Creating top-notch plastic parts goes beyond just the materials and machinery you use. At the core of quality manufacturing is the optimal design of your molds. To guarantee uniformity and endurance, the mold’s design is critical and must be perfect. Still, it might be difficult to get the ideal mold design without the appropriate tools. That’s where mold flow analysis comes into play.

This article goes over the details of mold flow analysis, why it’s important, and how it can help your manufacturing process. By using mold flow analysis early on in the planning process, you can find and fix problems before they affect the production line, which saves time and money in the long run.

Are you the one looking to upgrade your mold design and simplify your production operations? Read on to learn how mold flow analysis can help.

Basics of Mold Flow Analysis

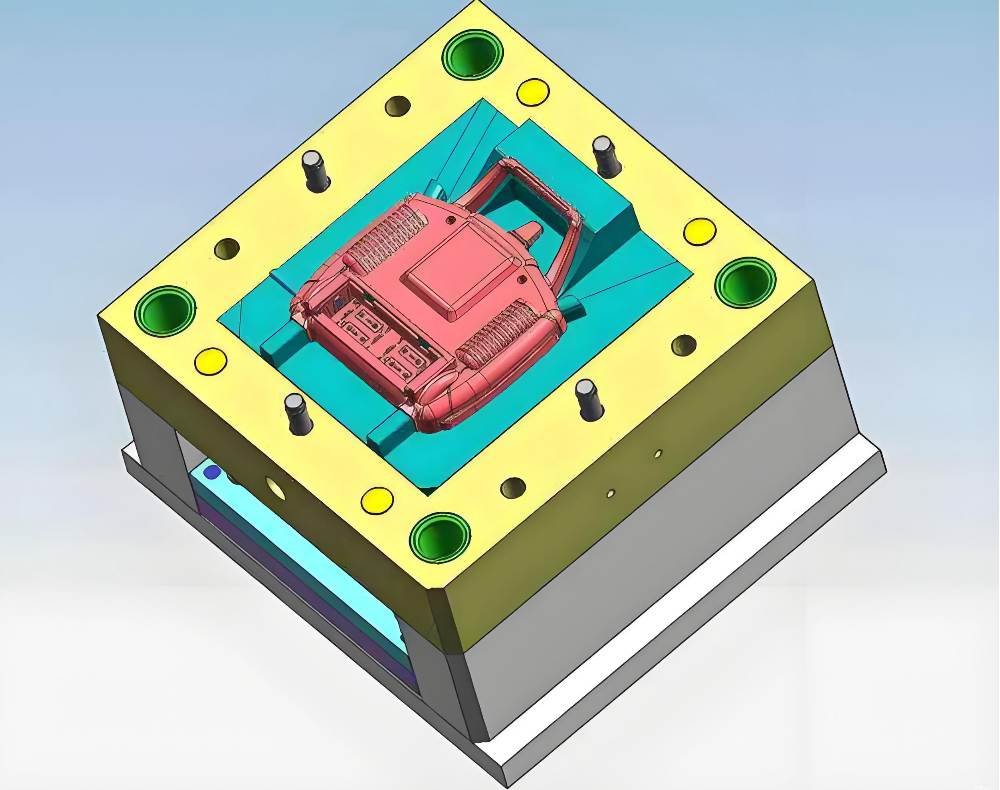

Mold flow analysis is a highly effective simulation technique widely used in the plastic injection molding industry. By utilizing advanced software, this method allows you to predict the flow and behavior of molten material as it moves through a mold cavity.

Essentially, mold flow analysis helps you optimize your mold designs, ensuring that the final products consistently meet high standards of quality and structural integrity.

You must be wondering when’s the best time to consider mold flow analysis? Ideally, it should be integrated early in the design phase of your project. This is particularly important when developing new mold tools or implementing substantial modifications to existing ones.

Conducting this analysis at the onset allows you to identify and address potential issues before they escalate to the production stage. By doing so, you not only enhance efficiency but also save valuable time and resources in the long run.

Recommended Mold Flow Analysis Software

Using certain tools can help to considerably simplify the mold flow analysis process and improve accuracy.

Any of these tools can help you make better choices about your mold design and the material you choose. They guarantee that your last creations satisfy the best criteria of structural integrity and quality. Reliable data will help you steer your judgments rather than depending on conjecture, therefore smoothing out and improving the manufacturing process.

