You rely on precise measurements every day, whether you’re designing a new product or ensuring the quality of a manufactured component. Metrology, the science of measurement, is the foundation upon which engineering precision is built.

Over time, it has evolved to incorporate sophisticated systems based on universal constants, ensuring consistency and accuracy in manufacturing processes.

As an engineer or quality assurance professional, understanding metrology basics is crucial for maintaining precision in your work. By grasping the principles of metrology, you’ll be better equipped to design and manufacture high-quality products that meet exacting standards.

What is Metrology in Engineering?

The science of measurement, known as metrology, is fundamental to engineering and manufacturing. It ensures that components are made to precise specifications, which is critical for the reliability and performance of final products.

The Definition and Origin of Metrology

Metrology is derived from the Greek words ‘metron’ meaning measure and ‘logos’ meaning study or discourse. It encompasses the study of measurement systems, units, and standards to ensure accuracy and consistency. Definitions of metrology often highlight its role in providing a common language for measurement across different fields and industries. In engineering, metrology is applied to ensure that measurements are traceable to recognized standards.

Historical Development of Measurement Systems

The historical development of measurement systems has been a gradual process, evolving from simple body parts as references to sophisticated systems based on universal constants. The establishment of the International System of Units (SI) in 1948 marked a significant milestone, replacing artifact-based definitions with units derived from fundamental physical constants. This transition has enabled measurements to become more accurate and consistent across global manufacturing. Today, metrology continues to play a vital role in advancing measurement technology.

The Importance of Metrology in Modern Engineering

The importance of metrology in modern engineering cannot be overstated, as it directly impacts product quality and reliability. Metrology ensures that components are manufactured to exact specifications, which is crucial in industries like aerospace, automotive, and healthcare.

Ensuring Quality and Precision

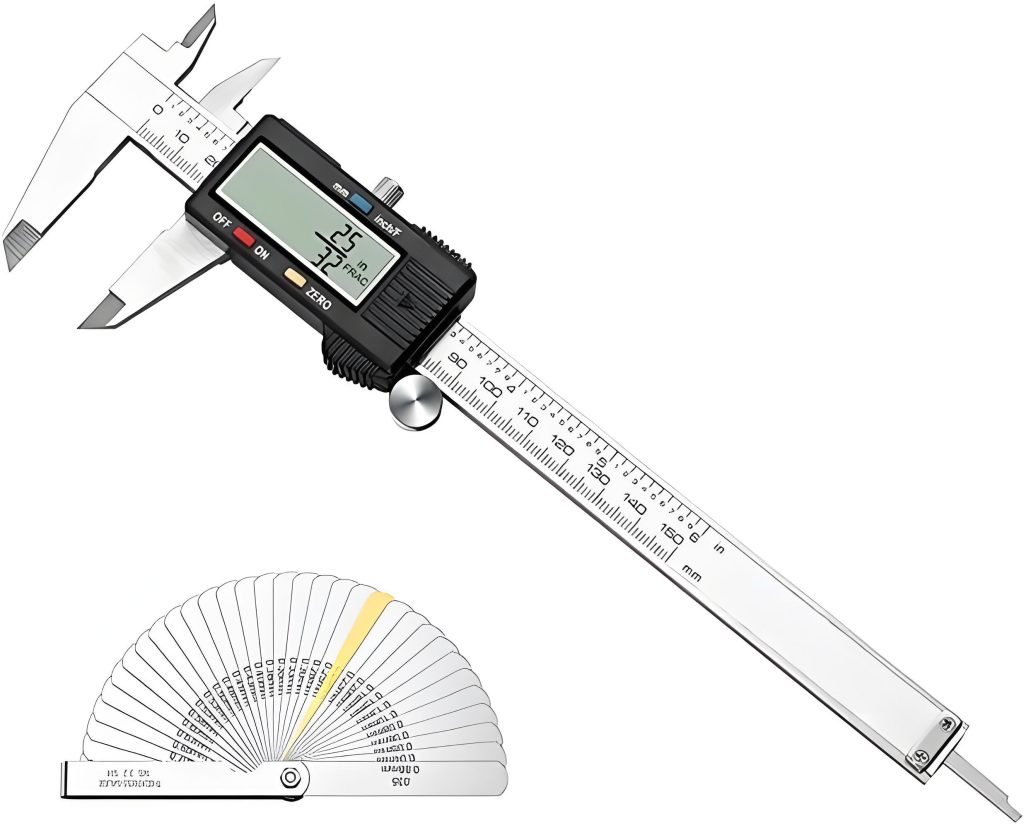

Metrology tools are used to take accurate measurements that help ensure parts are made to exact specifications. This precision is vital for maintaining high quality standards in manufacturing. By ensuring that components meet precise tolerances, metrology directly impacts the overall quality of the final product.

Cost Efficiency and Error Reduction

Consistent measurement standards help prevent errors that could lead to costly reworks, waste, and recalls. By reducing these errors, metrology contributes to significant cost savings in the manufacturing process. This not only improves cost efficiency but also enhances the overall reliability of the product.

Key Concepts and Principles in Metrology

Understanding metrology’s core concepts is crucial for ensuring precision in various engineering applications. You need to grasp these fundamental principles to appreciate how measurements are made accurately and consistently.

