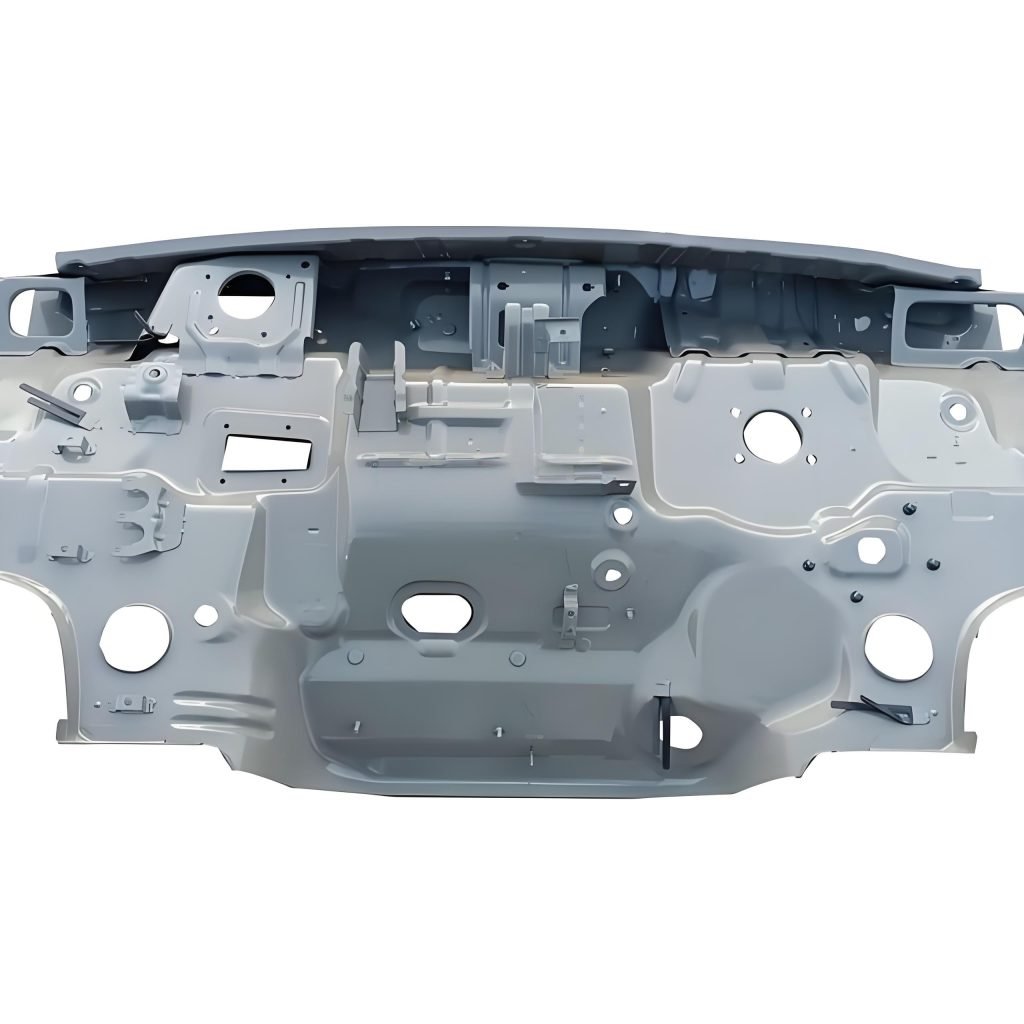

Have you ever thought about how you get everyday products, like car parts or electronic gadgets, at such an incredible rate in terms of accuracy and quantity? The answer is tooling in manufacturing. It refers to specialized, precision-engineered equipment used to produce components with accuracy and consistency. While it includes basic tools, the term primarily describes custom-designed production systems such as molds, dies, jigs, and fixtures that enable high-volume part manufacturing with exacting specifications.

Tooling is important for mass production so that companies can mass produce thousands or even millions of identical items. It is also important for prototyping use as well, so you can test your designs quickly before going to full production runs. In the end, effective tooling meaning in manufacturing brings cost savings, reduces waste, and affects the quality, speed, and scalability of your manufacturing process.

What Is Tooling In Manufacturing?

