Injection molding is a widely used manufacturing process that enables mass production of complex plastic parts with high accuracy and efficiency. The design and accuracy of mold parts directly influences the quality, durability, and performance of injection molded products. Each part of the injection molding mold is important in ensuring smooth production, stable quality, and minimal defects. This article explains the detailed breakdown of injection molding mold parts, their functions, materials, manufacturing processes, and maintenance, and helps manufacturers optimize mold performance.

1. The Importance of Mold Parts for Design Flexibility

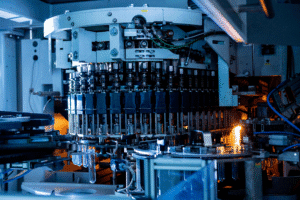

Role of injection molds in plastic manufacturing

Injection molding molds form the core of plastic production, facilitating the production of many plastic components across automotive, medical, electronic, and consumer product industries. Because these molds define the form, structure, and general quality of the end product, their construction is vital to production efficiency. The superb structure of the mold facilitates consistency, precision, and longevity of plastic components, minimizing defects and maximizing functionality.

Increase design flexibility with die parts.

The mold design flexibility is based on the different parts of the mold. Different mold parts enable one to modify cavity shapes, surface finishes, and material flows, making it possible for manufacturers to respond to shifting product demands. Design adjustment is facilitated by the use of standardized mold parts, cutting down on prototyping and production cycles.

Interchangeable mold inserts and modular base benefits

Modular mold bases and interchangeable die inserts are cost-saving options for companies that would like to produce several product variations. Rather than having to design an all-new mold every time you need to modify it, you can modify the function and shape of the end product by substituting some inserts. This lowers manufacturing downtime, lowers production expenses, and allows businesses to react strongly to market needs.

The Role of Hot Runner Systems in Improving Efficiency

Hot runner systems are critical in streamlining the injection molding process. In contrast to conventional cold runner systems that produce excess material waste, hot runners provide efficient material flow, minimize waste and enhance cycle time. Through constant temperature maintenance and pressure loss minimization, these systems enhance the quality of parts, minimize defective products, and maximize production efficiency.

Creating Complex Geometries with Sliders and Lifters

Sliders and lifters are essential for parts with complex designs, undercuts, and inner screws. These moving parts allow manufacturers to produce complex shapes that are not possible with basic mold structures. By integrating these advanced components, companies can expand their design capabilities and produce very detailed plastic parts.

Long-Term Benefits of Investing in High-Quality Mold Parts

Investing in premium die parts enhances durability, enhances accuracy and minimizes maintenance and expense. Premium mold parts prolong the life of the mold, reduce downtime, and optimize production consistency. Through the right choice of material and the addition of advanced mold technology, manufacturers are able to achieve the flexibility, efficiency, and cost-effectiveness of superior design in manufacturing.

2. Key Components and Their Functions of Injection Molds

Injection molding molds consist of several important components to mold molten plastic into the final product. Each part has a specific function that ensures smooth operation of the mold and high-quality production.

Image Source: Found via Google Images

- Mold base: This integrates all parts in the foundation of the injection molding mold. Structurally, it supports the mold and stores the core and cavity plate.

- Core and cavity: The main mold parts that form the internal and external shapes of plastic parts. The cavity forms an external shape, and the core forms an internal shape.

- Sprue and runner system: A system that sheds molten plastic from the injection device to the mold cavity. Sprue (main aisle), runner (distributor), and gate (entrance to cavity) are included.

- Ejector system: Composed of ejector pins, plates, and rods, the molded product is pushed out of the cavity after cooling.

- Cooling system: A network of cooling paths that circulate water and coolant to regulate mold temperature and enable uniform cooling and shortening cycle time.

- Vent system: Small grooves to prevent defects such as air pockets and burns by escaping air and gas trapped during the injection process.

- Slider and lifter: A moving part used for complex part shapes that enables undercut and complex shape molding.

- Hot runner system (when used): Instead of solidifying the plastic with the runner, the hot runner maintains a continuous flow of molten plastic, reducing the waste of material and improving efficiency.

Each of these components plays an important role in the successful injection molding process, and understanding its functionality helps troubleshoot and optimize mold performance.

3. Materials and properties of common mold parts

The selection of materials for injection mold parts is very important to ensure durability, accuracy, and wear resistance. Different mold parts require different material properties based on their function and stress, heat, and pressure exposure.

