Injection molding is a key method in modern manufacturing where melted plastic is injected into a mold, then cooled and hardened to form the needed shape. But one of the biggest challenges in this process is venting. Failure to remove trapped air and gases can result in defects like burn marks, short shots and incomplete filling. A solution to these age old problems is porous metal.

Porous metal, known for letting gases pass through while blocking molten plastic, is a game changer in venting efficiency and product quality in injection molding. This article will explore how porous metal revolutionizes venting in injection molding.

Understanding the Role of Mold Venting in Injection Molding

In injection molding, filling the mold cavity with molten plastic is key to producing good parts. However, as the plastic flows into the mold, it displaces the air that was previously inside the cavity. If this air can’t escape, it gets trapped and can cause serious manufacturing defects. That’s where mold venting comes in.

Why Venting Is Critical for Mold Performance

Venting is the controlled removal of air and gases from the mold cavity during the injection process. It’s an important design feature that directly affects how the mold works and the quality of the final product. Proper venting ensures that:

- Molten plastic, including thin and intricate sections, can fully fill the mold cavity.

- Air pressure doesn’t build up which can cause internal stress or deformation.

- Gas byproducts from heated materials are removed, preventing chemical or thermal damage to the part.

When venting is done right, you get a complete, well-formed part with good surface quality and structural integrity. When venting is done wrong, you reduce the efficiency of the injection molding process.

Common issues caused by poor venting

When the venting system fails to perform adequately, several issues can arise:

- Trapped Air: Leads to incomplete or weak areas in the molded part.

- Burn Marks: Caused by compressed, overheated gases that burn the material.

- Short Shots: Occur when air prevents the plastic from fully filling the cavity.

- Mold Damage: Continuous pressure and thermal stress can degrade the mold over time

These defects not only lower production efficiency due to increased scrap rates and rework but also degrade the reputation of manufacturers by delivering inferior products.

What is Porous Metal?

