Source for High-Quality Plastic Parts

Start your project now

ISO 9001:2015 Certified Processes

ISO 13485: 2016 Medical Device

IATF 16949: 2016 Automotive AS9100 Quality Management

Faster Lead Time for Production Needs

In-Process Inspection with CMM

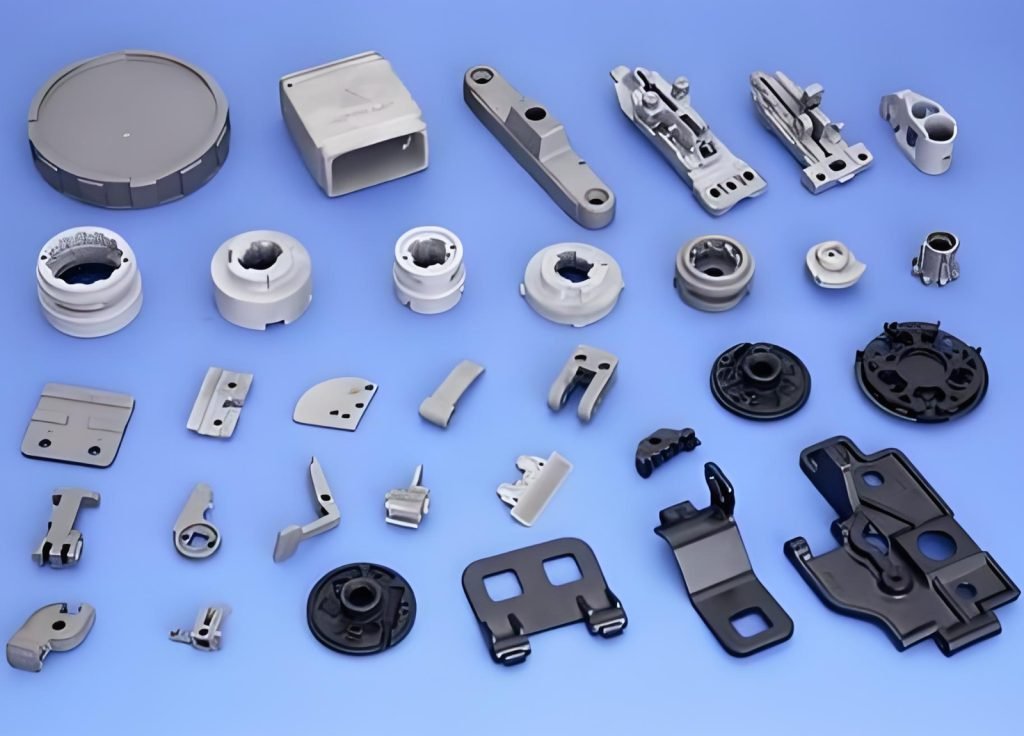

Plastic Part Manufacturing

Plastic part production is a versatile manufacturing process that creates functional components from various plastic materials. This technology has revolutionized industries by offering lightweight, durable, and cost-effective alternatives to metal and other traditional materials.

Modern plastic manufacturing processes include injection molding, thermoforming, compression, and CNC machining, among others. Each method offers distinct advantages in terms of production volume, part complexity, material selection, and cost efficiency.

The choice of manufacturing process depends on factors such as part design, material properties, production volume, and budget constraints. Advanced computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies have further enhanced precision and efficiency in plastic part production.

Excellent corrosion and chemical resistance

Lightweight yet durable construction

Design flexibility for complex geometries

Cost-effective production for both low and high volumes

Superior insulation properties for electrical applications

Fecision Plastic Part Production Services

Comprehensive plastic manufacturing solutions tailored to your specific requirements, from prototyping to full-scale production.

Our Plastic Manufacturing Capabilities

At Fecision, we offer end-to-end plastic part production services, combining state-of-the-art technology with decades of manufacturing expertise to deliver high-quality components that meet the most demanding specifications.

CNC Machining

Fecision delivers precise, custom fabrication via computer-controlled tools. It handles materials like ABS, PEEK, acrylic, producing complex geometries with tight tolerances. Ideal for prototypes or low-volume runs, serving automotive, electronics, medical sectors with high accuracy and repeatability.

Plastic Molding

Fecision provides custom manufacturing of plastic parts via processes like injection molding, thermoforming, or compression. It caters to diverse industries—automotive, electronics, packaging—with precise specs, material options (ABS, PP, PE), and scalable production, ensuring quality and efficiency for prototypes or mass production.