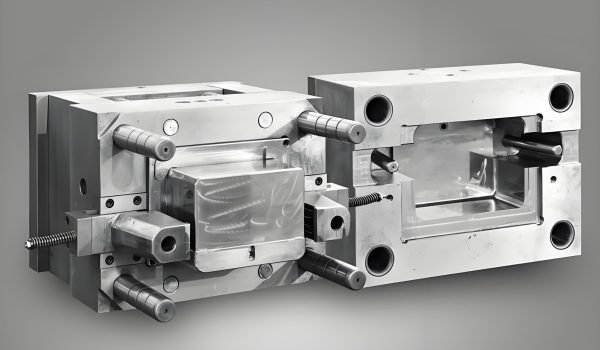

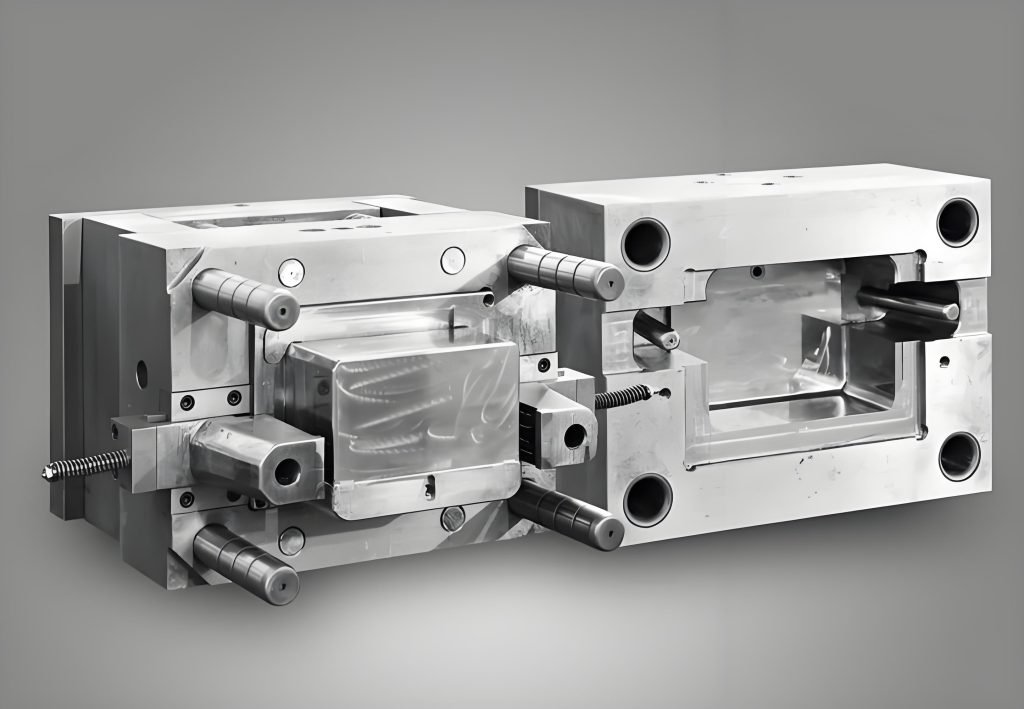

What is tooling in manufacturing? At its heart, tooling in manufacturing refers to the entire process of designing and building specialized tools, molds, fixtures, jigs, and dies that are individualized for that company’s purpose. These are not just any tools; they are custom-designed equipment that are used to shape, cut, form, and assemble components for different uses, like automotive, aerospace, electronics, and consumer goods.

What does tooling mean in manufacturing? It is custom-engineered types of equipment, such as injection molds for plastic parts, stamping dies for sheet metal, and CNC fixtures that hold the workpiece exactly used during machining. These tools give manufacturing incredible accuracy, productivity, and consistency, which ultimately leads to quality end products manufactured to specified requirements. They are important because they automate processes, replace labor, and create the ability to manufacture complex designs repeatedly.

Significance of Tooling In Manufacturing

Tooling plays a critical role in manufacturing for several reasons:

Efficiency

Tooling allows parts to be manufactured more quickly and efficiently by automating previously manual processes. Toolmaking enables exponential increases in production quantities while simultaneously reducing per-unit manufacturing time. This dual effect – higher output and faster cycle times – directly correlates with enhanced production capacity and operational efficiency.

