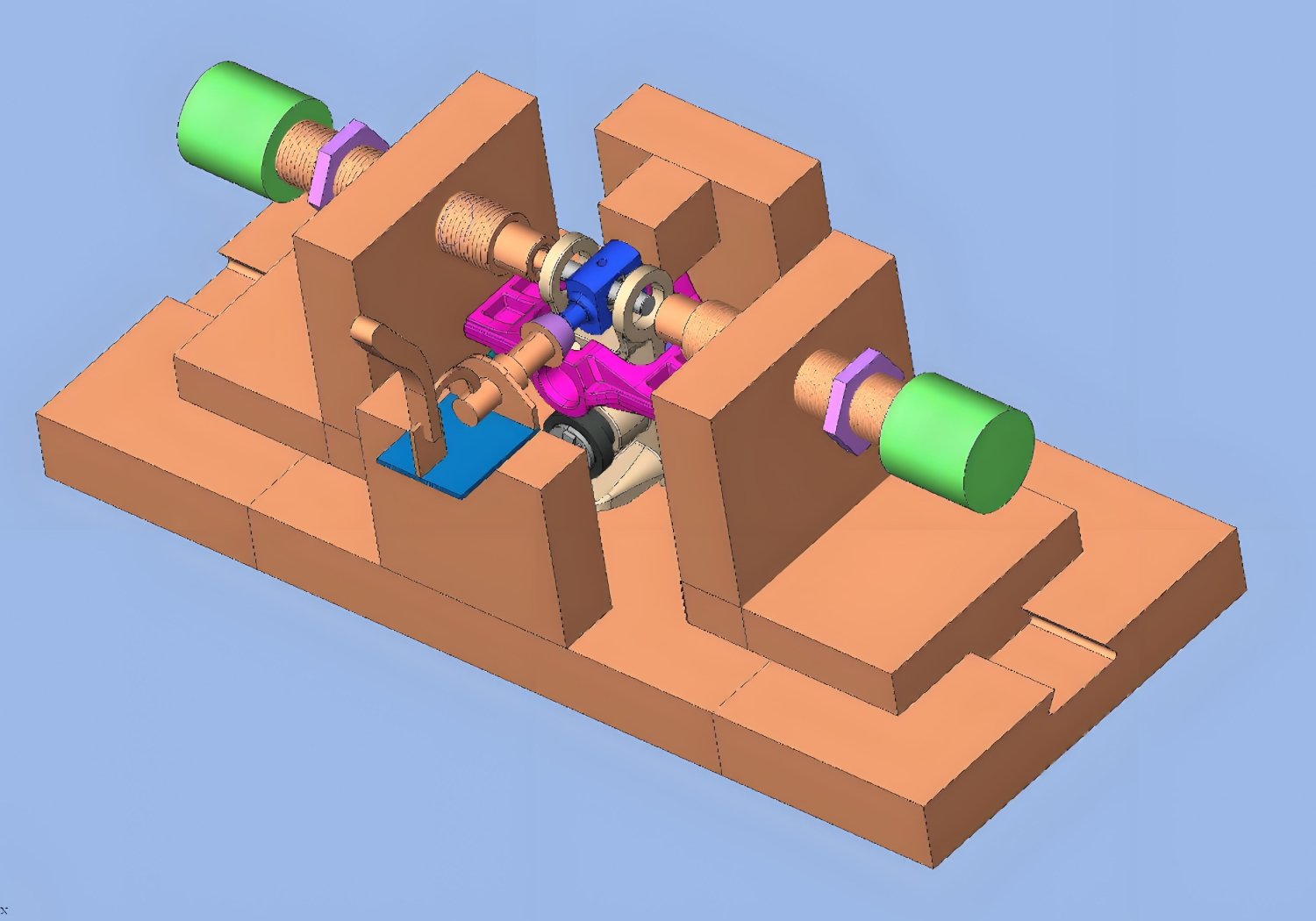

Fixture Design & Engineering

Custom fixture designs tailored to your specific manufacturing needs, using advanced CAD/CAM technology.

