Injection molds play a vital role in creating plastic articles. Almost any plastic product in your vicinity, such as your mobile phone case or the bumper on your car, can be the example. Plastic injection molds are important for rapid and efficient manufacturing of identical plastic parts.

There are different types of injection molds; each is designed for different production jobs. It is helpful for you to understand the many plastic injection mold types available, so that you can make informed decisions for your projects while producing better parts at the best price.

What Are Plastic Injection Molds?

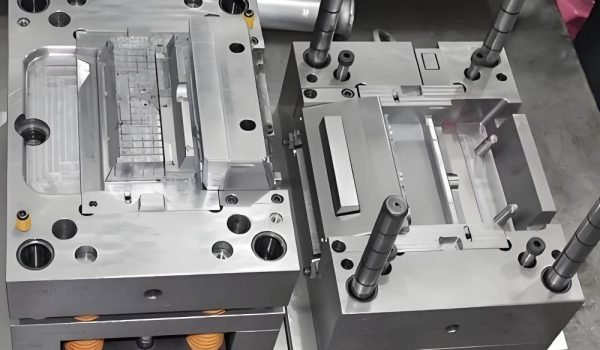

Plastic injection molds are basically custom tools for forming molten plastic into whatever shape is desired. Think of it as a high-tech cookie cutter that molds plastic. The molds, under very high pressure, can shape hot, liquid plastic into a specific part.

Every injection mold is specific to the part it will make. This is generally how the process works: Plastic pellets are melted first; then this molten plastic is injected into the mold cavity to cool into the desired shape. After the part solidifies, it is ejected, and the mold is set up for the next production cycle. The monitored process is desirable for high-volume production and making parts that meet close tolerances, or very exact to specifications.

Types of Injection Molds

Based on Feeding System

Hot Runner Injection Mold

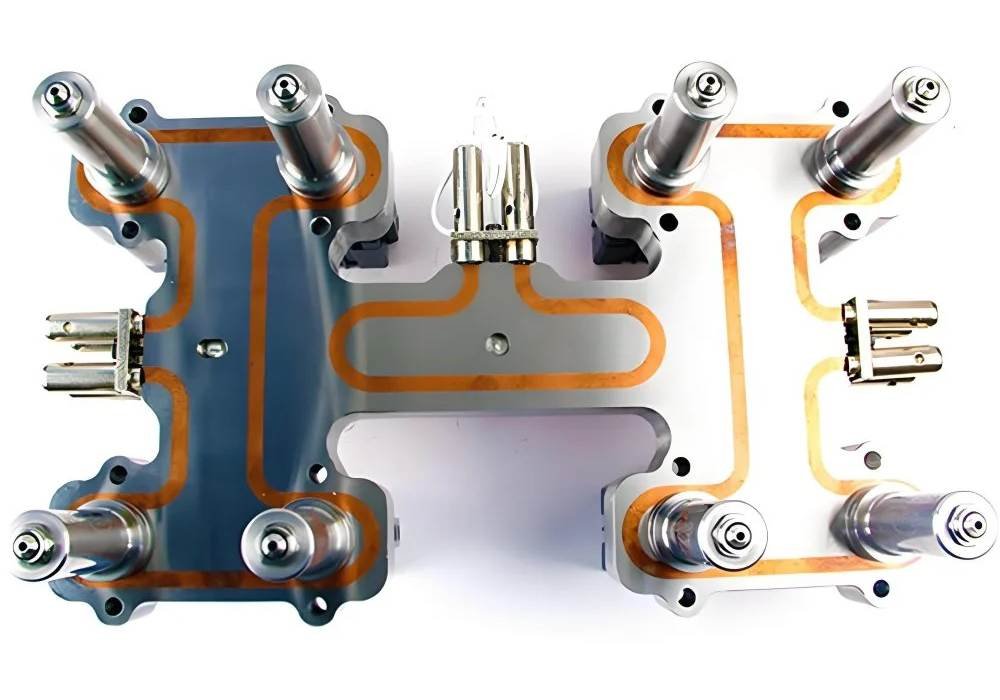

For a hot runner injection mold, the plastic remains molten in the runners since heated manifolds and nozzles are used. This helps prevent solidification until it enters the part cavity.