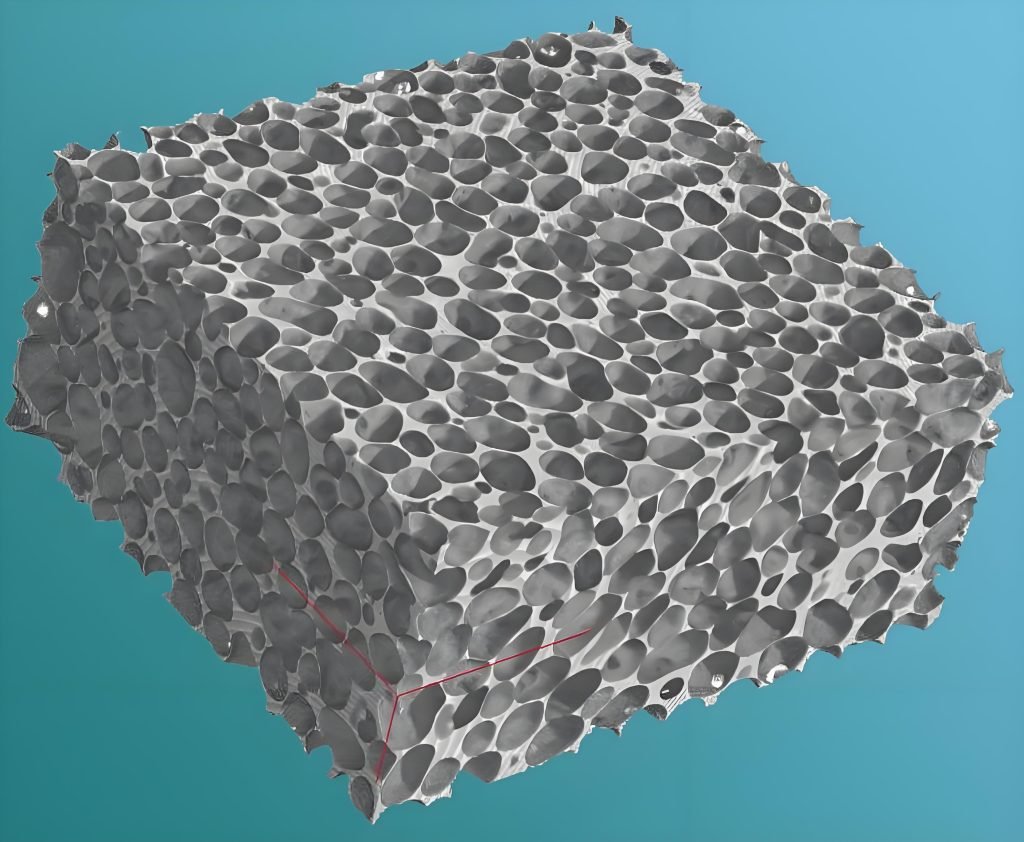

Porous metal represents a specialized category of engineered materials characterized by a fixed metal skeleton interspersed with numerous interconnected voids. Unlike conventional dense metals, porous metal contains a three-dimensional network of deliberately created cavities that fundamentally transforms its performance characteristics.

The structure of porous metal typically consists of fine particle spherical powdered stainless steel sintered at high temperatures, creating evenly distributed microscopic venting holes throughout the material. This unique architecture allows gasses to permeate through the entire metal body, making it particularly valuable for injection molding applications.

How does its structure differ from traditional solid metals

The core difference between porous metal and traditional solid metal lies in the microstructure:

| Property | Solid Metal | Porous Metal |

| Structure | Dense and non-permeable | Interconnected pores with open pathways |

| Gas Flow | Impermeable to gases | Allows controlled gas flow through the material |

| Surface Area | Low internal surface area | High internal surface area due to pores |

| Venting Use | Requires separate channels | Inherently vents across its surface |

This open-pore structure enables porous metal to act as a uniform venting medium across the mold surface, unlike traditional metals that rely on machined channels and gaps.

Porous Metal for Injection Molding: Why It’s a Game Changer

Porous metal is quietly changing the injection molding industry and for good reason. It’s solving problems that have plagued manufacturers for decades, especially when it comes to venting air and gas during the molding process. Instead of using traditional venting methods like machined channels or vent pins, porous metal allows trapped air to escape through countless tiny pores built directly into the material.

The Big Advantages of Using Porous Metal in Molds

Using porous metal for injection molding offers several clear advantages over conventional venting methods:

1. Better Gas Evacuation

The interconnected pores allow gas and air to escape naturally from the mold cavity without extra venting channels. This means less trapped air, fewer defects and better finishes.

2. Improved Product Quality

With proper venting, the molten plastic fills the cavity more uniformly, reducing issues like weld lines, burn marks and short shots. This means higher first pass yield and less rework.

3. Extended Mold Life

Traditional vent channels are prone to clogging or wear, leading to increased maintenance. Porous metal’s integrated design reduces the need for such frequent cleaning or repairs, prolonging tool life.

4. Process Efficiency

Less venting-related downtime means better cycle times, increased output, and cost savings. Manufacturers can achieve consistent results even in high-speed, high-volume environments.

Real-World Results: Where Porous Metal Really Shines

Take automotive manufacturing, for example. Some parts that used to have burn marks now look perfect straight out of the mold—no extra cleanup or polishing is needed. That’s a huge time and cost saver.

In the medical field, where precision and quality are critical, porous metal makes it possible to mold tiny, complex parts with thin walls and fine details that wouldn’t be possible using traditional venting methods. Consumer electronics brands are also getting on board. By using porous metal venting, they can produce sleek, high-gloss parts without blemishes — a must for premium product lines.

How Porous Metal Improves the Injection Molding Venting System

Traditional injection mold venting methods fail when dealing with complex part geometries. Traditional methods such as vent plugs, parting-line vents, and pins often fail to provide enough capacity to manage the high gas volumes produced during molding operations.

