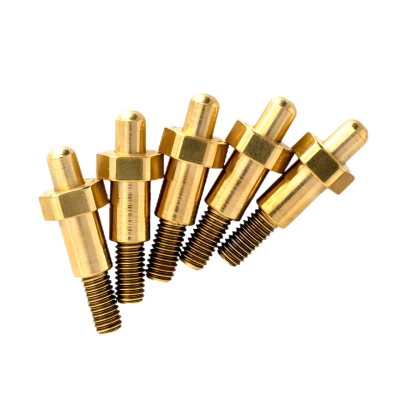

Threaded Pogo Pin

Why

Fecision?

Precision At Fecision

Precision Pogo Pins: CNC-Machined, Gold-Plated, Customizable

As a leading CNC machining and mold manufacturing service provider, we deliver tailored pogo pin solutions using advanced materials, surface finishes, and manufacturing techniques.

Rapid Prototyping

CNC + mold manufacturing in 7 days

End-to-End Testing

Validated for resistance, cycle life, and ESD resistance

Customizable

Tailored dimensions, plating, and materials for your application

Modular Design

Replace bulky soldered joints with compact, reusable solutions

Industry-Leading Durability

Engineered for 50K–100K+ cycles

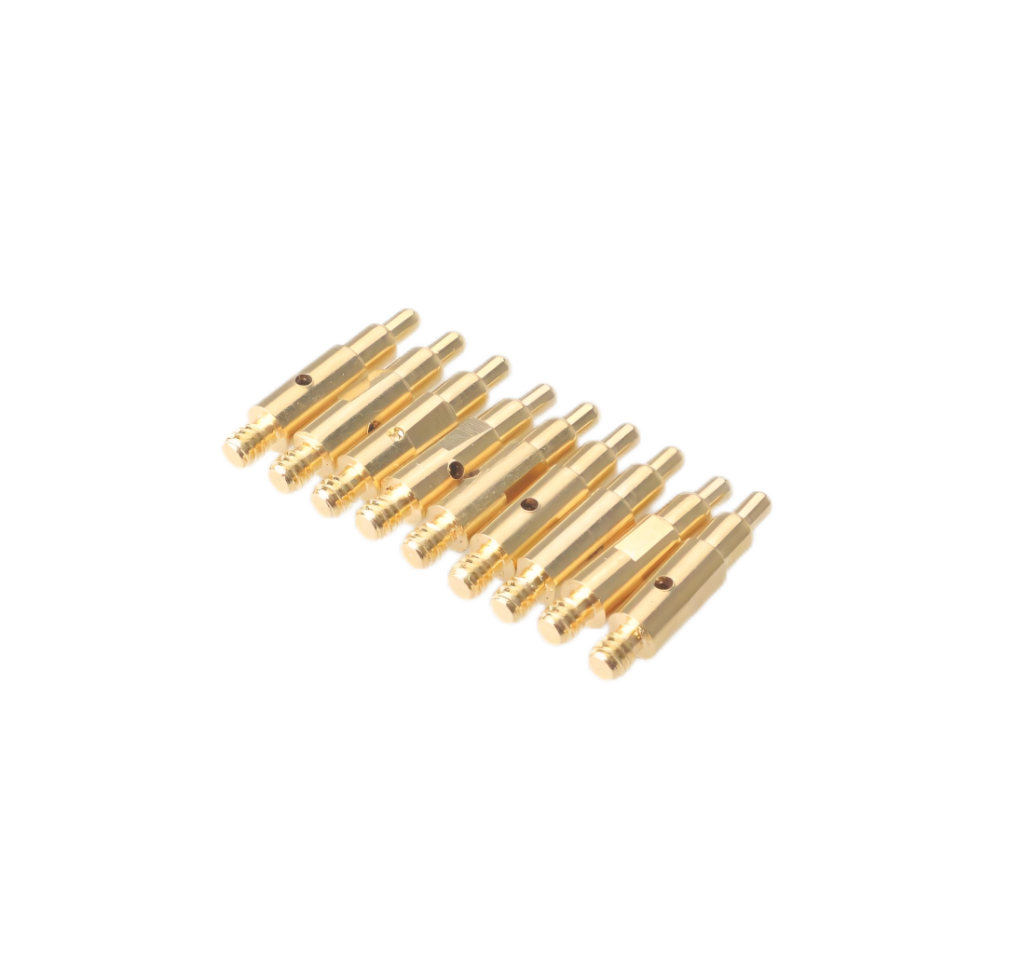

Threaded Pogo Pins - Engineered for Stability

- Threaded Design: M3, M4, or custom threads for panel mounting or fixture integration.

- Material Durability: Gold/nickel-plated contacts with stainless steel threads.

Why Choose Threaded Pogo Pins?