Our Commitment to Excellence

We combine technical expertise with state-of-the-art equipment to deliver plastic components that meet your exact specifications and exceed your quality expectations.

Engineering Support

Dedicated engineering team to assist with design for manufacturability (DFM) and material selection.

Quality Assurance

Comprehensive quality control processes with advanced inspection equipment to ensure precision and consistency.

Material Expertise

Extensive knowledge of plastic materials and their applications to recommend the optimal solution for your needs.

Production Flexibility

Capabilities to handle both small-batch prototyping and large-scale production runs efficiently.

Plastic Part Manufacturing Steps

From design to delivery, our streamlined manufacturing process ensures quality and efficiency at every stage.

Design & Engineering

The process begins with product design using CAD software. Our engineers conduct design for manufacturability (DFM) analysis to optimize the part for production, ensuring functionality, cost-effectiveness, and quality.

Production

Using the selected manufacturing process (injection molding, extrusion, etc.), we produce the plastic parts. Advanced process controls ensure consistency and adherence to specifications.

Material Selection

Based on the part's intended use, environmental factors, and performance requirements, we select the optimal plastic material from our extensive range of engineering resins and polymers.e replication of the desired part geometry.

Post-Processing

Parts may undergo secondary operations such as trimming, assembly, or surface treatment to meet final specifications and enhance performance or aesthetics.

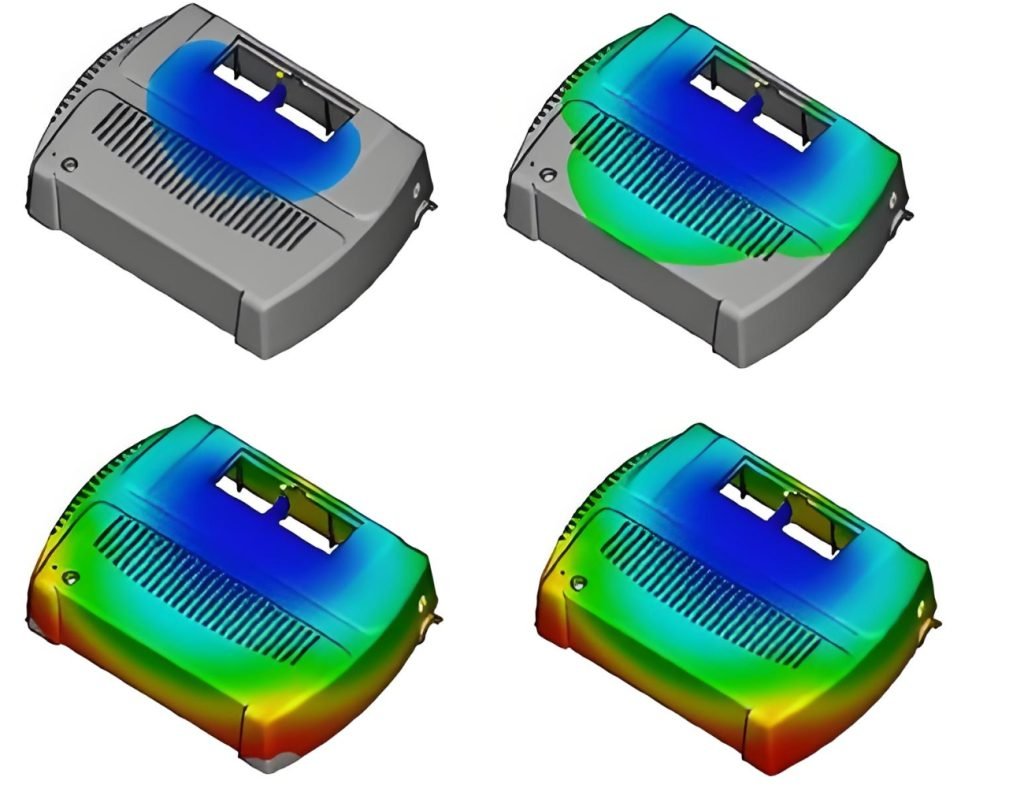

Tooling & Mold Design

For molding processes, custom tooling is designed and fabricated. Our mold makers create precision tools using advanced CNC machining, ensuring accurate replication of the desired part geometry.

Quality Inspection

Comprehensive quality checks are performed using advanced measurement tools to ensure dimensional accuracy, material properties, and overall quality meet customer requirements.

