Stamping dies are essential tools used in metalworking to cut, shape, and form materials, primarily metals, into desired shapes and sizes. They play a crucial role in various industries, from automotive to electronics. Understanding how stamping dies are made involves delving into the design, fabrication, and assembly process while considering cost, material selection, and applications. This comprehensive guide will explore the basics of stamping die, the manufacturing process, cost considerations, comparisons with other metal forming methods, and key considerations when choosing the right die for a specific application.

1. Basics of Stamping Dies

Stamping dies are specialized tools used in stamping presses to shape or cut material, typically sheet metal, into specific forms. The primary purpose of a stamping die is to perform high-volume, precise, and cost-effective metal forming operations. These dies are designed to create various metal parts, such as automotive body panels, electronic components, and industrial machinery parts. The stamping process involves placing a metal sheet between a die and a punch, and then applying force to the sheet. The force shapes or cuts the material into the required configuration, which is used for assembly or other production purposes.

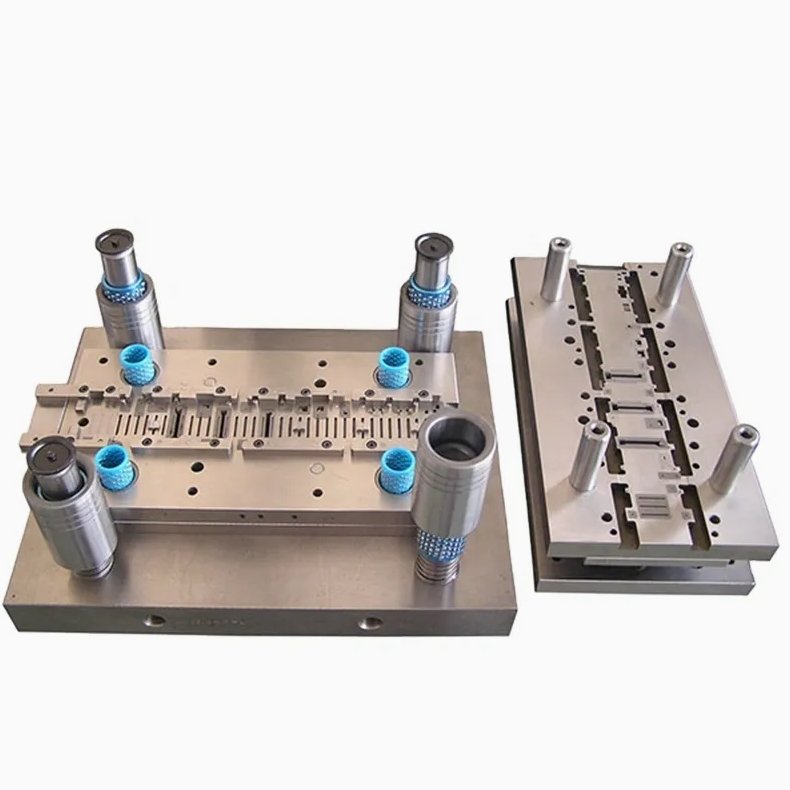

Components of a Stamping Die

A stamping die consists of several key components:

- Punch: The punch is the male part of the die that pushes through the material to shape or cut it.

- Die Block: The die block holds the components together and provides the support structure for the operation.

- Die Insert: The insert, which often consists of hard materials and houses the punch, can be interchangeable depending on the design needs.

- Stripper: The stripper plate is used to remove the stamped part from the die, ensuring it does not stick to the punch after the operation.

- Guide Pins and Bushings: These ensure the punch and die remain aligned during the stamping process, contributing to precision and accuracy.

Types of Stamping Dies

There are various types of stamping dies; each is designed for different applications and production needs. The main types include:

