Aluminum has a bit of a reputation. It’s heat-hungry, oddly strong for its weight, and just stubborn enough to cause problems if the laser settings aren’t just right. No wonder fabricators hesitate before throwing it under a laser.

So, here’s the big question: Is laser cutting aluminum possible?

Well, turns out, lasers can get the job done, but not without a few tricks up their sleeve.

Between heat conductivity and the sheer attitude of this silvery metal, you’ll need the right type of laser, the right settings, and honestly, a bit of patience.

Let’s break down the tactics and the reason why aluminum finally agreed to cooperate with light beams (under very specific conditions).

Is It Possible to Laser Cut Aluminum?

Yes, but aluminum doesn’t make it easy.

Unlike mild steel or acrylic, which practically invite lasers in, aluminum plays hard to get. Its high reflectivity and excellent thermal conductivity (237 W m-1 K-1) mean your average laser barely leaves a mark while the heat dissipates.

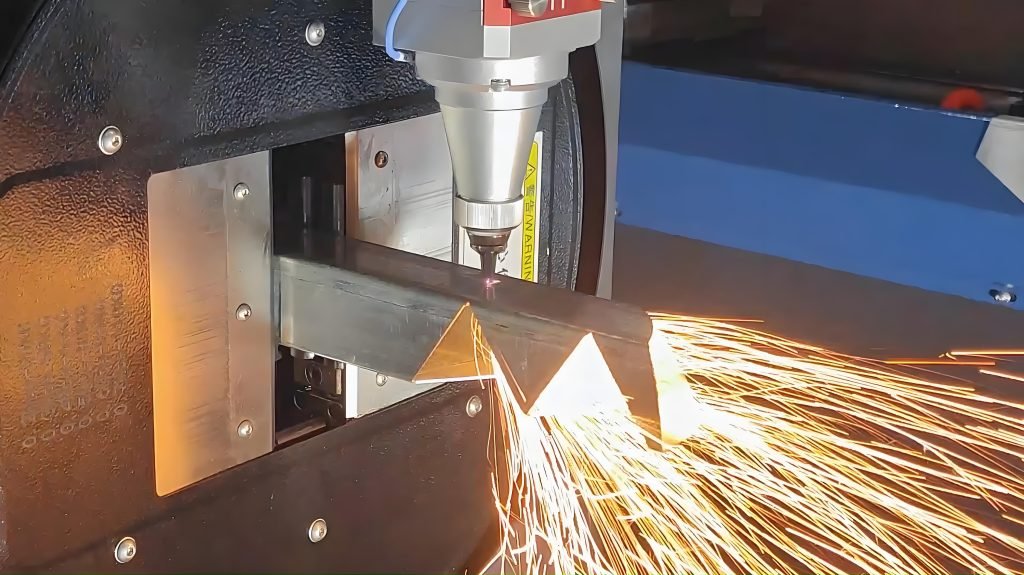

However, with the right type of laser, typically a high-powered fiber laser, and the right setup, aluminum folds beautifully.

So yes, laser cutting aluminum is not only possible; it’s done every day in industries that demand zero tolerance for jagged edges.

Challenges In Aluminum Laser Cutting

Aluminum has some high-maintenance habits that make the cutting process far from straightforward. Understanding these challenges up front is the key to taming this metal.

1. Reflectivity and Thermal Conductivity

Aluminum reflects a huge portion of the laser’s energy, which means a lot of power gets bounced back instead of cutting through the metal.

Then there’s thermal conductivity. Aluminum is excellent at spreading heat quickly, which sounds great for cookware but complicates laser cutting.

The heat from the laser doesn’t hang around long enough to melt the metal cleanly but disperses almost instantly.

Together, these properties create a tough environment for laser cutting aluminum.

