Have you ever seen a product or tool with a textured surface? You might have wondered how it’s made. Knurling is the process behind creating such surfaces. It’s a manufacturing technique used to improve grip or appearance.

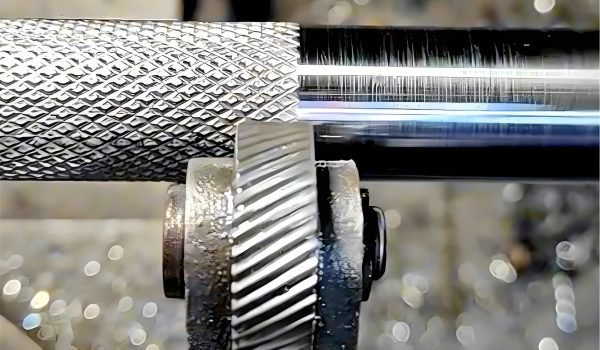

Knurling is a machining process that changes the surface of a workpiece. It involves displacing material to create patterns or textures. A special tool presses into the material to make the desired design.

Knowing about the knurling process is key for manufacturers and engineers. It helps them make products better in both function and looks. By using this technique, you can make components more useful and long-lasting.

The Fundamentals of Knurling

To understand knurling, we must first learn about its basics. This includes its definition, history, and uses. Knurling is key in machining, making products both functional and beautiful.

Definition and Purpose of Knurling

Knurling is a machining method that adds texture to a workpiece. It uses a knurling tool. The main goal is to improve grip or look of a product. Knurling can make patterns like straight, diamond, or spiral, boosting both use and beauty.

Historical Development of Knurling Techniques

Knurling’s history goes back to the early days of machining. At first, it was done by hand. But, with new tech, it became a precise, automated process. Now, CNC machines make knurling patterns more accurate and consistent.

How Knurling Enhances Product Functionality

Knurling makes products better by adding grip and beauty. It can also mark or decorate items. For example, in tools, knurling stops them from slipping, making them safer and easier to use. In decorations, it adds a special look, making products more attractive.

In short, knowing about knurling is vital for seeing its importance in many fields. It helps make tools better and adds beauty to products. By using knurling well, makers can greatly improve their products’ function and loo

Knurling Process: How It Works

Understanding the knurling process is key for manufacturers. It makes products better and look good. Knurling tools create patterns on workpieces, improving grip and looks.

Step-by-Step Knurling Operation

The knurling process is precise. First, the workpiece is held tight, often on a lathe or CNC machine. Then, the knurling tool makes the pattern by pressing and rotating.

“The precision of the knurling process depends on the accuracy of the knurling tools used,” experts say. This ensures the knurling is consistent and meets standards.

Form Knurling vs. Cut Knurling Methods

There are two main knurling methods: form and cut knurling. Form knurling displaces material, while cut knurling removes it. The choice depends on the material and desired pattern.

Form knurling is good for creating strong patterns without removing material. Cut knurling is better for materials that are hard to form or need specific patterns.

Material Considerations for Effective Knurling

Different materials react differently to knurling. Material hardness, ductility, and surface finish are key. Softer materials like aluminum are easier to knurl than harder ones like stainless steel.

Knowing your material’s properties is crucial. It helps choose the right tools and techniques. This ensures the pattern is as desired and the surface is durable.

“The quality of the knurling is directly related to the quality of the tools used,” said a leading manufacturing expert.

Common Challenges and Troubleshooting

The knurling process can face challenges like uneven patterns and tool wear. Troubleshooting needs a deep understanding of the process and its factors.

Solutions include adjusting tool pressure, changing tool orientation, or picking a different pattern. Regular tool maintenance is also key for consistent results.

Types of Knurling Patterns and Tools

To get the best results in knurling, knowing the different patterns and tools is key. The pattern and tool you choose greatly affect the quality and function of the final product.

Straight Knurling Patterns and Applications

Straight knurling patterns are widely used across many industries. They create straight lines or ridges, improving grip and looks. This pattern is perfect for tools and devices that need a simple yet effective grip.

Diamond Knurling Patterns and Applications

Diamond knurling patterns make a diamond texture, offering better grip than straight patterns. It’s great for places needing high friction, like medical gear and sports equipment.

Spiral Knurling Patterns and Applications

Spiral knurling makes a spiral or helical texture. It’s best for tools needing strong grip and control, like precision instruments and machinery parts.

