Are you aware of the type of electric motor powering your favorite appliances and industrial machinery? As you explore the world of electromechanics, understanding the fundamental differences between various motor types is crucial.

Electric motors convert electrical energy into mechanical energy, forming the backbone of countless industrial and consumer applications. The two main categories of motors are Alternating Current (AC) and Direct Current (DC) motors, each with distinct characteristics that make them suitable for specific applications.

Choosing the right motor solution requires consideration of factors like speed control requirements, power efficiency, and maintenance needs. As we delve into the world of motors, we’ll explore their construction, operation principles, advantages, and typical applications, helping you make informed decisions for your industrial needs.

The Fundamentals of Electric Motors

Electric motors are the backbone of modern machinery, converting electrical energy into mechanical energy. You rely on them daily, whether it’s in household appliances or industrial machinery.

The fundamental principle behind all electric motors is the conversion of electrical energy into mechanical energy through electromagnetic interaction.

How Electric Motors Convert Energy

Electric motors harness the relationship between electricity and magnetism to generate rotational force, or torque. When an electric current flows through a conductor within a magnetic field, it experiences a force that drives the motor’s rotation.

This interaction between the magnetic field and the current-carrying conductor is the core principle that enables electric motors to convert electrical energy into mechanical energy.

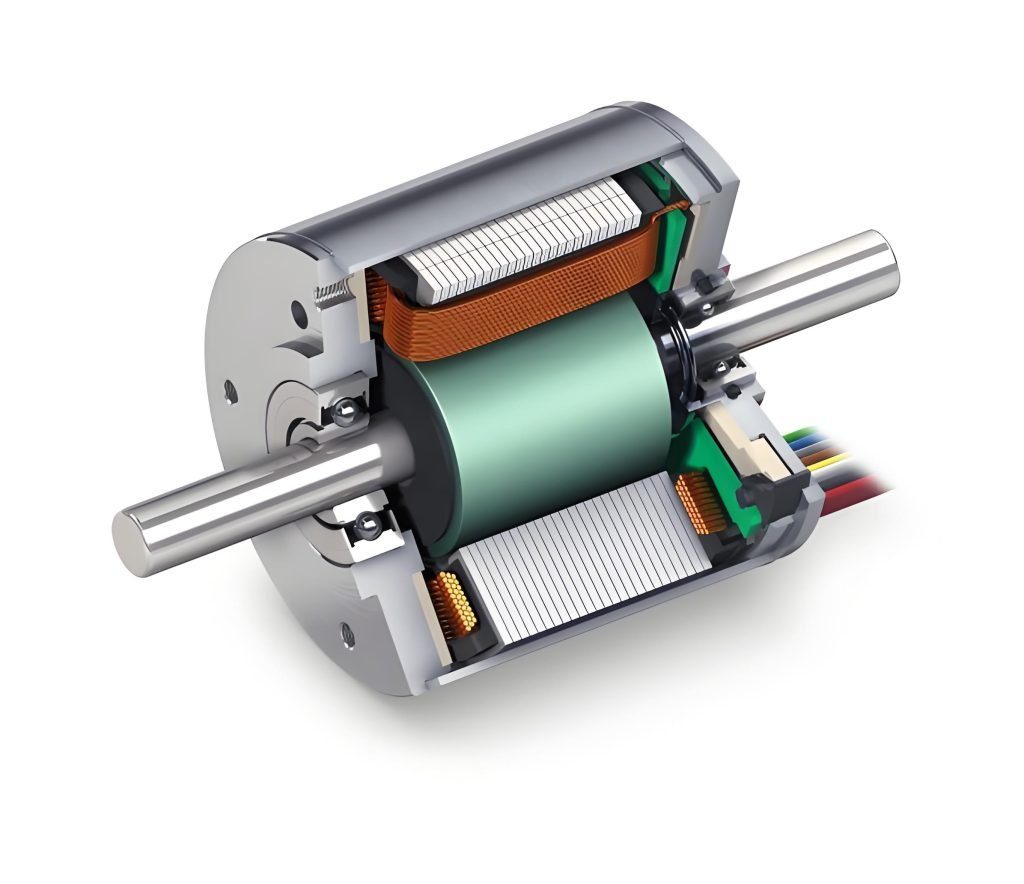

Main Components: Stator and Rotor

The two basic components of an electric motor are the stator and the rotor. The stator is the stationary component that typically houses the primary magnetic field-generating elements.

The rotor, on the other hand, is the rotating component that interacts with the magnetic field to produce motion. The interaction between the stator’s magnetic field and the rotor creates the rotational force that powers mechanical systems.

What is a Direct Current (DC) Motor?