Technical Specification Table

| Parameter | Specifications |

Threaded Size | M2, M3, M4, or Custom |

Plunger Travel | 0.5–3.0mm |

| Operating Temp | -40°C to +125°C |

| Contact Resistance | <20mΩ (Initial) |

Current Rating | 1A–30A (Continuous) |

| Material | BeCu Spring, SS316 Threads, Gold/Nickel Plating |

| Certifications | ISO 9001, IATF 16949, UL, MIL-STD-202H |

Types of Threaded Pogo Pins

Panel-Mount Threaded Pins

Applications: Industrial control panels, EV charging stations

High-Current Threaded Probes

Applications: Motor controllers, battery pack validation

Miniature Threaded Pins

Applications: Semiconductor testing, portable diagnostic tools

IP67 Sealed Threaded Pins

Applications: Marine electronics, agricultural machinery

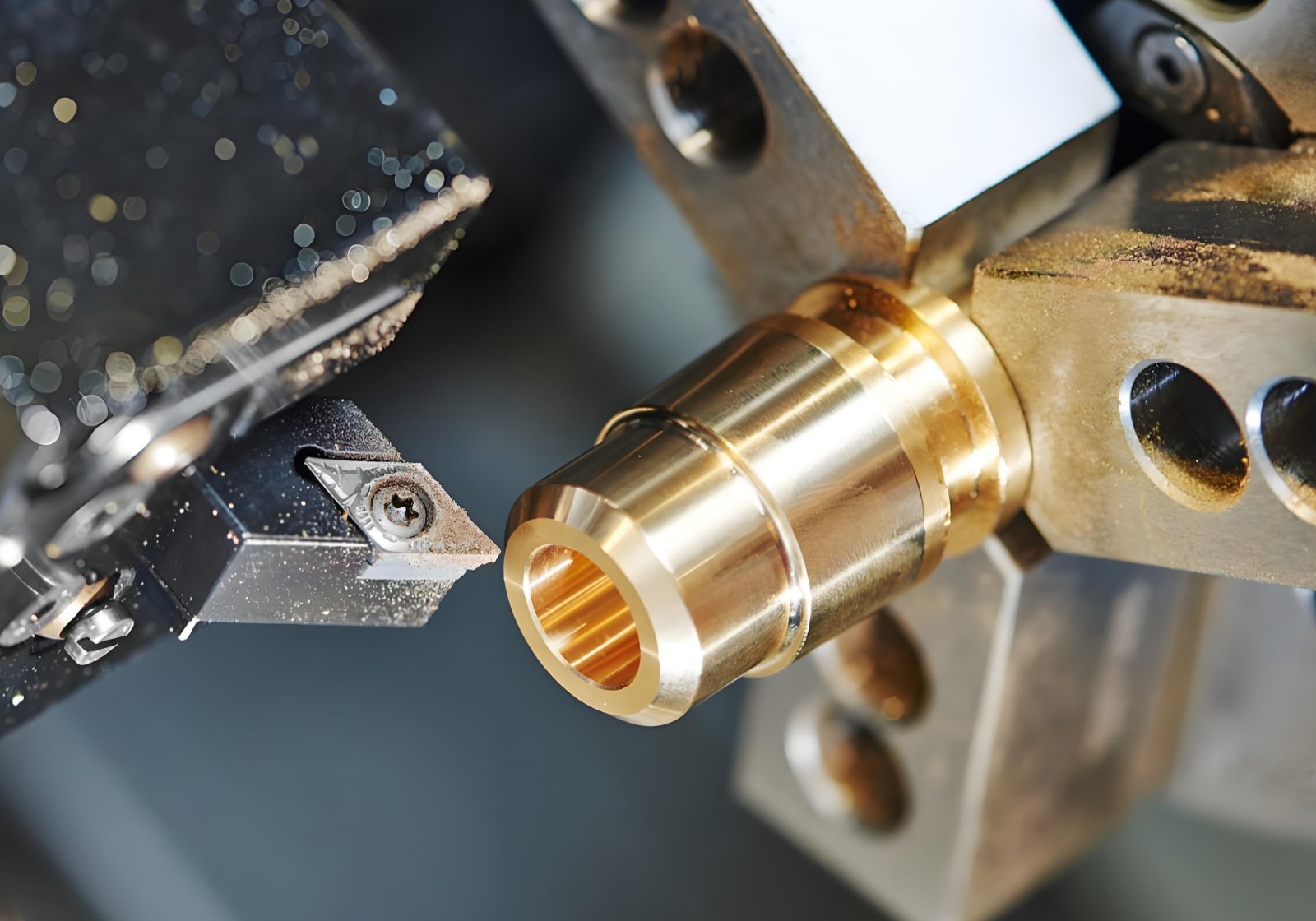

Manufacturing Processes

Pin Body Machining

- Precision turning to shape the pin body

- Thread-cutting tools to form threads

Spring Integration

- Stress-Relieved & Wire Forming

- Heat Treatment

Surface Treatment

-

Electroless Nickel Underplate (5μm)