Prototyping

Using the selected manufacturing process (injection molding, extrusion, etc.), we produce the plastic parts. Advanced process controls ensure consistency and adherence to specifications.

Packaging & Delivery

Finished parts are carefully packaged to prevent damage during transportation and delivered according to the agreed schedule, ensuring on-time delivery to our customers.

Our Production Capabilities

High-Volume Production

Capable of producing millions of parts annually with consistent quality and competitive pricing.

Precision Tolerances

Maintaining tight tolerances as low as ±0.0005" for critical dimensions and features.

Complex Geometries

Producing intricate part designs with undercuts, threads, and complex features.

Fast Turnaround

Efficient production processes with quick setup times for accelerated project timelines.

Advanced Manufacturing Facility

Our state-of-the-art production facility is equipped with the latest plastic manufacturing technology.

Molding Services for Plastic Part Production

Popular Features

High Precision & Consistency

Capable of producing parts with high precision and repeatability.

Cost Efficiency for High-Volume Production

The cost per unit decreases significantly with high-volume production.

Design Flexibility & Material Variety

Accommodate a wide variety of designs, from simple to highly complex shapes.

Plastic Molding Techniques

Injection Molding

Thermoforming

Compression Molding

Plastic Molding Capabilities

Plastic molding offers a broad range of capabilities, allowing manufacturers to create high-quality, precision parts for various industries.

Standard | Technical Data |

Tolerances | As tight as ±0.001 inches (0.025 mm) |

Dimensional Stability | Parts maintain shape and size over long production runs |

Cycle Time | Range from 15 to 60 seconds per part |

Output | Up to 1000+ parts per hour |

Material Waste | Less than 5% |

Recyclability | Many plastics such as PET, PP, and ABS, are recyclable |

Cost Per Unit | Offset by low per-unit costs in mass production |

Tooling Longevity | Hundreds of thousands to millions of cycles |

Surface Finishes | Typically Ra 0.4 – 1.6μm |

Energy Efficiency | Up to 30% improvement |

Material Variety | Over 200 different plastic materials |

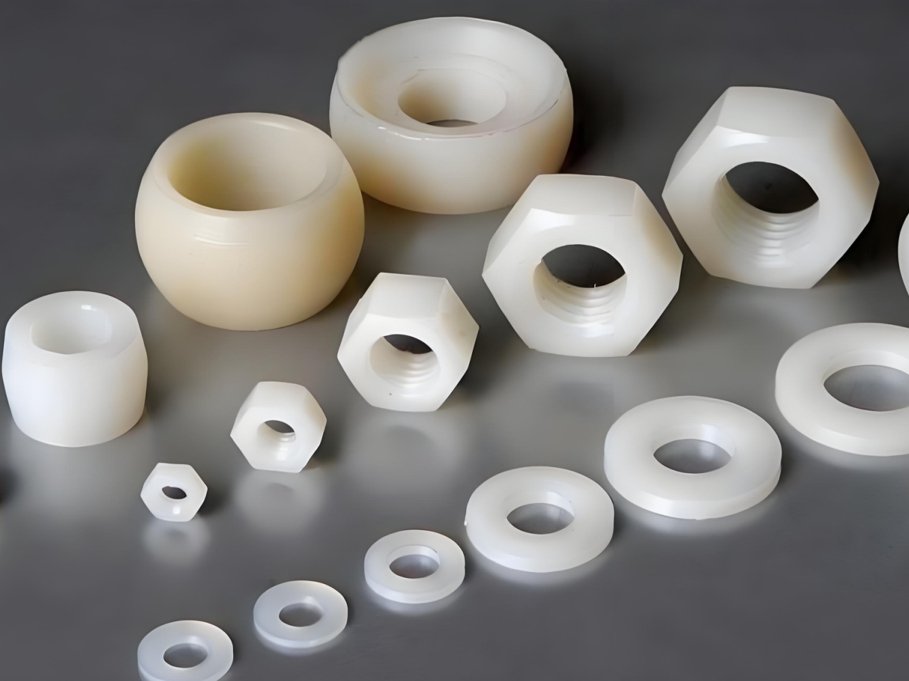

Plastic Molding Materials

We work with a wide range of plastic materials, each offering unique properties to meet specific application requirements.

