Precision CNC Turning Services for Your Needs

Reliable CNC turning services for cylindrical parts for industries ranging from aerospace to medical device manufacturing. ISO-certified, competitive pricing, and fast turnaround.

Whether you need prototype development or high-volume production, our precision CNC turning capabilities ensure consistent accuracy and superior surface finishes.

ISO 9001: 2015 Certified Processes

In-Process Inspection with CMM (Coordinate Measuring Machine)

ISO 13485: 2016 Medical Device

IATF 16949: 2016 Automotive

AS9100 Quality Management System Certification

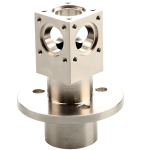

CNC Turning Service: Precision Manufacturing Solutions

CNC turning is a subtractive manufacturing process where a cutting tool removes material from a rotating workpiece to create cylindrical parts with high precision. Unlike CNC milling, where the tool rotates and the workpiece remains stationary, turning involves a stationary cutting tool and a rotating workpiece.

The process is controlled by computer numerical control (CNC) systems that follow programmed toolpaths to achieve exact specifications. This automation ensures exceptional repeatability and precision, making CNC turning ideal for creating components with circular cross-sections and complex external or internal features.

How CNC Turning Works

CNC turning transforms raw materials into precisely crafted cylindrical components through computer-controlled machining. It's process follows these essential steps:

The workpiece is secured in a chuck or collet that rotates at high speed

A stationary cutting tool moves along two axes (X and Z) to engage the material

The tool removes material as the workpiece rotates, creating the desired shape

Multiple tools can be used sequentially for different operations

The CNC controller precisely coordinates all movements based on the programmed instructions

Advanced CNC turning centers can also incorporate live tooling capabilities, allowing for milling and drilling operations without repositioning the workpiece, significantly enhancing efficiency and precision.

CNC Turning Capabilities

Our CNC turning services offer a comprehensive range of machining capabilities to meet diverse manufacturing requirements. From simple cylindrical components to complex parts with intricate features, our advanced turning centers deliver exceptional precision and surface quality.

Advanced Equipments

2-axis CNC lathes

Multi-axis turning centers

Swiss-type automatic lathes

Vertical turning centers

Live tooling capabilities

Diversified Operations

External Turning

Internal Boring

Threading

Knurling

Contour Turning

Multiple Certifications

ISO 9001 Quality management

AS 9100 Aerospace

ISO 13485 Medical device

IATF 16949 Automotive

RoHS & REACH

CNC Turning Solutions

Fecision offers tailored CNC turning solutions to meet your specific production requirements, whether you need rapid prototyping or efficient high-volume manufacturing.

Our versatile capabilities allow us to adapt our processes to your project scale while maintaining consistent quality and precision.

- Rapid turnaround times

- Low minimum order quantities (even single parts)

- Material selection flexibility

- Comprehensive inspection and reporting

- Design validation and testing support

Our prototype turning services help you validate designs quickly and cost-effectively before committing to full production, reducing development time and minimizing risks.

- Optimized production workflows

- Automated loading/unloading systems

- Cost-effective material sourcing

- Just-in-time delivery options

- Consistent quality across large batches

Our high-volume turning capabilities deliver consistent quality and competitive pricing for production runs ranging from hundreds to thousands of parts, with scalable capacity to meet your demand fluctuations.

CNC Turning Materials

Aluminum Alloys

Common grades include 6061, 7075, and 2024. They are favored for their ease of machining but require proper cleaning and protection post-processing due to oxidation.

Properties:

- Lightweight

- High strength-to-weight ratio

- Good electrical and thermal conductivity

- Corrosion resistant

Applications:

Aerospace, automotive, electronics, heat exchangers, consumer products

Stainless Steel

Grades like 303, 304 and 316 are popular for their durability and aesthetic appeal, though they are more challenging and costly to machine.

