Did you know 73% of aerospace manufacturers attribute defect reduction directly to advanced measurement systems? At the heart of this transformation lies coordinate measuring machines (CMMs), which have reshaped how industries verify product accuracy. These systems now serve as the backbone of modern quality assurance, ensuring everything from medical devices to automotive parts meet strict specifications.

This guide explores how CMM inspection drives consistency in manufacturing. You’ll learn how these tools capture precise 3D measurements, analyze complex geometries, and streamline workflows. We’ll break down different machine types and their unique applications.

What is CMM Inspection?

Behind every reliable product lies a hidden hero: precise measurement systems. Coordinate measuring machine (CMM) inspection uses probes and sensors to map objects in three dimensions, comparing them against digital blueprints. This process identifies deviations as small as a micron—thinner than human hair—ensuring parts match exact design specifications.

Definition and Overview

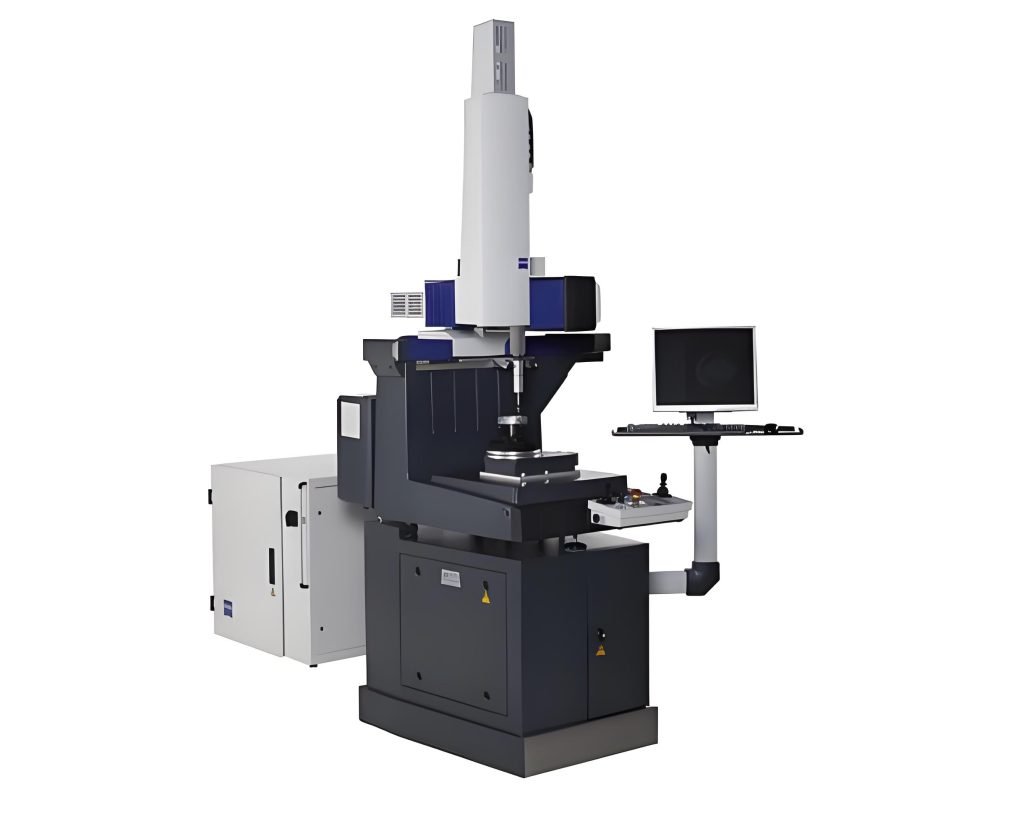

A coordinate measuring machine combines hardware and software to capture millions of data points on an object’s surface. Early CMMs required manual input, but modern systems automate measurements with laser scanners or touch-trigger probes. These tools create 3D models that reveal even microscopic flaws in manufacturing processes.