A DC motor is an essential component in many modern devices, converting direct current electrical energy into mechanical rotation. DC motors operate through the interaction between a fixed magnetic field and a variable magnetic field generated by an electric current passing through a coil.

Basic Design and Operation Principles

DC motors function by converting electrical energy into mechanical energy. The basic operating principle involves DC current flowing through conductor coils, creating a magnetic field that interacts with a permanent or electromagnet field to generate rotational force.

Types of DC Motors

There are several types of DC motors, including brushed and brushless DC motors. Each type has its unique characteristics and applications.

Brushed DC Motors

Brushed DC motors use a commutator and carbon brushes to facilitate current flow reversal as the rotor turns. This design is simple and cost-effective but requires more maintenance.

Brushless DC Motors

Brushless DC motor technology eliminates physical brushes by using electronic commutation, resulting in higher efficiency and reduced maintenance. This makes them ideal for applications requiring high reliability and precision.

Key Characteristics of DC Motors

DC motors are known for their excellent speed control, high starting torque, and compact size. They respond well to varying loads and can provide precise positioning in specialized applications. The speed-torque characteristics of DC motors make them suitable for various industrial and consumer applications.

What is an Alternating Current (AC) Motor?

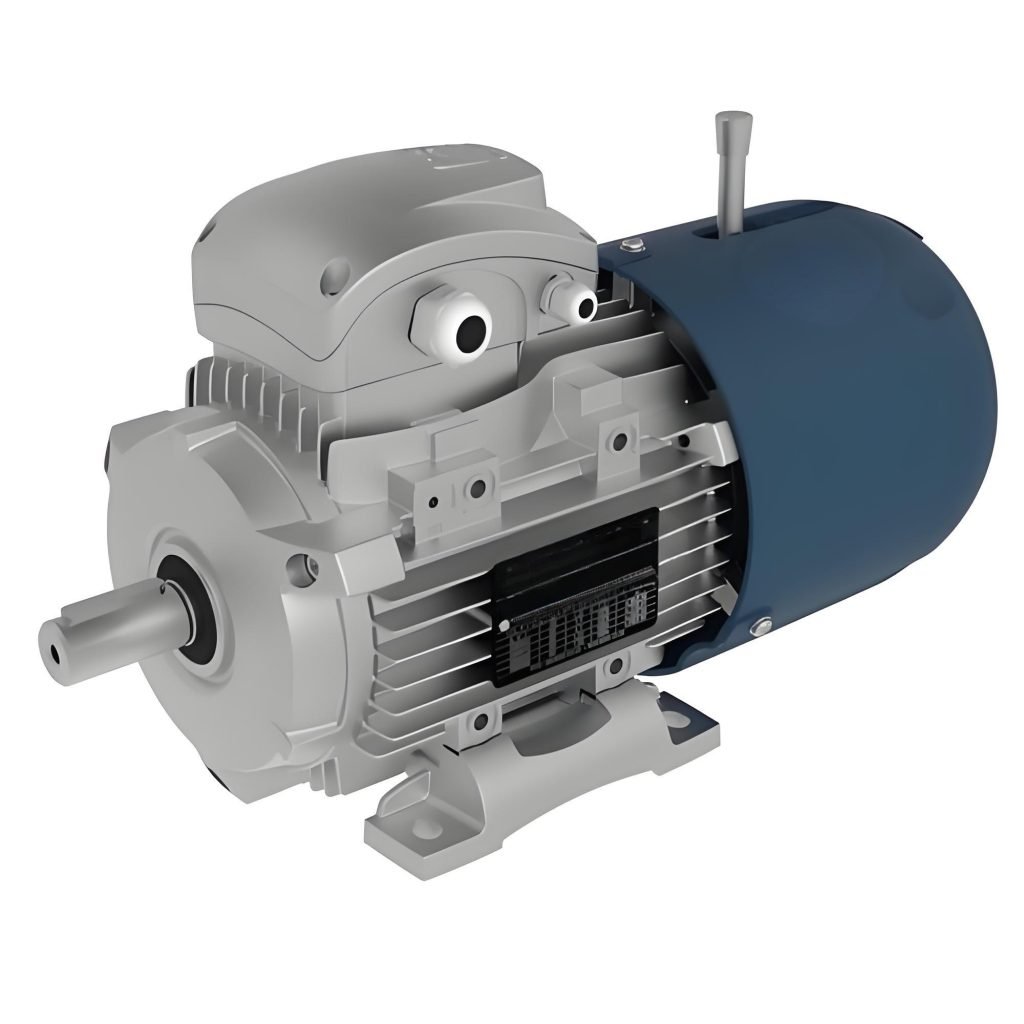

AC motors play a vital role in converting electrical energy into mechanical energy in numerous applications. They operate using alternating current, which periodically reverses direction.

