High Current Pogo Pins

Why

Fecision?

Precision At Fecision

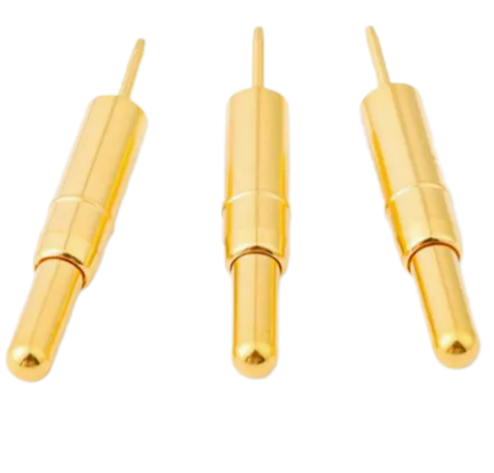

Precision Pogo Pins: CNC-Machined, Gold-Plated, Customizable

As a leading CNC machining and mold manufacturing service provider, we deliver tailored pogo pin solutions using advanced materials, surface finishes, and manufacturing techniques.

Rapid Prototyping

CNC + mold manufacturing in 7 days

End-to-End Testing

Validated for resistance, cycle life, and ESD resistance

Customizable

Tailored dimensions, plating, and materials for your application

Modular Design

Replace bulky soldered joints with compact, reusable solutions

Industry-Leading Durability

Engineered for 50K–100K+ cycles

High Current Pogo Pins for Extreme Power Transfer

- Material Excellence: Beryllium copper springs with gold/nickel plating for minimal resistance and oxidation.

- Thermal Management: Integrated heat sinks or thermal pads for sustained high-current operation.

Why Choose High Current Pogo Pins?

Technical Specification Table

| Parameter | Specifications |

Contact Resistance | <10mΩ (Initial) |

Plunger Travel | 1.0–5.0mm |

| Current Rating | 15A–100A (Continuous), 200A (Peak) |

| Voltage Rating | Up to 600VDC |

Insulation | PBT, Ceramic, or Silicone (Customizable) |

| Operating Temp | -40°C to +150°C |

| Certifications | ISO 9001, IATF 16949, UL, IEC 60529 (IP Ratings) |

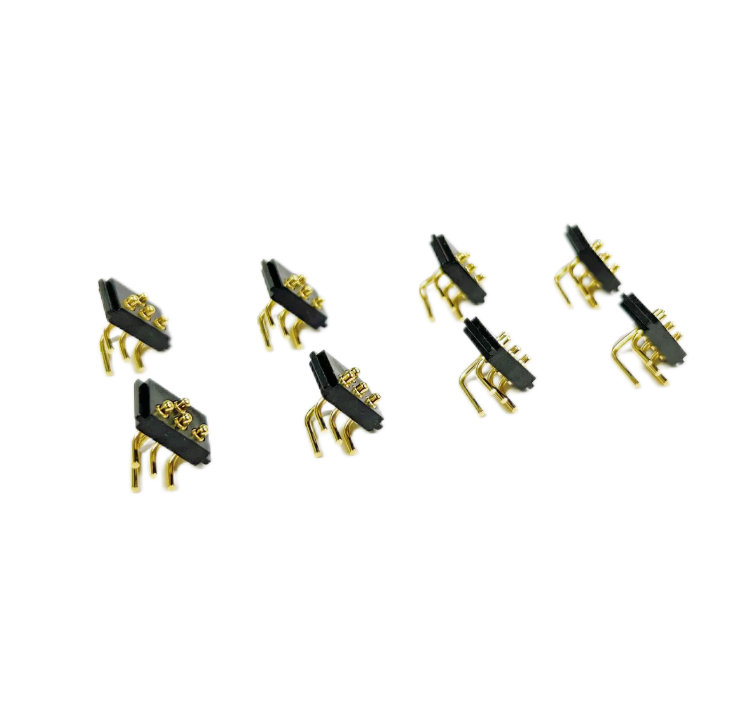

Types of High Current Pogo Pins

EV Charging Pogo Pins

IP67-rated, 50A+ pins for EV battery module testing and fast-charging docks.

Applications: EV battery validation, charging station interfaces

Industrial Power Connectors

100A-rated pins with ceramic insulation for arc-resistant industrial tooling.

Applications: Welding robots, CNC machinery

Energy Storage Probes

Thermally optimized pins for lithium-ion battery pack assembly/testing.

Applications:Solar energy storage, UPS systems

Custom High-Power Arrays

Multi-pin arrays for parallel current sharing in power converters.