-

Selective Gold Deposition (15μm)

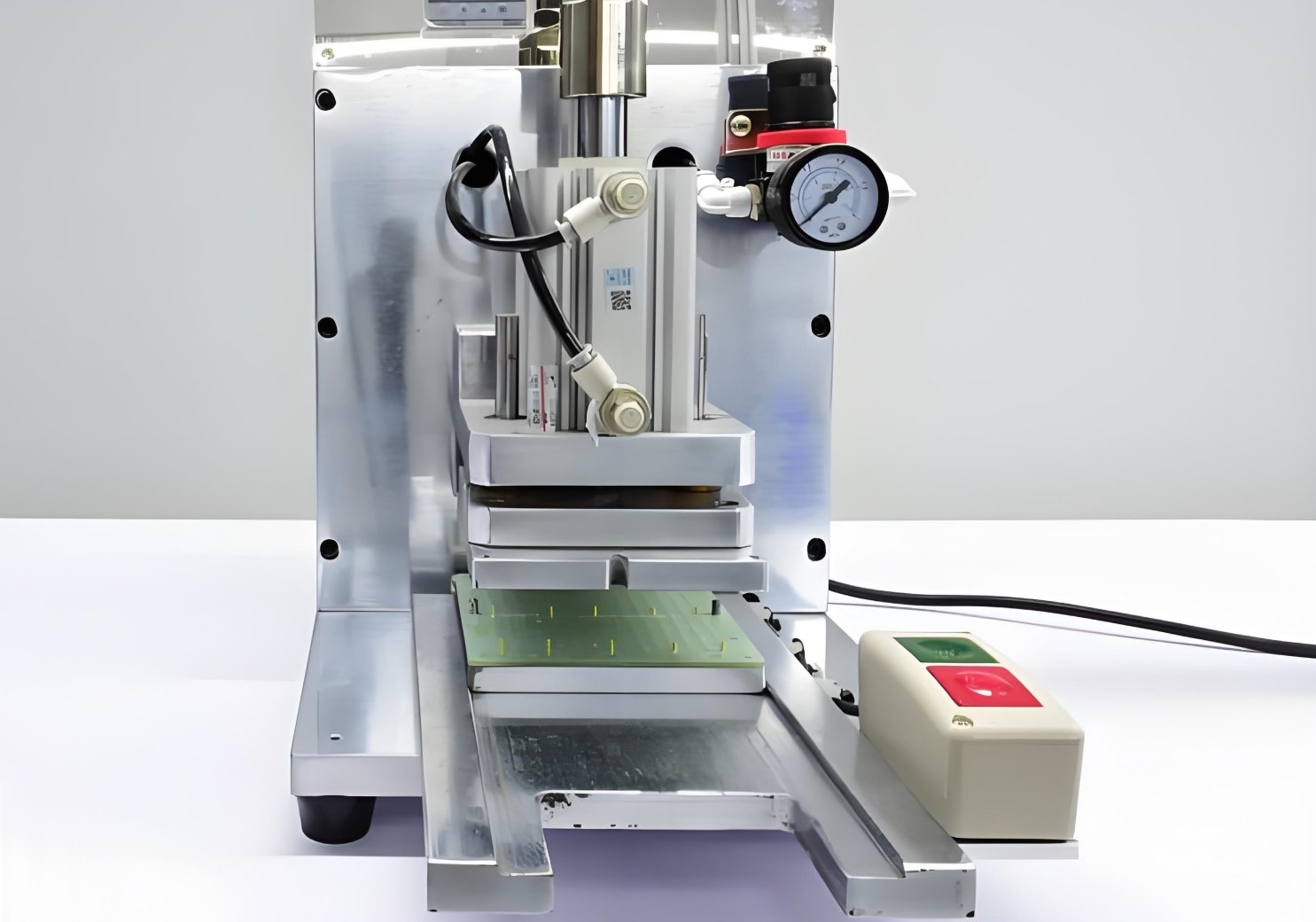

Quality Inspection

- Dimensional Inspection

- Electrical Performance Testing

- Elasticity Testing

Applications & Industries

Automotive Testing

Aerospace Systems

Industrial Robotics

Energy Infrastructure

Start your project now

Workflow

Customization Process

Share your thermal requirements, size constraints, and environmental conditions.

We provide 3D CAD models and thermal analysis reports.

Test functional prototypes for performance validation.

Seamless transition to full-scale manufacturing.

Trusted for Mission-Critical Systems

Certifications & Quality Assurance

ISO 9001:2015 & IATF 16949

RoHS/REACH Compliance

IP67 (IEC 60529)

MIL-STD-202H & UL 1977

Request a Proposal

Let us bring your vision to life.

Share your project details, and we’ll craft a tailored proposal just for you.