Precision Manufacturing

High-precision machining using 5-axis equipment and premium Japanese and German machinery.

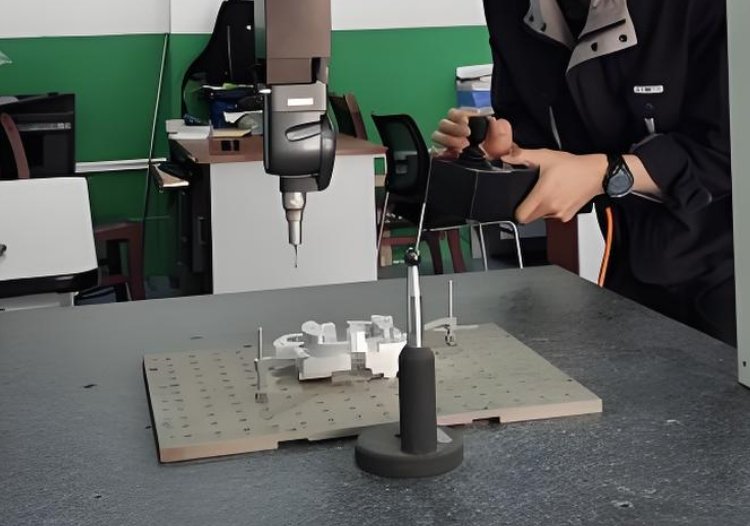

Quality Inspection & Validation

Rigorous inspection using CMM technology and other precision measurement tools to ensure compliance with specifications.

Different Types of Jigs and Fixtures

Explore the various types of jigs and fixtures designed to meet specific manufacturing needs.