Properties:

- Excellent corrosion resistance

- High strength

- Heat resistant

Applications:

Medical devices, aerospace, automotive, consumer goods, industrial equipment

Steel

Steel’s high strength and versatility fit various applications. Common grades include 1018, 1045, 4140, 4340.

Properties:

- High tensile strength

- Good durability

- Adjustable hardness via heat treatment

Applications:

Construction structures, automotive parts, machinery components, tools

Brass

Its good mechanical properties and machinability make it suitable for intricate designs. Common grades includes C360, C932, and C954.

Properties:

- Good corrosion resistance

- Aesthetic appeal

- Easy to machine

Applications:

Decorative items, musical instruments, electrical components

Copper

Copper’s excellent conductivity and workability suit diverse uses. Common grades include C11000, C17200, C26000.

Properties:

- High thermal/electrical conductivity

- Good malleability

- Decent corrosion resistance

Applications:

Electrical wiring/components, plumbing systems, heat exchangers, decorative items

Titanium

Despite its high cost and difficulty in machining, titanium’s exceptional properties make it indispensable in high-performance applications. Common grades includes Grade 2, Grade 5 (Ti-6Al-4V).

Properties:

- High strength-to-weight ratio

- Corrosion resistant

- Biocompatible

Applications:

Medical implants, aerospace, automotive, high-performance machinery

Engineering plastics

Engineering plastics (e.g., ABS, PC, POM/Acetal, Nylon, PEEK, PTFE, PMMA/Acrylic) offer a balance of lightweight, cost-effectiveness, and ease of machining, although they may lack the heat resistance and strength of metals.

Properties:

- Lightweight

- Cost-effective

- Corrosion resistant

- Easy to machine

Applications:

Electronics, automotive, environmental applications, consumer products

Exotic Materials

Exotic Materials (e.g., Inconel, Hastelloy, Monel, Kovar. Invar, Tungsten) provide exceptional performance in extreme conditions, though they often come with higher costs and machining challenges.

Properties:

- High temperature resistance

- Superior strength-to-weight ratio

- Excellent corrosion resistance

- Unique thermal/electrical properties

Applications:

Aerospace components, medical implants, high-performance racing parts, energy sector equipment

Material Selection Assistance

Not sure which material best suits your application?

Our materials experts can help you select the optimal material based on your performance requirements, budget constraints, and environmental considerations.

CNC Turning Surface Finishes

As Machined

- Standard finish directly from the turning process

- Applied for internal components, non-visible parts

- Suitable for all materials

Passivation

- Chemical process to improve corrosion resistance

- Applied for medical devices, food processing equipment

- Suitable for stainless steel

Anodizing

- Protective oxide layer with color options

- Applied for consumer products, aerospace parts

- Suitable for aluminum, titanium

Polishing/Buffing

- Smooth, reflective surface (Ra 0.2-0.4μm)

- Applied for optical components, fluid flow parts

- Suitable for metals, some plastics

Electroplating

- Metal coating for appearance and protection

- Applied for decorative hardware, electrical components

- Suitable for most metals

Powder Coating

- Durable, corrosion-resistant finish with customizable colors/textures

- Applied for outdoor equipment, consumer products

- Suitable for metals

Bead Blasting

- Uniform matte texture

- Applied for architectural components, consumer products

- Suitable for most metals, some plastics

Black Oxide

- Black conversion coating for corrosion resistance

- Applied for tooling, firearms, industrial equipment

- Suitable for carbon steel, stainless steel

Our finishing processes are carefully controlled to maintain dimensional accuracy while achieving the desired surface characteristics. We can recommend optimal finishing methods based on your specific application requirements and environmental considerations.

