CNC Milling Services: Precision Manufacturing

ISO 9001: 2015 Certified Processes

In-Process Inspection with CMM (Coordinate Measuring Machine)

ISO 13485: 2016 Medical Device

IATF 16949: 2016 Automotive

No Minimum Order Quantities

CNC Milling Capabilities

CNC Milling Solutions: From Prototype to Production

Our CNC milling services scale seamlessly from rapid prototyping to high-volume production, providing consistent quality and cost-efficiency at every stage of your product development cycle.

Rapid Prototyping

Transform your concepts into physical parts. Our rapid prototyping services allow you to validate designs, test functionality, and iterate quickly before committing to full production.

- Quick turnaround times

- Design verification and testing

- Iterative improvements

- Low setup costs

Production Manufacturing

Scale from prototypes to production with our high-volume CNC milling services. As quantities increase, we optimize tooling and processes to reduce per-unit costs while maintaining consistent quality.

- Dedicated tooling for efficiency

- Volume-based pricing

- Quality assurance protocols

- Inventory management options

How CNC Milling Works

CNC milling transforms digital designs into physical parts through a systematic process that combines computer programming with precision machining. Understanding this workflow helps you better prepare your projects for successful manufacturing.

CAD Design: The process begins with creating a detailed 3D model using Computer-Aided Design (CAD) software, specifying dimensions, tolerances, and features.

CAM Programming: Computer-Aided Manufacturing (CAM) software converts the 3D model into a series of tool paths and machine instructions (G-code) that control the CNC mill.

