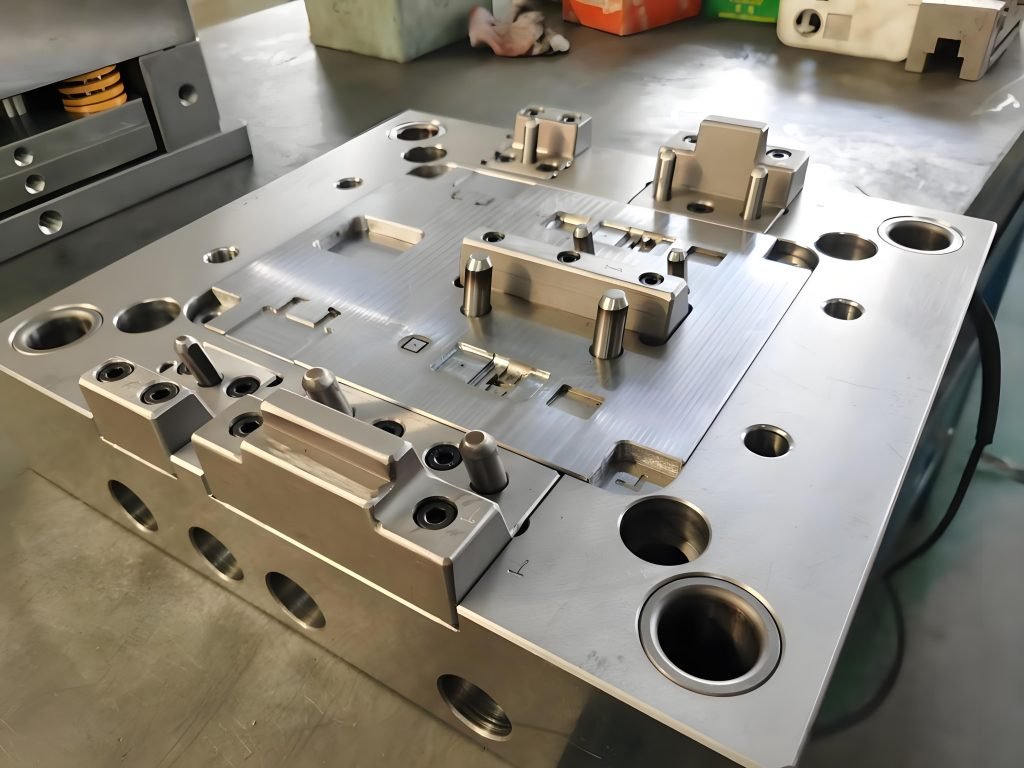

Choosing the right tool for plastic injection molds is a strategic decision. The material you select directly affects the mold’s durability, cycle time, part quality, and overall cost-efficiency of your production line.

But with so many options like P20, H13, S7, 420 stainless, and NAK80, how do you know which one fits your unique manufacturing needs?

That’s why we’re here. We’ll break down the most commonly used mold tool steels, what they’re best suited for, and how to match them with your production goals. But before that, let’s start with the key properties to consider.

Key Properties to Consider When Choosing Mold Tool Steel

The right mold tool steel impacts everything from tool longevity and part consistency to production cost and downtime. Here’s a breakdown of the most important properties to consider before locking in your selection.

1. Hardness and Wear Resistance

Hardness directly correlates with how well a mold resists wear over time, especially in high-volume production or when working with abrasive resins. The harder the steel, the longer its shape is under pressure, reducing maintenance and retooling costs.

If you’re molding over a million parts, go for hardened steels like H13 or 420 stainless. For prototyping or short-run jobs, pre-hardened steel like P20 might offer a better balance of cost and performance.

2. Thermal Conductivity

Thermal conductivity determines how quickly a mold can heat up and cool down. This directly affects cycle time, part quality, and energy efficiency. Faster heat transfer means shorter cycles and more consistent part dimensions.

Tool steels with better conductivity, like beryllium-copper hybrids, can significantly improve cooling in complex molds.

3. Corrosion Resistance

In environments with high humidity, water cooling, or corrosive resins, rust is more than a cosmetic problem. It can damage the surface finish and cause premature mold failure.

Steels like 420 stainless or NAK80 are excellent injection molding tool steel grades if corrosion is a concern. For molds using aggressive plastic (e.g., PVC, flame retardants), corrosion resistance becomes a critical priority.

4. Machinability

Machinability depends on how easily the steel can be milled, drilled, or EDM-cut during the mold-making process. Better machinability means faster build time, which is equal to lower upfront tooling costs.

P20 and NAK80 are pre-hardened and known for excellent machinability, making them great for tight timelines. Harder grades like H13 take longer to machine and may require more advanced tooling.

Common Types of Mold Tool Steel for Injection Molds

Each mold tool steel has its strengths, costs, and ideal applications. Below are five of the most commonly used tool steels in plastic injection molding and the features that make each one unique.