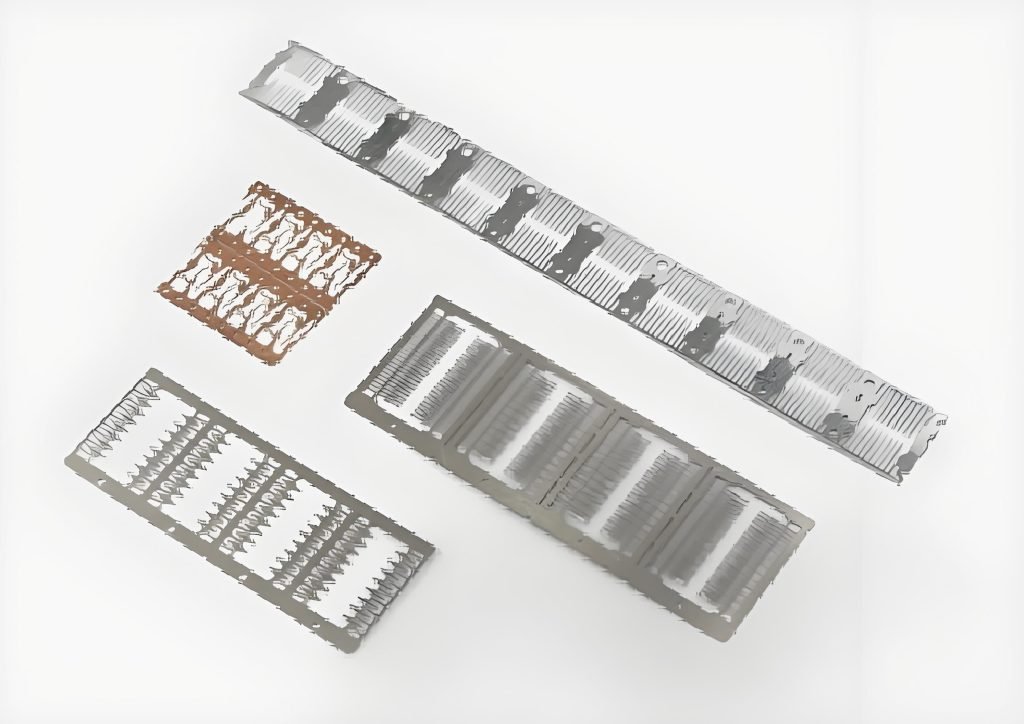

Progressive Dies

Progressive dies are used in high-volume production where multiple operations, such as cutting, punching, and bending, occur in a single cycle. The material moves through the die in stages, with each stage performing a different operation. Progressive dies are ideal for efficiently manufacturing small parts.

Compound Dies

Compound dies are designed to perform more than one operation simultaneously, usually cutting and shaping. Unlike progressive dies, compound dies handle all the operations in a single press stroke. These dies are commonly used for simpler, high-quantity parts.

Transfer Dies

Transfer dies are used when parts within the die need to be transferred from one station to another. This type of die is often used for more complex operations and parts that require multiple stages but cannot be produced with a progressive die.

Applications of Stamping Dies

Stamping dies are used in various industries due to their versatility, precision, and cost-efficiency. The following are some of the key industries that rely on stamping dies:

Automotive Industry

In the automotive industry, stamping dies are used to manufacture a wide range of parts, from body panels to structural components. These dies help in creating high-quality, durable parts required for vehicle assembly, such as door panels, hoods, and fenders.

Aerospace and Electronics

In aerospace, stamping dies produce lightweight yet strong parts used in aircraft, such as brackets, frames, and structural components. Similarly, in the electronics industry, stamping dies create small, precise components for circuit boards and electronic devices.

Consumer Goods Manufacturing

Stamping dies are also used in the production of consumer goods, such as home appliances, hardware, and packaging. They enable high-volume production of durable and intricate parts for everyday items like refrigerators, washing machines, and cans.

2. Stamping Die Manufacturing Process

Creating a stamping die is a multi-step process that requires careful planning, precision, and expertise. This section will outline the steps involved in designing, fabricating, and assembling a stamping die.

Designing a Stamping Die

CAD/CAM Software for Die Design

The first step in creating a stamping die is designing the die itself. Modern die design relies heavily on Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software. These tools allow designers to create precise 3D models of the die components, optimizing the design for functionality and manufacturability. CAD software lets designers visualize the die components, including the punch, die block, stripper plate, and other elements. CAM software is then used to generate machine instructions for fabrication.

Material Selection for Die Construction

Selecting the right material for the die is critical for ensuring its performance, durability, and cost-effectiveness. The most common materials used in die construction are tool steels, which are selected based on factors such as strength, hardness, wear resistance, and machinability. Popular tool steels for stamping dies include:

- D2 Tool Steel: Known for its excellent wear resistance, making it ideal for heavy-duty dies.

- A2 Tool Steel: Provides a good balance of toughness and wear resistance.

- P20 Steel: Often used for molds and dies due to its ease of machining.

Other materials, such as high-speed steel (HSS) and carbide, may also be used depending on the specific requirements of the die and the material being stamped.

Die Fabrication Techniques

CNC Machining for Die Manufacturing

Computer Numerical Control (CNC) machining is the most common technique used to manufacture stamping dies. CNC machines allow for high precision and repeatability in cutting and shaping die components. Milling, turning, and drilling operations are typically used to create intricate features in die blocks and inserts. The CNC process is often used to machine the die cavities, guide pin holes, and other key features that need to be precisely crafted. With CNC machining, manufacturers can produce dies with tight tolerances, ensuring that each die part fits together perfectly.

Wire EDM and Laser Cutting for Precision Parts

For highly detailed and precise components, Wire Electrical Discharge Machining (Wire EDM) and laser cutting are often used. Wire EDM is especially effective for cutting complex shapes and fine details in hardened materials, which is essential for stamping dies that require high precision. Laser cutting, on the other hand, uses a focused laser beam to cut or engrave metal parts. It offers superior accuracy and can be used to produce intricate die components without the need for expensive tooling.