CNC Turning Tolerances & Standards

| Dimension Type | Standard Tolerance | Precision Tolerance | Ultra-Precision Tolerance |

| Diameters | ±0.05mm | ±0.025mm | ±0.005mm |

| Lengths | ±0.1mm | ±0.05mm | ±0.01mm |

| Concentricity | 0.05mm | 0.025mm | 0.01mm |

| Surface Finish | Ra 1.6μm | Ra 0.8μm | Ra 0.2μm |

| Roundness | 0.02mm | 0.01mm | 0.002mm |

Size Capacity

- Diameter: 0.5mm to 500mm

- Length: up to 1000mm

- Wall thickness: as thin as 0.3mm

- Micro-precision components

- Large industrial parts

Precision Levels

- Tolerances: ±0.005mm

- Surface finish: Ra 0.2μm

- Roundness: 0.001mm

- Concentricity: 0.01mm

- Thread accuracy: 6g/6H

Quality Certifications

- ISO 9001:2015: Quality management systems

- AS9100D: Aerospace quality management

- ISO 13485: Medical device quality management

- IATF 16949: Automotive quality management

- RoHS & REACH: Environmental compliance

Design Guidelines for CNC Turning

Optimizing your design for CNC turning can significantly improve manufacturability, reduce costs, and enhance part quality. Our engineering team provides comprehensive design for manufacturing (DFM) feedback, but these guidelines will help you create more efficient designs from the start.

Geometry Considerations

✅ Maintain minimum wall thickness of 0.8mm for metals and 1.5mm for plastics

✅ Include radii on internal corners (min. 0.4mm) to reduce stress concentration

✅ Design with standard thread sizes where possible

✅ Limit length-to-diameter ratio to 4:1 for unsupported turning

✅ Consider part orientation and fixturing requirements

Tolerance Optimization

✅ Specify tight tolerances only where functionally necessary

✅ Consider material properties when defining tolerances

✅ Account for thermal expansion in precision applications

✅ Use geometric dimensioning and tolerancing (GD&T) appropriately

✅ Group similar tolerance features to minimize tool changes

Cost Reduction Tips

✅ Minimize the number of setups required

✅ Use standard material sizes and grades when possible

✅ Design parts that can be machined with standard tooling

✅ Consider surface finish requirements carefully

✅ Consolidate features to reduce machining time

CNC Turning Application

Industries We Serve

CNC turning produces critical components for numerous industries, each with unique requirements for precision, materials, and performance.

Our expertise spans multiple sectors, delivering custom turning solutions for diverse applications.

Medical

Turbine and engine components

Landing gear parts

Fasteners and structural elements

Fuel system components

Automotive

Steering system parts

Brake system components

Engine parts and fittings

Suspension components

Aerospace

Implant components

Diagnostic equipment parts

Drug delivery device components

Laboratory equipment parts

Electronics

Heat sinks and thermal management

Enclosure components

Precision shafts and spindles

Test equipment fixtures

Advantages of CNC Turning

- Exceptional Precision: Achieves tolerances as tight as ±0.005mm for critical dimensions

- Consistent Quality: Computer control ensures part-to-part repeatability across production runs

- Complex Geometries: Creates intricate internal and external features in a single setup

- Material Versatility: Processes virtually any machinable material from soft plastics to hardened steels

- Surface Finish: Delivers superior surface quality with minimal post-processing

- Cost-Effective: Economical for both prototyping and production volumes

- Quick Turnaround: Rapid setup and efficient machining reduce lead times

- Design Flexibility: Accommodates design changes without expensive tooling modifications

- Automation Potential: Integrates with robotic systems for lights-out manufacturing

Why Fecision for CNC Machining?

Advanced Technology

Traditional machining methods may not be able to deal with complex geometries and high-precision parts. Our multi-axis machines, ranging from 3-axis to 5-axis CNC machines, enable us to perform intricate cuts, angles, and curves.

Experienced Engineering Team

Our engineering team has decades of experience in CNC machining and design optimization. At Fecision, we specialize in Design for Manufacturability (DFM) and leverage advanced CAD/CAM software to ensure smooth integration between design and machining processes.