Why It Matters in Quality Control

Why does this matter? Without CMMs, factories risk shipping defective components. A medical implant 0.1mm off-spec could harm patients. Automotive gears with uneven teeth might cause engine failure. By validating quality standards, these machines prevent costly recalls and protect brand reputations.

Data from CMM inspections also fuels continuous improvement. Manufacturers analyze trends to refine production lines, reduce waste, and speed up approvals for certifications like ISO 9001. From aerospace turbines to smartphone casings, this technology keeps modern manufacturing competitive and compliant.

The Role of CMM Inspection in Quality Control

In high-stakes sectors, a single micron’s deviation can trigger product recalls or safety hazards. CMM inspection bridges the gap between digital designs and physical components, ensuring every part aligns with exact requirements. This process isn’t just about catching errors—it actively shapes how products evolve.

Enhancing Design Specifications

How do engineers refine prototypes into flawless products? CMMs scan components, generating 3D maps that reveal deviations from CAD models. This data allows teams to adjust design specifications before mass production. For example, automotive manufacturers use these insights to perfect gear alignments, reducing engine wear.

Feedback loops from CMM inspections also accelerate innovation. When a medical device maker detects uneven surfaces in prototypes, they tweak machining parameters. This iterative process ensures final parts meet both functional and regulatory demands.

Supporting Industry Quality Standards

Industries like aerospace demand zero tolerance for defects. CMMs validate components against AS9100 and ISO 9001 quality standards, certifying parts for extreme conditions. A jet turbine blade, for instance, undergoes 200+ measurements to confirm heat resistance and aerodynamic profiles.

Regular machine calibration maintains measurement integrity. Automotive suppliers perform daily checks to ensure CMM accuracy within 0.0002 inches. This rigor prevents assembly line stoppages and keeps warranty claims under 1% in top-tier factories.

By converting raw data into actionable insights, CMM inspection doesn’t just maintain quality—it elevates entire production ecosystems. You’re not just measuring parts; you’re building trust in every product that leaves the factory.

How Does CMM Inspection Work?

CMM inspection combines precision hardware with smart software to map objects atom by atom. The process starts by securing your component on a granite table, ensuring stability for micrometer-level accuracy.

