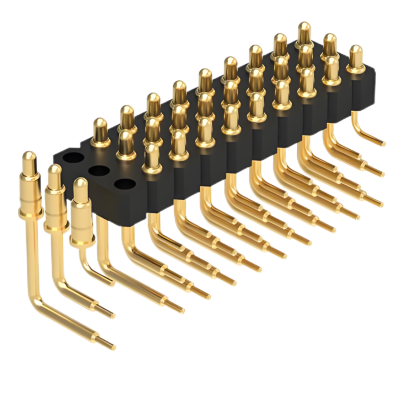

Right Angle Pogo Pins

✓ 10,000–100,000+ Mating Cycles

✓ Gold/Nickel-Plated Contacts for Low Resistance (<30mΩ)

✓ Current Ratings from 0.5A to 5A+

✓ ISO 9001 & RoHS Certified

Why

Fecision?

Precision At Fecision

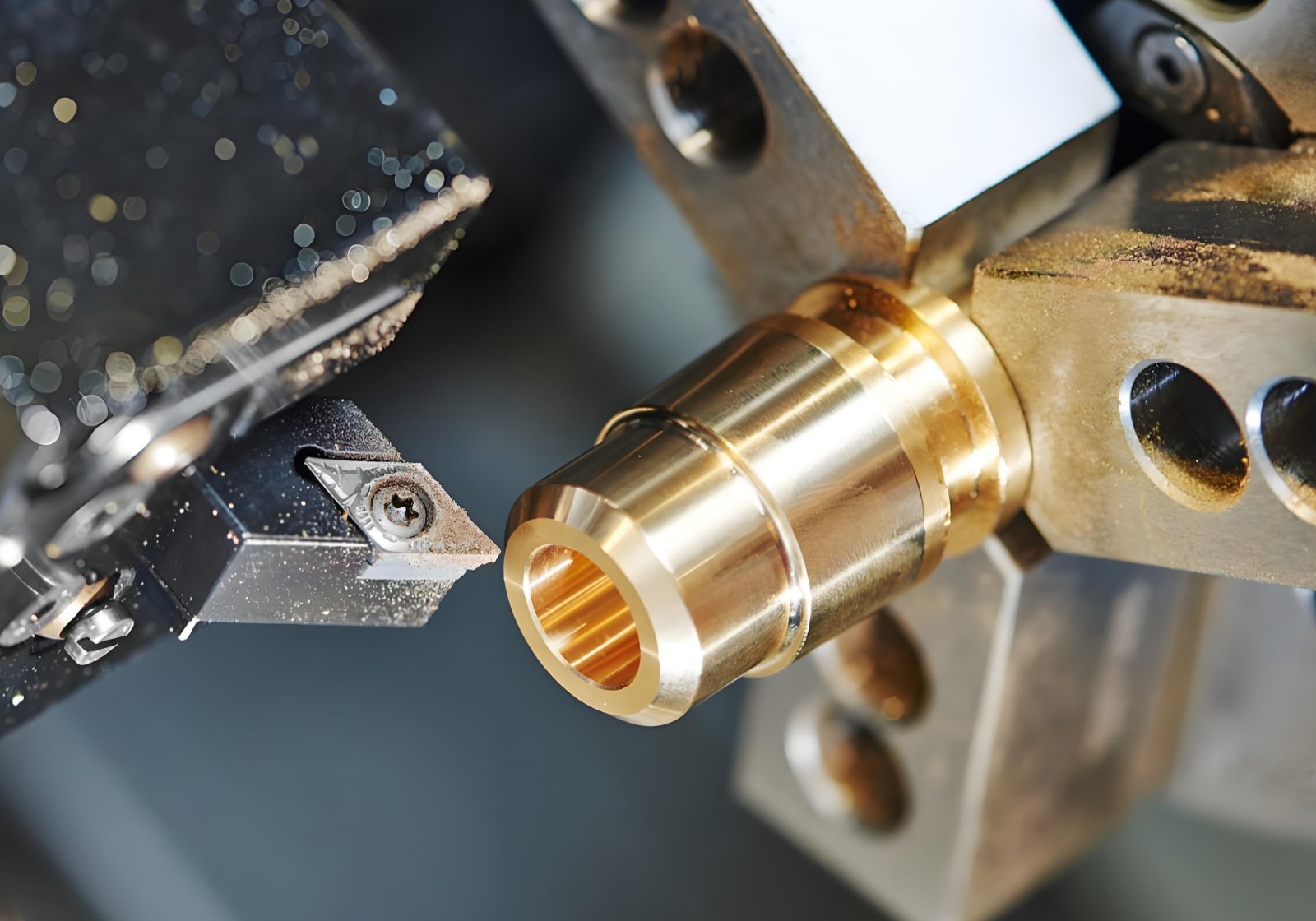

Precision Pogo Pins: CNC-Machined, Gold-Plated, Customizable

As a leading CNC machining and mold manufacturing service provider, we deliver tailored pogo pin solutions using advanced materials, surface finishes, and manufacturing techniques.

Rapid Prototyping

CNC + mold manufacturing in 7 days

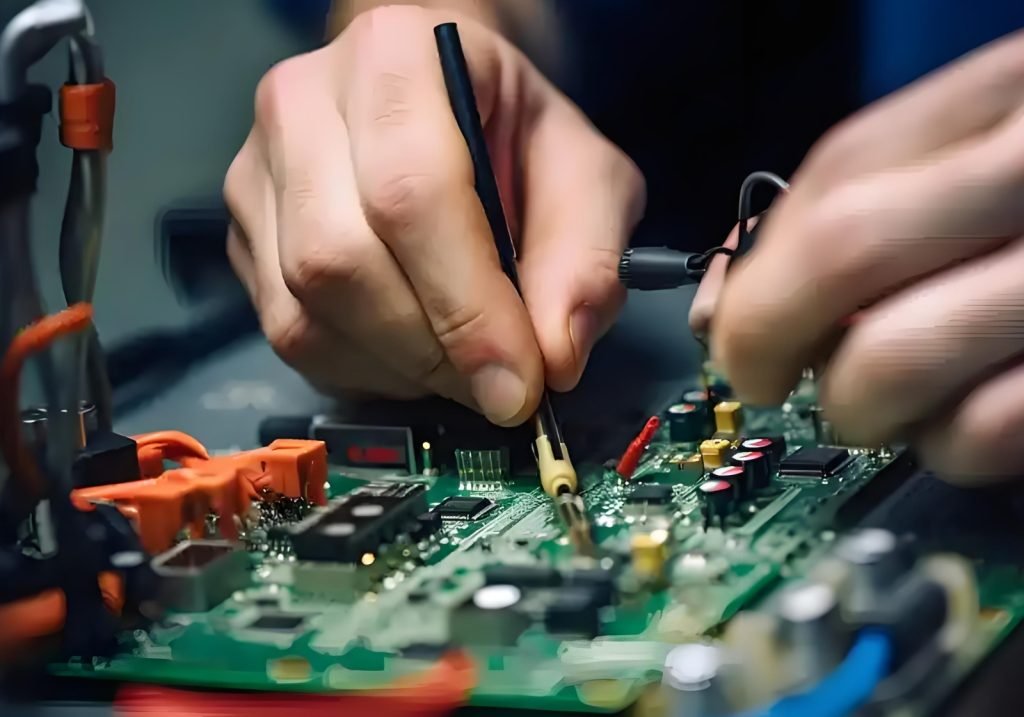

End-to-End Testing

Validated for resistance, cycle life, and ESD resistance

Customizable

Tailored dimensions, plating, and materials for your application

Modular Design

Replace bulky soldered joints with compact, reusable solutions

Industry-Leading Durability

Engineered for 50K–100K+ cycles

Compact 90° Spring Probes for Space-Saving Designs

Right angle pogo pins are spring-loaded connectors with a 90° bend, designed to enable electrical connections in tight or complex PCB layouts. They are ideal for applications requiring space optimization, such as wearable devices, modular electronics, and test fixtures.

Our Design ensures precise 90° alignment and consistent contact force, validated in MIL-STD-202H vibration tests.

- 90° Design: Saves space and allows flexible routing in compact devices.

- Material Excellence: Beryllium copper springs with gold/nickel plating for corrosion resistance.

Why Choose Right Angle Pogo Pins?

