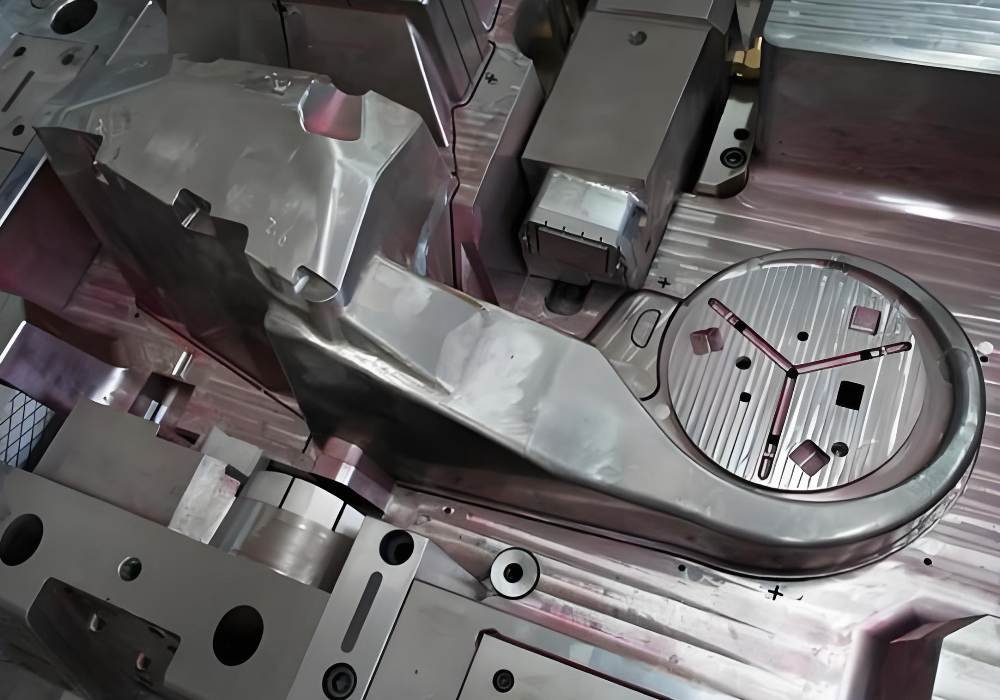

Injection mold tooling is the process of designing and manufacturing molds used to produce plastic components in the injection molding process. These molds define the shape, dimensions, and surface quality of the final products. A well-designed mold ensures efficiency, durability, and high precision in mass production. Injection mold tooling is widely used in industries such as automotive, medical, and packaging due to its ability to produce consistent and high-quality plastic parts.

Introduction to Injection Mold Tooling

Injection mold tooling involves the creation of custom-designed molds that shape molten plastic into final parts. The tooling process includes material selection, mold cavity design, runner systems, cooling channels, and ejector mechanisms. A properly manufactured mold ensures optimal production efficiency and minimizes defects.

Basic Structure of an Injection Mold

The basic structure of an injection mold contains important elements whose functions play a critical role in product shaping.

Mold Cavity: Molten plastic enters and takes form in the cavity space which serves as the hollow manufacturing area. The mold cavity sets both the dimensions of the product and the way it looks externally and its surface texture.

Core and Cavity Plates: The plates known as core and cavity plates compose the inside along with outside boundaries of molded shapes. Their main purpose is to maintain product accuracy and keep the structure strong.

Runner System: The runner system runs molten plastic through channels until it reaches the mold cavity. This system maintains uniform material spread throughout the mold.

Sprue: The main pathway for molten plastic to reach the runner system operates under the name of sprue. A mold cavity depends on this point as its main access through which plastic materials enter.

Gates: Gates work as narrow entrances which manage the movement of molten plastic into the cavity area. Each channel within the system helps to control pressure and maintains ideal filling during production.

Cooling System: The cooling system contains channels filled with coolant which fastens plastic solidification after the injection process. Working cooling systems stop defects during manufacturing while enhancing production speed.

Ejector System: The ejector system uses ejector pins or ejector plates to remove finished products from mold cavities.The exit method enables parts to release easily without sustaining any harm.

All components play a crucial role in ensuring accurate production together with operational efficiency and high product quality during injection molding operations.