Operation Process and Equipment

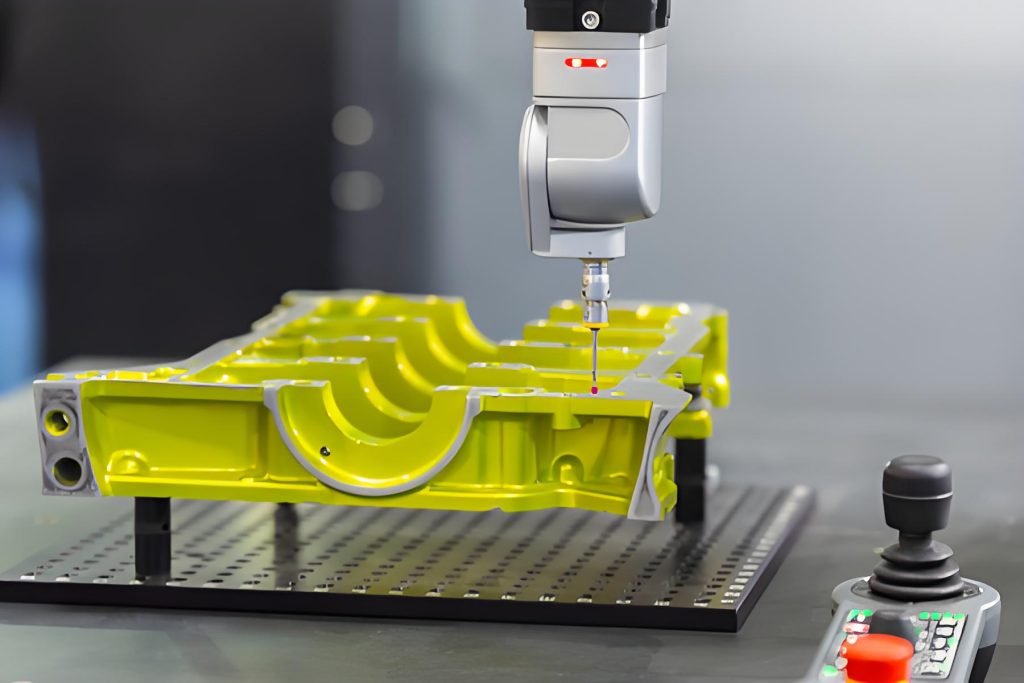

A touch-trigger probe or laser scanner moves along X, Y, and Z axes, capturing dimensions at programmed points. Encoder systems track positions down to 0.1 microns—equivalent to 1/1000th of a human hair. Temperature-controlled rooms prevent material expansion from skewing measurement results.

Calibration happens first. Machines self-check using master artifacts to confirm alignment. Portable CMMs use articulated arms for flexible coordinate mapping, while bridge-style models excel at repeatability for high-volume inspections.

Data Collection and Software Analysis

Every probe contact generates a data point, forming a 3D “point cloud.” Specialized software compares this cloud to CAD models, flagging deviations in color-coded maps. You’ll see red zones where parts exceed tolerance limits—often revealing machining errors or tool wear.

Advanced systems process millions of points per second. Laser scanners capture complex curves faster than tactile probes. This data feeds into quality control dashboards, showing real-time pass/fail rates. Automated reports streamline audits for certifications like ISO 9001.

From aerospace turbines to medical implants, this blend of machine precision and digital analysis ensures products meet life-critical standards. It’s not just about measuring—it’s about building trust through microscopic accuracy.

Types of Coordinate Measuring Machines

Coordinate measuring machines come in multiple configurations, each optimized for specific tasks. Your selection depends on part size, accuracy needs, and workflow demands.

Articulated Arm vs. Horizontal Arm

Articulated arm CMMs offer unmatched flexibility. These portable systems use rotating joints to measure complex geometries in tight spaces. Automotive teams use them for on-site inspections of engine blocks or curved body panels.

Horizontal arm models excel with heavy components. Their rigid structure supports large castings in aerospace and energy industries. While less mobile, they deliver consistent precision for turbine blades or hydraulic manifolds.

Bridge, Cantilever, and Gantry Designs

Bridge-style CMMs dominate high-precision measuring labs. Their enclosed structure minimizes vibration errors, ideal for medical device parts requiring micron-level accuracy. Cantilever models suit smaller components, allowing easy loading from one side.

Gantry systems handle massive objects like aircraft wings. With overhead rails spanning 30+ feet, they capture data across entire assemblies. These machines often integrate with robotic systems for automated production line checks.

Match your machine to component size and tolerance needs. Articulated arms adapt to field work, while gantry CMMs secure quality in large-scale applications. The right choice accelerates inspections without compromising your design standards.

Capabilities of CMM

How do manufacturers verify complex parts fit perfectly every time? Modern coordinate measuring systems tackle this challenge through advanced technical features. These machines deliver both foundational measurements and cutting-edge scanning solutions that redefine precision.

Dimensional and Profile Measurements

At their core, these systems excel at capturing exact dimensions and surface profiles. A tactile probe collects hundreds of data points per minute, mapping angles and curves against CAD models. This process identifies deviations as subtle as 0.5 microns—smaller than bacteria.

For intricate geometries like turbine blades, operators program thousands of measurement points. The precision remains consistent across repeated tests, ensuring reliable results. This repeatability proves vital when validating batches of medical implants or automotive components.

Advanced Features like Laser Scanning

Laser-equipped models take measurements to new speeds. Non-contact scanners map entire surfaces in seconds, capturing details missed by touch probes. Aerospace teams use this to inspect wing contours, while electronics makers verify circuit board flatness.

Multi-sensor capabilities allow switching between laser and tactile tools mid-inspection. You can measure a gear’s hard edges with a probe, then scan its textured surface without recalibrating. This flexibility slashes inspection times by up to 70% in some applications.