Image Source: Found via Google Images

Mold Base Material:

Generally, P20 made from steel, mild steel or stainless steel, providing high strength and resistance to deformation. These materials ensure that the mold structure is stable even under high pressure and high-temperature conditions.

Core and cavity materials:

Usually made from H13, S136, or 420 stainless steel, it is known for its excellent wear resistance and heat resistance. Since machining is possible, it can be precisely finished to the details, and high-quality molded products are obtained.

Runner and gate material:

To withstand continuous molten plastic flow, high wear resistance hardening tool steel is required. Durable materials prevent erosion and maintain stable material distribution.

Ejector pins and sleeves:

Made from high hardness steel or nitriding steel, it resists wear and corrosion from prolonged use. Its strength promotes smooth release of parts and keeps molded parts undamaged.

Cooling System Components:

Made of beryllium copper or copper alloy for maximum thermal conductivity. Such materials promote enhanced cooling performance, shortened cycle time, and faster production rates.

Material selection has a direct influence on mold life and efficiency. Material selection effectively minimizes wear, decreases downtime for maintenance, and enhances the life of the whole mold.

4. Manufacturing Processes for Mold Components

High-quality mold parts require advanced manufacturing techniques that guarantee accuracy and durability. The most commonly used processes for manufacturing mold parts include:

Image Source: Found via Google Images

CNC machining: Using computer-controlled milling and lathe processing, precise mold cavities, mesons, and bases are manufactured with severe tolerances.

EDM: Used to process complex shapes and details that are difficult for conventional machining.

Grinding and polishing: Realizes smooth surface finish of mold parts, reduces friction, and improves protrusion of parts.

Heat treatment: Increase the hardness and wear resistance of the mold steel and extend the life of the mold. Surface coating Hard chrome plating, nitriding treatment, PVD coating, improve wear resistance, reduce friction.

These manufacturing processes ensure that mold parts meet the requirements for accuracy and durability and achieve stable performance.

5. Precision of Injection Mold Components

Precision is a very important factor in injection molding. Because even a slight deviation can lead to defective products and decreased production efficiency. The accuracy of mold parts directly affects:

Image Source: Found via Google Images

Part dimensions:

Ensure the uniformity and accuracy of the final product by maintaining the precise dimensions of the mold part. Even small deviations can lead to defects, affecting overall quality and functionality.

Die alignment:

If the alignment of the mold half body is appropriate, it can prevent problems such as burrs stained with excess plastic from the seam. Accurate alignment improves parts’ accuracy and reduces post-processing labor.

Cooling efficiency:

Properly designed cooling groove regulates mold temperature to prevent warping and shrinkage. Efficient cooling system improves cycle time, leading to rapid production and stable quality.

Emission mechanism:

Smoothly functioning ejector pins can easily retrieve parts without damaging the surface. The proper fit of the ejector reduces dent, scratch, and adhesion during demolition.

Advanced measurement tools such as three-dimensional measuring machines (CMMs) and laser scanners are used to check the accuracy of mold parts before assembly.

6. How Do Mold Parts Affect Mold Durability and Life?

The durability of injection molds depends on several factors, such as component quality, material selection, and maintenance methods. The main aspects affecting the life of the mold are:

Image Source: Found via Google Images

Hardness of material: Hardness of material: High hardness material ensures wear resistance and deformation resistance and extends the operating life. Durable materials maintain mold accuracy and reduce defects and maintenance needs.

Lubrication and coating: Proper lubrication and wear-resistant coatings minimize friction between moving parts. This reduces part wear, prevents overheating, and extends the life of the mold.

Cooling system efficiency: Properly designed cooling system prevents thermal stress and reduces material fatigue over time. Efficient cooling maintains a stable temperature during production and extends the life of the mold.

Regular maintenance: regular inspection and timely replacement of wear parts to prevent unexpected failure. Regular maintenance ensures stable performance and prevents costly production delays.

By investing in high quality mold parts and practicing appropriate maintenance methods, the life of the mold can be greatly extended.

7. Quality Control Measures for Mold Components

Ensuring the quality of die parts is essential for stable production and molding without defects. The main quality control measures are:

Image Source: Found via Google Images

Dimensional inspection:

Precision measurement tools such as noise and three-dimensional measuring machines verify the tolerance of mold parts. Ensure accurate dimensions to prevent misalignment and defects in the final product.

Material inspection:

Test hardness, tensile strength and corrosion resistance to confirm durability. High quality materials extend the life of the mold and maintain stable performance even under high pressure.