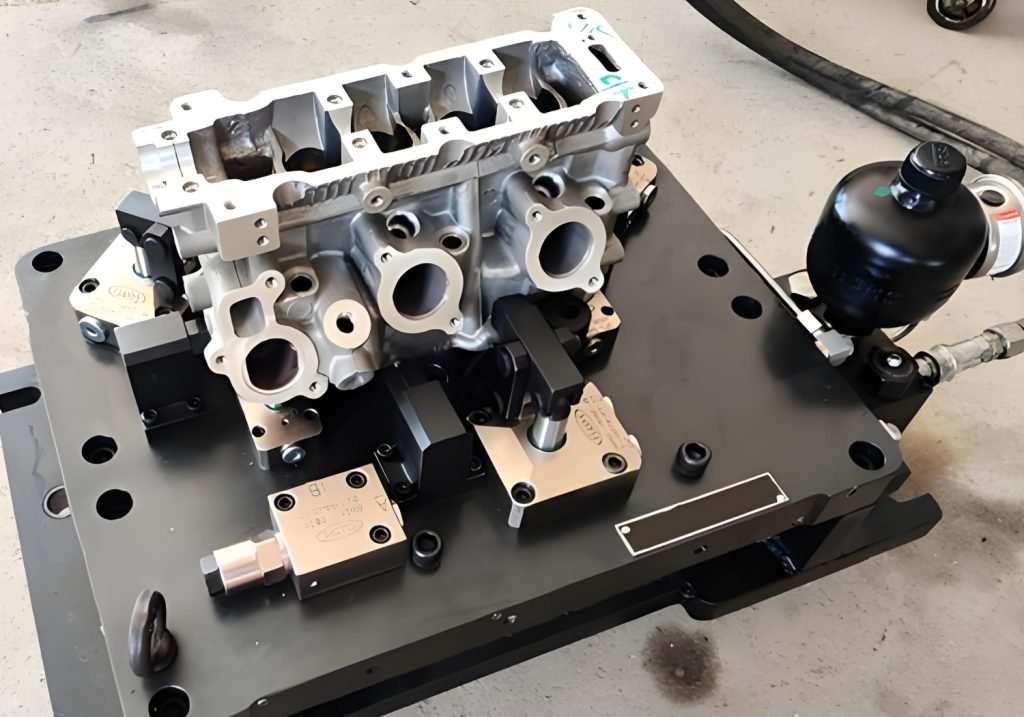

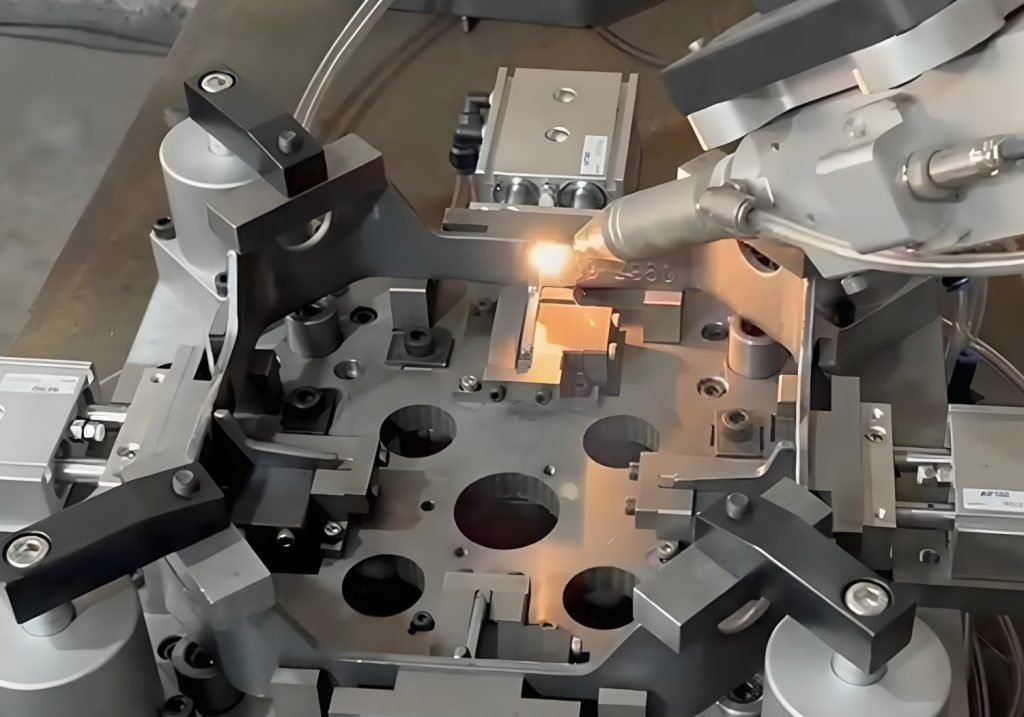

CNC Fixtures

Specialized fixtures designed for CNC milling, turning, and grinding operations, ensuring precise positioning and repeatability.

Assembly Fixtures

Fixtures designed to facilitate the accurate and efficient assembly of complex components, improving productivity and quality.

Modular Fixture

Consist of a wide range of interchangeable components that can be assembled to form a customized fixture setup.