By combining foundational coordinate measuring techniques with modern innovations, these systems become indispensable for quality-driven production. Their evolving capabilities ensure even the most complex parts meet exact specifications.

Benefits of CMM Inspections

Manufacturers using coordinate measuring systems report 38% fewer defects and 27% faster production cycles. These machines transform quality assurance by turning raw data into actionable improvements across entire workflows.

Enhanced Accuracy and Efficiency

Precision measurements eliminate guesswork in manufacturing. You catch errors early—like a misaligned gear tooth or uneven medical implant surface—before defective parts reach assembly lines. One automotive supplier reduced rework costs by $1.2 million annually through real-time dimensional checks.

Automated inspection routines slash downtime. Portable CMMs measure complex components in minutes instead of hours. This speed lets you test more parts per shift while maintaining strict quality standards.

Reduction in Waste and Improved Compliance

Exact data cuts material waste by up to 19%. Aerospace teams use CMM reports to adjust machining parameters, minimizing excess metal removal. Fewer scrapped components mean lower production costs and reduced environmental impact.

Consistent quality control ensures compliance with FDA and ISO certifications. Regular audits using measurement histories prove adherence to tolerances as tight as ±0.0005 inches. This documentation builds trust with regulators and customers alike.

By merging accuracy with efficiency, these systems create ripple effects—better products, leaner operations, and stronger market reputations. You’re not just inspecting parts; you’re future-proofing your manufacturing process.

The Essential Guide to CMM Inspection for Quality Control

What separates top-tier manufacturers from competitors? Their ability to transform raw measurement data into strategic quality improvements. This section reveals how leading companies merge advanced inspection techniques with real-time analytics to achieve unmatched product consistency.

Comprehensive Measurement Strategies

Modern systems use automated inspection routines that adapt to component geometries. By integrating measurement data directly into CAD software, you spot deviations during machining. One aerospace supplier reduced rework by 41% using live feedback to adjust cutting tools.

Multi-sensor technology captures both tactile and optical data. This hybrid approach handles complex surfaces like turbine blades or injection molds. You maintain control across production stages while meeting tight tolerance standards.

Data-Driven Quality Assurance

Analytics platforms turn inspection results into actionable insights. Predictive algorithms flag tool wear patterns before they affect components. Automotive teams use this data to schedule maintenance, preventing assembly line delays.

Cloud-based dashboards track compliance across global facilities. Medical device makers validate process efficiency by comparing real-time reports against ISO 13485 requirements. This approach cuts audit preparation time by 60% in regulated applications.

Through coordinated technology and strategic data use, manufacturers achieve two goals: flawless products and streamlined operations. The result? A quality ecosystem where every measurement fuels continuous improvement.

Industries That Utilize CMM Inspection

From jet engines to artificial joints, industries requiring microscopic accuracy rely on coordinate measurement systems. These tools verify parts across sectors where errors carry life-or-death consequences. Their adaptability makes them indispensable in both mass production and custom fabrication.

Aerospace and Automotive Applications

Aerospace manufacturers use these systems to validate turbine blades and fuel nozzles. Each component undergoes 500+ measurements to ensure aerodynamic profiles and heat resistance. A single flawed part could compromise an entire engine assembly.

Automotive teams depend on them for transmission gears and engine blocks. One luxury carmaker reduced warranty claims by 34% after implementing real-time inspection of brake calipers. The technology catches alignment issues invisible to traditional gauges.

Medical Devices and General Manufacturing

Medical implant producers scan hip replacements and spinal rods to ±0.002mm tolerances. This precision prevents rejection risks in patients. FDA audits require full traceability of these quality checks through digital reports.

General manufacturing benefits from portable systems that adapt to factory floors. A Midwest machinery plant cut inspection times by 50% using articulating arms for large hydraulic components. Whether producing consumer electronics or industrial valves, these systems maintain design integrity across diverse environments.

Exploring the CMM Inspection Process

How do factories ensure every component meets exact specifications? The answer lies in a methodical three-stage approach: preparation, execution, and analysis. Each phase builds on the last to maintain accuracy while aligning with quality assurance protocols.

