You slide your smartwatch onto its charging dock before bed—a satisfying click confirms it’s aligned. The next morning, your wireless earbuds snap seamlessly into their case, battery topped up. At work, your tablet magnetically docks to a conference room station, charging as it shares data. These moments feel effortless, almost invisible. Yet behind this simplicity lies an unsung hero: the pogo pin charger.

From wearables to electric vehicles, these pogo pins connectors quietly power modern life. They’re the reason your devices charge without fumbling with cords, survive daily wear-and-tear, and even resist sweat during workouts. Unlike bulky ports, pogo pin systems hide in plain sight—embedded in sleek gadgets, medical tools, and factory robots. Their ubiquity is no accident. Its engineering brilliance is distilled into millimeter-sized components, working tirelessly to keep our world connected.

What Is a Pogo Pin Charger?

Do you know that satisfying snap when your smartwatch locks onto its charger? Or how does your wireless earbuds case charge without plugging anything in? That’s a pogo pin charger at work—but here’s the twist: the real genius isn’t the charger itself. It’s the pogo pins hidden inside, acting like tiny mechanical negotiators between your device and power.

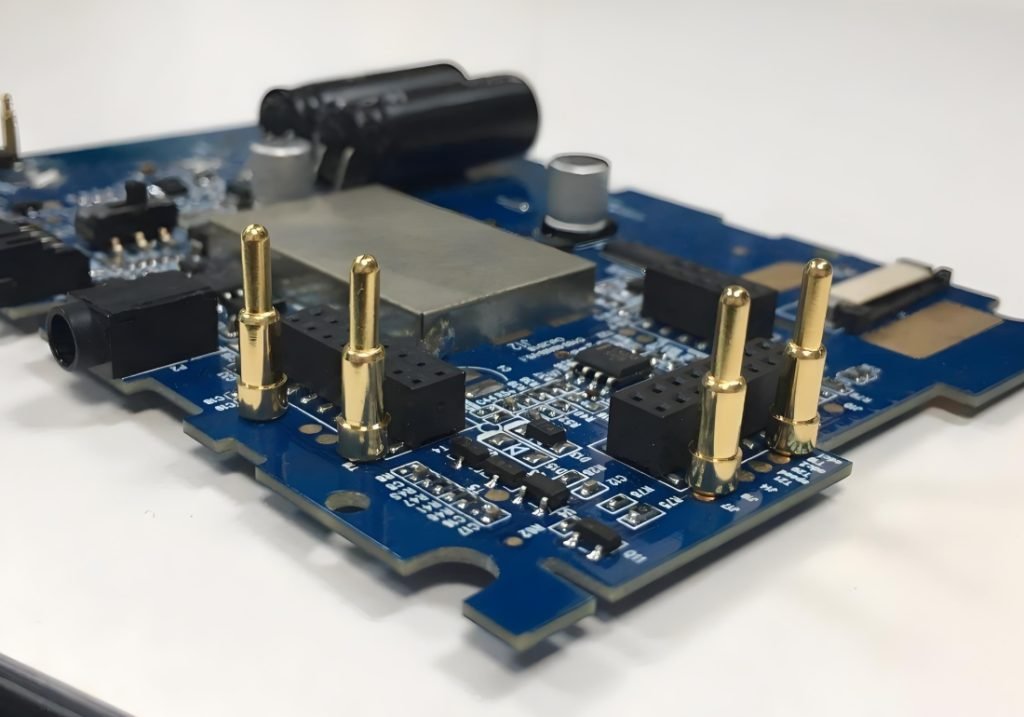

A pogo pin is basically a spring, a metal tip, and a tube—all working together to move electricity where it needs to go. When you drop your device onto the charger, those pins press down (like a retractable pen), maintain perfect contact, then spring back when you remove it. No holes to clog with lint, no fragile ports to break. Just pure physics.

Now, here’s why manufacturers care:

• The metal tip (plunger) needs to be shaped just right—often by CNC machines—to hit the charging spot dead-on, every time.

• The spring’s tension has to balance durability with gentle pressure—too stiff, and it’ll scratch devices; too weak, and the connection flickers.

• The tube (barrel) holding it all together? If it’s not machined to hair-thin precision, the whole pin jams or wobbles.

A “pogo pin charger” is just a fancy name for a system that lives or dies by the quality of these pins. Better pins mean chargers that survive coffee spills, factory floors, or being tossed in a gym bag daily. And that’s where the real engineering happens—not in the charger’s glossy exterior, but in those millimeter-sized components most people.