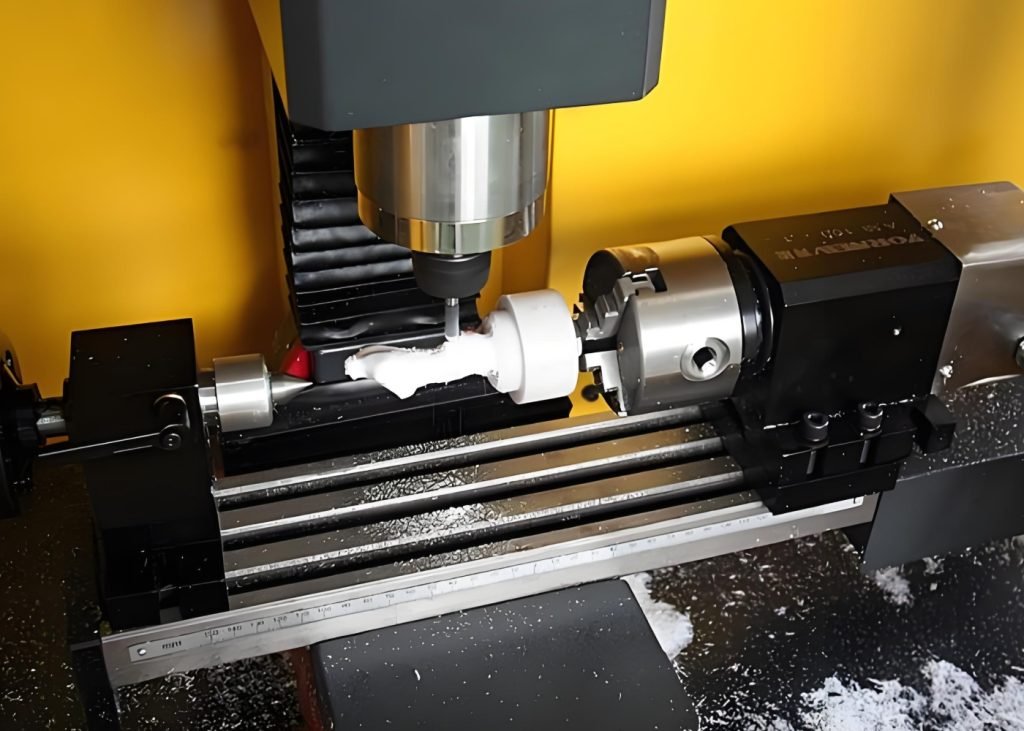

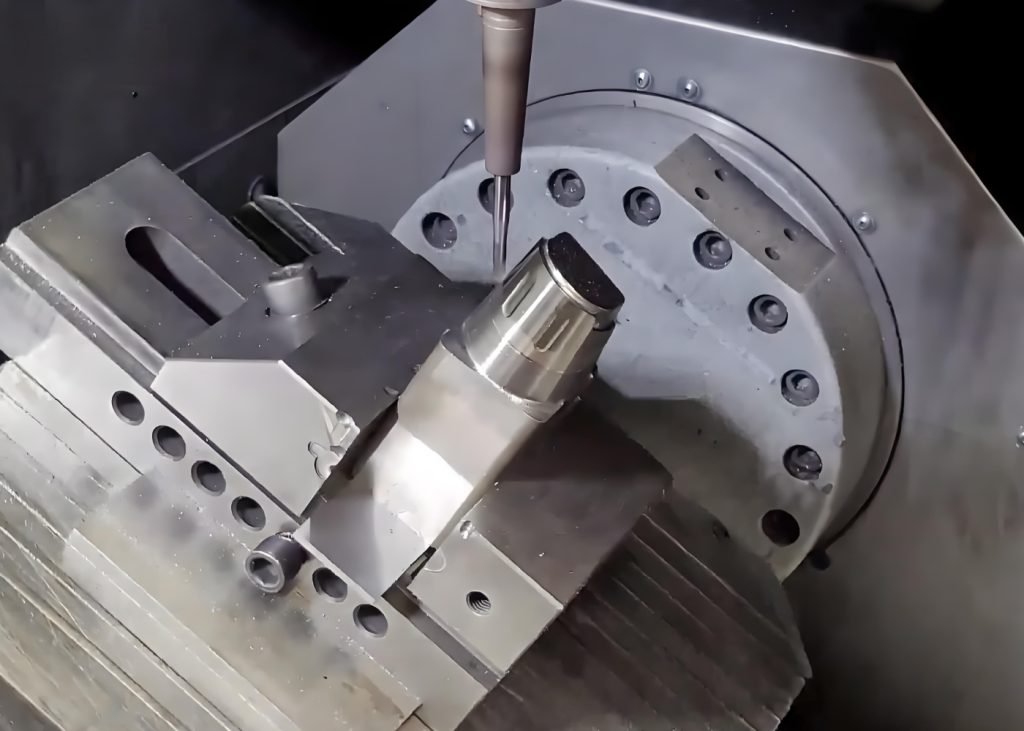

Machine Setup: The workpiece material is securely mounted on the machine bed, and cutting tools are loaded into the tool carousel according to the programmed sequence.

Machining Operation: The CNC controller executes the G-code, precisely moving the cutting tools to remove material from the workpiece according to the programmed tool paths.

Quality Inspection: Finished parts undergo dimensional verification using precision measuring equipment to ensure they meet specified tolerances.

Surface Finishing: If required, parts receive additional treatments such as deburring, polishing, anodizing, or other surface finishes to enhance appearance and performance.

