Pecision Injection Molds for Plastic Housings of Connectors

- ISO 9001 & IATF 16949 Certified: Adhering to global quality and automotive standards.

- In-House Tooling & Maintenance: Rapid mold revisions and spare-parts readiness.

- Rapid Prototyping to Full Production: Quick-turn 3D-printed inserts and pilot runs in under two weeks.

- Global Logistics & Support: Coordinated shipping and after-sales mold maintenance agreements.

ISO 9001:2015 Certified Processes

ISO 13485: 2016 Medical Device

IATF 16949: 2016 Automotive

No Minimum Order Quantities

In-Process Inspection with CMM

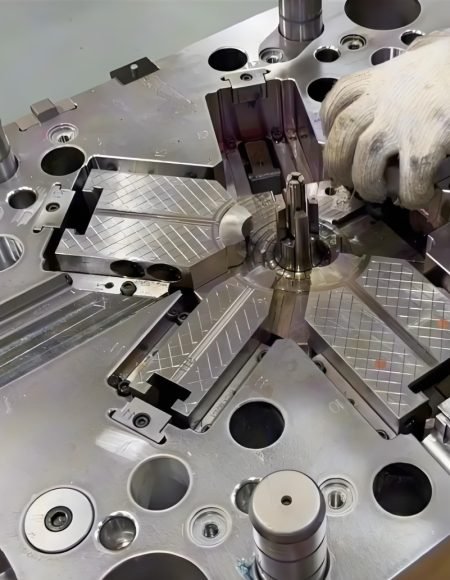

Precision Molds for High-Performance Connector Housings

Key Features

Molds for Different Connector Plastic Housings

Our connector mold manufacturing services involve many industries and can meet the manufacturing needs of connector plastic shells in different industries, from appearance and structure differences to special performance requirements.

Technical Specifications

| Parameter | Specification |

| Mold Material | High-grade steel (e.g., P20, H13) for durability and precision |

| Mold Type | Single or multi-cavity molds (up to 64 cavities) for high-volume production |

| Tolerances | Capable of achieving tight tolerances as low as ±0.005 inches |

| Mold Life | ≥ 100,000 shots |

| Cycle Time | Optimized for fast production cycles, reducing lead times |

| Injection System | Cold-runner or Mold-Master/Yudo hot-runner |

| Cooling Channel | Conformal cooling for uniform temperature control |

| Surface Finish | Mirror polish, textured or high-gloss; Customizable to meet specific aesthetic and functional requirements |

| Plastic Compatibility | Suitable for a wide range of thermoplastics, including ABS, polycarbonate (PC), nylon, PPS, and LC |

Injection Mold Design

Design Suggestions for Connector Plastic Housings

Uniform Wall Thickness

Maintain consistent wall thickness to prevent warping and ensure even cooling.

Incorporate Draft Angles

Incorporate draft angles to facilitate easy mold release for further production needs.

Avoid Sharp Corners

Use rounded corners to reduce stress concentrations and improve material flow.

Minimize Undercuts

Design to avoid undercuts or use side actions where necessary to simplify mold design.

Suitable Gate Placement

Strategically place gates to minimize visible marks and ensure smooth material flow.

Manufacturing Process & Techniques

Design & Engineering

CNC Machining

EDM (Electrical Discharge Machining)

Polishing and Texturing

Quality Control

Connector Housing Injection Mold Manufacturing

Main Technical Challenges in Connector Mold Manufacturing

Tight Tolerances

Connectors require precise dimensions for proper fit and function. We use advanced machining techniques to achieve tolerances as low as ±0.005 inches.

Complex Geometries

Connector housings often feature intricate designs. Our expertise in multi-cavity molds and EDM allows us to handle complex shapes with ease.

Material Compatibility

Different plastics have unique flow and shrinkage properties. We select and test materials carefully to ensure compatibility with your design.

Durability for High-Volume Production

Molds must withstand thousands of cycles. We use high-grade steel and rigorous testing to ensure longevity.

Fecision Mold Manufacturing Network

In response to different service types and diverse business needs, we have deployed suppliers with different manufacturing capabilities.

Your Strategic Partner for Connector Mold Success

The Fecision Advantage: Why Partner With Us?

Let's Start!

Together, we can make something remarkable!

Let us turn your vision into reality. Provide us with your project details, and we’ll create a customized proposal designed specifically for you.