Consistency

When operating on thousands or millions of parts, you can’t replicate consistency. Specialized tooling creates parts via exact specifications, thus providing consistency for every batch. It is especially critical in industries where any small discrepancy can have far-reaching impacts, such as automotive or medical devices.

Quality Control and Precision

Proper tooling is your guarantee of a quality end product. You can ensure that every operation is executed with repeatable and reliable accuracy, which reduces errors and defects in your project. Precision is key when your tolerances are tight, as you want to consistently manufacture a product that meets expected quality.

Cost-Effectiveness

Initial costs can make tooling appear expensive, but the savings are tremendous over the life of the tool. You can recognize savings through productivity, less wasted materials from mistakes, and producing components with a lower cost per part. You’ve likely recouped your upfront tooling costs in no time and will continue to benefit from the efficiency.

Custom Parts

Tooling allows for the development of highly customized parts that satisfy very specific design parameters. Without tooling, developing complicated or obscure geometries could be nearly impossible, if not very difficult to do so readily and economically.

Typical Two Types of Tooling In Manufacturing

You will see primarily two types of tooling in manufacturing: soft tooling and hard tooling. Both have unique advantages depending on the production level required.

Soft Tooling

Soft tooling is generally considered in prototyping and low-to-medium production, using machinable materials like aluminum, mild steels, or engineering plastics. These materials allow a faster build time in fabrication – an advantage when compared to hard tooling – particularly for iterative development or complex geometry. They are generally less robust than hard tooling and not intended for high-volume production applications.

Pros & Cons

Soft tooling is affordable and gives flexibility to prototype and low-volume production; however, size, durability, and materials will always be limitations.

| Aspect | Pros | Cons |

| Cost & Lead Time | Low upfront cost; fast to produce for quick prototyping and initial batches. | Wears out quickly, especially with abrasive materials, leading to a shorter lifespan and potential frequent replacement. |

| Production Volume | Ideal for prototypes and low-volume runs (e.g., under 10,000 parts) for design validation. | Limited material compatibility; not suitable for very hard, abrasive, or high-temperature materials due to rapid wear. |

| Flexibility | Easier and cheaper to modify for design adjustments, offering flexibility during development. | Expect wear and potential deformities over time, which can impact part quality and consistency in longer runs. |

