Ever watched a robot smoothly assemble a car or pack your online shopping? Pretty cool, right? These mechanical marvels aren’t working with just their bare metal arms. They’ve got something special at the end—their “hands”. And that’s where our star of the show comes in: EOAT.

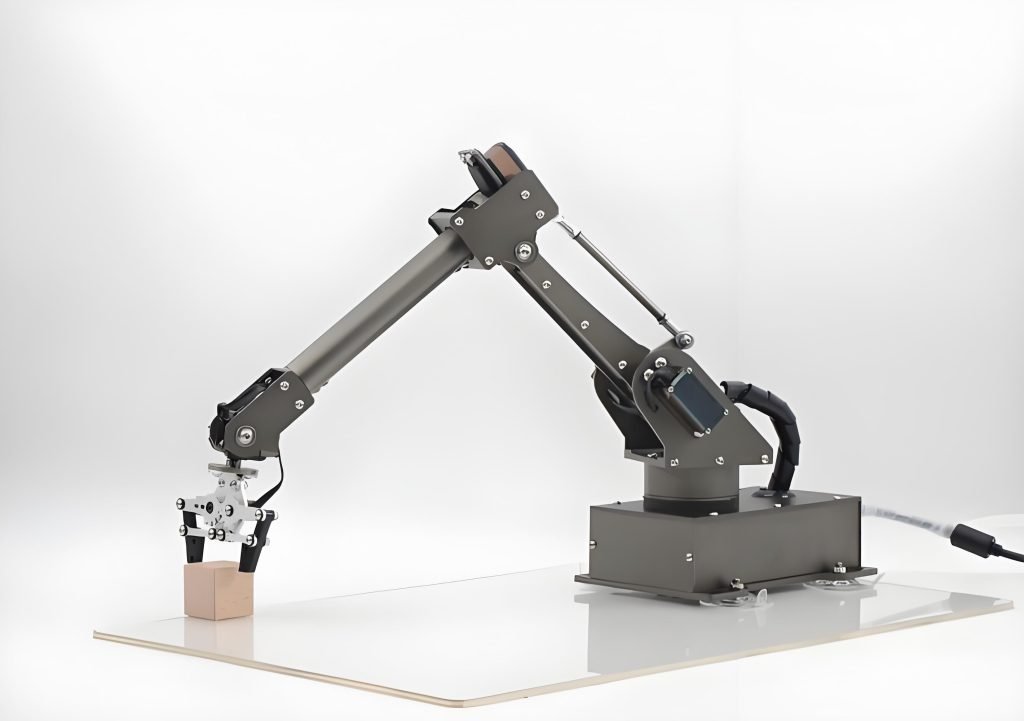

So, what exactly is this mysterious acronym? EOAT stands for “end of arm tooling”. Think of it as the Swiss Army knife for robots. It’s the specialized attachment at the end of a robotic arm that allows it to actually do stuff.

In this article, we’re going to take a fun and easy-to-understand journey into the world of EOAT. We’ll explore what it is, the different types you might encounter, why it’s a game-changer for industries, and where you can find these amazing robotic helpers in action. Get ready to become an EOAT expert!

What Is EOAT? Let’s Break It Down

Okay, so we know EOAT means “end of arm tooling”. But what does that really mean in the robotic world? Let’s get a clearer picture.

Definition: End of Arm Tooling Explained Simply

Think about your own arm. Your hand is the “end of arm tooling”, allowing you to grab a cup, type on a keyboard, or give a high-five to a friend. In robotics, the EOAT is the “hand” or tool that allows the robot to physically interface with the world and perform specific tasks.

A standard EOAT configuration often involves several key end of arm tooling components:

- The Actual Tool: This is the star of the show – the gripper, the vacuum cup, the welding gun, the paint sprayer, you name it! It’s designed for a specific action.

- The Mounting Interface: This is the part of the EOAT that connects the tool to the robot arm. It needs to be solid and reliable.