Among the best choices are:

Autodesk Moldflow

Renowned for its strong simulation features that meet diverse design requirements, Autodesk Moldflow is one of a kind. It lets you see and analyze in great detail how liquid materials move, which helps you make the mold design and production process better.

SolidWorks Plastics

Perfectly merging with the SolidWorks system, this software provides a thorough understanding of your mold designs. It offers simple simulations that enable you to make required changes early in the design process by helping to forecast how molten plastic will fill the mold cavity.

Moldex3D

Renowned for its thorough and intuitive UI, Moldex3D provides complete analysis tools. It clarifies possible problems such as warpage, shrinkage, and cooling, therefore allowing you to confidently hone your mold designs.

Simpoe-Mold

Simpoe-Mold, a part of the Dassault Systèmes portfolio, is another powerful tool in mold flow analysis. It provides fast and accurate simulations, helping to predict potential molding issues such as air traps, weld lines, and sink marks. Its ease of integration with CAD environments allows for seamless alterations and optimization throughout the design process, ensuring a streamlined manufacturing experience.

ANSYS Mold Simulation

ANSYS Mold Simulation is another highly regarded tool in the industry. It offers detailed insights into the mold filling process, allowing designers to identify and rectify potential issues before they become significant problems. This software helps in enhancing the quality and performance of molded products by providing reliable data and sophisticated simulation capabilities.

The Relationship Between Mold Flow Analysis and DFM

Design for Manufacturing (DFM) and mold flow analysis are essential partners in creating high-quality products efficiently and cost-effectively. While DFM focuses on designing products that are easy to manufacture, mold flow analysis helps pinpoint potential issues in the production process early on.

In sectors like automotive, aircraft, medical equipment, consumer products, and electronics, DFM is indispensable.

For instance, in the automotive industry, designers use DFM to optimize product designs for easier and cheaper manufacturing. This involves evaluating manufacturability, selecting the best manufacturing methods, and refining designs to cut costs and reduce complexity.

Mold flow analysis complements DFM by simulating how materials will flow into mold cavities. This analysis identifies potential challenges such as air traps, weld lines, and uneven cooling. By addressing these issues early, manufacturers can avoid defects and ensure a smoother production process.

In the aerospace and medical equipment industries, precision and reliability are critical. Combining DFM with mold flow analysis helps create high-quality parts that meet strict safety and performance standards.

Basically, DFM’s cooperation with mold flow analysis guarantees product quality, increases production efficiency, and reduces costs. Industries can save waste and improve customer satisfaction by combining these techniques.

How to Carry out Mold Flow Analysis?

You may ask: What pre-preparation is needed for mold flow analysis?

So, before conducting a mold flow analysis, you need to:

- Ensure you have an accurate and detailed CAD model of both the part and the mold. This serves as the foundation for the analysis.

- Gather detailed material properties such as viscosity, thermal conductivity, and specific heat of the material you’re using. These parameters are crucial for the simulation to be precise.

- Collect all relevant processing parameters such as injection pressure, mold temperature, and cooling times. These will need to be input into the analysis software.

The Basic Process of Mold Flow Analysis

Let’s start with the fundamental actions needed for a mold flow analysis. Making sure you grasp each step will help the process go more smoothly and quickly.

Step 1: Import CAD Model

First up, you’ll need to import the detailed CAD model of your part and mold into the analysis software. This is your starting point and sets the stage for everything that follows. Having an accurate model is crucial because any inconsistencies here can impact the entire analysis.

Step 2: Generate Computational Mesh

Next, the software will automatically create a computational mesh, which essentially breaks down your geometry into small, manageable elements or cells. This mesh is essential for discretizing the domain, enabling the software to solve the intricate mathematical equations related to fluid flow and heat transfer effectively.

Step 3: Define Material Properties

Now, input the material properties into the software. This includes specifics like viscosity, thermal conductivity, and specific heat. These properties help the software predict how the material will behave during the injection process. Make sure you use precise data to ensure reliable results.

Step 4: Set Up Boundary Conditions

After the mesh is ready, it’s time to define the process parameters. This involves specifying the injection speed, pressure, and cooling time. These parameters act as boundary conditions for the simulation, essentially setting the rules for how the simulation will run and what it will analyze.