Preparation and Calibration

Start by reviewing CAD models and part drawings. Operators select probes based on surface complexity—spherical tips for flat surfaces, needle-like tips for tight spaces. Machines undergo calibration using certified artifacts to verify measurement consistency within 0.0001 inches.

Conducting the Inspection

Programmed paths guide probes across components, capturing hundreds of points per minute. Automated systems adjust probe speed to prevent surface damage. Real-time software converts raw data into color maps, highlighting deviations from design tolerances.

Post-Inspection Evaluation

Reports compare results against ISO or ASME standards, flagging out-of-spec parts. Teams analyze trends to adjust machining parameters, reducing scrap rates by up to 22%. This feedback loop transforms data into actionable process improvements.

By standardizing each step—from probe selection to final analysis—manufacturers achieve repeatable accuracy. The systematic approach minimizes human error while ensuring compliance with evolving industry control requirements.

Overcoming Challenges in CMM Inspection

Precision measurement systems face unexpected hurdles when inspecting intricate components. Complex geometries like turbine blades or porous medical implants often challenge traditional probing methods. Material differences—from aluminum alloys to carbon fiber—require customized approaches to maintain accuracy.

Common Obstacles in Complex Geometries

Internal channels and organic shapes block standard probes from reaching critical surfaces. Temperature shifts in factories cause metal parts to expand, skewing measurement results. Soft materials like rubber deform under contact probes, creating false readings.

Environmental vibrations also disrupt data collection. A study found 18% of measurement errors stem from unstable work surfaces. These factors complicate compliance with ISO 9001 standards, especially for aerospace and medical components.

Innovative Solutions and Best Practices

New laser scanning systems capture 10,000 points per second on curved surfaces. Multi-sensor technology combines touch probes with optical scanners, adapting to material properties mid-inspection. Automated software compensates for thermal changes using real-time temperature data.

Implement daily machine calibration and vibration-dampening mounts. Train operators to program adaptive scanning paths for tricky geometries. Cloud-based data analysis tools flag recurring issues, boosting efficiency by 30% in automotive case studies.

Regular maintenance and updated probing techniques turn obstacles into opportunities. By addressing these challenges head-on, you ensure reliable quality control across all production stages.

Key Considerations in Choosing a CMM Inspection Service

How do you ensure your parts meet exact specifications every time? Selecting the right inspection partner requires balancing technical capabilities with industry-specific knowledge. Three factors separate adequate services from exceptional ones: validated credentials, cutting-edge tools, and adaptability to your workflow.

Accreditation and Expertise

Always verify certifications like ISO/IEC 17025 or ASME B89. These prove a service follows quality standards for measurement traceability. Look for experience in your sector—medical device inspectors need different skills than aerospace teams. A provider familiar with your components reduces errors by 23% in automotive case studies.

Technology, Equipment, and Scalability

Demand precision-focused tools: bridge-style machines for lab work, portable arms for factory floors. Integrated software should generate reports aligning with your quality systems. One manufacturer boosted production speed by 18% using services with automated data analysis.

Confirm scalability. Can they handle 50 parts or 50,000 monthly? Cloud-connected services adapt to demand spikes without sacrificing measuring accuracy. Regular equipment upgrades ensure compatibility with new materials and industry regulations.

Prioritize partners who document every step. Detailed records simplify audits and help refine your machining processes. The right choice becomes an extension of your quality team—proactive, precise, and prepared for tomorrow’s challenges.

Conclusion

In an era where manufacturing tolerances define market leaders, precise measurement systems separate top performers from competitors. This guide has shown how advanced inspection processes validate part geometries, ensure compliance, and drive continuous improvement. From aerospace components to medical devices, micrometer-level precision isn’t optional—it’s the foundation of consumer trust.

Prioritize service providers with sector-specific expertise and cutting-edge tools. Explore how modern measurement capabilities can transform outcomes—one precise point at a time.