CNC Milling Technical Specs

| Specs | Tolerance |

| Tolerance Range | ±0.001″(0.025mm) |

| Surface finish options | Ra 0.8μm to 3.2μm |

| Max workpiece size | 2000×1500×1500mm |

| Minimum Feature Size | 0.2mm |

| Tool magazine capacity | 40+ tools |

| Milling Capabilities | 3-axis, 4-axis, 5-axis |

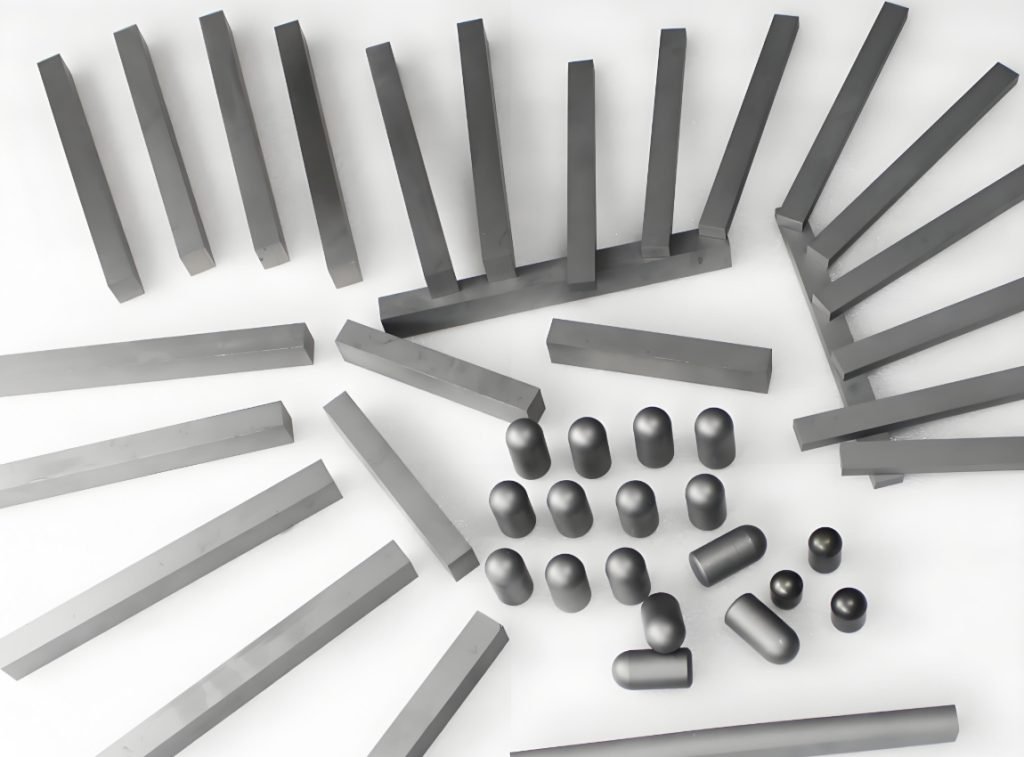

CNC Milling Materials

Aluminum Alloys

Common grades include 6061, 7075, and 2024. They are favored for their ease of machining but require proper cleaning and protection post-processing due to oxidation.

Properties:

- Lightweight

- High strength-to-weight ratio

- Good electrical and thermal conductivity

- High Corrosion Resistance

- Good Machinability

Applications:

- Aerospace: aircraft components such as wing structures, fuselage parts, engine mounts

- Automotive:engine blocks, wheels, transmission components

- Electronics:heat sinks for computers and other electronic devices

Steel

Steel (e.g., A36, 4140, 304, 1018) is widely used in milling for its strength and versatility, though it may be harder to machine than softer metals.

Properties:

- High tensile strength

- Good durability

- Adjustable hardness

- Moderate corrosion resistance (with alloys)

Applications:

- Automotive: engine parts, chassis components

- Construction: structural brackets, fasteners

- Industrial: machinery parts, tooling

- Aerospace: precision structural components

Stainless Steel

Grades like 304 and 316 are popular for their durability and aesthetic appeal, though they are more challenging and costly to machine.

Properties:

- Excellent corrosion resistance

- High strength

- Heat resistantce

- Aesthetic appeal

Applications:

- Medical: surgical instruments, implants, medical equipment

- Food and Beverage: food processing machinery, storage tanks, kitchen equipment

- Architecture: building facades, handrails,structural components

Brass

Its good mechanical properties and machinability make it suitable for intricate designs.

Properties:

- Good corrosion resistance

- Aesthetic appeal

- Easy to machine

- Electrical conductivity

Applications:

- Electrical: electrical connectors, terminals, switches

- Decorative:jewelry, door handles, architectural ornaments

- Musical Instruments: trumpets, trombones, other brass instruments

Copper

Copper (e.g., C11000, C26000, C17200) is favored in milling for its machinability and conductivity, though it’s softer than metals like steel.

Properties:

- Excellent machinability

- High thermal/electrical conductivity

- Good ductility

- Decent corrosion resistance

Applications:

- Electrical: connectors, busbars, terminal blocks

- Plumbing: valve components, fittings

- Precision parts: gears, small mechanical components

- Decorative: intricate ornamental elements

Titanium

Despite its high cost and difficulty in machining, titanium’s exceptional properties make it indispensable in high-performance applications.

Properties:

- High strength-to-weight ratio

- Excellent corrosion resistance

- Biocompatibility

- High temperature resistance

Applications:

- Aerospace: jet engine parts, airframe structures, landing gear

- Medical: dental implants, orthopedic implants, surgical tools

- Marine: propellers, shafts, underwater structures

Magnesium

Magnesium (e.g., AZ31, AZ91, WE43) is valued in milling for its lightweight nature and machinability, though it’s less rigid than steel.

Properties:

- Ultra-lightweight

- Good machinability

- High strength-to-weight ratio

- Moderate corrosion resistance

Applications:

- Aerospace: structural components, brackets

- Automotive: engine parts, chassis components

- Electronics: casings, heat sinks

- Medical: lightweight device parts

Engineering plastics

Engineering plastics (e.g., ABS, POM/Derlin, PA/Nylon, PEEK, PMMA/Acrylic) offer a balance of lightweight, cost-effectiveness, and ease of machining, although they may lack the heat resistance and strength of metals.

