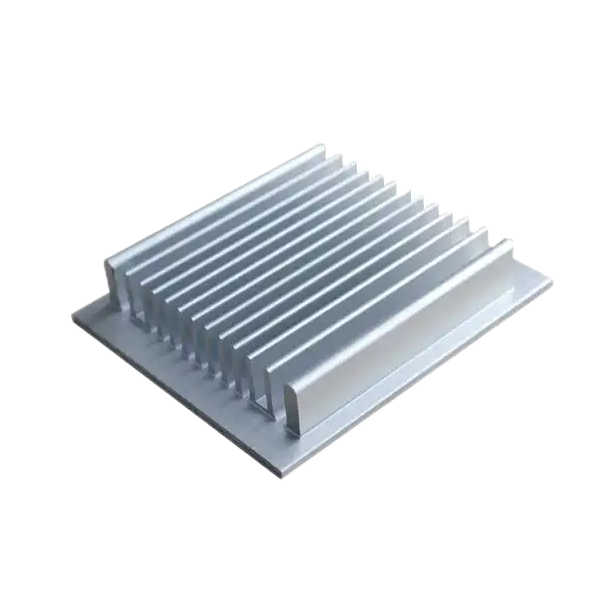

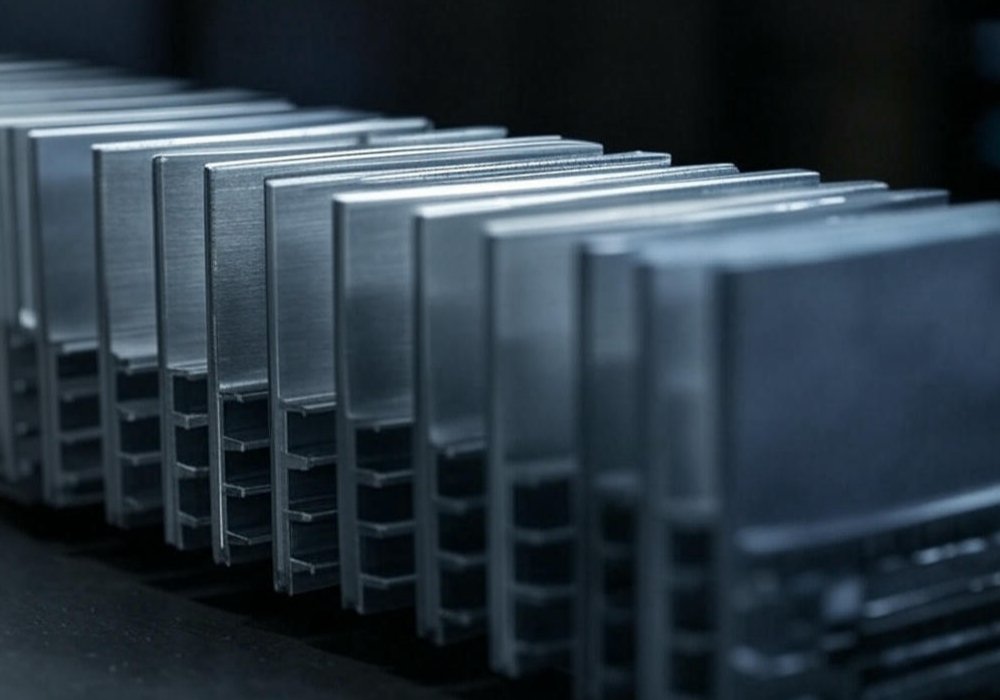

Stamped Heat Sink

Why

Fecision?

Precision At Fecision

Custom CNC Machining & Molded Solutions

As a leading CNC machining and mold manufacturing service provider, we deliver tailored heat sink solutions using advanced materials and manufacturing techniques, including CNC milling, extrusion, die-casting, and bonded fin technology.