Versatility Across Materials

Fecision offers a broad spectrum of material options to match the needs of your specific application. Meanwhile, we provide guidance on material selection based on part performance requirements such as strength, corrosion resistance, or wear resistance, ensuring optimal results.

Quality Assurance

Our products are trusted by high-profile customers from industries across global, meeting strict and complete quality standard. Access to ISO 9001: 2015 quality certification and our manufacturing partners certified to ISO 13485: 2016, ISO 14001: 2015, and IATF 16949: 2016.

Fast Turnaround Times

We recognize the critical need for timely delivery. Most machines of our partner manufactuers run 7*24 hours with integrated process. Through streamlined workflows and optimized production processes, we ensure fast lead times while maintaining the highest standards of quality.

Commitment to Sustainability

Fecision is committed to minimizing waste and reducing our environmental impact. We prioritize sustainable practices such as material recycling, energy-efficient operations, and waste reduction in our machining processes.

Start CNC Turning

Submit Technical Files

xport your design to a CNC-compatible CAD format. For CNC machining, we advise STEP format as it’s more standardized and can be used across platforms. A technical drawing is helpful, especially for threads, tolerances, or specific finishes.

DFM & Quotation

Our engineers analyze your design for manufacturability, check tolerances and materials. Please be aware that further discussions may be needed during the process. We then provide a detailed quote including lead time, costs, and other infomation you may need.

Precision Manufacturing

Upon your confirmation to the design, our team will begin CNC machining. Using advanced CNC machines, we mill, turn or grind parts per your design. Real-time monitoring ensures adherence to tolerances, with material traceability maintained throughout production.

Inspection & Delivery

Parts undergo strict QC via CMM or 3D scanning. We issue inspection reports, pack securely and ship, offering tracking info. Rush delivery options are available upon request.

Ready to Start Your CNC Turning Project?

Our expert team is ready to help you bring your designs to life with precision CNC turning services.

Whether you need rapid prototypes or high-volume production, we have the capabilities to deliver exceptional quality parts on time and within budget.

CNC Turning FAQs

CNC turning and milling differ primarily in how the workpiece and cutting tool move. In CNC turning, the workpiece rotates while a stationary cutting tool removes material. This makes turning ideal for cylindrical parts. In CNC milling, the cutting tool rotates while the workpiece remains stationary, making it better suited for prismatic parts with complex features. Many modern CNC turning centers combine both capabilities with live tooling options.

Our standard CNC turning tolerances are ±0.05mm, but we can achieve precision tolerances of ±0.025mm and ultra-precision tolerances of ±0.005mm for critical dimensions. The achievable tolerance depends on several factors including material properties, part geometry, feature size, and specific dimension requirements. We recommend discussing your tolerance needs during the quoting process.

We have no strict minimum order quantity (MOQ) requirements. We can produce as few as one prototype part or thousands of production components. However, the per-unit cost is typically higher for very small quantities due to setup and programming costs being distributed across fewer parts. We're happy to provide pricing options for different volume scenarios to help you make the most cost-effective decision.

Yes, we provide material certifications (mill certs) and detailed inspection reports upon request. Our standard quality process includes first article inspection and batch sampling according to industry standards. For critical applications, we can perform 100% inspection and provide comprehensive measurement data for all specified dimensions. Additional documentation such as material traceability, process certifications, and special testing reports are available to meet specific industry requirements.

Lead times for CNC turned parts vary based on complexity, quantity, material availability, and current production schedule. Typical lead times range from 3-5 business days for rush prototypes to 2-3 weeks for standard production orders. We offer expedited services for time-critical projects. Please contact us with your specific requirements for an accurate timeline estimate.

We accept most standard CAD file formats including STEP, IGES, Parasolid, SolidWorks, AutoCAD, and others. 3D models are preferred for complex parts, but we can also work from 2D drawings with complete dimensioning and tolerancing. For optimal results, we recommend providing both 3D models and 2D drawings with GD&T callouts for critical features.