Surface finish evaluation:

Smooth surface finish prevents fastening, improves protrusion of parts and reduces defects. Proper polishing and coating treatment improves mold performance and product quality.

Functional test:

Assembly of mold parts and test under actual molding conditions. This ensures proper fit, movement and efficiency before full-scale production begins.

Strict quality control helps in the early detection of defects and in maintaining high standards in production.

8. Maintenance and Troubleshooting of Mold Components

Regular maintenance of mold parts helps prevent breakdowns and ensure long-term performance. Common maintenance methods include:

Cleaning

Regular removal of plastic residue, dust, and contaminants can prevent defects and extend the life of the mold. Proper cleaning ensures smooth molding and maintains the quality of parts. Clean mold minimizes cycle time fluctuations and improves efficiency. A dedicated cleaner protects the delicate surface from damage.

Lubrication

Grease and oil are applied to moving parts, such as ejector pins and sliders, to reduce friction and wear. Proper lubrication prevents adhesion and ensures smooth discharge of molded products and stable performance. To prevent contamination of molded parts, excessive lubrication must be avoided.

Periodic Checking

By periodically checking inspection wear, cracks, and misalignment, potential failures can be detected early. Identifying parts with wear and damage can prevent costly repairs and production delays. Detailed inspection maintains mold accuracy and product consistency. The enlargement tool allows you to detect small defects before they expand.

Cooling system cleaning

Removing the garbage in the cooling conduit realizes efficient heat dissipation and prevents overheating. Clogging causes uneven cooling and leads to defects such as warp and brace. By washing regularly with cleaning liquid, cooling efficiency can be kept optimal.

Troubleshooting common die problems such as flushing, short shots, and warping involves identifying defective parts and making necessary adjustments.

9. How to Replace Parts of Injection Mold?

To replace the mold parts, you need the following steps:

1. Identify worn or damaged parts.

2. Carefully decompose the mold.

3. Install new parts accurately.

4. Reassemble and test the mold before production.

Ensure proper exchange and continuous efficiency by following manufacturer guidelines.

10. Final Thoughts

Molds for injection molding are the core parts of plastic manufacturing, forming products precisely and efficiently. Each molded part plays an important role in ensuring smooth operation, high-quality production, and long-term durability. Understanding these factors, from core and cavity design to advanced cooling and injection systems, helps manufacturers optimize performance. Material selection, precision processing, and regular maintenance greatly affect the life of the mold and the stability of production. By investing in high-quality parts and adopting advanced manufacturing processes, reliability and cost-effectiveness can be ensured. As the industry continues to evolve, innovation in mold technology will further increase flexibility and efficiency. Using die parts is key to realizing excellent product quality and reasonable production.

11. Frequently Asked Questions

What are the most common challenges in injection mold maintenance?

Regular maintenance is essential to prevent wear, corrosion and deviation of mold parts. Accumulation of residue, obstruction of cooling system, wear of ejector pins and runners, etc., can lead to defects in molded products.

How do different types of gate systems affect mold performance?

Gate systems such as edge gates, hot runners, and submarine gates affect the flow of molten plastic, cycle time, and the quality of molded products. Selecting the right gate type improves efficiency, reduces waste, and improves surface finish.

What role does the surface finish of the mold play in the quality of the final product?

The surface finish of the mold determines the texture, gloss, and appearance of the molded product. Highly polished molds reduce friction, prevent adhesion, and improve demolition efficiency.

Can I use a single mold for multiple materials?

Some molds are designed with an emphasis on versatility, but when using different plastic materials, temperature settings, cooling channels, and injection pressure may be required to prevent defects and ensure optimal molding conditions.

How does a mold vent prevent injection molding defects?

Proper vents allow air and gas trapped during the injection to be discharged to prevent problems such as burning traces, air pockets and incomplete filling. Strategic placement of vents improves molded products uniformity and overall production quality.

What factors determine the life of injection molds?

The lifetime of the mold depends on the quality, frequency of use, efficiency, and maintenance of the cooling system. High-grade steel, protective coating, and regular maintenance extend the durability of the mold.

How does the temperature and cooling speed of the mold affect production efficiency?

Temperature control is very important to prevent warping, shrinkage, and variations in component dimensions. Efficient cooling channels reduce cycle times, improve parts quality, and increase overall manufacturing efficiency.

What are the advantages of modular mold design?

Modular mold can replace specific inserts and components without redesigning the entire mold. This approach reduces downtime, reduces costs, and increases flexibility for product variations.