Thermoplastic

- PE, Polyethylene

- PP, Polypropylene

- PVC, Polyvinyl Chloride

- PS, Polystyrene

- PU, Polyurethan

- PC, Polycarbonate

- ABS, Acrylonitrile Butadiene Styrene

- PTFE, Polytetrafluoroethylene

- TPE, Thermoplastic Elastomer

Thermosets

- EP, Epoxy Resin

- PF, Phenolic Resin

- UP, Unsaturated Polyester Resin

- MF, Melamine Formaldehyde Resin

- PUR, Polyurethane

- Melamine Resin

Elastomers

- TPU, Thermoplastic Polyurethane Elastomer

- TPO, Thermoplastic Olefin Elastomer

Biodegradable Plastics

- PLA, Polylactic Acid

- PCL, Polycaprolactone

- PHA, Polyhydroxyalkanoates

- PV, Polyvinyl Alcohol

- PB, Polybutylene Succinate

- PBA, Polybutylene Adipate Terephthalate

Engineering Plastics

- PEEK, Polyetheretherketone

- PPS, Polyphenylene Sulfide

- PI, Polyimide

- PA, Polyamide, Nylon

- POM, Polyoxymethylene, Acetal

- PET, PBT, Polyester

Composite

- GFRP, Glass Fiber Reinforced Plastic

- CFRP, Carbon Fiber Reinforced Plastic

- Flame-Retardant Materials

- Medical-Grade Plastics

- Food-Grade Plastics

- Conductive Plastics

Material Selection Guide

| Material | Key Properties | Typical Applications | Max Temp (°C) |

| ABS | Good impact resistance, rigid, easy to machine | Consumer goods, automotive parts, enclosures | 80-100 |

| Polycarbonate (PC) | High impact strength, transparent, good heat resistance | Safety glasses, medical devices, electrical components | 120-130 |

| Nylon (PA6/66) | High strength, good wear resistance, oil resistant | Gears, bearings, automotive parts, fasteners | 100-120 |

| Acetal (POM) | Low friction, high stiffness, good dimensional stability | Gears, bearings, precision mechanical parts | 100-120 |

| PEEK | Excellent heat resistance, chemical resistance, high strength | Aerospace components, medical implants, high-performance parts | 260-280 |

Surface Finishing for Plastic Parts

Enhance the appearance, performance, and durability of your plastic components with our comprehensive surface finishing options.

Painting & Coating

High-quality painting and coating services to improve aesthetics, provide color coding, and enhance chemical resistance.

✅ Custom color matching

✅ Textured and matte finishes

✅ UV-resistant coatings

✅ Anti-microbial coatings

Metallization

Application of metal coatings to plastic parts for decorative purposes, EMI (Electromagnetic Interference) shielding, or conductivity.

✅ Chrome plating

✅ Electroplating (nickel, copper, chrome)

✅ Vacuum metallization

✅ Electroless plating

Polishing & Buffing

Precision polishing to achieve high-gloss surfaces or smooth finishes for improved aesthetics and functionality.

✅ High-gloss polishing

✅ Matte finishing

✅ Micro-finishing

✅ Deburring and edge rounding

Pad Printing & Labeling

Application of logos, text, images, and graphics to plastic parts for branding, identification, and instructions.

✅ Multi-color pad printing

✅ UV-cured ink printing

✅ Label application

✅ Barcode and QR code printing

Protective Coatings

Specialized coatings to enhance durability, chemical resistance, and performance in harsh environments.

✅ Hard coatings for abrasion resistance

✅ Chemical-resistant coatings

✅ Waterproofing treatments

✅ Anti-fog and anti-static coatings

Texturing & Engraving

Creation of surface textures and precision engraving for improved grip, aesthetics, or functional purposes.

✅ Custom texture patterns

✅ Laser engraving

✅ Etching for part identification

✅ Knurling for improved grip

Enhancing Your Plastic Components

The right surface finish can transform a basic plastic part into a high-performance component that meets both functional requirements and aesthetic expectations. Our finishing experts can recommend the optimal solution based on your specific application needs. solution that grows with your needs.

- Improve part durability and extend service life in demanding environments

- Enhance visual appeal and brand recognition with custom colors and finishes

- Add functional properties such as conductivity, chemical resistance, or UV protection

- Meet industry-specific requirements for medical, food, or aerospace applications

Factors That Influence Plastic Part Design

Successful plastic part design requires careful consideration of multiple factors to ensure manufacturability, functionality, and cost-effectiveness.

The chosen manufacturing method significantly impacts design considerations. Injection molding requires different design features than extrusion or 3D printing.

- Wall thickness uniformity

- Draft angles for mold release

- Undercut considerations

Material selection influences design decisions based on mechanical properties, thermal resistance, chemical compatibility, and processing characteristics.