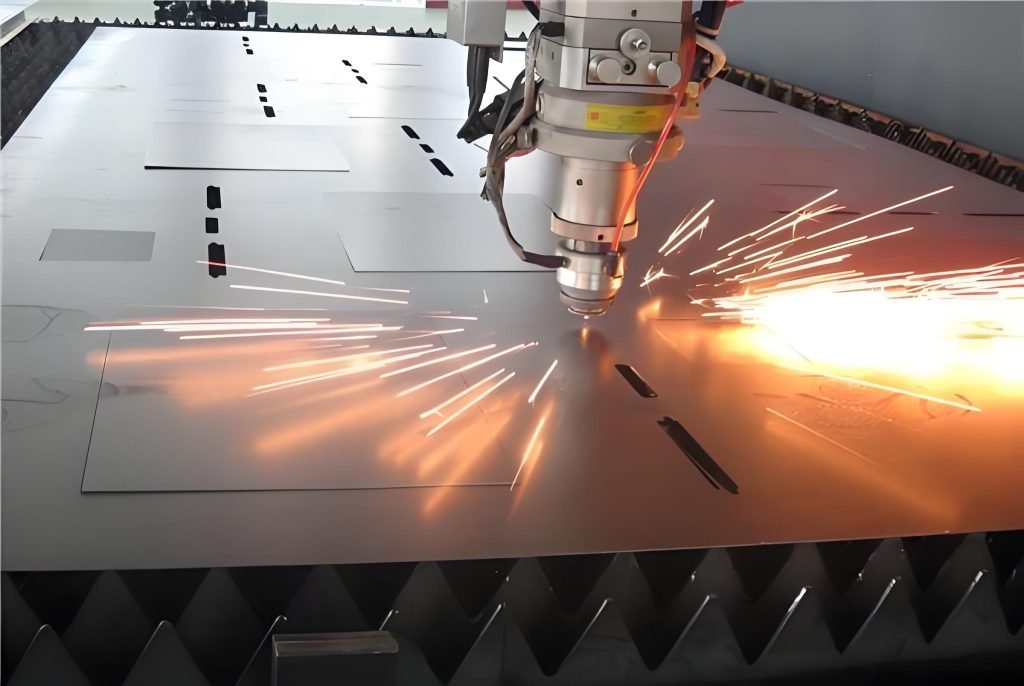

2. Edge Quality Issues

Unlike other metals, aluminum’s surface can end up rough, with dross (that pesky leftover slag), or even slight warping. These edge imperfections can compromise the part’s fit and function.

Why does this happen?

It all boils down to aluminum’s unique reaction to laser heat and how the molten metal cools. Without the right equipment, the edge quality suffers, turning what should be a sharp finish into a frustrating mess.

3. Fire Risks and Safety

Research published by ASM International highlights that aluminum powder is “very flammable” and “hazardous to handle.”

That means fire risks are not something to shrug off. In fact, in the past, numerous fire incidents have been reported due to aluminum dust.

Managing these risks takes proper ventilation and carefully controlled environments.

Can You Laser Cut Aluminum for Injection Mold Components?

Metal laser cutting is efficient, but mold components demand more than speed. They need ultra-tight tolerances and perfect finishes.

So, can aluminum be laser cut to meet those high standards in mold-making? The answer isn’t a flat yes or no. It depends on a few key factors.

1. Prototyping Aluminum Mold Inserts

Prototyping is where ideas meet reality, and that reality can be expensive and painfully imperfect if you’re not careful.

That’s why laser cutting aluminum for mold inserts is getting serious attention. It lets you test before committing to full CNC manufacturing.

For early-stage mold designs, laser cutting can help you move fast and break nothing.

Need to tweak dimensions? No problem. How about a quick turnaround to test fit and flow? Done! You’re essentially gathering insights without burning time or budget.

Sure, laser cutting might not be your go-to for final inserts, but for prototypes it’s a clever move. You get just enough accuracy to know if your mold idea holds water (or if it’s back to the drawing board).

2. Trimming Gates or Vents

Trimming gates or vents might sound like a small detail, but anyone in the mold-making industry knows: it’s where clean design complements clean execution.

The goal is to create burr-free edges without compromising the rest of the component. And while traditional machining can get the job done, aluminum laser cutting offers something a little more precise.

It allows for clean removal of excess material, especially in tight spots where tools struggle or risk damaging delicate features.

The precision is on point, and the heat-affected zone is minimal when done right.

Best Laser Types for Cutting Aluminum

You can’t just fire up any machine and expect smooth edges. Between reflectivity and material thickness, aluminum demands the right kind of firepower. So, choosing the right laser is the starting line.

1. Fiber Laser

Fiber lasers deliver high beam intensity with minimal reflection issues, making them a top pick for cutting aluminum.

What sets them apart? Efficiency, for one. They use less power, require minimal maintenance, and handle reflective surfaces far better than older tech.

In other words, you get cleaner cuts and faster runs with fewer headaches.

2. CO2 Laser

CO₂ lasers had their glory days, and they’re still solid for cutting wood and some metals. But when it comes to aluminum? Let’s just say… things are complicated.

The high reflectivity of aluminum makes CO₂ lasers less efficient and way more prone to bounce-back issues. In short: not ideal.

That doesn’t mean they’re useless. You can cut aluminum with a CO₂ laser, especially thinner sheets, but you’ll likely deal with more energy consumption and a higher risk of inconsistent results.

Three Tips for Successfully Cutting Aluminum

Even with a top-tier machine, one misstep can mean poor edge quality and wasted time and material.

Make sure you consider these tips to get it right from the start.

1. Use Assist Gases

Assist gases help clear molten metal away, cool the cut zone, and prevent oxidation.

Choosing the right gas (usually nitrogen or oxygen) can make the difference between a jagged, slag-covered mess and a smooth edge.

2. Pre-treatment

Jumping straight into cutting aluminum without prepping the surface? That’s asking for trouble. Dirt and oxidation layers can all mess with how the laser interacts with the metal.

However, a quick wipe-down or even a light chemical clean can drastically improve absorption and cut quality.

3. Slow Cutting Speed and High Power

Slowing down gives the laser time to melt through the reflective, heat-sapping metal, while cranking up the power ensures it actually gets there.

This combo reduces dross buildup and sharpens edge quality. It’s a challenge, sure, but mastering it means your cuts come out clean every time.

The Finish You Want Starts With a Team Who Listens

Aluminum might be lightweight, but its reflective nature and heat conductivity make laser cutting aluminum demanding.

This means the laser has to work smarter, with the right wavelength and power. But once you get the hang of it, it’s far from impossible to tackle, and the results are stunning.

If your project deserves more than a blunt approach, and demands a finish that impresses, you know who to call.

At Fecision, we guide every beam and pulse to get your design exactly right. Our aluminum laser cutting services are primed to deliver the quality you seek. Get in touch today and watch your concepts come to life with our tech and talent!