The main advantage to them is that there is less scrap because the material in the runners is not wasted. This means material costs are lower, and cycle times are shorter as well, which increases productivity and efficiency. Gate quality on the finished part is often superior as well, since there is usually a smaller gate.

On the downside, hot runner systems are typically more expensive to build or repair and have a higher cost of maintenance. Hot runner molds usually need technicians to work on the heating technology, and repairs can require downtime. They can function for many different plastics, but not all materials may work in hot-runner molds, such as heat-sensitive materials or abrasive materials.

Cold Runner Injection Mold

Cold runner injection molds use unheated runners, meaning the plastic in these channels cools and solidifies along with the part.

Their primary advantages are simplicity and cost. They are easier to design and construct, therefore, they make economic sense for lower volume production or prototypes. Cold runner injection molds are also simpler to maintain, and it’s easier to clean the mold.

The main drawback is material waste. The solidified runners (“sprue”) are excess material that often needs to be reground or discarded. While sometimes recycled, this adds a step and can increase material costs for high-volume production, making material use less efficient.

Insulated Runner Molds

Insulated runner molds are a middle ground. They use insulated runner channels, often with heating elements, to keep the plastic molten within them without the full complexity of a hot runner system.

Benefits include lower cost than hot runners while still offering reduced waste. They also allow easier material and color changes than hot runners, making them versatile.

However, they have limitations. They may not be suitable for all materials, particularly materials that have tight temperature tolerances or are very heat-sensitive. It can be delicate to maintain molten plastic only using insulation, and there is a potential risk for solidification while waiting for cycle times or if the temperatures are not managed. They are generally less efficient than true hot runner systems for very high-volume, high-precision applications.

Based on the Number of Cavities

Single Cavity Injection Mold

A single cavity injection mold produces just one part per molding cycle. It’s the simplest type in terms of cavity count.

The main advantage of single cavity injection molds is lower tooling cost, making it ideal for low-volume production, prototyping, or when you need a custom part quickly without a huge investment. It also offers better process control for that single part.

The one major downside is production rates. If you need to produce thousands of parts, producing them one by one will take a long time. The time greatly increases the cost per part, making injection molding unideal for mass production.

Multi-Cavity Injection Mold

A multi-cavity injection mold produces multiple identical parts in a single molding cycle.

The main advantage is production speed, increasing output on larger volume runs. Although the initial tooling cost is higher due to the additional complexity of the tooling, the total landed cost per unit part decreases substantially, making it a cost-efficient solution for mass production.

A consideration is ensuring consistency across all cavities; precise engineering is needed to avoid variations.

Family Injection Mold

A family injection mold is a special multi-cavity mold that produces several different parts in one molding cycle, for example, a cap, body, and base for a product.

The key benefit is cost savings and time savings, especially on the sub-assembly of the product assembly. Producing all necessary parts simultaneously reduces overall cycle time and simplifies inventory.

A key limitation is that all parts must be made from the same material and typically the same color, since they share a common runner system. Balancing the fill for different part geometries can also be challenging.

Based on Mold Plate

Two Plate Injection Mold

The two plate injection mold is the simplest and most common type of injection mold. It consists of a fixed platen and a moving platen on a single parting line.

It has less tooling cost due to its simplicity, which is a benefit for many applications, especially for single-cavity molds and less complex parts. The single parting line also simplifies construction. When the mold opens, the part and runner are ejected together.

A minor point is that separating the runner from the molded part might require an extra step, either manually or automated, adding a small amount of post-processing time.

Three Plate Injection Mold

A three plate injection mold adds an extra plate, creating two parting lines. The main benefit is the automatic separation of the runner system from the molded parts when the mold opens. This leads to faster production cycles as no manual or robotic degating is needed, streamlining post-molding. It also allows for more flexible gate locations, which can improve part quality.