Properties:

- Good Impact Resistance

- Easy to Machine

- Good Surface Finish

- Low Cost

Applications:

- Consumer Electronics: smartphone cases, computer keyboard keys, TV housings

- Automotive: interior trim parts, dashboard components, bumper covers

- Toy Industry: toys

Engineering plastics

Specialty Materials (e.g., composites, machinable ceramics, carbon fiber, G10/FR4, medical-grade materials) offer tailored performance for demanding applications, though they often require specialized machining.

Properties:

- Customizable strength-to-weight ratios

- Excellent chemical/thermal resistance

- Unique electrical properties

- Biocompatibility (for medical grades)

Applications:

- Aerospace: high-strength structural parts

- Electronics: insulators, circuit boards

- Medical: implants, surgical instruments

- Industrial: high-performance components

Material Selection Assistance

Not sure which material best suits your application?

Our materials experts can help you select the optimal material based on your performance requirements, budget constraints, and environmental considerations.

Surface Finishes for CNC Milled Parts

As Machined

- Natural finish directly from the milling process

- Suitable for functional parts, prototypes, cost-sensitive applications

Anodizing

- Protective oxide layer with color options

- Suitable for aluminum parts requiring corrosion resistance and color

Polishing/Buffing

- Smooth, reflective surface

- Suitable for mold components, optical applications, aesthetic requirements

Powder Coating

- Durable, thick coating with extensive color options

- Suitable for parts exposed to harsh environments, decorative applications

Bead Blasting

- Uniform matte finish that hides tool marks

- Consistent appearance, light diffusion, preparation for coating

Black Oxide

- Forms black conversion coating for corrosion resistance

- Suitable for steel parts needing wear resistance and dark finish

Electroplating

- Coated with metal layer for protection/conductivity

- Suitable for steel, copper parts needing corrosion resistance or conductivity

Passivation

- Removes free iron to enhance corrosion resistance

- Suitable for stainless steel parts requiring long-term rust protection

3-Axis vs. 4-Axis vs. 5-Axis CNC Milling

| Feature | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling |

| Movement Axes | X, Y, Z (linear) | X, Y, Z + A (rotation) | X, Y, Z + A, B (rotation) |

| Part Complexity | Simple to moderate | Moderate to complex | Highly complex |

| Setup Requirements | Multiple setups for complex parts | Fewer setups than 3-axis | Single setup for most parts |

| Undercuts | Limited capability | Moderate capability | Excellent capability |

| Relative Cost | $ | $$ | $$$ |

| Ideal Applications | Flat surfaces, pockets, holes | Cylindrical parts, indexed features | Complex contours, aerospace parts |

Design Guidelines for CNC Milling

Optimizing your design for CNC milling can significantly improve manufacturability, reduce costs, and enhance part quality.

Consider these key design guidelines to ensure your parts can be efficiently machined while meeting functional requirements.

Wall Thickness

Maintain minimum wall thickness of 0.8mm for metals and 1.5mm for plastics. Thin walls can flex during machining, causing dimensional inaccuracies and potential tool breakage.

Internal Corners

Design internal corners with radii at least equal to the tool radius. Sharp internal corners are impossible to machine with rotating tools and require a radius.

Deep Pockets

Limit pocket depth-to-width ratio to 4:1 where possible. Deeper pockets require specialized tooling and increase machining time and cost.

Hole Depth

Keep hole depth-to-diameter ratio under 4:1 for optimal results. Deeper holes may require specialized drilling operations and can affect dimensional accuracy.

Thread Specifications

Specify standard thread sizes where possible. Custom threads require specialized tooling and increase manufacturing costs.

Tolerances

Apply tight tolerances only where functionally necessary. Overly tight tolerances increase machining time and cost without adding value.

Advantages and Limitations of CNC Milling

CNC milling offers numerous benefits that make it an ideal manufacturing process for a wide range of applications.

From exceptional precision to material versatility, these advantages contribute to its widespread adoption across industries.