Hard Tooling

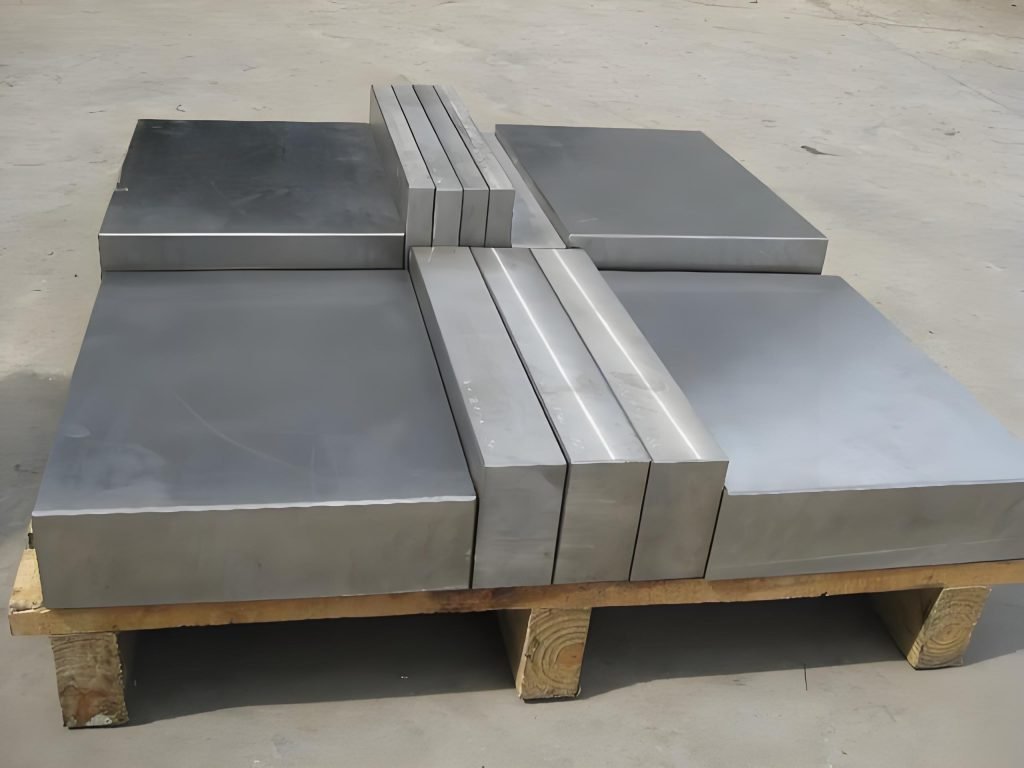

The primary application for hard tooling is high-volume production applications, and the choice of tooling materials is different too. Hard tooling can be found in much tougher and more rigid materials, such as hardened steels, nickel alloys, or strong aluminum alloys that have been selected for hardness, wear resistance, thermal stability, and cycle precision over millions of operations. While it takes a larger investment to create hard tooling, it delivers many years of usability with the ability to manufacture volumes.

Pros & Cons

Hard tooling comes with durable solutions for high volume and high precision related manufacturing; however, it is more of an investment than soft tooling and has less flexibility.

| Aspect | Pros of Hard Tooling | Cons of Hard Tooling |

| Durability & Performance | Long lifespan, handles high-pressure production | Expensive and slower to produce (higher upfront cost) |

| Material Compatibility | Suits abrasive/high-temp materials (e.g., carbon fiber, glass-filled resins) | Less flexibility for design changes (costly modifications) |

| Cost Efficiency | Long-term cost savings (lower per-part cost over time) | — |

| Precision & Consistency | Superior precision, maintains tight tolerances | — |

Choose Soft Tooling or Hard Tooling?

Soft Tooling or Hard Tooling? The decision to choose between soft and hard tooling is not always easy, and it depends on your unique production requirements, tool lifespan, and budget.

Volume

Suppose you are working with low-volume production work (generally under 1,000 parts, potentially even up to 10,000 depending on complexity). In that case, soft tooling is often the more cost-effective and faster alternative. If you are producing large quantities of parts (millions of parts), hard tooling is an obvious choice.

Budget

If you are looking to keep your upfront cost low and need to validate a design in the short term, soft tooling is a better option. If you are looking for a long-term return on investment (ROI) with a sustained production period, hard tooling will recoup its higher initial cost in the end.

Material

If you’re working with abrasive materials or high-temperature applications, hard tools are necessary so as to avoid rapid wear and provide consistent part quality. If the part application is not as demanding, or you are experimenting with several different compounds, then soft tools may provide sufficient solutions for early runs.

| Decision Factor | Soft Tooling | Hard Tooling |

| Cost | Low upfront cost | High upfront cost |

| Lead Time | Fast (days/weeks) | Slow (weeks/months) |

| Lifespan | Short (hundreds-thousands of parts) | Long (millions of parts) |

| Material Compatibility | Limited (soft plastics, non-abrasives) | Broad (metals, composites, abrasives) |

| Best For | Prototypes, low-volume | Mass production, harsh materials |

Consider the expected lifespan of your product, the demand for it, and the criticality of part consistency when making your decision.

Different Stages of Tooling In Manufacturing

Tooling often progresses through distinct stages, each serving a different purpose in the product development and manufacturing lifecycle.

Prototype Tooling

Prototype tooling is the very first stage, designed for designing and testing parts. These are typically rapid, low-cost tools—often 3D-printed molds or simple machined aluminum tools—used to validate a concept, test form and fit, and identify potential issues before committing to more expensive production tools. They are best suited for very low production scales, as their primary goal is quick iteration and learning.

Bridge Tooling

Bridge tooling acts as a temporary solution for short-to-medium-term production needs. It serves as a transition between the prototyping phase and full-scale manufacturing. These are often semi-durable tools, frequently made from aluminum, that can produce a few thousand to tens of thousands of parts. Bridge tooling allows you to get pre-production units into the market, perform market testing, or bridge the gap while the final production tools are being built.