Optimized Thermal Performance

CFD-simulated designs for maximum heat dissipation

Durability

Corrosion-resistant finishes for harsh environments

Custom Designs

Collaborate with our engineers for application-specific solutions

Cost Efficiency

Competitive pricing for both low/high-volume orders

Global Compliance

Meet RoHS, REACH, and ISO 9001 standards

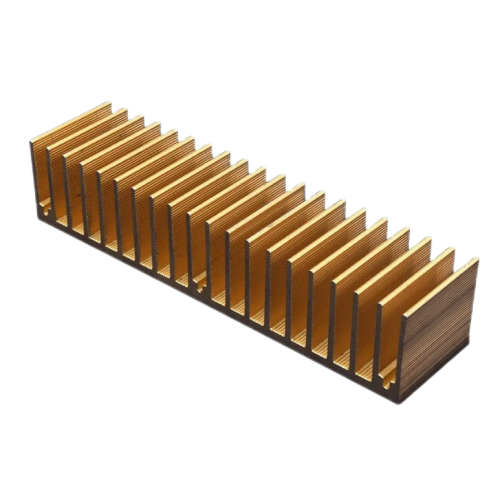

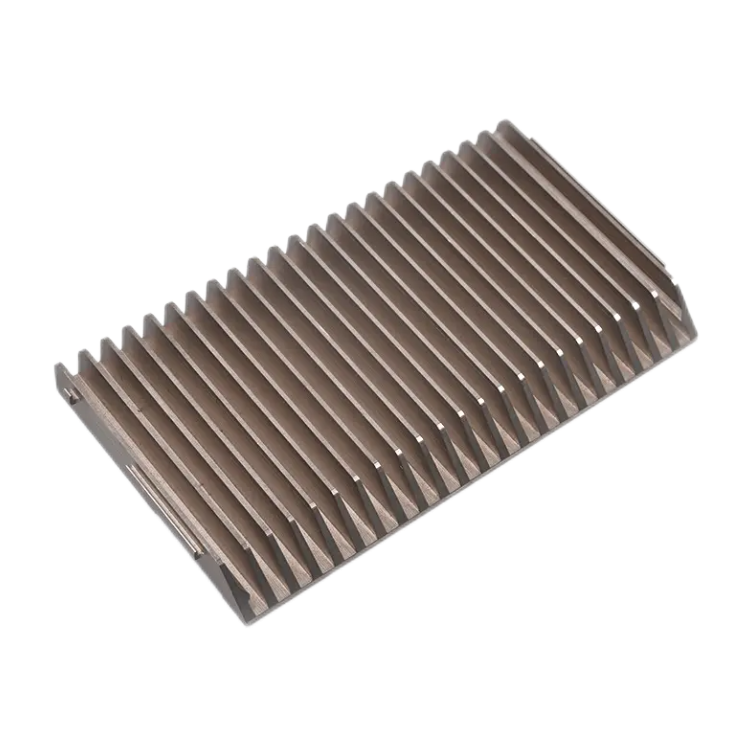

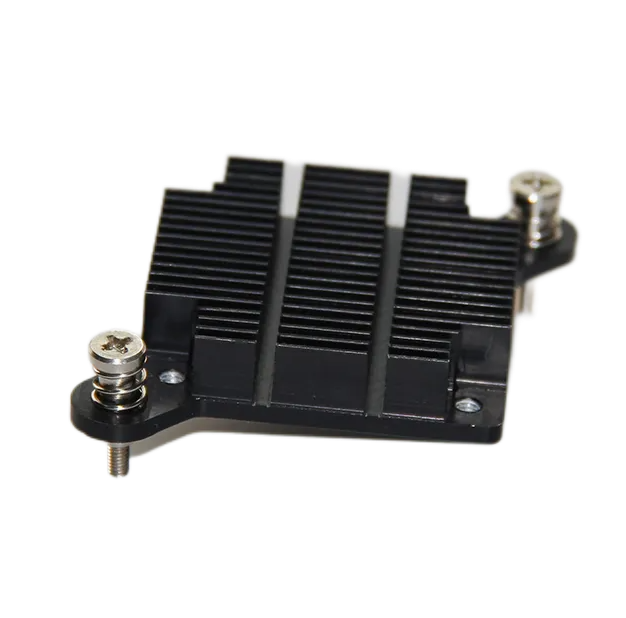

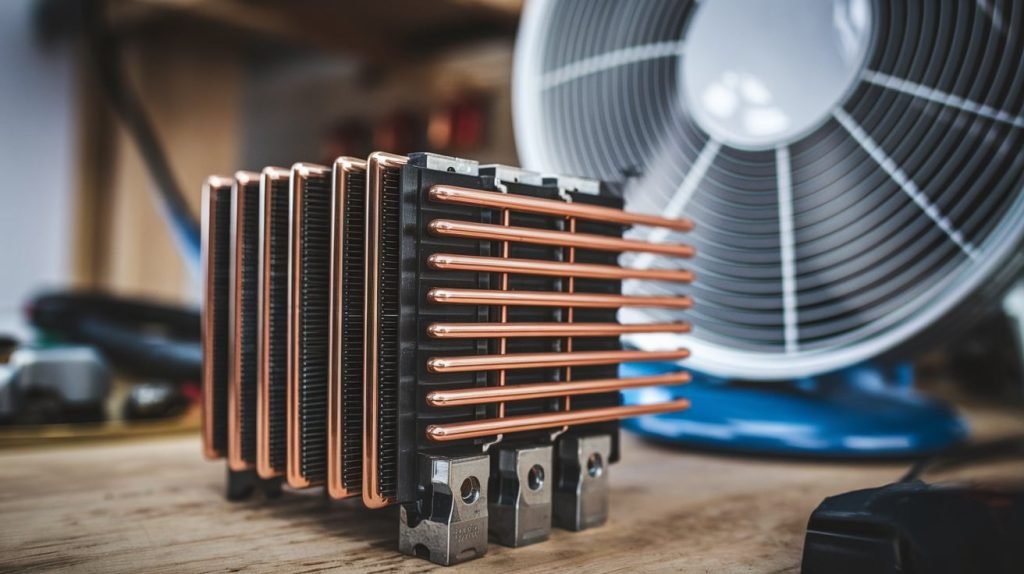

Stamped Heat Sinks

Why Choose Stamping?

Technical Specification Table

| Parameter | Specifications |

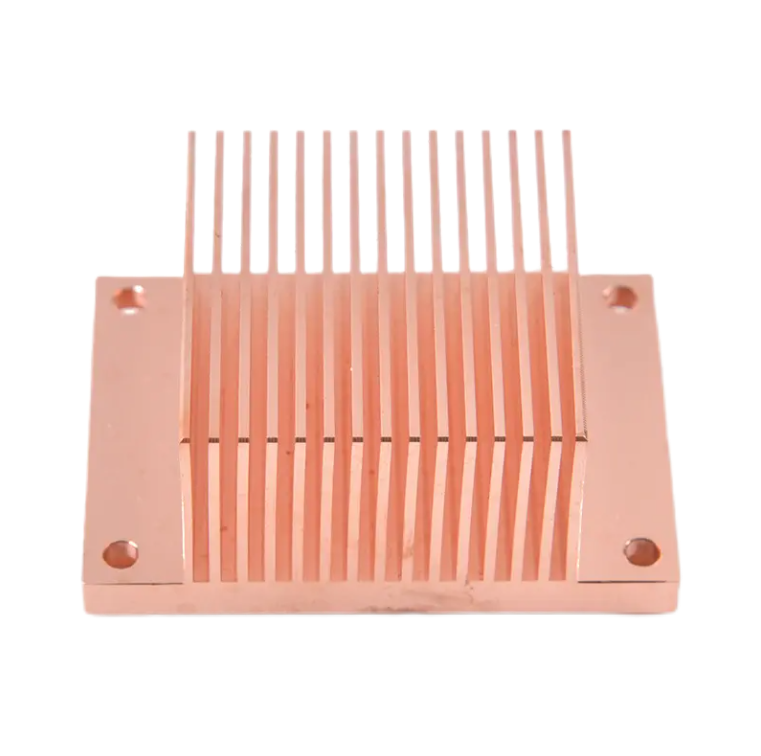

| Material | Aluminum 1050/1100, Copper C110, Stainless Steel |

Thickness Range | 0.2–2.0mm |

Max Dimensions | 150mm (L) x 100mm (W) x 25mm (H) |

Tolerance | ±0.1mm (standard), ±0.05mm (precision) |

| Surface Finish | Mill finish, anodized, tin-plated |

| Certifications | ISO 9001, RoHS, UL, IEC 62368 (electronics) |

Types of Extruded Heat Sinks

Standard Stamped Fins

Custom-Shaped Stampings

Hybrid Stamped-Assembled Heat Sinks

Micro-Fin Stampings

Applications & Industries

Consumer Electronics

Automotive Electronic

Home Appliances

Telecom Equipment

Start your project now

Workflow

Customization Process

Share your thermal requirements, size constraints, and environmental conditions.

Test functional prototypes for performance validation.

Seamless transition to full-scale manufacturing.