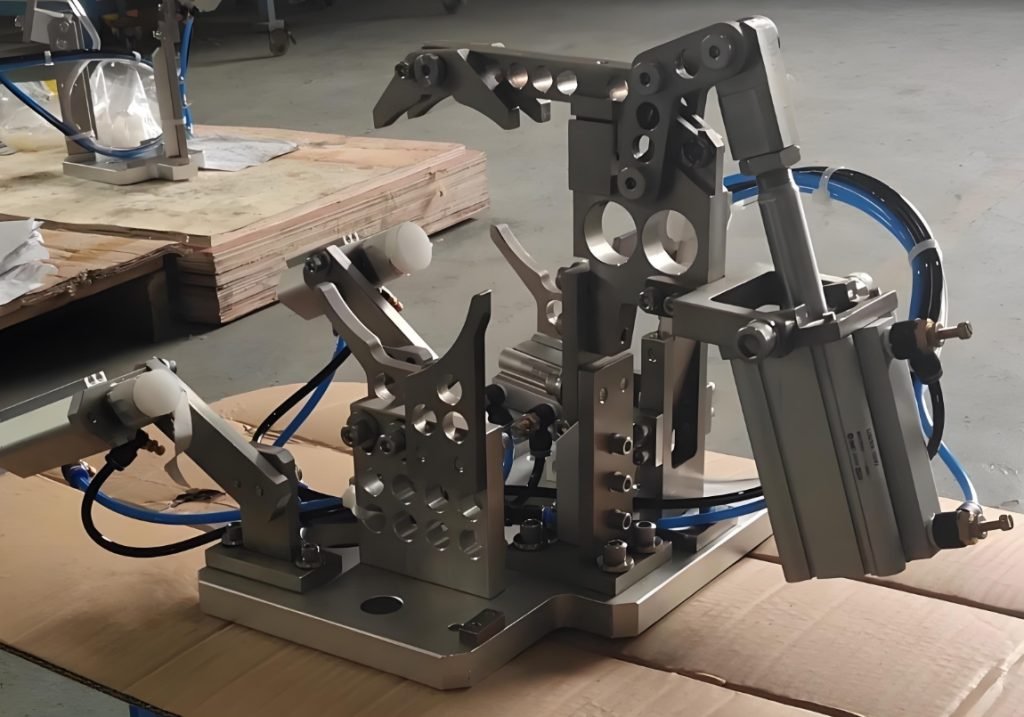

Clamping Fixtures

Secure tools that hold workpieces firmly during machining, enhancing precision and stability in manufacturing tasks.

Hydraulic Fixtures

Use pressurized fluid to apply consistent clamping force. These fixtures are often seen in applications that demand repeatability and speed.

Pneumatic Fixtures

Use compressed air to clamp and secure the workpiece during CNC machining, eapecially for industries like automotive and electronics.

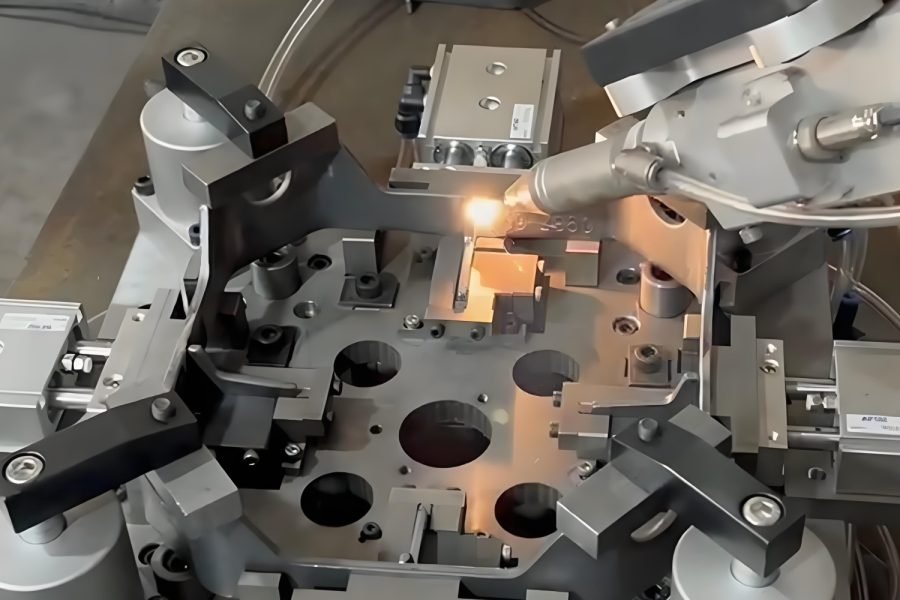

Welding Jig

Precision fixtures that hold components in place during welding processes, ensuring accurate alignment and consistent results.