Advantages of CNC Turning

- Exceptional Precision: Achieves tolerances as tight as ±0.001" for critical dimensions

- Consistency: Produces identical parts across production runs with minimal variation

- Material Versatility: Compatible with metals, plastics, composites, and specialty materials

- Complex Geometries: Creates intricate features and contours, especially with multi-axis machines

- Surface Quality: Delivers excellent surface finishes with minimal post-processing

- Scalability: Efficiently handles both prototypes and production volumes

- Design Freedom: Accommodates design changes without expensive tooling modifications

Limitations to Consider

- Internal Corners: Cannot create perfectly sharp internal corners

- Deep Features: Challenging to machine very deep, narrow features

- Material Waste: Subtractive process generates material scrap

- Initial Cost: Higher setup costs for low volumes compared to some processes

- Size Limitations: Maximum part size constrained by machine dimensions

CNC Milling Application

Industries We Serve

CNC milling delivers precision components across diverse industries, each with unique requirements and specifications. Our expertise spans multiple sectors, providing tailored solutions for even the most demanding applications.

Medical

★ Biocompatible

★ Sterilizable

Automotive

★ Volume Production

★ Durability

Electronics

★ Thermal Management

★ EMI Shielding

Aerospace

★ High Precision

★ Exotic Materials

Why Fecision for CNC Machining?

Advanced Technology

Traditional machining methods may not be able to deal with complex geometries and high-precision parts. Our multi-axis machines, ranging from 3-axis to 5-axis CNC machines, enable us to perform intricate cuts, angles, and curves.

Experienced Engineering Team

Our engineering team has decades of experience in CNC machining and design optimization. At Fecision, we specialize in Design for Manufacturability (DFM) and leverage advanced CAD/CAM software to ensure smooth integration between design and machining processes.

Versatility Across Materials

Fecision offers a broad spectrum of material options to match the needs of your specific application. Meanwhile, we provide guidance on material selection based on part performance requirements such as strength, corrosion resistance, or wear resistance, ensuring optimal results.

Quality Assurance

Our products are trusted by high-profile customers from industries across global, meeting strict and complete quality standard. Access to ISO 9001: 2015 quality certification and our manufacturing partners certified to ISO 13485: 2016, ISO 14001: 2015, and IATF 16949: 2016.

Fast Turnaround Times

We recognize the critical need for timely delivery. Most machines of our partner manufactuers run 7*24 hours with integrated process. Through streamlined workflows and optimized production processes, we ensure fast lead times while maintaining the highest standards of quality.

Commitment to Sustainability

Fecision is committed to minimizing waste and reducing our environmental impact. We prioritize sustainable practices such as material recycling, energy-efficient operations, and waste reduction in our machining processes.

Start CNC Machining

Submit Technical Files

xport your design to a CNC-compatible CAD format. For CNC machining, we advise STEP format as it’s more standardized and can be used across platforms. A technical drawing is helpful, especially for threads, tolerances, or specific finishes.

DFM & Quotation

Our engineers analyze your design for manufacturability, check tolerances and materials. Please be aware that further discussions may be needed during the process. We then provide a detailed quote including lead time, costs, and other infomation you may need.

Precision Manufacturing

Upon your confirmation to the design, our team will begin CNC machining. Using advanced CNC machines, we mill, turn or grind parts per your design. Real-time monitoring ensures adherence to tolerances, with material traceability maintained throughout production.

Inspection & Delivery

Parts undergo strict QC via CMM or 3D scanning. We issue inspection reports, pack securely and ship, offering tracking info. Rush delivery options are available upon request.

Validated Performance, Guaranteed Quality

Commitment to Quality & Validation

We employ rigorous validation protocols, including in-process and final CMM inspection, steel certifications, heat treat certifications, and comprehensive mold trials (T1, T2...) to ensure your mold performs flawlessly and meets all specifications from the first shot. Trust our ISO-certified quality system.