Types of Injection Molds

Single-Cavity Mold: Using a single-cavity mold results in generating a single piece of product throughout each cycle. For small production needs and prototype development this tool offers benefits because it needs less initial equipment funding and modifications are simpler to perform. The single-cavity mold operates at a slower output speed than its counterpart with multiple cavity features.

Muti-Cavity Mold: The production efficiency and reduced manufacturing expenses of a multi-cavity mold become possible because it creates numerous identical items during each operating cycle. Manufacturers choose this method when they need quick procedures alongside consistent outcomes during high-volume operations.

Family Mold: Different product parts get manufactured through the single family mold process. The production of several product components simultaneously becomes more efficient through family molds because they merge manufacturing expenses and maintain uniformity. The process of distributing material between multiple cavities remains difficult to manage.

Two-Shot Mold: By combining two-shot molds manufacturers can process materials of different kinds in a single molding operation. This process serves various multi-material and multi-color plastic parts to enhance functionality with better aesthetics and simplified assembly needs.

Hot Runner Mold: The hot runner mold maintains melted plastic materials inside its system to prevent runners from solidifying. The hot runner technology reduces waste material while speeding up the production cycles so large-scale manufacturing becomes more efficient. The superior heating technology of this system increases its manufacturing cost.

Cold Runner Mold: The cold runner mold incorporates a cooling mechanism that makes plastic solid before product removal. A cold runner mold provides a less expensive and straightforward solution than its hot runner alternative at the cost of additional material waste that requires removal and typically ends up in disposal or recycling.

Companies choose distinct injection mold types depending on their manufacturing requirements including product complexity and material usage and production numbers to achieve best results for specific applications.

Key Design Considerations for Injection Molds

Multiple essential factors need attention throughout the injection mold design process.

- Select a material which meets the requirements of your application.

- The mold needs uniform wall thickness to permit consistent cooling of the material.

- Draft Angles should be implemented to facilitate the extraction of parts from the mold.

- Gates should be arranged for optimal material flow.

- The efficiency improves through appropriate cooling channel designs in the system.

- The design must focus on surface finishes since they influence both texture and appearance requirements.

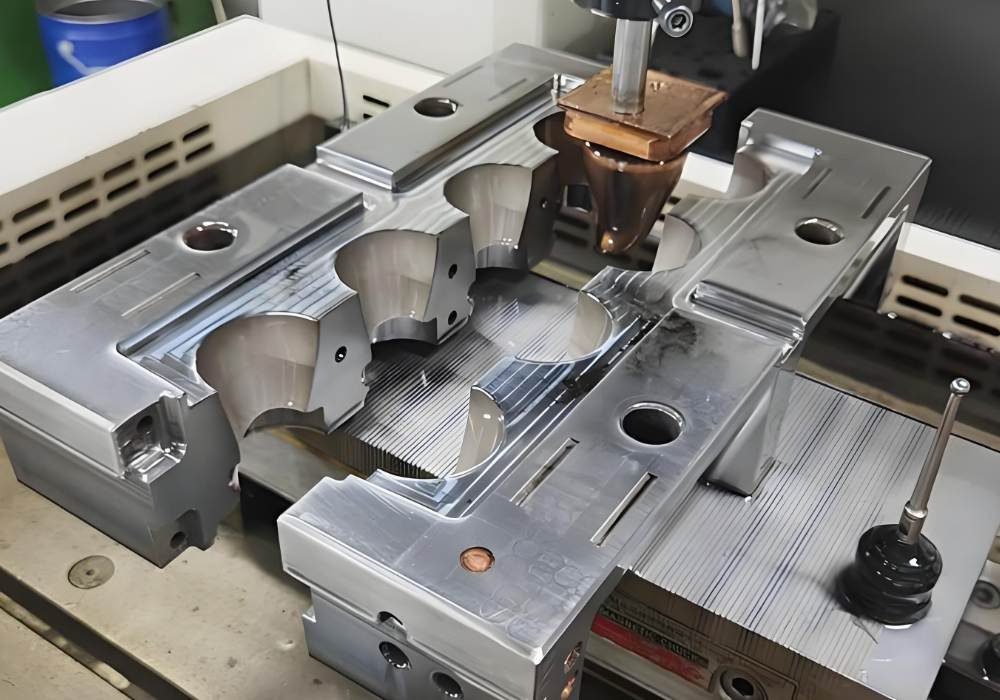

Tooling Techniques Employed in Injection Molds

CNC machining: CNC machining operates through computer-guided equipment for making accurate mold components. The system guarantees both high precision and repeated results during mold manufacturing processes.