Quality Built for Global Markets

Certifications & Quality Assurance

ISO 9001:2015 Certified Manufacturing

RoHS/REACH Compliant Materials

IEC 62368 (Audio/Video & IT Equipment)

Request a Proposal

Other Products

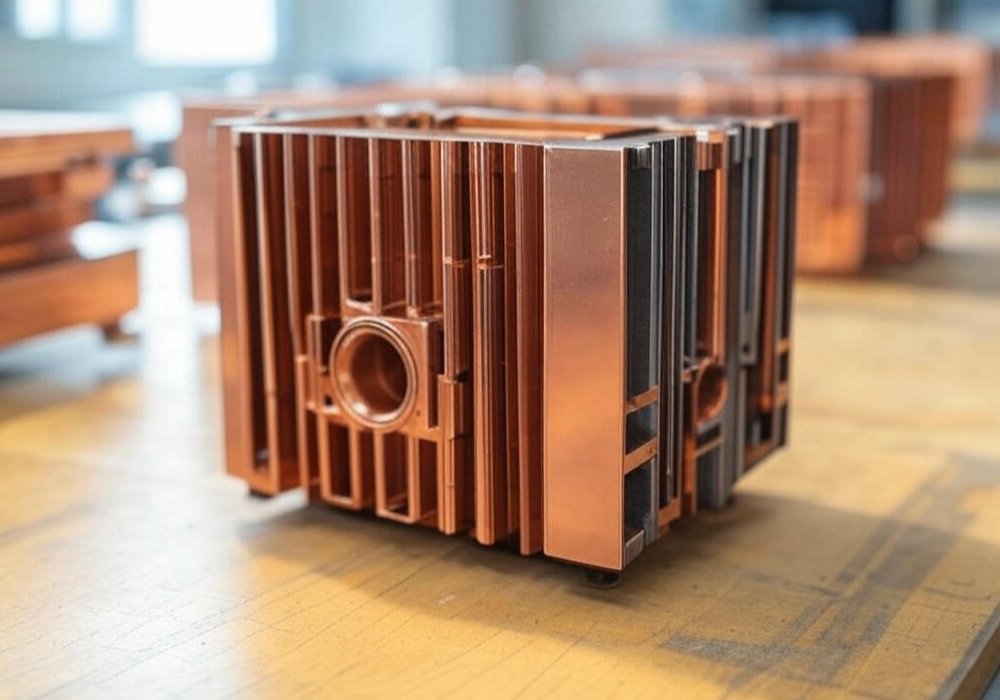

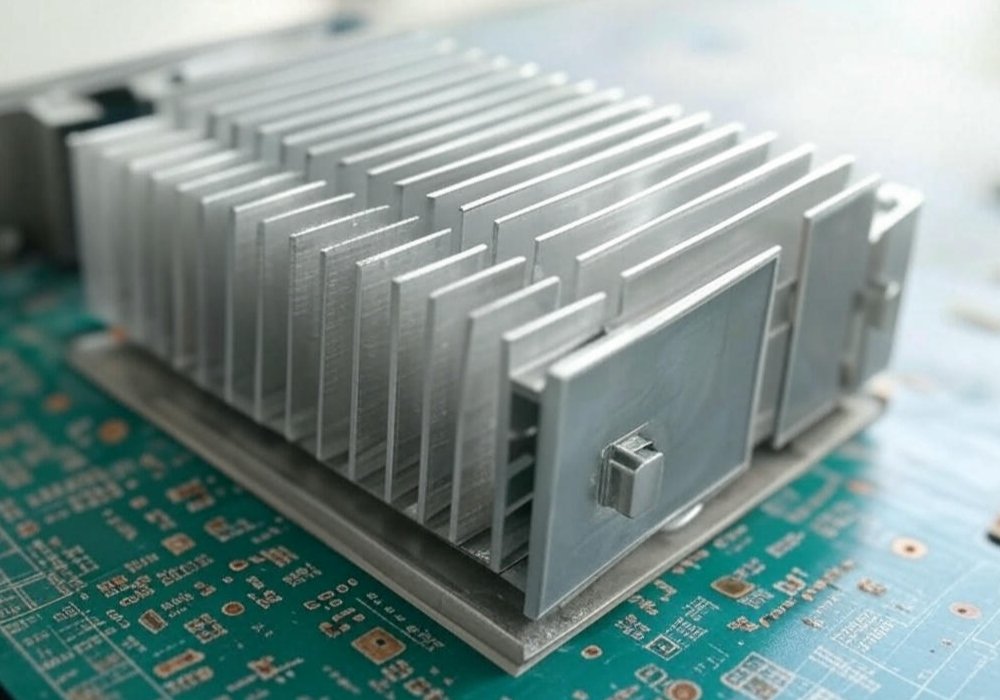