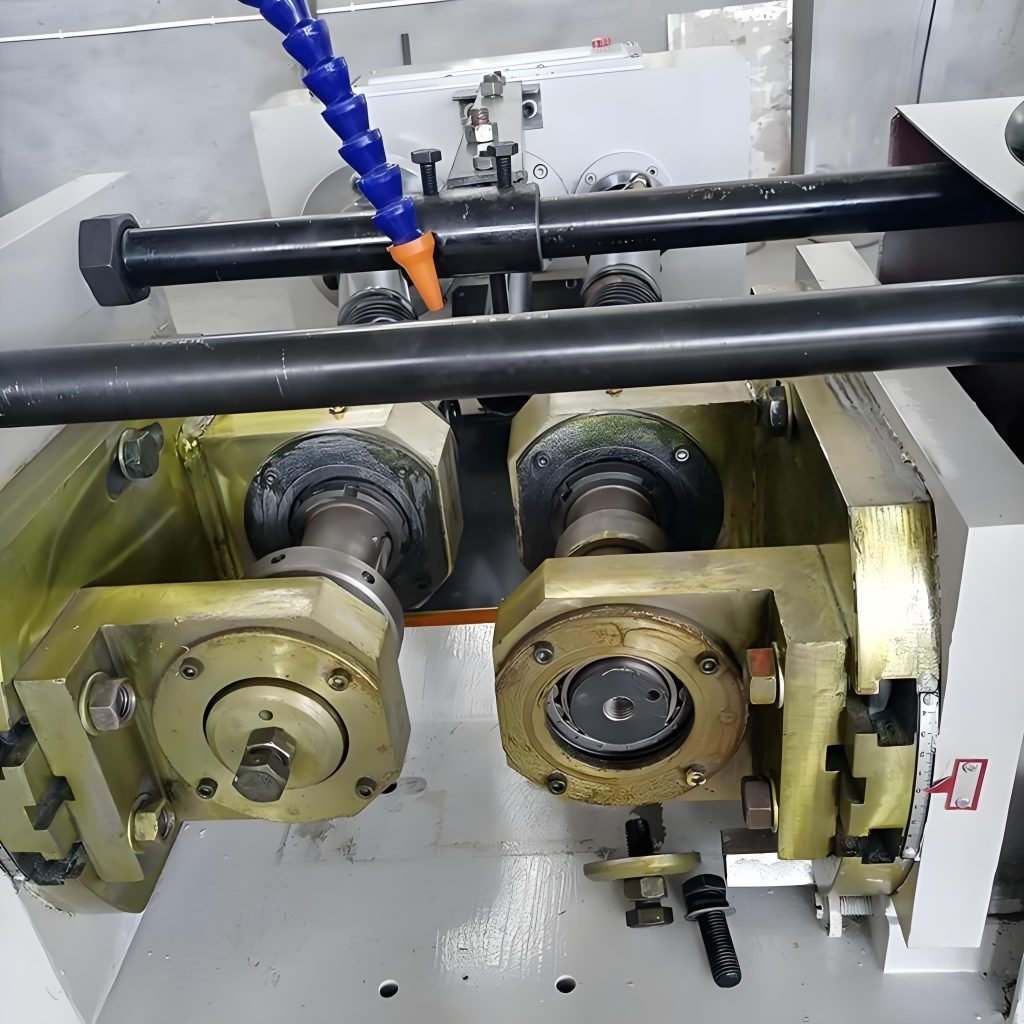

Single-Wheel vs. Multi-Wheel Knurling Tools

Knurling tools come in single-wheel and multi-wheel types. Single-wheel tools are good for simple tasks and small batches. Multi-wheel tools are more versatile and better for complex patterns, ideal for big industrial projects.

Advanced CNC Knurling Equipment

CNC technology has changed knurling, allowing for precise control. Advanced CNC equipment makes complex patterns with high accuracy. It meets the needs of today’s manufacturing.

Practical Applications of Knurling in Manufacturing

Knurling in manufacturing adds value and beauty to products. It’s not just a process; it’s a way to enhance products in many industries.

Enhancing Grip on Hand Tools and Components

Knurling makes hand tools and components easier to hold. It creates textured surfaces that improve tool usability. This reduces accident risks.

“A good grip is essential for safety and efficiency,” says an industry expert. This is crucial in industries where tools are used a lot.

Decorative Applications in Consumer Products

Knurling adds beauty to consumer products. It creates unique patterns that make products more appealing. This is seen in consumer electronics, luxury goods, and more.

Industrial and Mechanical Applications

In industrial and mechanical fields, knurling is key. It makes parts precise and durable. This is vital for parts like handles or grips on machinery.

Automotive and Aerospace Applications

The automotive and aerospace sectors also use knurling. It helps create high-quality components. Knurling improves grip on vehicle and aircraft controls and adds beauty.

Best Practices for Different Application Requirements

Following best practices is crucial for knurling success. Choose the right tool, understand material properties, and optimize the process. This ensures the best results.

By understanding knurling’s many uses and following best practices, manufacturers can enhance their products. This helps them stay ahead in the market.

Conclusion: The Future of Knurling Technology

Knurling is key in making products better and looking good. It adds textures that improve grip and looks. This process is used in many fields.

There are many knurling tools to pick from. This lets makers choose the best one for their needs. Knowing about knurling helps many industries, from cars to everyday items.

New tech will change knurling a lot. Expect better, more precise ways to make products. This means products will look and feel even better.

Keeping up with knurling tech is important. It helps you make better products and stay competitive. Whether you’re experienced or new, knurling offers many benefits.