Technical Specification Table

| Parameter | Specifications |

Contact Material | Beryllium Copper Spring, Gold/Nickel Plating |

Plunger Travel | 0.5–3.0mm |

| Height Profile | 2.5mm-15mm |

| Contact Resistance | <30mΩ (Initial) |

Current Rating | 0.5–5A (Customizable up to 15A) |

| Operating Temp | -55°C to +150°C |

| Certifications | ISO 9001, RoHS, UL, IPC-A-610 |

Types of Right Angle Pogo Pins

Precision Solutions for Compact Designs

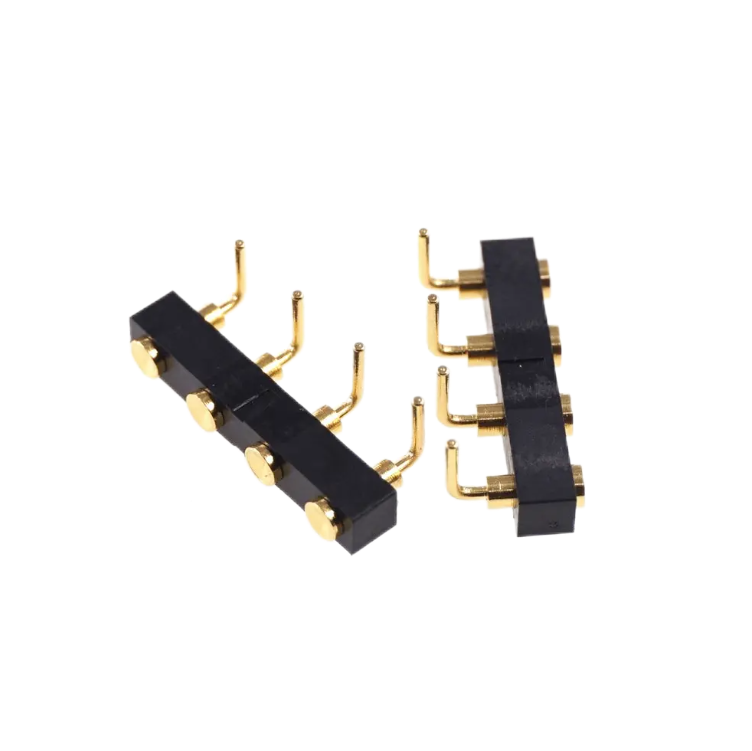

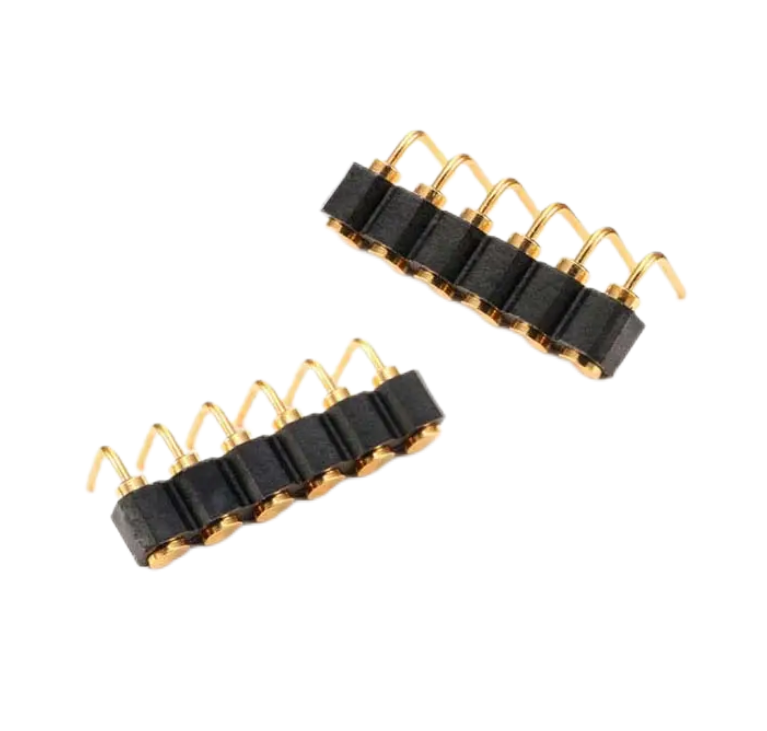

Low-Profile Right Angle Pins

Ultra-compact designs for wearable devices and IoT sensors.