- Sometimes, Extra Goodies: Depending on the task, you might also find sensors (to “feel” or “see”), cameras (to guide the robot), or other auxiliary equipment integrated into the EOAT.

Role in Robotics: The Robot’s “Hand” at Work

- The Gripping Game: Think about a robot in a factory assembling parts. It needs to pick up components, move them, and place them precisely. That’s often the job of a gripper, a type of EOAT designed to hold and manipulate objects.

- Beyond Just Gripping: But EOAT isn’t just about grabbing. It can be anything from a welding torch that joins metal pieces to a paint sprayer that gives your car its shiny finish. It’s the business end of the robot, the part that gets the actual work done.

- Making Manufacturing Magic: Without EOAT, a robot arm is just an arm. The tooling is what gives it purpose and allows it to contribute to all sorts of manufacturing processes.

Why EOAT is a Big Deal: The Importance Factor

- Super Precision: Robots are controllable, and their precision is often attributed to EOAT. These specialized tools are designed to achieve a degree of precision that human beings seldom approach, ensuring a high-quality outcome every time.

- Excellent Efficiency: Robots do not get tired or take coffee breaks. Automating work processes with the addition of adequate end of arm tooling for robots allows you to complete a task with greater efficiency, getting more done in a shorter period without interruption.

- Taking on the Tough Stuff: Some jobs are just not safe or pleasant for humans – think handling hazardous materials or performing repetitive, physically demanding tasks. Robot EOAT allows robots to take on these roles, keeping people safe and sound.

Different Types of End-of-Arm Tools: A Variety of Tools Exist

Just like you have different tools in your toolbox for different jobs, robots have a range of EOAT options to tackle various tasks. As part of your design process, you will want to consider all the EOAT possibilities based on the tasks you want your robots to perform. Let’s take a look at some basic EOAT types.

- Grippers: The Masters of Manipulation

Grippers are probably what come to mind when you think of a robot “hand.” They’re designed to grasp and hold objects. But did you know there are different kinds?

| Gripper Type | How They Work | Advantages | Ideal For |

| Vacuum Grippers | Create a vacuum seal on the object’s surface. | Gentle on surfaces, quick and easy to use. | Handling delicate or flat materials like glass panels or sheet metal. |

| Bag Grippers | Use inflatable bladders or specialized fingers to conform to the bag’s shape. | Versatile for different bag sizes and shapes, with gentle handling. | Food packaging, logistics, and handling soft goods. |

| Pneumatic Grippers | Use compressed air to open and close their jaws. | Fast, strong grip, and relatively simple to operate. | General pick-and-place tasks in manufacturing. |

| Servo-Electric Grippers | Use electric motors for precise control of grip force and position. | High precision, adjustable grip force, and feedback capabilities. | Delicate assembly tasks and applications requiring variable grip force. |

- Vacuum End Effectors: Sucking Up the Competition

We already touched on vacuum grippers, but vacuum end effectors can be even more intricate systems involving several suction cups or a specialized vacuum tool for handling objects of certain shapes or sizes.

- How they work: They utilize one or more vacuum cups to create a holding force on the object.

- Ideal applications: Handling large panels, automotive body parts, and other items with relatively flat surfaces.

- Tool Changers: The Quick-Change Artists

Now, imagine a robot has to do numerous different tasks. Instead of having a robot allocated for each task, tool changers can provide a robot with the capability of switching EOAT in a fraction of a second.

- How they work: They are like quick-release mechanisms that allow a robot arm to automatically disengage one EOAT and replace it with another.

- How they maximize robot capabilities: This greatly adds to the overall flexibility and efficiency of a robotic system, because that capability enables one robot to perform all the necessary tasks.

- Welding Guns: Automated Unions and Assemblage

In many manufacturing industries, including automotive and heavy equipment, welding is one of the major core processes required to achieve the end product. Robotic welding guns are the EOATs that accurately and efficiently join two or more parts together using metal.

- How they work: A welding gun delivers electric current and welding wire to create a fused and strong bond of metal parts.