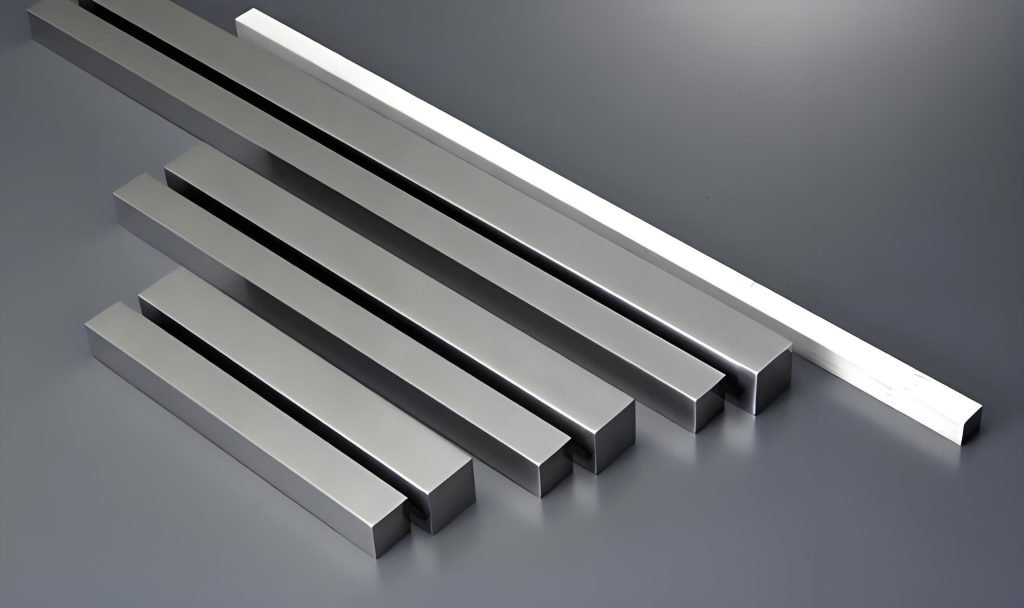

1. P20 Steel – The Reliable All-Rounder

P20 is a pre-hardened tool steel that offers a solid balance of machinability, strength, and cost. It’s the most popular choice for medium to high-volume production and is often used for plastic parts that don’t require ultra-tight tolerances or extreme surface finishes.

Key Benefits

- Pre-hardened to ~28–32 HRC, making it easier to machine

- Cost-effective for molds with expected production of up to 500,000 cycles

- It can be polished and textured for basic cosmetic parts.

Best for: Consumer goods, automotive interior parts, and general-purpose mold bases.

2. H13 Steel – Built for Heat and Longevity

H13 is a chromium-molybdenum hot work steel that excels in high-temperature, high-volume environments. It’s extremely durable and can withstand the thermal shock of repeated heating and cooling, which makes it perfect for demanding applications.

Key Benefits

- Heat-treated to ~48–52 HRC for excellent wear resistance

- Great for molds using hot-runner systems or abrasive plastics

- Good thermal conductivity and toughness

Best for: High-volume parts, engineering plastics, and tight-tolerance tooling.