Applications: Smartwatches, fitness trackers

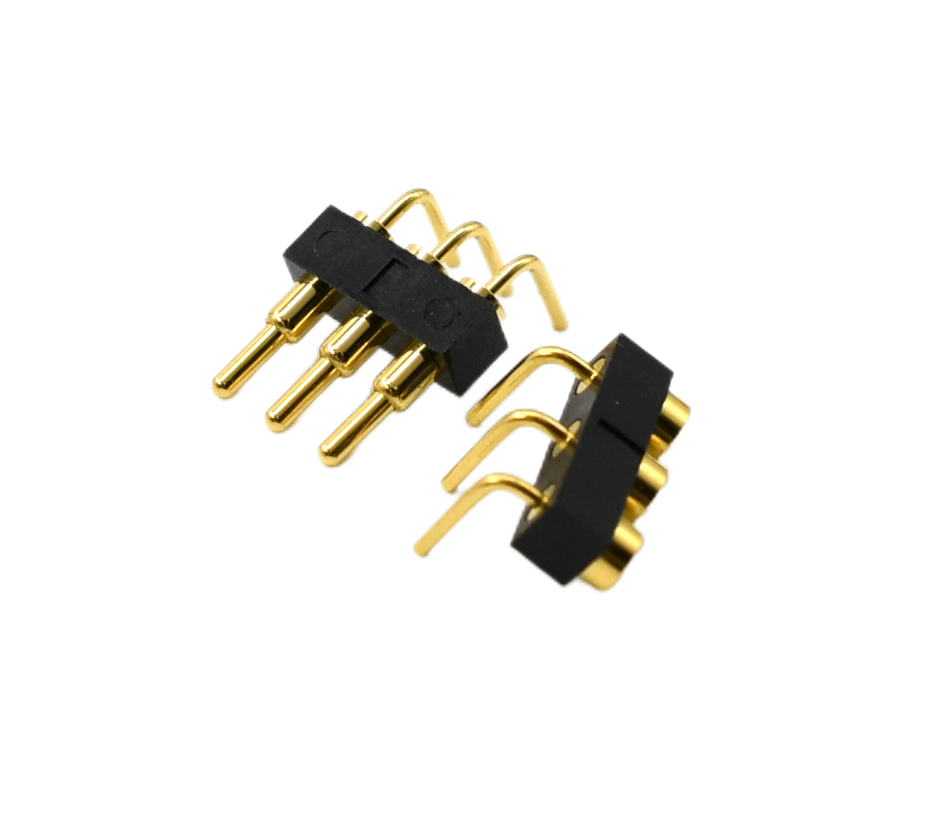

High-Current Right Angle Pins

5A+ rated pins for charging and power transfer in tight spaces.