Benefits of Pogo Pin Chargers

Pogo pin charging solves pain points that frustrate users of older charging methods. Let’s break down their real-world advantages:

1. They’re Built to Last

While micro-USB ports wobble loose after months of plugging/unplugging, pogo pins thrive on repeated use. The secret? A spring inside each pin acts like a shock absorber. When you dock your smartwatch, the pins compress slightly instead of scraping against contacts – this gentle touch prevents the metal fatigue that kills ordinary connectors.

2. No More “Jiggling the Cable” Moments

Ever struggled to charge a device because the port’s alignment was slightly off? Pogo pins self-correct. Their floating design allows little positional drift, which matters when charging drones on uneven surfaces or industrial sensors vibrating on machinery.

3. Space Efficiency That Enables Innovation

Traditional charging ports force engineers to waste space on reinforced housings. Pogo pins work in tight spaces – think wireless earbud cases where 3 pins smaller than a sesame seed handle both charging and data sync. This compactness lets designers create sleeker devices.

4. The Real MVP: The Pogo Pin Connector Itself

Every benefit traces back to the pin’s mechanical intelligence. A stainless-steel plunger slides inside a brass sleeve, with a spring balancing contact pressure. Too stiff, and it damages device contacts; too loose, and power flickers. Precision-machined pins (think CNC tolerances tighter than a human hair) hit the Goldilocks zone – firm enough for reliability, forgiving enough for real-world use.

5. Weathering the Storm

Unlike open ports inviting dust bunnies, pogo pin contacts stay protected. When your fitness tracker’s charging dock gets splashed at the gym, the closed-pin design resists corrosion that would kill exposed copper pads.

This isn’t a lab-theory performance – it’s why leading manufacturers quietly switched to pogo pins for mission-critical applications. From hospital IV pumps needing sterile connections to construction tablets surviving job site abuse, the technology just works where others fail.

Applications of Pogo Pin Chargers

The true value of pogo-pin chargers lies in their ability to solve real-world problems across industries. Let’s explore how this technology quietly powers devices we interact with daily:

Everyday Gadgets Reinvented

Your smartphone might already use pogo pins without you realizing it. Many rugged phones and tablets designed for outdoor use or industrial workplaces hide their charging contacts behind protective flaps. Instead of fumbling with fragile USB ports in the rain or dust, users drop their devices onto magnetic docks. The spring-loaded pins push through dirt or moisture, ensuring reliable contact—ideal for field engineers or delivery drivers whose gear faces harsh conditions.

Wearables That Keep Up With You

Think about wireless earbuds charging overnight in their case. The tiny gold-plated pins inside the case’s charging slots are pogo pin connectors. Their compact size allows manufacturers to shrink charging compartments while maintaining fast charging speeds. For swimmers tracking laps with waterproof fitness trackers, these pins eliminate the need for exposed ports that could leak. Even medical alert pendants use them to enable seniors to charge devices without struggling with tiny cables.

On the Road and Beyond

Next time you rent an electric scooter, notice how its docking station powers up the battery. Pogo pins handle the constant plugging/unplugging without wearing out—a critical feature for shared mobility systems. In car repair shops, technicians use handheld diagnostic tools that snap onto charging cradles during breaks. The pins’ vibration resistance keeps connections stable even when engines rumble nearby.

Life-Saving Precision

Hospitals rely on pogo pin chargers for portable ultrasound machines and patient monitors. Unlike traditional plugs, these contacts can be fully sealed, allowing thorough disinfection with alcohol wipes—a non-negotiable requirement in sterile environments. During surgeries, instrument trays with embedded pogo pins recharge specialized tools between procedures, eliminating downtime.

Factories That Never Sleep

In automated warehouses, robots that sort packages often recharge during brief idle moments via floor-mounted pogo pin stations. The connectors withstand metal shavings, oil mist, and accidental impacts that would destroy ordinary ports. Even handheld barcode scanners used in freezing storage facilities benefit from pogo pins’ ability to maintain conductivity in sub-zero temperatures.

From the gym to the operating room, pogo pin chargers bridge the gap between convenience and durability. Their spring-loaded design isn’t just about charging—it’s about enabling technology to survive and thrive where traditional connectors fail.

How to Ensure the Quality of Pogo Pin Charger During Processing?