Step 5: Run Simulation

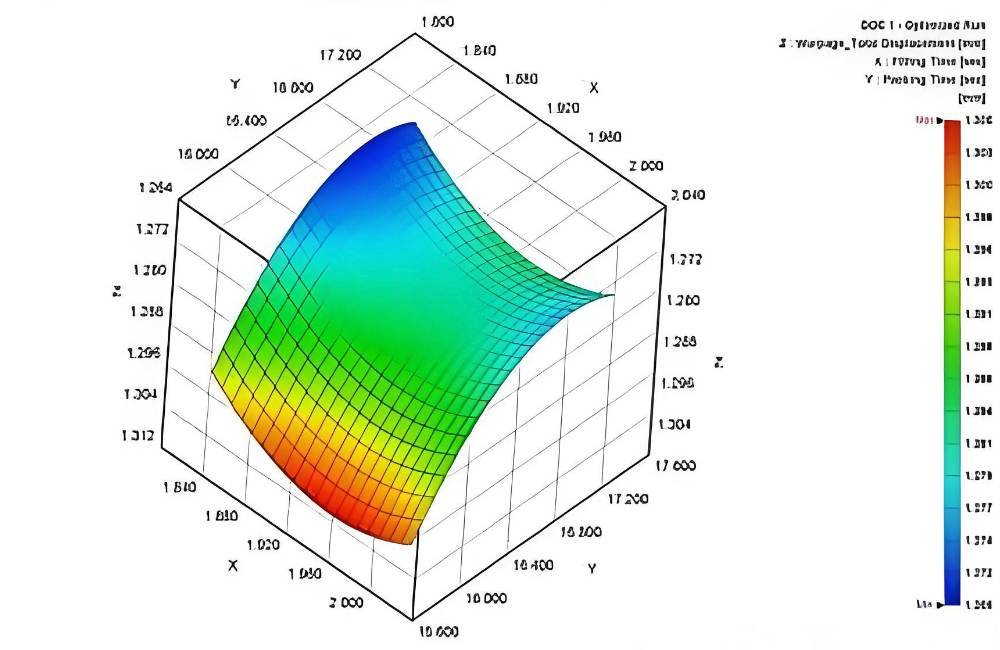

With everything set up, it’s time to run the simulation. The software will process all the inputs and predict various factors such as flow patterns, pressure changes, and temperature distribution. The software uses numerical methods to solve the mathematical equations that simulate the flow of molten plastic within the mold cavity, taking into account the flow rate, pressure, temperature, shear stress, and cooling effects. This step can take some time depending on the complexity of your model, but it’s where the magic happens.

Step 6: Analyze Results

Once the simulation is complete, you will need to dive into the results. Look for common issues like air traps, weld lines, and areas that might suffer from sink marks. Understanding these results can help you identify any potential problems in the molding process.

Step 7: Optimize Design

The final step involves making necessary adjustments to the mold design based on the results. You might need to alter gate locations, tweak cooling channels, or change the part geometry. Once changes are made, it’s a good idea to run the analysis again to ensure the modifications have resolved the issues.

Key Benefits of Conducting a Mold Flow Analysis

Taking the time to conduct a mold flow analysis can lead to some game-changing advantages in your manufacturing process.

Let’s talk about the key benefits here:

● Better Quality Products

By spotting potential defects like air traps and sink marks early on, you can ensure that your final products are top-notch. This kind of proactive approach means happier customers and fewer returns.

● Saving Money

Using Mold Flow Analysis cuts down on trial-and-error in mold tooling. This leads to big savings on materials and labor, making your production process much more affordable.

● Shorter Development Time

By catching and fixing issues early, you can speed up the process from design to production. The insights you gain from the analysis help you make smarter decisions about materials, design, and process parameters. This ensures that your production is as efficient and effective as it can be.

● More Process Efficiency

Knowing the flow patterns and pressure variations lets you fine-tune the injection molding process. This means shorter cycle times and smoother production runs.

● Risk Mitigation

Seeing potential problem areas before they become big issues allows you to take preventive actions. This helps you avoid costly redesigns or delays, keeping your projects on track and within budget.

Is Mold Flow Analysis Always Necessary?

While highly beneficial, mold flow analysis may not always be necessary. For simple parts with straightforward designs, the added cost and time may not be justified. However, for complex parts or high-volume production runs, this analysis proves invaluable in ensuring quality and efficiency.

Conclusion

Maximizing product quality and manufacturing efficiency depends critically on including mold flow analysis in your design process. Simulating and knowing how molten material flows through molds can help you prevent any problems and improve your technique.

Contact us for your molding requirements and use our knowledge to improve your manufacturing process!