However, the added plate and complexity mean higher tooling costs and a more intricate design process. Despite the upfront investment, it can quickly pay off for high-volume production where cycle time efficiency is crucial.

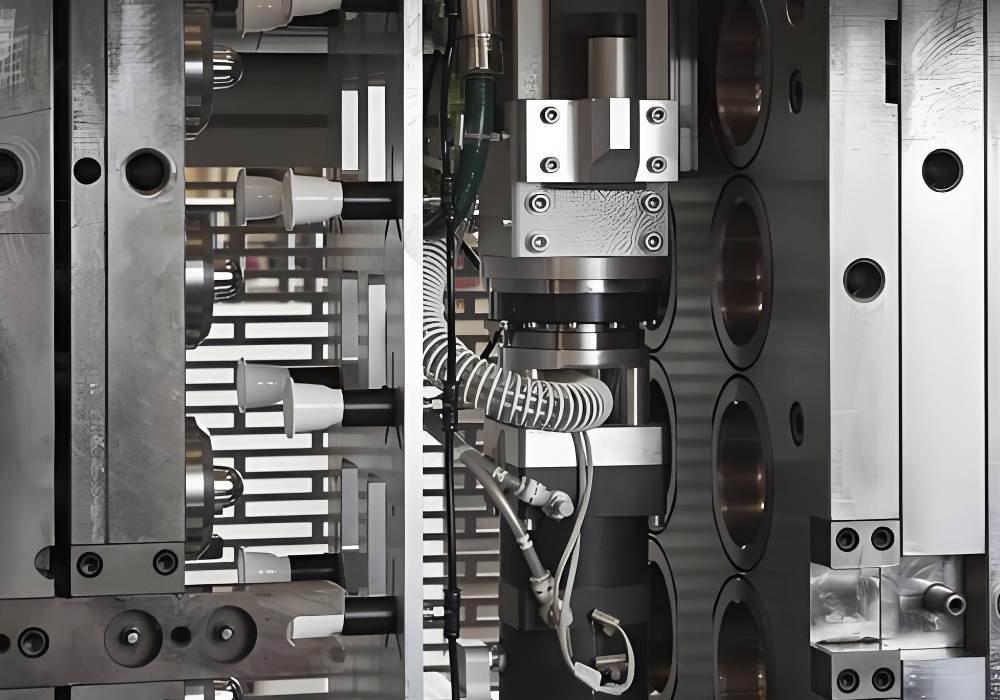

Stack Injection Mold

Stack injection molds are innovative, using multiple parallel mold plates to stack two or more mold faces. This allows for twice (or more) the number of parts per cycle without increasing the clamping tonnage of the machine.

The key advantage is incredible efficiency, doubling output with the same machine footprint. This leads to significant productivity increases and reduced per-part costs. They can also accommodate multiple materials or colors with a rotary platen, making them versatile for complex assemblies.

However, stack molds have higher upfront costs due to intricate design and manufacturing. They also require larger injection molding machines with higher opening strokes. While offering immense benefits for high-volume production, the initial investment needs careful consideration.

Based on Unscrewing Injection Mold

An unscrewing injection mold creates plastic parts with internal or external threads (like bottle caps). It uses a drive system to rotate a core or cavity, unscrewing the molded part.

This specialized design enables high-speed production of threaded components that are difficult or impossible with standard molds for plastic injection. The unscrewing action ensures accurate threads and undamaged part removal, making them crucial for industries like packaging and plumbing.

Threads are a type of undercut, a feature preventing straight ejection. Unscrewing molds solves this, allowing complex parts to be released without damage. While more complex and costly than conventional molds for plastic injection, their ability to produce perfect threaded parts at high volumes makes them indispensable for specific applications.