Applications: Server power supplies, DC-DC converters

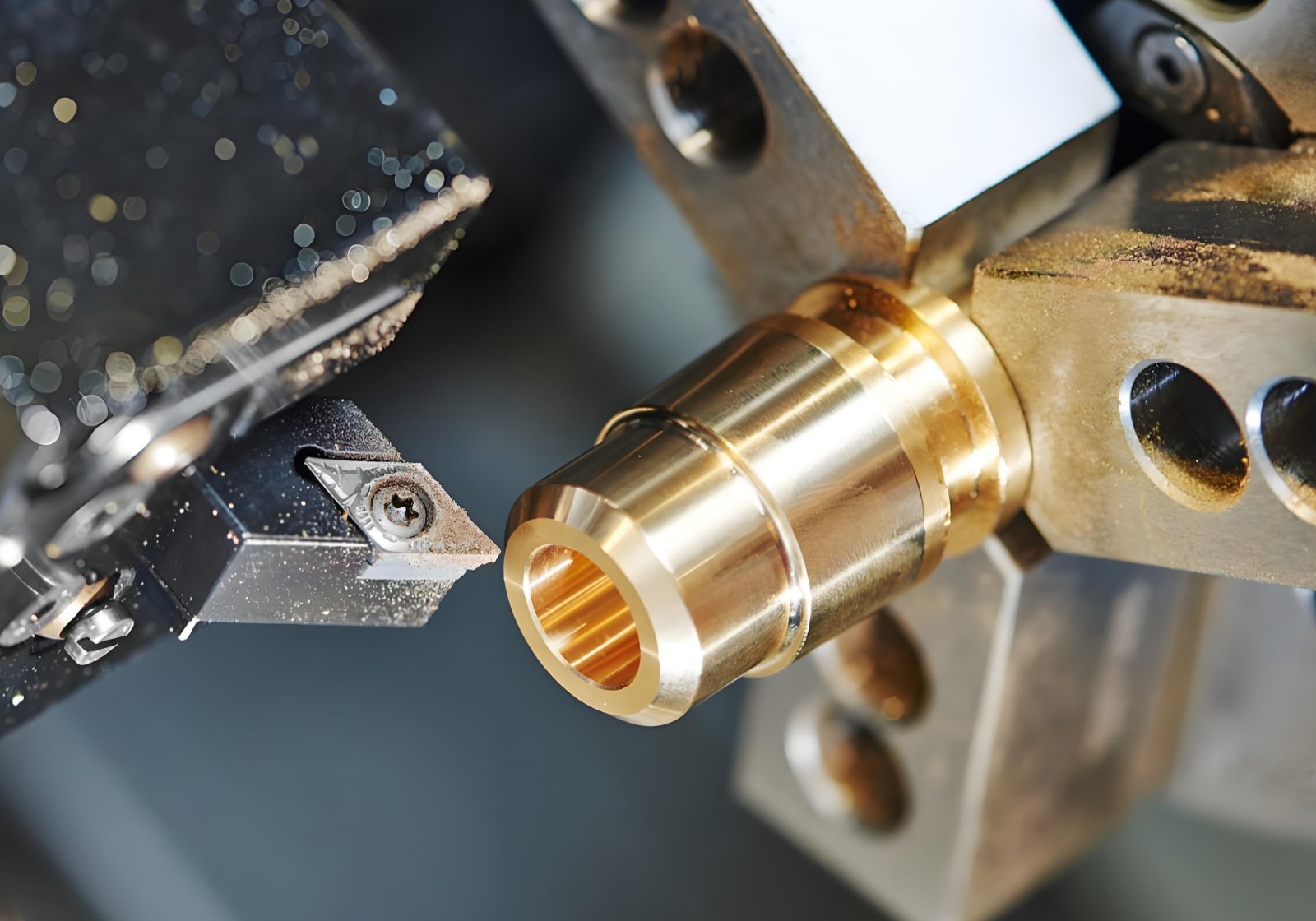

Manufacturing Processes

Bulk Material Forging

-

Hot Isostatic Pressing (HIP) for pore-free structure

Precision Machining

-

5-Axis CNC Profiling (±0.005mm)

-

Micro-Finish Surface (Ra 0.2μm)

Surface Treatment

- Common electroplating materials include gold, silver, nickel, etc.