Comparison of traditional venting channels vs porous metal solutions

Conventional venting systems rely on strategically placed channels or pins that provide a limited surface area for gas evacuation. Unfortunately, these methods create several inherent challenges:

- Traditional vents require precise machining and exact placement

- They’re prone to clogging with material residue

- Coverage is limited to specific areas, leaving potential dead spots

In contrast, porous metal solutions transform the entire component into a venting mechanism. Materials like Porcerax II incorporate a network of interconnected pores that allow trapped gasses to permeate through the steel itself. Since these materials comprise 25% air by volume, one-fourth of the surface area effectively becomes a vent.

Mechanism: How air and gasses escape through the porous structure

The secret behind porous metal’s effectiveness is in its microscopic structure. Indeed these materials have a system of interconnected pores with average diameters ranging from 7 micrometers (0.0003 inch) to 20 micrometers (0.0008 inch) dispersed throughout the material. This network creates countless pathways for gas molecules to escape.

During injection, as plastic enters the cavity, air molecules migrate through these tiny channels and exit out of the mold component. The 20-micron grade has about 25% more venting capacity than an equal surface area with 7-micron pores.

Real-world benefits for manufacturers

On account of its unique venting capabilities, porous metal tooling delivers substantial production advantages:

- Faster cycle times – With less back pressure in the mold, plastic fills the cavity faster, lower temperatures and shorter cooling times

- Better part quality – Trapped air eliminated means fewer defects, burns, short shots and sink marks

- Easier maintenance – Though periodic cleaning is required, porous inserts can be cleaned with ultrasonic, baking or solvent cleaning

Plus, you need less injection pressure overall, which means less scrap and rejects. Sometimes the biggest benefit is simplifying the mold design itself as complex venting channels become unnecessary in some applications.

Industries and Applications Using Porous Metal Mold Venting

Porous venting is used in various industries due to its reliability and ease of integration.

- Automotive: Modern vehicles have many plastic parts that must meet quality standards. Porous metal ensures consistent molding of dashboards, connectors, under-hood parts and aesthetic parts like grilles and trim.

- Medical: Precision is critical in medical components. Porous venting ensures dimensional accuracy and no surface flaws in parts like syringe bodies, tubing connectors and surgical instruments.

- Consumer Goods: Improved mold venting benefits high volume production of items like appliance housings, cosmetic containers and toys by reducing cycle times and increasing yield rates.

- Electronics: In electronics, parts like battery cases, charger housings and switch panels require flawless finishes and exact fits. Porous metal aids in manufacturing components that are free from bubbles and defects.

Selecting the Right Porous Metal for Your Injection Molding Needs

Proper material selection remains the cornerstone of successful porous metal implementation in injection molding applications. The right choice balances porosity requirements with mechanical performance, ensuring optimal venting without compromising structural integrity.

Key factors to consider

- Porosity Level: Higher porosity allows more gas flow but affects material strength. Choose based on your application.

- Material Strength: Use sintered metals like stainless steel for high pressure applications.

- Temperature Resistance: Ensure the material can withstand your molding process temperatures.

- Corrosion Resistance: Important for long term durability especially in high moisture or chemically reactive environments.