- Importance: They provide welds of high quality, improve production speed, and protect workers from a potentially dangerous task by performing it automatically.

Advantages of End of Arm Tooling for Robots

Why does EOAT really matter in the automation world? Let’s take a look at one of the main benefits of any operation:

- Increased Productivity– Faster, Better, Stronger: You can dramatically increase production rates when you automate a process with robots, and the right EOAT, because robots will work hours without breaks without sacrificing speed or quality, and you just get more out of them.

- Cost Efficiency– Saving You Money in the Long Run: Although you will initially invest in a robotic system and EOAT, the savings you recognize over time can really add up. You’ll menu fewer total labor hours, less wasted material, and increased efficiency of the process, all equating to a healthier bottom line.

- Consistency and Quality– Fewer Errors, Happier Customers: Robots don’t get distracted or tire and make mistakes. EOAT eliminates variability, and with consistent accuracy, the quality of the product is increased and defects are reduced.

- Reduced Maintenance– Less Downtime, More Uptime: End of arm tooling components are designed for longevity and would typically require less maintenance than manual processes. This results in reduced downtime when machines can run continuously.

- Versatility– Adapting to Different Needs: With EOAT and tool changers, a single robot can perform numerous varying tasks. This capacity for versatility makes robotic systems a progressive solution developed to fit evolving manufacturing needs and different product lines.

While EOAT has a lot of positives, it’s worth pointing out some potential roadblocks. Knowing your challenges ahead of time will help when you face them!

Challenges When Working with Robot End of Arm Tooling

- Complex Design & Integration: The design of custom EOAT can be complex and often requires a specific engineering skillset, and integrating with existing robot systems can be challenging.

- Investment & Ongoing Costs: The upfront cost of setting up EOAT can be a burden, with ongoing costs for maintenance and potential replacement.

- Specialized Servicing & Downtime: EOAT generally requires skilled technicians to service, and even planned maintenance may have system downtime.

- Safety Considerations: When designing and using EOAT, risk assessment and reliable safety procedures are essential.

Applications of EOAT: Where You’ll Find These Robotic Helpers

EOAT is utilized in many industries. Some of the applications include the following examples.