EDM (Electrical Discharge Machining): EDM removes material using electrical sparks. It is ideal for shaping complex mold features that are difficult to machine with conventional tools.

3D Printing: Rapid prototyping applies 3D printing technology as its main method. Designers can check mold designs through the testing process before proceeding with full-scale manufacturing through this method to cut development time.

Milling & Grinding: Milling and grinding help achieve smooth surfaces and accurate dimensions. These techniques are essential for precision in mold manufacturing.

Polishing & Texturing: The surface finish of the mold gets better because of texturing and polishing steps. Using this step enhances both product appearance as well as functionality and makes part release easier.

Soft Tooling vs. Hard Tooling: Pros and Cons

| Feature | Soft Tooling | Hard Tooling |

| Material | Aluminum, soft steel | Hardened steel |

| Cost | Low | High |

| Durability | Short-term | Long-term |

| Modification | Easy | Difficult |

| Production Volume | Low | High |

Soft Tooling: The manufacturing field defines soft tooling as mold production tools which use aluminum or non-expensive soft steel. The main purpose of these molds centers on creating prototypes and small batches because their production costs less while requiring less time. Manufacturers use soft tooling during design testing to create modifications that will later guide mass production solutions. These types of molds possess limited durability which restricts their use in extensive manufacturing periods.

Pros of Soft Tooling:

- Lower Cost:The cost for soft tooling remains lower than what hard tooling requires.

- Faster Production: Molds enable engineers to produce prototypes much faster for their prototyping needs.

- Easier Modifications: Design changes can be made without high costs.

Cons of Soft Tooling:

- Limited Durability: Not suitable for high-volume production.

- Shorter Lifespan: Wears out faster due to material limitations.

- Less Precision: May not achieve the fine tolerances required for complex parts.

Hard Tooling: Hard tooling represents molds whose production includes hardened steel as their material choice. The molds recruit durable materials which grant higher precision for extensive and high-throughput manufacturing operations. The higher initial cost of developing hardened steel molds results in reduced manufacturing prices across big production volumes which offers cost effectiveness for large-scale manufacturing rates.

Pros of Hard Tooling:

- High Durability: Can withstand thousands to millions of production cycles.

- Greater Precision: Ensures consistent quality and tight tolerances.

- Cost-Effective for Large Runs: Reduces long-term production costs.

Cons of Hard Tooling:

- High Initial Investment: Expensive to manufacture and set up.

- Longer Lead Time: Takes more time to design and produce.

- Difficult to Modify: The process of modification for these tools becomes both complex and expensive.

Each method of tooling presents both favorable and unfavorable conditions for manufacturing. The selection process depends on production amount along with budget constraints and required materials and product longevity duration. Customers should select soft tooling tools when making prototypes or for short-term usage but hard tooling when manufacturing precise products for extended periods.

Common Materials Utilized in Injection Mold Tooling

Aluminum: Aluminum stands out because of its economical nature and weight benefits which favor prototyping applications. The material enables rapid changes to patterns although it does not match steel’s durability level.

Steel: The robustness of steel material makes it the ideal choice for producing large quantities of products at once. The material works well under high pressure together with temperature conditions though it has a greater price tag.

Beryllium-Copper: This material offers excellent thermal conductivity, which helps in cooling. It is often used in areas requiring rapid heat dissipation.

P20 Steel: The fabrication of general-purpose molds makes widespread use of P20 steel due to its widespread adoption. The material strikes a good compromise between affordability and longevity which makes it appropriate for various applications.

How to Select the Right Tooling Material for Your Project?

- Production Volume: The selection of steel becomes optimal for creating multiple parts because it provides durability benefits. Aluminum stands as an economical solution when designing small numbers of parts or creating prototypes.

- Material Compatibility: Each plastic substance needs a specific mold material for optimal formation. Molds that handle hot temperature plastics should be made from steel or beryllium-copper since these materials maintain their structural integrity when subjected to heat.

- Cost Considerations: You should consider Aluminum and P20 steel for affordable production yet hardened steel provides the best longevity at an expensive cost. Select materials that fit your financial plan along with your future requirements.