CNC-Machined Heat Sink

Extruded Heat Sink

Die-Cast Heat Sink

Aluminum Heat Sink

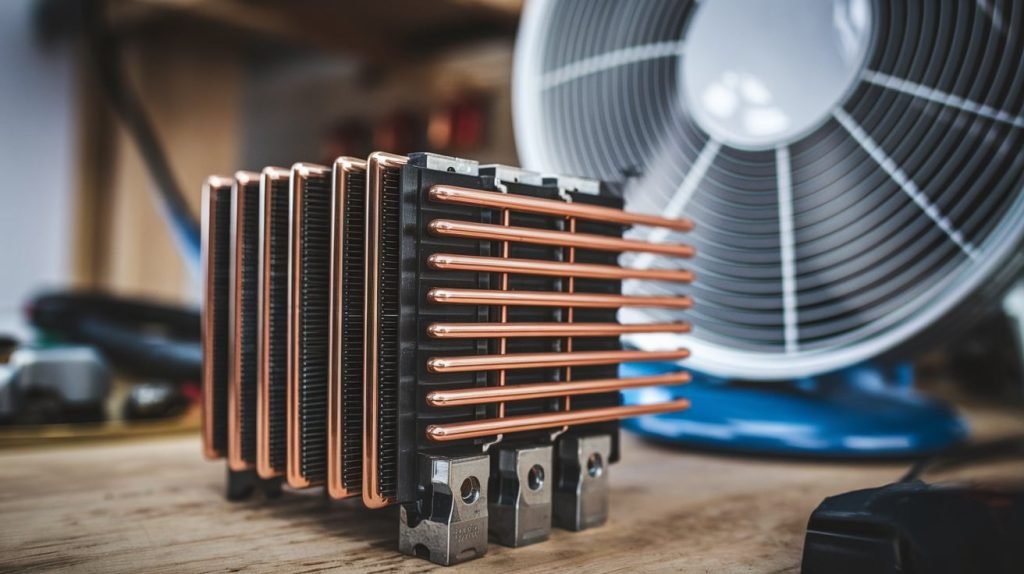

Copper Heat Sink

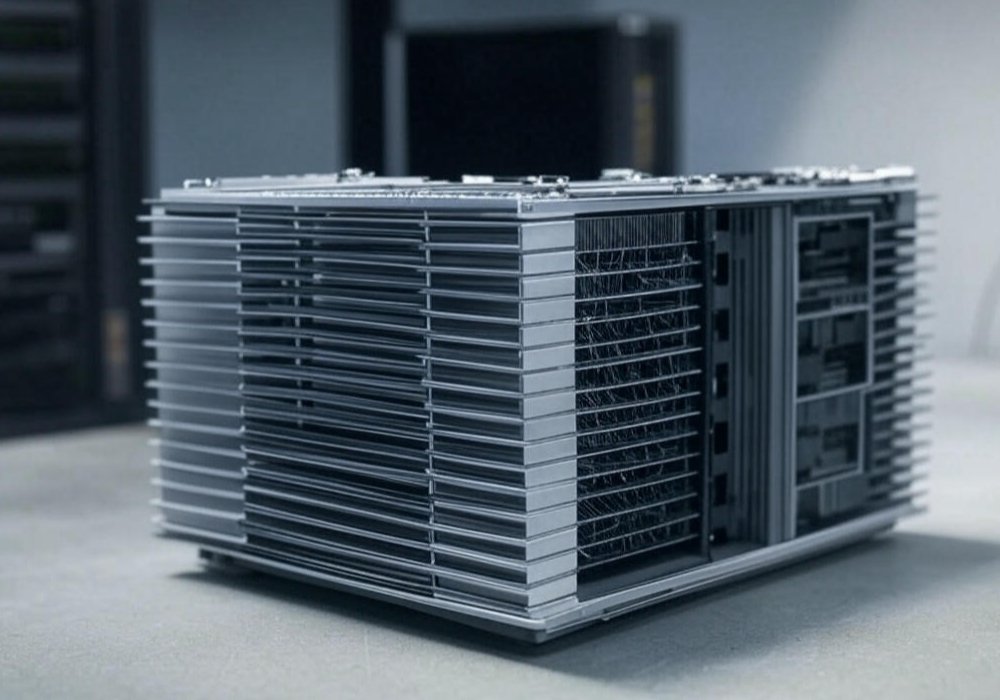

Hybrid Heat Sink

Active Heat Sink

Passive Heat Sink

Finned Heat Sink

Pin Fin Heat Sink

Folded Fin Heat Sink