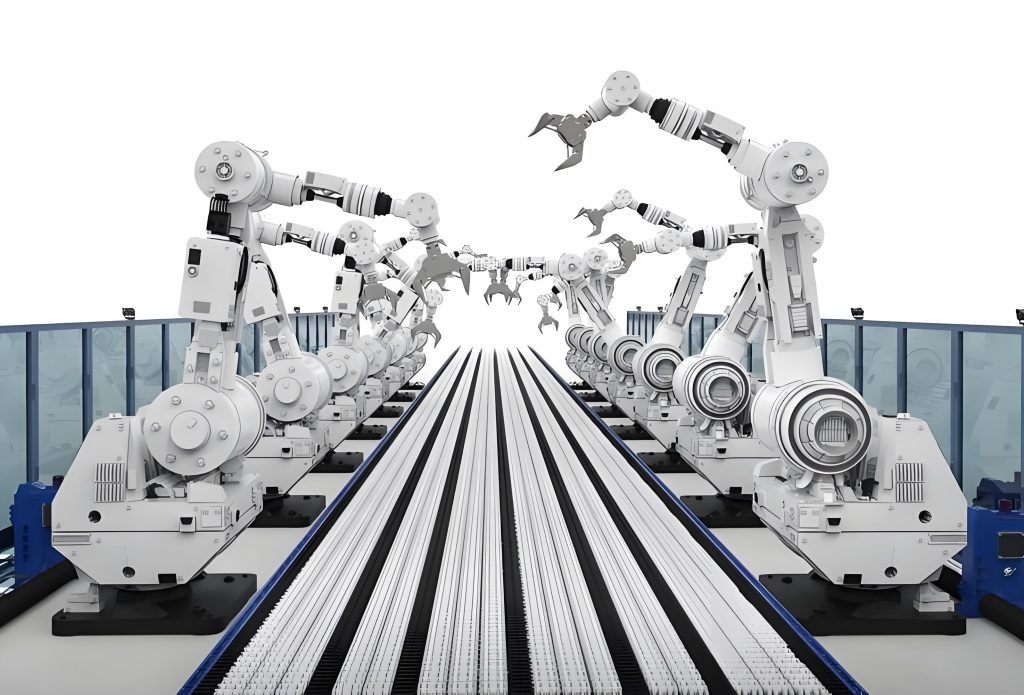

Auto Industry: The Assembly Line Heroes

- Assembly Line Applications: Grippers will be an important part of the EOAT when assembling car parts such as doors, dashboards, engines, and transmissions.

- Welding and Painting Processes: Robotic welding guns and paint sprayers are another type of EOAT that will provide consistent and reliable welds and paint finishes.

Electronics: Precision You Require

- Circuit Board Assembly: Automation of placing tiny electronic components onto a circuit board is a task that requires specialized robot end of arm tooling for precision and control.

Food & Beverage: Ultimate in Care and Hygiene

- Handling and Packaging Applications: The safest and most effective way to handle food and beverage products for packaging is to use robots that are equipped with hygienic grippers and vacuum end effectors.

- Safety and Hygiene Considerations: In this industry, hygiene standards for EOAT significantly exceed normal situations because the processes are preparing food for consumption.

Warehousing & Logistics: Streamlining the Supply Chain

- Sorting and Palletizing: Robots equipped with grippers and/or vacuum tools can be used to sort packages, build pallets, and automate processes in warehouses.

- Automation in Warehouse Management: EOAT plays an important role in developing efficient, automated warehouse systems.

Custom Machining Services for Premium End of Arm Tooling Components

We have looked at how important EOAT is when it comes to utilizing robots to their fullest potential, essentially turning them into dynamic machines for specialized tasks. However, for specialized operations, sometimes off-the-shelf solutions just do not cut it. That is where the creation of custom end of arm tooling injection molding components designed for the specific requirements of your application becomes essential.

At Fecision, we focus on precision manufacturing. We provide high-quality components that satisfy the stringent requirements of the robotics industry. The requirement for custom EOAT solutions that specifically fit your needs is where we provide our advanced CNC machining services.

CNC Machining at Fecision: Precision and Flexibility for Your EOAT Needs

- High Precision: Accuracy You Can Rely On

- Exacting Specifications: Our CNC machining means that every piece fits perfectly and is designed to work in a specific manner, thus limiting errors and increasing efficiency for your robotic systems.

- Quality Assurance: We use state-of-the-art CNC technology and stringent quality control measures to ensure the accuracy of every part we create.

- Material Variety: The Right Stuff for the Right Job

- Wide Range of Materials: We offer a range of materials from lightweight but strong aluminum alloys to certain plastics that are uniquely grippy to enable a very diverse set of EOAT applications.

- Material Selection Guidance: Unsure which material works best for your exact application? Our experts can assist you in weight and material selection to help enhance both performance and longevity.

- Diverse Applications: We Machine What You Need

- Versatile Machining Capabilities: Whether you need a delicate set of gripper fingers (perhaps initially prototyped or produced via end of arm tooling injection molding) or a simple and strong tool changer, our CNC machining capabilities can accommodate many shapes and sizes.

- Customization: We respect your individual needs, and our machining methods can be customized to you so that you have EOATs that are right for you.

From industrial automation to service robotics to autonomous systems, Fecision supports the vanguard of automation. Our high-precision CNC machining service for End-of-Arm Tooling robotic tooling applications is the precise, durable, and reliable service model that meets these precision requirements. Our dedication to quality begins with our commitment to the regulated standards of ISO and CE certifications. We maintain oversight and unbiased quality on each standard component we provide for you to feel confident and safe when using our EOAT.

Do you want to give your robots “hands” that are custom-machined to the highest level? Discover Fecision’s CNC machining service precision and flexibility for robotics, and learn how we have the right level of experience to support your robotic automation projects for the future. Let’s build the future of automation one reliable component at a time!