Angle Plate Jig

Featuring angled surfaces, designed to secure workpieces and ensure accurate alignment during machining processes.

Template Jig

Precision tool for holding workpieces during machining, ensuring accuracy and repeatability in manufacturing processes.

Classification

Discover our comprehensive selection of fixtures and jigs designed for precision and durability.

Fixtures can be powered manually or through automated systems.

Classification by application or function (Based on CNC machining operations)

According to different uses, fixtures can be divided into different types.

According to different forms, fixtures are divided into many categories.

Material Selection for Jigs and Fixtures

The right material choice is critical for achieving optimal performance and longevity in your fixtures.

Aluminum Alloys

✅ Lightweight with high strength-to-weight ratio

✅ Excellent machinability and corrosion resistance

✅ Ideal for fixtures requiring quick setup changes

✅ Common grades: 6061, 7075, 2024

Steel Alloys

✅ High strength and wear resistance

✅ Excellent dimensional stability

✅ Suited for heavy-duty applications

✅ Common grades: 4140, 4340, 1045

Hardened Tool Steel

✅ Exceptional hardness and wear resistance

✅ Resistant to deformation under high loads

✅ Used for precision components and wear surfaces

✅ Common grades: D2, H13, A2

Cast Iron

✅ Good damping properties to reduce vibration

✅ Excellent machinability and thermal stability

✅ Used for bases and frames requiring stability

✅ Common grades: ASTM A48, A536

Polymer Composites

✅ Lightweight with good chemical resistance

✅ Non-marring surfaces for delicate components

✅ Used for fixtures in cleanroom environments

✅ Materials: Acetal, UHMW, PEEK, Nylon, Delrin, ABS

Titanium Alloys

✅ High strength with extremely low weight

✅ Excellent corrosion resistance

✅ Aerospace and high-performance applications

✅ Common grades: Ti-6Al-4V, Ti-5Al-2.5Sn

Factors to Consider in Material Selection

Load Requirements

Consider the weight and forces the fixture will encounter during operation.

Environmental Conditions

Evaluate exposure to temperature, humidity, chemicals, and corrosion.

Production Volume

High-volume applications may require more durable materials than low-volume projects.

Machinability

The ease of machining affects production time and cost.

Dimensional Stability

Materials must maintain their shape and size under operating conditions.

Cost Considerations

Balance material cost with performance requirements and budget constraints.

Manufacturing Methods

Our advanced manufacturing techniques ensure precision and quality in every fixture we produce.