Die Assembly and Finishing

Heat Treatment and Coating

Once the die components are fabricated, they must undergo heat treatment to improve their hardness, wear resistance, and overall performance. Heat treatment processes such as quenching and tempering are commonly used to achieve the desired hardness and toughness of the die steel. In addition, many stamping dies are coated with materials such as nitriding or chrome plating to enhance their durability and resistance to wear and corrosion.

Die Testing and Quality Control

Before a stamping die is put into production, it must undergo rigorous testing to ensure it functions as designed. This includes checking for proper fit and alignment, as well as performing trial runs to evaluate the die’s performance under actual operating conditions.

Quality control processes, including dimensional checks, visual inspections, and functionality tests, are used to verify that the die meets the required specifications and will perform reliably in production.

3. Cost Considerations in Stamping Die Manufacturing

The cost of manufacturing a stamping die can vary greatly depending on several factors, such as the complexity of the design, the materials used, and the labor required. Below are the key factors that influence the cost of stamping die manufacturing:

Factors Affecting Cost (Material, Complexity, Labor)

- Material Costs: High-quality tool steels and other materials required for die fabrication can significantly impact the overall cost. Additionally, the amount of material needed to produce the die affects the cost.

- Design Complexity: The more intricate the design, the higher the cost. Complex dies with multiple stages or sophisticated features require additional time and resources to manufacture.

- Labor Costs: Skilled labor is necessary for die design, machining, assembly, and testing. Labor costs are a key factor in determining the overall cost of die production.

Cost Comparison: Single vs. Progressive Dies

- Single Dies: These dies are simpler and are typically less expensive to manufacture. However, they are generally limited to making simple parts in low to moderate quantities.

- Progressive Dies: While progressive dies are more expensive to design and manufacture due to their complexity and multi-stage operation, they provide significant cost savings in high-volume production. They can produce parts quickly and with high precision.

4. Stamping Dies vs. Other Metal Forming Methods

Stamping dies offer several advantages over other metal forming methods, such as casting and forging. Here’s a comparison:

Differences from Casting and Forging

- Casting involves pouring molten metal into a mold to create parts, while forging involves shaping metal by applying compressive forces. Stamping, on the other hand, uses dies to cut, shape, or form material using high-pressure presses.

- Cost and Efficiency: Stamping dies are generally more cost-effective for high-volume production, while casting and forging may be more suitable for larger, more complex parts or materials that require specific properties.

Cost and Production Efficiency Comparisons

Stamping dies offer faster production times, lower material wastage, and high precision in comparison to casting and forging. The ability to produce parts in high volumes makes stamping dies the preferred choice for mass production, particularly in industries like automotive manufacturing.

5. FAQ’s

Here are five frequently asked questions (FAQs) about stamping dies:

What is the primary purpose of a stamping die?

The primary purpose of a stamping die is to shape, cut, or form metal sheets into specific shapes or sizes using high-pressure presses. It is an essential tool for producing precise, high-volume metal parts, commonly used in industries like automotive, aerospace, electronics, and consumer goods manufacturing.

What are the main types of stamping dies?

The three main types of stamping dies are:

- Progressive Dies: These perform multiple operations in a sequence as the material moves through the die.

- Compound Dies: These handle multiple operations in a single press stroke.

- Transfer Dies: Used when parts need to be moved between different stages within the die for more complex operations.

How is a stamping die designed and fabricated?

Stamping die design begins with CAD/CAM software to create a 3D model of the die components. Material selection, typically tool steels like D2, A2, or P20, is crucial for durability. The die is then fabricated using precision methods such as CNC machining, wire EDM, and laser cutting to ensure accuracy. After fabrication, the die undergoes heat treatment and coating to improve performance.

What factors affect the cost of manufacturing stamping dies?

The cost of manufacturing a stamping die depends on factors such as the complexity of the die design, the material used, the labor required, and the required production volume. Progressive dies are more expensive to design and manufacture but are more cost-effective for high-volume production. Material costs and labor expenses also significantly impact the overall cost.

How do stamping dies compare to other metal forming methods like casting and forging?

Stamping dies are more cost-effective for high-volume production and provide greater precision and faster production times compared to casting and forging. While casting involves pouring molten metal into a mold and forging shapes with compressive forces, stamping dies are ideal for making intricate, high-precision parts with minimal material wastage, especially in industries like automotive manufacturing.

6. Conclusion

The process of creating stamping dies is a complex, multi-step procedure that includes designing, fabricating, and assembling the die components. Modern CAD/CAM software plays a crucial role in designing the die, while CNC machining, wire EDM, and laser cutting are essential for precise fabrication. Heat treatment and coating further enhance the die’s performance, and rigorous testing ensures its functionality in production. When choosing the right stamping die, factors such as material selection, design complexity, required production volume, and cost must all be considered.