In the realm of compact electronic connectors, pogo pins represent a critical intersection of precision engineering and user safety. Their role in high-frequency charging applications demands a holistic quality management approach that integrates advanced manufacturing techniques with rigorous validation protocols. This systematic framework ensures each component not only meets dimensional specifications but also delivers reliable performance under real-world stress conditions.

1. Precision-Centric CNC Machining

The foundation of pogo pin quality lies in controlled subtractive manufacturing processes. Brass, known for its balanced conductivity and machinability, requires temperature-stabilized CNC environments to maintain great tolerance thresholds. Operators implement adaptive toolpath compensation to counteract material thermal expansion during high-speed CNC turning – a technique proven to reduce post-machining dimensional drift compared to conventional methods.

Key operational safeguards include:

• Tool Lifecycle Management: Diamond-coated cutters undergo scheduled replacements based on real-time wear analytics, preventing surface micro-scratches that compromise contact integrity

• Surface Finish Optimization: Non-contact polishing systems achieve mirror-grade finishes, crucial for minimizing signal loss at contact interfaces

• Operator Certification: Machinists complete brass-specific training modules covering anti-static handling and humidity-controlled storage protocols

2. Surface Engineering for Enhanced Durability

Post-machining treatments transform mechanical components into robust electrical interfaces. A typical dual-layer plating sequence combines nickel’s barrier properties with gold’s oxidation resistance, requiring nano-scale process control:

• Plating Bath Chemistry: Automated dosing is used in plating bath chemistry to maintain nickel sulfamate solutions at a specific temperature and pH level, which are crucial parameters for achieving a certain – thickness adhesion layer.

• Contamination Control: Class 1000 cleanrooms with HEPA filtration reduce particulate contamination.

• Thickness Verification: In-line eddy current sensors reject pins with gold deposits <0.75µm, a threshold ensuring 10,000+ mating cycle stability

3. Multi-Dimensional Performance Validation

Three-phase testing bridges laboratory conditions with operational realities:

A. Geometric Compliance

• Optical comparators resolution verifies plunger concentricity

• Automated CMM stations audit spring preload dimensions

B. Electrical Integrity

• Dynamic contact resistance (DCR) profiling loads identify micro-arcing risks

• HiPot testing confirms dielectric stability between adjacent pins

C. Accelerated Life Simulation

• Thermal shock cycling exposes solder joint fatigue vulnerabilities

4. Closed-Loop Quality Improvement

All test data feeds machine learning models that predict tool wear patterns and plating bath degradation. This predictive maintenance approach has been demonstrated.

By synergizing precision manufacturing, surface science, and data-driven validation, this framework achieves low DPPM in pogo pin production. It exemplifies how modern quality systems transform empirical craftsmanship into repeatable engineering excellence – a prerequisite for connectors powering next-generation IoT and medical devices.

Customizing Pogo Pins for Precision Applications

While pogo pins serve as the backbone of modern connectivity solutions, their effectiveness hinges on precise customization to match specific use cases. This is where specialized manufacturers streamline the process for engineers and designers.

Take Fecision’s online platform as an example. Engineers can specify critical parameters through an intuitive interface:

- Mechanical Requirements: Adjust pin length, plunger head geometry (flat, domed, or slotted), and spring force (light-touch medical probes vs. high-pressure industrial contacts)

- Material Selection: Choose brass for cost efficiency or stainless steel for corrosive environments, with optional nickel/gold plating for signal integrity

- Environmental Resilience: Request IP68-rated seals for underwater robotics or high-temperature coatings for engine sensors

The platform’s real-time simulation tool flags potential conflicts – like spring tension mismatches with housing thickness – before prototyping. This prevents costly redesigns, particularly for complex arrays in multi-pin connectors.

Behind the scenes, automated CNC workflows translate these specs into physical components within 72 hours for prototypes. What sets such services apart isn’t just speed, but traceability: each batch ships with material certifications and test reports validating current load capacity and insertion cycle performance.

For startups developing compact IoT devices or medical OEMs upgrading diagnostic tools, this tailored approach bridges the gap between off-the-shelf limitations and bespoke solutions – without traditional tooling fees or MOQ constraints.

If you want to learn more about the spring needle charger and explore how to use this advanced technology to improve the performance of your pogo pin solutions, welcome to Fecision. Here, you will unlock more about the possibility of precision connection and open a new journey of intelligent charging.

From Prototype to Production: Custom Pogo Pin Solutions That Deliver→