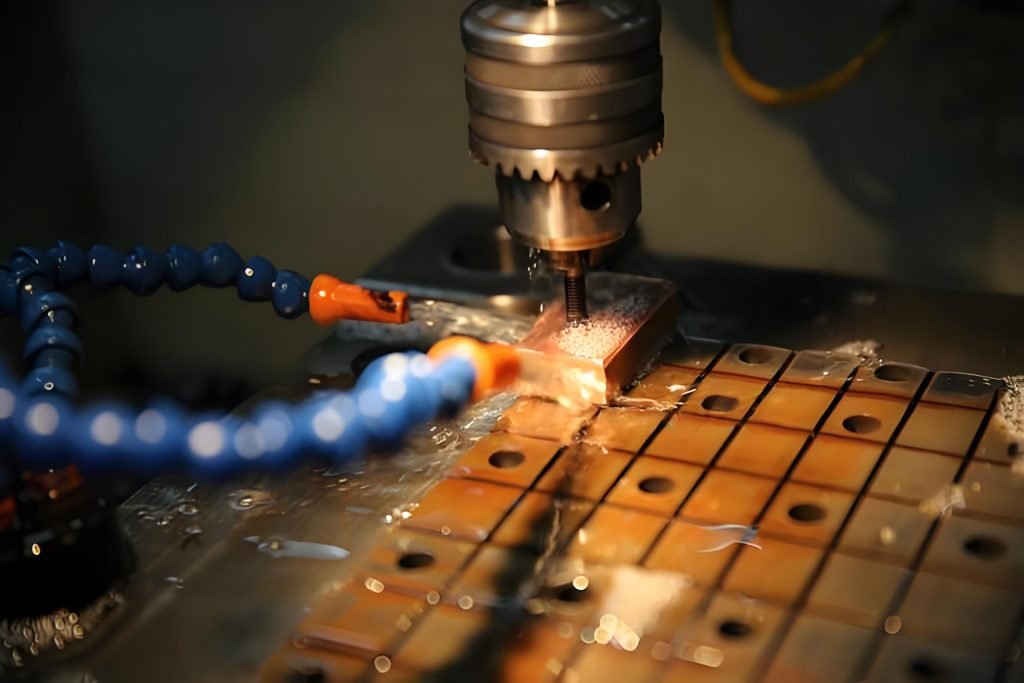

CNC Machining

CNC machining is our primary manufacturing method to produce custom jigs and fixtures , offering unparalleled precision and repeatability.

✅ 5-axis machining capabilities for complex

✅ CNC milling (3-axis, 4-axis, and 5-axis capabilities)

✅ High-speed machining for efficient production

✅ Advanced toolpath optimization for surface finish

Wire EDM

Wire Electrical Discharge Machining is used for intricate shapes and tight tolerances that are challenging to achieve with conventional machining.

✅ Capable of cutting complex contours and angles

✅ Precision down to ±0.001mm

✅ Ideal for hardened materials and thin-walled parts

✅ No mechanical stress on the workpiece

Precision Welding

Our precision welding techniques are used for rigid, structural frames and ensure strong, durable joints without compromising dimensional accuracy.

✅ TIG and MIG welding for various materials

✅ Laser welding for high-precision applications

✅ Welding distortion control and mitigation

✅ Post-weld heat treatment for stress relief

Manufacturing Equipments

Inspection Equipments

Manufacturing Methods

Our advanced manufacturing techniques ensure precision and quality in every fixture we produce.

Concept & Design

Our engineers work closely with clients to understand requirements and develop initial fixture concepts.

Precision Machining

Using advanced CNC and EDM equipment, we machine components to exact specifications with tight tolerances.

Quality Inspection

Every fixture undergoes comprehensive inspection using CMM and other precision measurement tools.

Material Selection

Based on application requirements, we select the optimal materials for durability, precision, and cost-effectiveness.

Assembly & Testing

Components are meticulously assembled and rigorously tested to ensure performance and precision.

Delivery & Support

We deliver the finished fixture and provide comprehensive support, including installation and training.

Why Choose Our Jigs & Fixtures Services

Our specialized focus on manufacturing services provides distinct advantages for clients seeking custom workholding solutions.

Manufacturing Expertise

Our team brings extensive experience in manufacturing processes, allowing us to design fixtures that not only hold parts securely but also optimize the entire machining process.

Customization

We work as an extension of your manufacturing team, taking time to understand your specific challenges and production environment before proposing solutions.

Rapid Response

Our streamlined process allows for quick turnaround on both quotes and finished fixtures, helping you meet tight production schedules and minimize downtime.

End-to-End Services

Every fixture we produce undergoes thorough inspection and testing to ensure it performs as specified from the first day in your facility.

Ongoing Support

Our relationship continues after delivery, with support for implementation, maintenance, and modifications as your production needs evolve.

Validated Performance, Guaranteed Quality

Commitment to Quality & Validation

We employ rigorous validation protocols, including in-process and final CMM inspection, steel certifications, heat treat certifications, and comprehensive mold trials (T1, T2...) to ensure your mold performs flawlessly and meets all specifications from the first shot. Trust our ISO-certified quality system.

Start Your Custom Fixture Project Today

Contact our team to discuss your specific jigs and fixtures requirements.

We’ll work with you to develop custom workholding solutions that enhance your manufacturing precision and efficiency.