- Complexity of Design: Steel represents the best material for intricate parts because CNC machining with EDM techniques achieve successful results. The use of aluminum is suitable for simpler designs.

- Cycle Time Requirements: Better thermal conductor materials, especially beryllium-copper, help shorten cooling periods during production. The production speed depends on this step during the manufacturing process.

The process of recognizing along with fixing typical problems involving injection mold tooling

Common Issues in Injection Mold Tooling

Flash: Flash occurs when excess material escapes the mold cavity, creating thin extensions on the final product. This happens due to improper clamping pressure or worn-out mold components.

Short Shots: Short shots develop when the mold space remains unfilled or ends up partially empty. As a result, parts become unfinished. The cause of short shots results from insufficient injection pressure combined with poor venting practices together with material fluidity concerns.

Warping: The deformation of a component that appears following its cooling process is known as warping. Short shots occur when the mold does not fill completely because of temperature inconsistencies, wrongly chosen material types, or variations in wall diameter.

Sink Marks: Small depressions which form due to improper molding processes appear on the surface of molded parts as sink marks. Unsmoothed cooling processes combined with weak holding strength and extended material wall structure result in these defects.

Burn Marks: Burn marks appear as black or brown discolorations on the molded part. They result from trapped air, excessive injection speed, or overheating.

Troubleshooting Techniques

- Adjusting Mold Design: Optimizing gate location, cooling channels, and wall thickness can prevent defects and improve product quality.

- Optimizing Process Parameters: Adjusting injection speed, pressure, and temperature settings helps control material flow and cooling rates.

- Proper Material Selection: Using the right plastic material reduces defects like warping and sink marks.

- Regular Maintenance: The systematic inspection process and mold cleanings help stop problems caused by worn-out equipment parts and accumulation of foreign contaminants.

Factors Affecting Injection Mold Costs

Several factors influence the cost of injection mold tooling, including:

- Mold Material: High-quality materials like hardened steel are more expensive but offer durability.

- Mold Complexity: Complex molds with intricate features and multiple cavities require more machining and higher costs.

- Production Volume: Higher production demands often justify the investment in more durable molds.

- Surface Finishes: Specialized textures or polishing increase costs.

- Tooling Techniques: Advanced methods like EDM and CNC machining add to expenses.

- Maintenance & Longevity: Proper maintenance extends mold life, reducing long-term costs.

The total mold expenditure depends on these parameters when companies make right decisions concerning their efficiency and financial resources.

Injection Mold Applications: High, Medium, and Low Precision

High Precision (Automotive & Medical): The automotive sector together with medical uses high-precision molds due to their vital need for accurate production. The production process for these molds needs innovative materials together with exact manufacturing specifications to generate quality parts. Medical devices together with car engine components require manufacturing quality that remains perfect because precision acts as the fundamental requirement.

Medium Precision (Consumer Goods): Consumer goods like household items and electronics cases require medium precision. These molds need to be durable but allow slight variances in dimensions. This category balances cost and quality, ensuring mass production remains efficient while maintaining product consistency.

Low Precision (Packaging): Packaging products, such as plastic bottles and containers, prioritize cost and speed over fine details. These molds allow for more variation in dimensions as high precision is not essential. The overall objective focuses on rapid manufacturing of high volumes at minimal costs.

FAQs

What materials are used in injection mold tooling?

Common materials include aluminum, steel, beryllium-copper, and P20 steel. The choice depends on durability, cost, and thermal conductivity.

What are common injection mold tooling defects?

Defects include warping, sink marks, flash, short shots, and burn marks. These issues arise due to material selection, temperature control, or mold design problems.

What are the three main parts of an injection mold?

The three main parts are the mold cavity (shapes the part), runner system (guides molten plastic), and ejector system (removes the finished part).

Conclusion

Injection mold tooling is the backbone of efficient, repeatable, and high-quality plastic part production. From selecting the right tool steel to optimizing mold design, gating, cooling, and surface finishes, every decision directly impacts part performance, cycle time, and long-term cost efficiency. Investing in well-engineered tooling ensures smoother production, fewer defects, and a longer mold lifespan—critical benefits for any industry relying on plastic components.

At Fecision, we specialize in custom injection mold manufacturing, combining advanced machining technologies with expert engineering to deliver durable, high-precision molds tailored to your production needs. Contact us today to discuss your project and discover how our tooling expertise can elevate your injection molding results.