Types of Injection Molding Molds

| Category | Mold Type | Key Characteristic | Main Advantage | Main Consideration |

| Feeding System | Hot Runner | Heated runners keep plastic molten. | No runner waste, faster cycles. | Higher cost, more complex. |

| Cold Runner | Unheated runners, plastic solidifies. | Lower cost, easy material changes. | Runner waste, slower cycles. | |

| Insulated Runner | Uses plastic insulation and some heat. | Reduced waste (like hot runner), lower cost. | Not for all materials, design complexity. | |

| Number of Cavities | Single Cavity | Makes one part per cycle. | Low tooling cost, high control. | Slow for high volume. |

| Multi Cavity | Makes many identical parts per cycle. | Faster production, lower unit cost. | Higher tooling cost, potential imbalance. | |

| Family Mold | Makes different parts (same material/color) per cycle. | Cost/time efficient for assemblies. | Material/color limited, complex design. | |

| Mold Plate Design | Two Plate | Simplest, one parting line. | Low tooling cost, simple. | Part & cold runner ejected together. |

| Three Plate | Adds plate, two parting lines, separates runner automatically. | Automatic runner separation, more gate options. | Higher tooling cost, larger machine opening. | |

| Stack Mold | Multiple parallel mold plates, doubles/triples output. | High output with the same clamp force. | Very high upfront cost, complex. | |

| Special Mechanism | Unscrewing Mold | Rotates core/cavity to release threaded parts. | High-speed production of threaded components. | High mechanical complexity, higher cost. |

Why Are Injection Molds Necessary?

Injection molds aren’t just tools; they’re critical enablers for modern manufacturing. Here’s why they are absolutely necessary:

Precision & Consistency

Think about the exact fit needed for electronic enclosures or medical devices. Injection molds ensure that every single part produced is identical to the other one, with incredibly tight tolerances. This consistency is paramount for product quality and functionality.

Cost-Efficiency

While the initial expense for an injection mold can be considerable, it pays back wonderfully in the long term. When you’re making thousands or millions of parts in rapid and repeat succession, the per-unit cost plummets and injection molding becomes the most cost-effective option for mass production.

Material Flexibility

Injection molding molds are flexible and can work with an incredible array of thermoplastic and thermoset materials. Whether you need a flexible, rigid, transparent, or opaque part, there is most likely a plastic that can be injection molded to meet your needs.

Industry–Specific Needs: Each industry has its own requirements, and the world of injection molding molds can align with them.

- Medical: For sterile, micro-sized components or intricate medical devices, injection molds produce the precision and repeatability necessary for these critical components.

- Automotive: As manufacturers, safety and performance are the highest priorities, and injection molds enable manufacturers to apply some level of consistency to the mass manufacture of durable, complex geometries for both interior and exterior automotive parts.

- Consumer Goods: Conventional products dispose of aesthetic characteristics along with functional components, and injection molds allow manufacturers to rapidly mass produce both.

Fecision – Reliable Injection Mold Tooling Services Provider

Deciding on the correct type of plastic injection mold is an absolutely critical decision that can affect the success of your project. It can directly affect your efficiency of production, quality of manufactured parts, and total cost. You might need a partner who understands these complexities and will provide their expertise.

This is where Fecision can help. Fecision offers specialized Mold Tooling Services that can accommodate a variety of needs from Rapid Tooling solutions for functional prototypes and low volume manufacturing, to Production Tooling for large set orders or very precise mass manufacturing, so that you can manufacture with quality and efficiency for your projects.

Key Advantages of Partnering with Fecision:

- Experienced Team: Qualified engineers will optimize the mold design while aiming for improved performance, reduced downtime, and increased efficiency.

- Advanced Equipment: Our tooling uses modern CNC, EDM, and grinding equipment. We utilize major brand equipment, like Sodick, Trumpf, and DMG MORI.

- Quality Assurance: With ISO certification (ISO 9001, ISO 13485, IATF 16949), our clients from all over the world trust us to maintain the highest standards.

- End-to-End Support: Services from design to production provide you with a shorter time-to-market for your products of 30% or more.

Need a durable, high-performance mold that’s tailored to your exact specifications? Contact Fecision for a tailored solution today! We’re here to help you turn your concepts into reality with world-class tooling.