Basic Design and Operation Principles

AC motors generate a rotating magnetic field in the stator, inducing current in the rotor and creating electromagnetic interaction that produces rotational force. This fundamental principle allows AC motors to efficiently convert electrical energy into mechanical rotation.

Types of AC Motors

There are primarily two types of AC motors: Synchronous Motors and Asynchronous (Induction) Motors.

Synchronous Motors

Synchronous motors rotate at a speed precisely synchronized with the frequency of the supplied current. They are used in applications requiring precise speed control.

Asynchronous (Induction) Motors

Asynchronous or induction motors are the most common type, operating with the rotor turning slightly slower than the magnetic field. They are known for their simplicity and durability.

Key Characteristics of AC Motors

AC motors typically operate at constant speeds determined by the supply frequency. However, variable frequency drives (VFDs) can provide speed control. They are known for their efficiency, particularly at constant loads and speeds, making them ideal for continuous operation applications.

AC motors are generally more durable, require less maintenance, and are more economical to manufacture than DC motors. They are widely used in industrial, domestic, and commercial applications due to their simplicity, robustness, and low cost.

The Difference Between AC Motor and DC Motor

The primary differences between AC and DC motors revolve around their power source, control capabilities, and design complexity. Understanding these differences is crucial for selecting the appropriate motor for your specific needs.

Power Source and Supply Requirements

DC motors operate using direct current from sources like batteries or rectified power supplies. In contrast, AC motors are designed to work with alternating current directly from the grid. This fundamental difference impacts their application and suitability for various uses.

Speed Control Capabilities

DC motors offer straightforward speed control by adjusting the voltage, making them suitable for applications requiring variable speeds. AC motors, however, typically run at fixed speeds unless equipped with variable frequency drives, which can adjust their speed.

Construction and Complexity

The construction of DC motors is more complex, featuring commutators and brushes, which can lead to higher maintenance needs. AC motors, on the other hand, have a simpler and more robust design, contributing to their reliability and lower maintenance requirements.

Efficiency and Maintenance Needs

DC motors can offer better efficiency at variable speeds, making them ideal for applications with changing load conditions. AC motors excel in constant speed operations and generally require less maintenance due to their simpler design.

Cost Considerations

The cost of AC and DC motors varies, with AC motors typically being less expensive due to their simpler construction. However, the overall cost, including installation, energy consumption, and maintenance, should be considered when choosing between the two.

Applications of AC and DC Motors

The versatility of AC and DC motors makes them suitable for numerous applications, from industrial machinery to household appliances. Understanding their applications is key to selecting the right motor for your needs.

Common DC Motor Applications

DC motors are widely used in applications that require precise control and variable speed. They are particularly useful in battery-powered devices and vehicles.

Electric Vehicles and Portable Tools

DC motors power electric vehicles, providing high starting torque and energy efficiency. They are also used in portable tools like cordless drills and saws, offering compact size and precise control.

Precision Equipment and Medical Devices

In medical equipment such as infusion pumps and ventilators, DC motors provide exact speed and torque control, essential for patient safety. They are also used in robotics and CNC machines for precise positioning.

Common AC Motor Applications

AC motors are commonly used in applications that require high power and reliability. They are often used in industrial settings and household appliances.

Industrial Machinery and Equipment

AC motors are used in industrial machinery like pumps, compressors, and conveyors, highlighting their reliability and durability in demanding environments.

Household Appliances and HVAC Systems

They are also used in household appliances such as refrigerators and washing machines, and in HVAC systems for fans, blowers, and compressors, emphasizing their energy efficiency.

| Motor Type | Common Applications | Key Characteristics |

| DC Motor | Electric vehicles, portable tools, precision equipment | Variable speed control, high starting torque, energy efficiency |

| AC Motor | Industrial machinery, household appliances, HVAC systems | High power, reliability, durability, energy efficiency |

Selecting the Right Motor for Your Application

The decision between AC and DC motors hinges on a thorough assessment of your application’s operational requirements. To make an informed choice, consider factors such as speed control, maintenance needs, and the available power source.

For applications requiring variable speed, DC motors are often preferred, while AC motors with Variable Frequency Drives (VFDs) offer precise speed control with AC power. Evaluating the starting and running torque requirements of your application is also crucial.

Additionally, consider environmental factors like temperature and humidity that may impact motor performance. Assessing the total cost of ownership, including energy consumption and maintenance, will help you make a cost-effective decision. Consulting with motor specialists can provide valuable insights, especially for complex applications or when optimizing for energy efficiency is a priority.