- Anodizing & Passivation

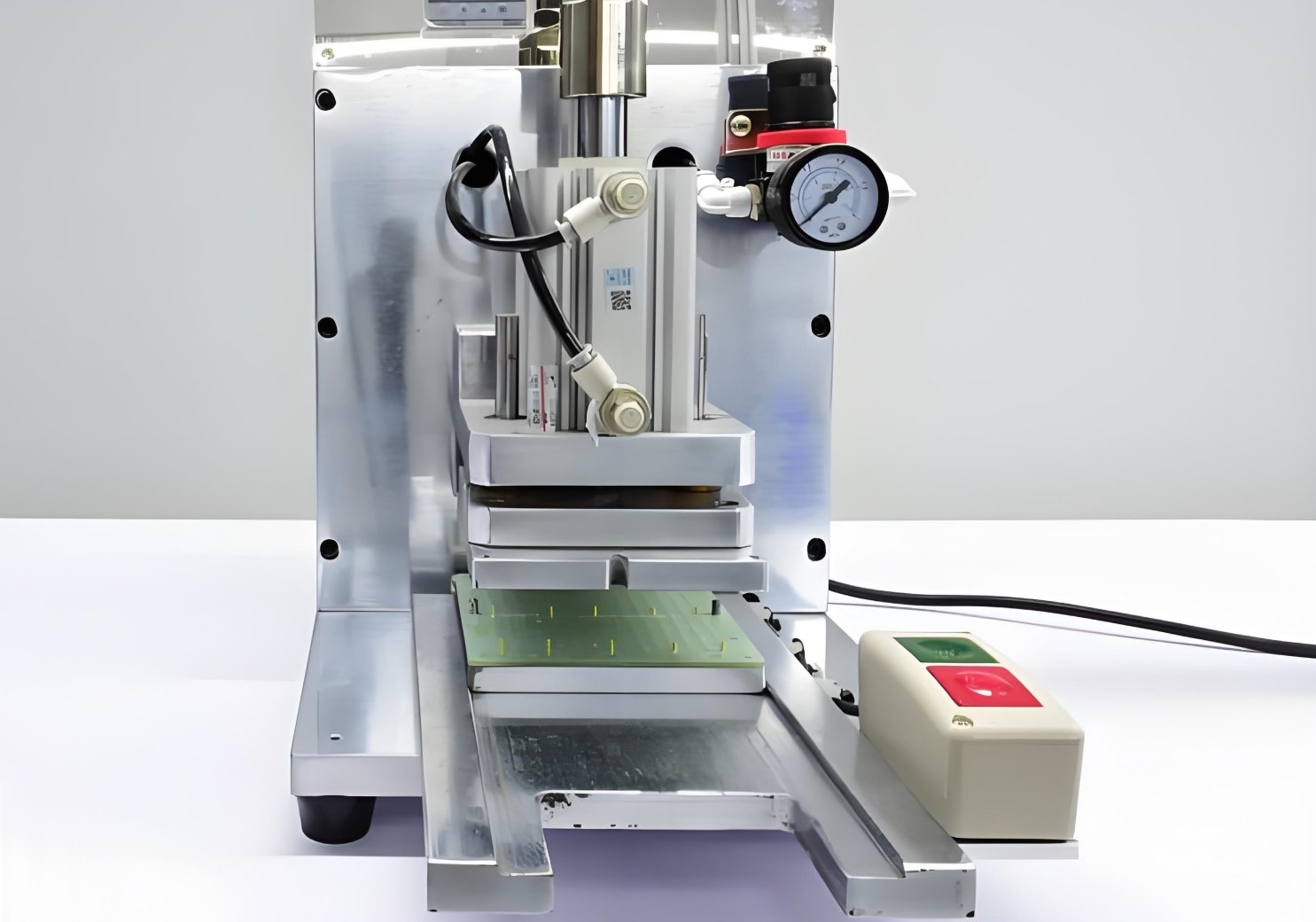

Validation Testing

-

100% Hi-Pot Testing (2000V AC)

-

Thermal Cycling (-55°C ↔ +200°C)

-

Current Burn-In (125% Rated Load)

Applications & Industries

Electric Vehicles

Renewable Energy

Industrial Automation

Data Center Power

Start your project now

Workflow

Customization Process

Share your thermal requirements, size constraints, and environmental conditions.

We provide 3D CAD models and thermal analysis reports.

Test functional prototypes for performance validation.

Seamless transition to full-scale manufacturing.

Trusted for High-Stakes Power Systems

Certifications & Quality Assurance

ISO 9001:2015 & IATF 16949

RoHS/REACH Compliance

UL 1977 & IEC 60529 (IP67/IP68)

MIL-STD-202H

Request a Proposal

Let us bring your vision to life.

Share your project details, and we’ll craft a tailored proposal just for you.