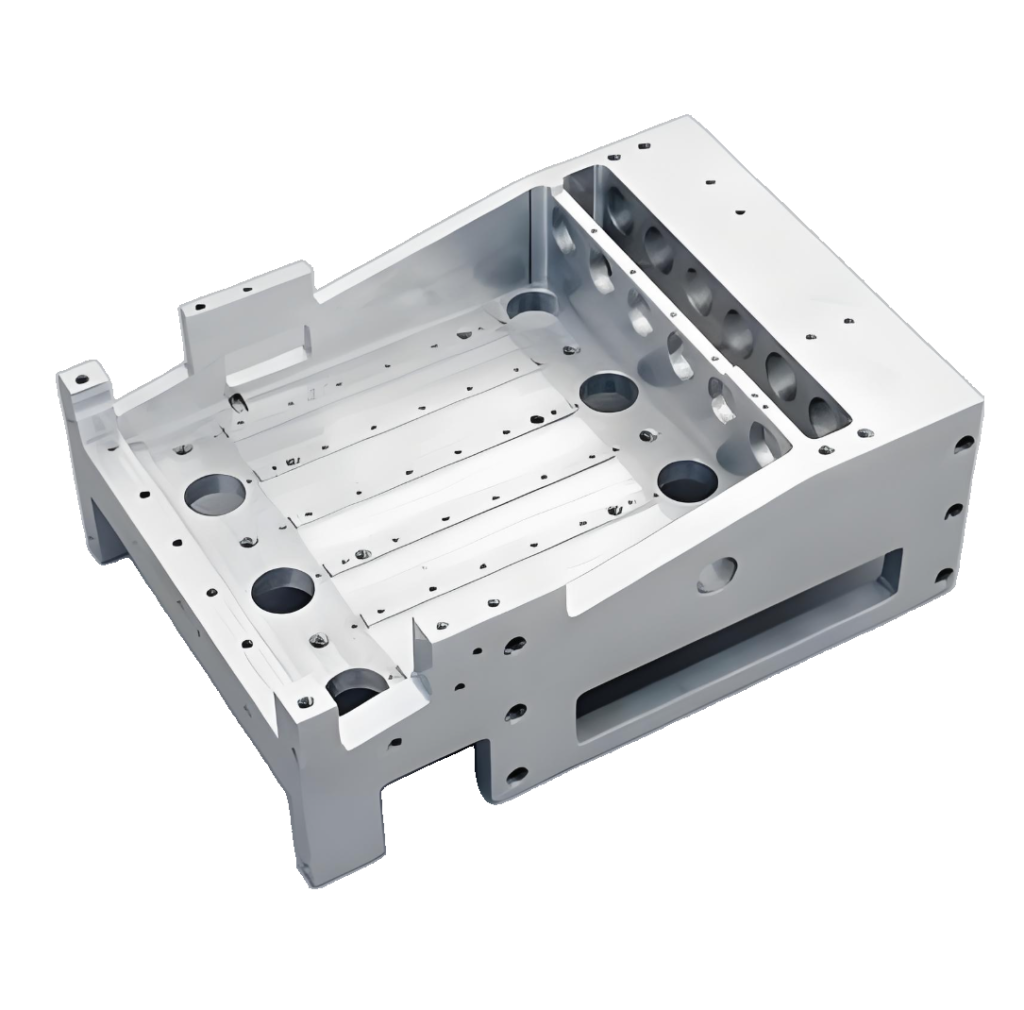

Recent Projects

Start Your CNC Milling Project Today!

Together, we can make something remarkable!

Upload your design files for a free quote or contact our engineering team to discuss your specific requirements.

CNC Milling FAQs

CNC milling uses rotating cutting tools that move around a stationary workpiece to remove material. The cutting tool rotates while the workpiece remains fixed. In contrast, CNC turning involves a rotating workpiece with stationary cutting tools. Milling is ideal for creating complex shapes with flat surfaces and features, while turning is best for cylindrical or round parts.

CNC milling works with a wide range of materials including metals (aluminum, steel, titanium, brass), plastics (ABS, acrylic, PEEK, nylon), and composites. Material selection depends on your application requirements such as strength, weight, temperature resistance, and cost considerations. Our engineering team can help you select the optimal material for your specific needs.

We accept most standard CAD file formats including STEP, IGES, X_T (Parasolid), SolidWorks (.sldprt), and Autodesk Inventor (.ipt). For optimal results, 3D models are preferred over 2D drawings. If you only have 2D drawings, our engineering team can help convert them to 3D models for a nominal fee.

Our standard tolerance for CNC milling is ±0.005" (0.127mm). For critical dimensions, we can achieve tolerances as tight as ±0.001" (0.025mm). Tighter tolerances require more precise machining operations and may increase cost. We recommend specifying tight tolerances only for features where they're functionally necessary.

We have no minimum order quantity and can produce as few as one part. However, there are setup costs associated with each CNC milling job, so unit costs decrease significantly as quantities increase. For prototypes or low-volume production, we offer optimized processes to keep costs reasonable even for small quantities.

Yes, we can provide material certifications (Mill Certs) upon request for most materials. These certifications verify the chemical composition and mechanical properties of the material used. This service is particularly important for aerospace, medical, and defense applications where material traceability is required.