Production Tooling

Production tooling is the last step of tooling and is necessary for high-volume, mass production. These are the reinforced, hardened tools usually made from high-grade steel, designed for the utmost durability, precision, and consistent performance for millions of cycles. This is where your larger costs are, as these tools are meant to withstand constant manufacturing for the life of your product.

Considerations and Tips When Machining Tooling

Creating effective tooling requires careful consideration of several factors.

Part Geometry

Your part design is important in determining which tooling is best for you. Soft tooling is mostly common with designs that are simplistic or in development, where frequent changes may be required. If your design has complexity or precise geometries with detail, tight tolerances, or very thin wall thickness, hard tooling is required. Even more complex designs may require multi-cavity molds (producing multiple parts per cycle), or special processes, such as Electrical Discharge Machining (EDM) for fine features.

Tooling Lifespan

Consider the number of parts that require production in the life of your product. If you are expecting high production volumes over many years, you will choose hard tooling because of its longevity. Although hard tools can last much longer, they still require maintenance by way of polishing and specialized coatings to prolong their life and ensure consistent quality in your parts. For short runs or products with a limited market life, soft tooling will be perfectly adequate and more cost-effective. The expected maintenance and overall lifespan of the tooling directly impacts your long-term costs.

Material Selection

Choosing the right material to make your tool is very important because it directly affects durability, performance, and cost.

Tool Material

| Material | Characteristics | Ideal Use Cases |

| Aluminum | Lightweight, generally cheaper, and machines quickly. | Bridge tooling, rapid prototyping, and short production runs where speed and cost-efficiency are key. |

| Stainless Steel | Offers superior corrosion resistance. | Tooling for medical, food processing, and other industries where hygiene and contamination prevention are critical. |

| Tool Steel | High-wear resistance, capable of withstanding significant stress and abrasion (e.g., P20, H13 grades). | Long production runs and hard tooling for high-volume manufacturing. |

Part Material

- Plastics (e.g., ABS, nylon) vs. metals (e.g., aluminum, steel): Softer plastics generally put less stress on tooling, while harder metals require much more robust tool materials.

- Abrasive materials (e.g., glass-filled polymers): If your part material contains abrasive fillers, it will accelerate tool wear. In such cases, hardened tool steel is absolutely necessary to maintain tool integrity and part quality over time.

The right material selection also impacts the cycle time (how quickly a part can be produced) and the overall throughput of your manufacturing process.

Fecision – Your Reliable Mold Tooling Partner

Tooling is a delicate balance of managing cost, speed, and quality, and getting it right is fundamental to the success of your product. This is where a reliable partner like Fecision comes into play.

Comprehensive Mold Tooling Services

Fecision offers end-to-end mold tooling in manufacturing services designed to meet your precise manufacturing needs, from concept to mass production.

- Mold Design: We begin every stage with mold design and DFM (Design for Manufacturability) optimization, and optimize the part design via advanced CAD/CAM software so that it is manufacturable and economical from the start.

- Mold Machining: We employ precision machining practices, such as CNC, EDM and grinding, to produce complex mold shapes with solid accuracy. We offer material choices for molds from aluminum (for a fast prototype) to hardened steel (for hard and high-volume production).

- Mold Assembly & Testing: After machining, we perform rigorous quality checks during assembly to guarantee tight tolerances and smooth operation. We then run trials with actual production materials to confirm the mold works perfectly, consistently delivering high-quality parts before full production starts.

Why Choose Fecision?

By working with Fecision, you are signing up with a company that is committed to precision, efficiency, and quality in mold tooling:

- Expertise in Both Soft & Hard Tooling: Whether your project is for low-volume prototypes, or for high-volume production masses, we have the experience to deliver the best tooling options.

- Material Mastery: We help you select the best tool steel (H13 or P20, for example) and coatings to extend the life and performance of the mold.

- Speed & Cost Efficiency: Time-to-market is always a top priority for your project. Our processes have been developed to reduce lead times while ensuring consistent quality and cost to allow your project to stay on budget.

Ready to make your solution, with precision and efficiency? Contact Fecision for a tailored solution right away!