Applications: Drones, portable medical devices

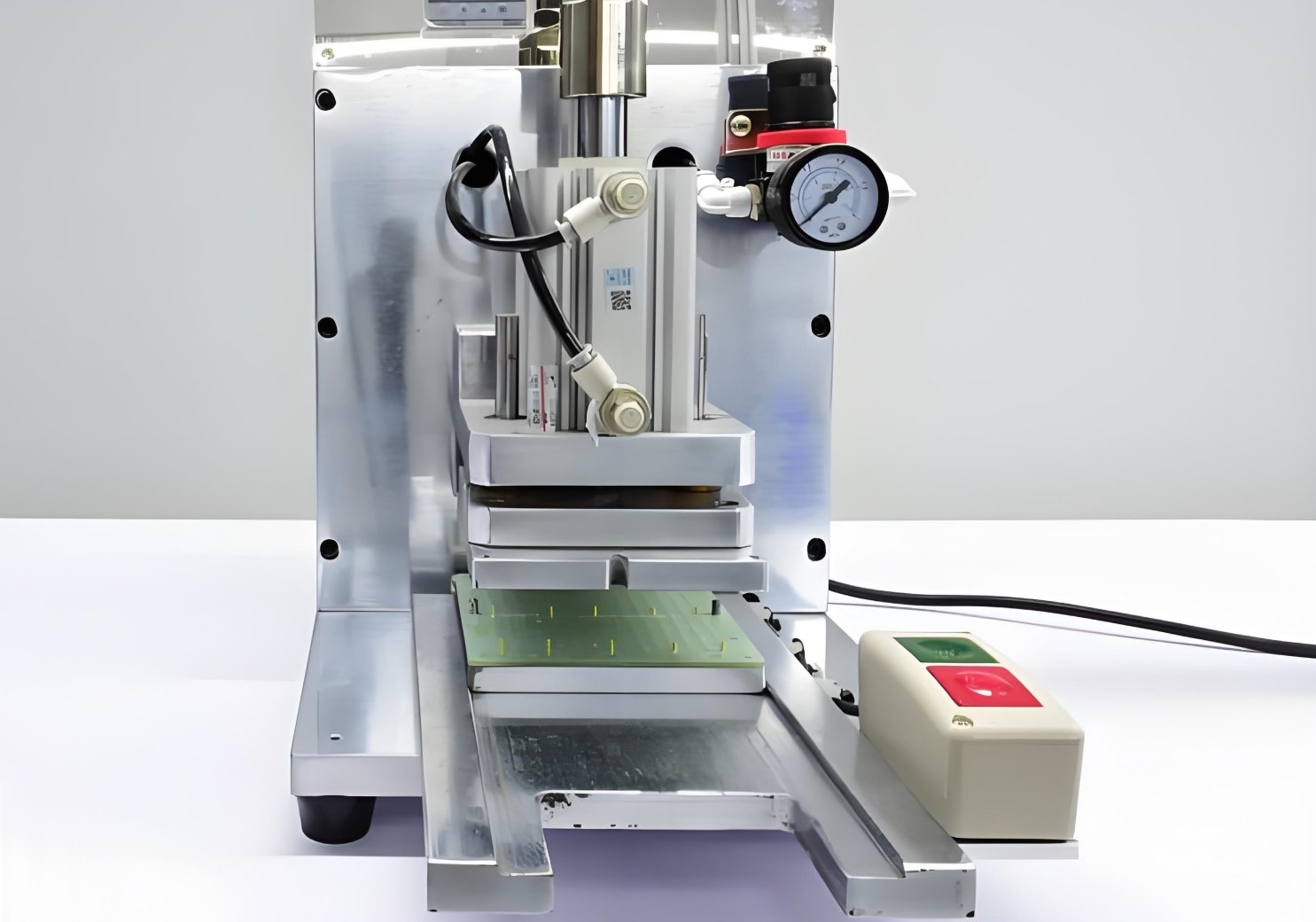

Test & Measurement Probes

90° pins for automated PCB testing (ICT/FCT) in compact fixtures.

Applications: PCB validation, semiconductor testing

Modular Connectors

Self-aligning 90° pins for modular electronics and robotics.

Applications: Modular IoT systems, robotic arms

Manufacturing Processes

Precision Machining

- Brass/Stainless Steel Housing: ±0.005mm Tolerance

Angle Fabrication

-

Laser Micro-Welding for 90° Joints

-

Robotic 3-Point Angle Verification

Surface Engineering

-

Multi-Stage Electrocleaning Process

-

Pulse Reverse Gold Plating

-

Post-Plate Baking

Quality Validation

-

100% Contact Resistance Test

-

Angular Force-Deflection Curve Analysis

-

Thermal Cycling

Applications & Industries

Right Angle Pogo Pins in Action

PCB Testing

Wearable Devices

Industrial Automation

Consumer Electronics

Start your project now

Submit your specs for a free right angle pogo pin design review and quote within 24 hours!

Workflow

Customization Process

Share your thermal requirements, size constraints, and environmental conditions.

We provide 3D CAD models and thermal analysis reports.

Test functional prototypes for performance validation.

Seamless transition to full-scale manufacturing.

Trusted for High-Reliability Systems

Certifications & Quality Assurance

ISO 9001:2015 & IATF 16949

RoHS/REACH Compliance

UL 1977 & IPC-A-610 Class 3

Request a Proposal

Let us bring your vision to life.

Share your project details, and we’ll craft a tailored proposal just for you.