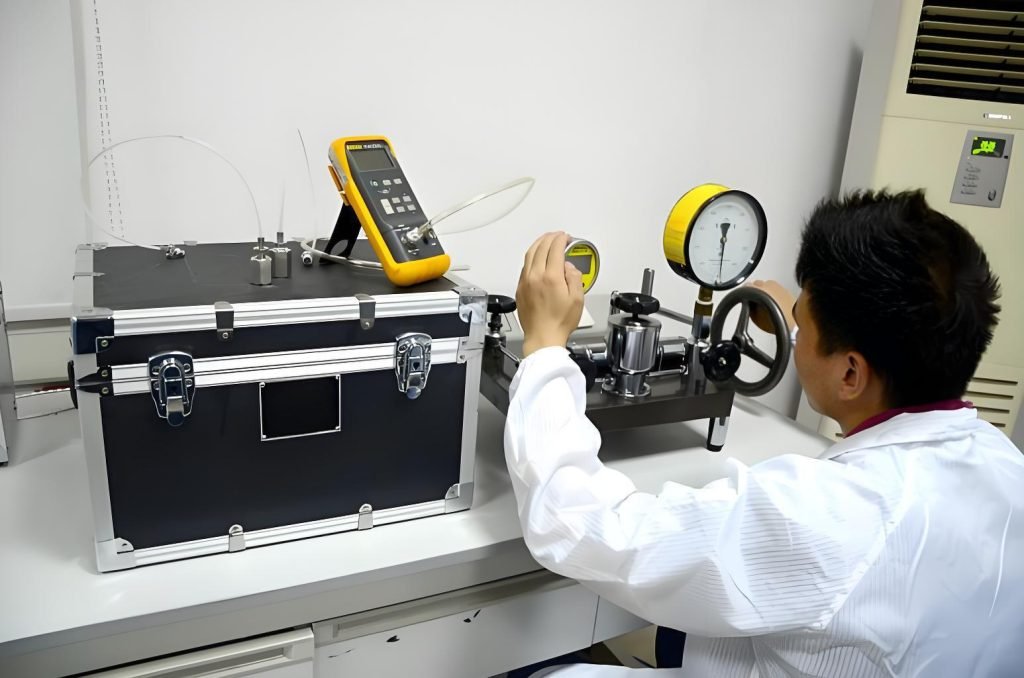

Calibration and Traceability

Calibration is a critical process that involves comparing your measuring instruments against known standards to verify their accuracy and consistency. This process ensures that your instruments measure accurately and consistently, which is essential for reliable results. Traceability is also vital as it creates an unbroken chain of comparisons linking your measurements to national or international standards, thereby ensuring reliability.

By linking measurements back to their source, such as test certificates, traceability ensures accuracy and minimizes errors in tests and results. This is crucial for quality control as it ensures your measurements can be trusted as reliable sources.

Measurement Uncertainty and Accuracy

You must understand the principles of measurement uncertainty to properly interpret your results. Measurement uncertainty refers to the limitations of your measurements, and quantifying this uncertainty is essential for making informed decisions about product conformity. Accuracy differs from precision, and both are necessary for effective metrology applications. While precision refers to the consistency of measurements, accuracy refers to how close your measurements are to the true value.

Understanding the difference between accuracy and precision is vital for ensuring that your measuring instruments provide reliable data. By managing measurement uncertainty, you can ensure that your products meet the required specifications and standards.

Measurement Standards in Metrology

In the realm of metrology, measurement standards play a pivotal role in ensuring the accuracy and reliability of measurements. These standards are the benchmarks against which all other measurements are compared.

International and Primary Standards

International standards are defined by international agreements and represent fundamental units of measurement. The Bureau International des Poids et Mesures (BIPM) maintains these standards. Primary standards are the most accurate and stable, defining units in absolute terms using fundamental physical constants rather than artifacts.

The International System of Units (SI) has evolved to define units like the meter, kilogram, and second using universal constants for greater precision.

Secondary and Working Standards

Secondary standards are less accurate than primary standards but more accessible, serving as a practical link between primary standards and everyday measuring instruments. Working standards are calibrated against secondary standards and are used regularly in laboratories to govern measurements, calibrate instruments, and verify measurement methods.

These standards ensure that measurements are traceable to international standards, maintaining global consistency in manufacturing and scientific research.

Metrology Applications Across Engineering Fields

As you explore the world of engineering, you’ll discover that metrology is a vital component in multiple fields.

Manufacturing and Quality Control

In manufacturing, metrology is used to define and establish datums and tolerances on blueprints for inspection. Quality inspection executes the best practices of metrology by physically inspecting and validating that a product conforms to its blueprint and specifications. Metrology tools are essential in ensuring components meet specifications and tolerances throughout production.

3D Metrology and Advanced Applications

3D metrology is widely used in different industries to ensure that parts meet all specifications. It helps identify defects in the early stages of production, reducing waste. Many manufacturers use 3D metrology to reverse engineer legacy parts or parts for which original design documents are unavailable.

Process Capability and Optimization

Metrology is used in process capability studies to determine if manufacturing processes can consistently produce parts within specified tolerances. By analyzing metrology data, manufacturers can optimize their processes, identify areas for improvement, and reduce variability.

Conclusion

Metrology is the unsung hero of engineering, providing the precision and accuracy necessary for innovation. You’ve gained a comprehensive understanding of how metrology ensures measurement accuracy and precision in various engineering fields. By applying metrology principles, you can maintain consistent product standards across manufacturing processes, directly impacting product design and overall quality. With the right instruments and tools, engineers can make informed decisions based on reliable data, reducing errors and enhancing reliability. As a result, manufacturers can achieve cost savings and gain a competitive edge in today’s precision-focused marketplace.