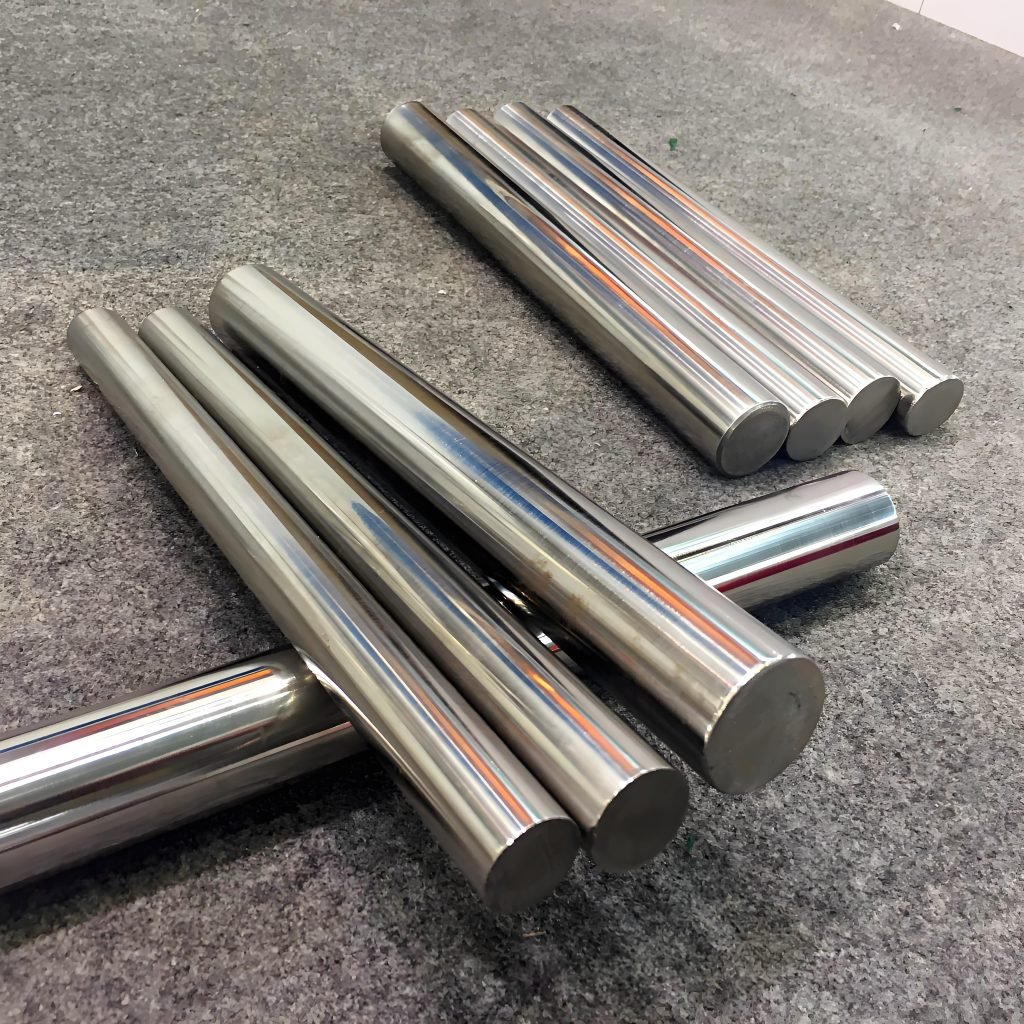

3. S7 Steel – Shock Resistant Performer

S7 tool steel is designed to absorb shock and impact without cracking. While not as commonly used as P20 or H13, it’s extremely valuable for specific mold types, especially when impact and stress are involved during ejection or molding.

Key Benefits

- Air-hardening tool steel with high toughness

- Withstands repeated impact without fracturing

- Can be hardened to ~58 HRC while retaining ductility

Best for: Molds with complex ejection systems, core pins, or high-shock molding applications.

4. 420 Stainless Steel — The Rust-Proof Solution

420 Stainless steel is ideal when corrosion resistance is a top priority. This steel grade is hardened and polished, making it an excellent fit for molds that need mirror finishes or will be exposed to humid environments or corrosive plastics.

Key Benefits

- Heat-treated to ~50 HRC, combining hardness with corrosion protection

- Excellent polishing ability — great for optical or cosmetic parts.

- Reduces maintenance downtime between operations

Best for: Medical parts, clear plastics, cosmetics packaging, or long-idle mold storage.

5. NAK80 – The EDM and Polishing Favorite

NAK80 is a pre-hardened, high-performance steel that bridges the gap between machinability and surface quality. It’s particularly loved for electrical discharge machining (EDM) work and its ability to achieve high-gloss finishes with minimal effort.

Key Benefits

- Pre-hardened to ~40 HRC — no post-hardening needed

- Highly polishable and great for texturing

- Machinable with high dimensional stability

Best for: Transparent parts, electronic housings, and molds requiring fine surface finishes.

How to Match Mold Tool Steel with Your Molding Application

Whether you’re producing a few hundred or several million parts, the type of steel you use can significantly impact your tooling costs, cycle times, and part quality. Here’s how to select the right plastic mold tool steel for your application:

1. High-Volume vs. Low-Volume Production

Production volume is one of the biggest drivers when selecting mold tool steel. The higher the number of cycles a mold will go through, the more durable and wear-resistant the steel must be.

For low-volume runs, you can use P20 or NAK80, which are pre-hardened and easy to machine. These are cost-effective for prototypes or production runs.

As for medium to high-volume production, consider H13 or 420 stainless, as these can be heat-treated for greater hardness and wear resistance.

2. Abrasive Plastics or Filled Resins

Not all plastics behave the same. Some are highly abrasive, particularly those filled with fiberglass, minerals, or flame-retardant additives, and may quickly wear down unprotected molds.

If you’re using glass-filled nylon, polycarbonate, or flame-retardant reins, choose a more wear-resistant option like H13, 420 stainless, or S7.

For clear or cosmetic plastics, like polycarbonate or acrylic, 420 stainless and NAK80 are ideal because they polish well and resist corrosion from outgassing.

Partner with Fecision for Precision Tooling

The success of your injection molding project starts with the right mold tool steel. The right choice can extend the life of your mold, cut cycle times, reduce maintenance, and ensure consistent, high-quality parts over thousands of production runs.

If you’re looking for someone to help out with your plastic injection molds, Fecision is here to help.