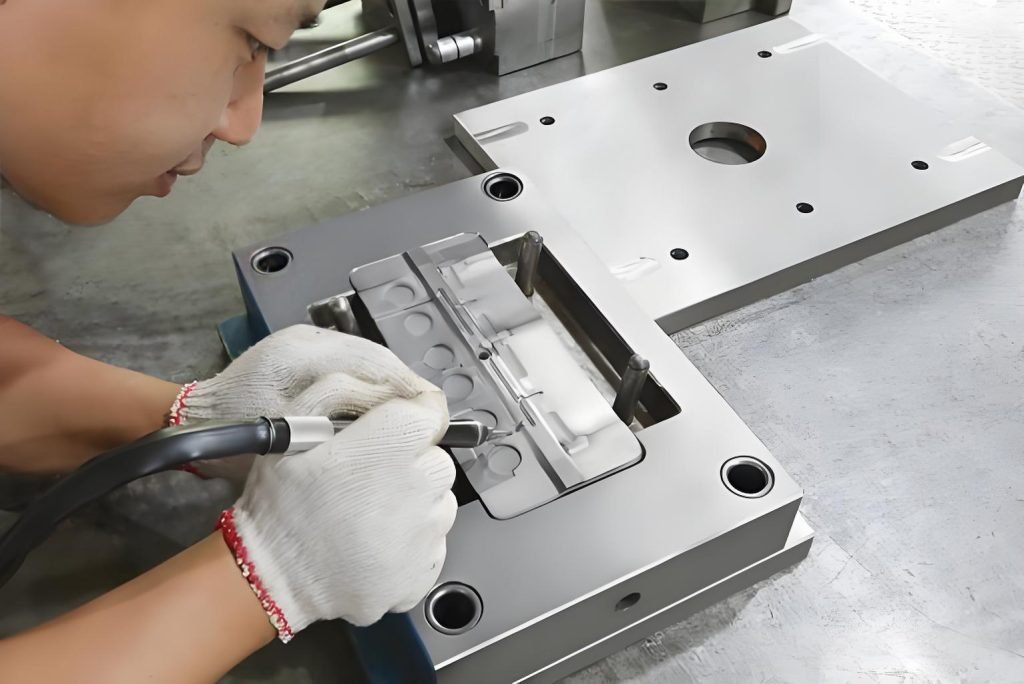

Tips for Integrating Porous Metal into Your Molding System

- Work with mold designers to identify areas prone to air entrapment.

- Use porous metal inserts or blocks instead of regular vent channels.

- Combine porous metal with traditional venting in complex molds for hybrid benefits.

- Ensure proper compression fit to avoid leakage around the insert.

- Regularly inspect porosity to ensure consistent airflow over time.

Challenges and Best Practices

While porous metal offers great benefits for injection molding venting, implementing this technology has unique challenges that require specific maintenance strategies. Understanding these challenges helps manufacturers get the most out of their investment in porous tooling components.

- Clogging and Blockage: Over time, resins, fillers or additives can accumulate within the pores reducing permeability. This is more common when using highly filled or recycled materials.

- Cleaning and Maintenance: Unlike open vents, clogged porous inserts may not be easily cleaned with compressed air. May require ultrasonic cleaning or solvent flushing.

- Initial Cost: Porous metal inserts are more expensive than traditional venting components. However, the long term ROI is favorable due to reduced scrap and downtime.

- Material Misuse Using porous inserts in areas exposed to high shear or direct plastic flow without proper design can lead to erosion or degradation.

Best Practices for Maximizing Effectiveness and Longevity

- Scheduled Cleaning: Clean inserts regularly using approved solvents or ultrasonic baths to maintain pore integrity.

- Avoid Over-Tightening: Handle porous components carefully during installation to avoid crushing the internal structure.

- Monitor Performance: Implement quality checks to detect early signs of vent failure, such as short shots or burning.

- Replace When Needed: Despite good maintenance, porous inserts will eventually wear out. Have a proactive replacement strategy in place.

- Use Protective Coatings (If Needed): Some porous metals can be coated to enhance resistance to clogging or chemical attack depending on your molding materials.

Conclusion

Porous metal has changed the game for venting in injection molding. By allowing consistent and efficient gas escape it improves product quality, reduces waste and extends mold life. Porous metal for injection molding is a game changer for the injection molding venting system across industries. With the demand for precision, speed and reliability in manufacturing increasing, porous metal will be a staple in modern tooling.

Ready to upgrade your molding? Contact a supplier today and see how porous metal can help your injection molding venting system.