- Strength and impact resistance

- Heat deflection temperature

- Shrinkage rates

The intended function of the part dictates critical design elements such as load-bearing capabilities, dimensional accuracy, and assembly features.

- Load distribution and stress points

- Tolerance requirements

- Assembly with other components

Operating environment influences design choices related to temperature resistance, chemical exposure, UV stability, and moisture resistance.

- Temperature extremes

- Exposure to chemicals or solvents

- Outdoor vs. indoor use

Design decisions impact manufacturing costs through factors like material usage, production complexity, and secondary operations.

- Part consolidation to reduce assembly

- Minimizing complex features

- Optimizing material usage

Industry-specific regulations may dictate design features, material selection, and manufacturing processes for compliance.

- Medical device certifications

- Automotive safety standards

- Food contact compliance

Design for Manufacturability (DFM)

Our engineering team provides comprehensive DFM analysis to optimize your plastic part designs for efficient production, reduced costs, and improved quality. We work closely with you from the initial design phase to ensure manufacturability while maintaining functionality.

- Design Optimization: Recommendations to improve part design for your chosen manufacturing process, including wall thickness, draft angles, and feature placement.

- Material Selection: Expert guidance on material selection based on functional requirements, environmental factors, and manufacturing considerations.

- Cost Reduction: Identification of opportunities to reduce manufacturing costs through design modifications without compromising quality or performance.

Discuss your specific application challenges with our specialists.

Advanced Manufacturing Facility

Our design engineers have extensive experience in plastic part design and manufacturing processes, ensuring your parts are optimized for production.

Key Factors in Process Selection

How to Choose the Right Plastic Production Technique

Selecting the optimal manufacturing process for your plastic parts depends on several key factors, including part design, material, volume, and budget.

Part Complexity

Highly complex parts with intricate details may require injection molding, while simpler shapes can be produced with extrusion or other methods.

Production Volume

High-volume production typically favors injection molding, while low-volume runs may be more economical with CNC machining.

Material Requirements

Certain processes work better with specific materials, with injection molding offering the widest range of material options.

Budget Constraints

Initial tooling costs, production costs per part, and lead times all factor into the overall cost-effectiveness of each process.

Applications of Plastic Parts

Our plastic manufacturing capabilities serve a wide range of industries, delivering custom components tailored to specific application requirements.

Automotive

Custom plastic components for interior, exterior, and under-the-hood applications, providing lightweight solutions with excellent performance.

Interior trim components

Engine compartment parts

Electrical system component

Aerospace

High-performance plastic parts for aerospace applications, meeting stringent requirements for weight, strength, and environmental resistance.

Cabin interior components

Avionics enclosures

Lightweight structural parts

Medical

Medical-grade plastic components manufactured in controlled environments, meeting strict regulatory requirements for safety and biocompatibility.

Medical device components

Diagnostic equipment parts

Surgical instruments

Robotics

Precision plastic components for robotic systems, offering lightweight construction, low friction, and excellent wear resistance.

Gear systems and linkages

End effector components

Structural and housing parts

Industrial Equipment

Durable plastic parts for industrial machinery, providing resistance to chemicals, wear, and harsh operating environments.

Conveyor system components

Hydraulic and pneumatic parts

Protective covers and guards

Electronics

Precision plastic components for electronics and semiconductor manufacturing, offering excellent insulation and dimensional stability.

Enclosures and housings

Semiconductor handling parts

Insulators and spacers

Why Choose Fecision for Plastic Part Production?

Quality Commitment

Our ISO 9001:2015 and ISO 13485 certifications demonstrate our commitment to quality. We implement strict quality control processes throughout production.

Advanced Manufacturing

State-of-the-art production facilities with the latest plastic manufacturing equipment, ensuring precision, efficiency, and consistency.

Engineering Expertise

Our experienced engineering team provides design support, material selection guidance, and DFM analysis to optimize your plastic parts.

Material Expertise

Extensive knowledge of plastic materials and their applications, helping you select the optimal material for your specific requirements.

On-Time Delivery

Efficient production planning and project management ensure we meet your deadlines, with reliable delivery performance.

Customer Collaboration

We work closely with our customers throughout the process, providing transparent communication and tailored solutions.

How to Work with Us

Submit Drawings

For a free quote, please submit a product description along with a technical drawing. We also offer reverse engineering services to assist you.

DFM & Quotation

We will provide a DFM (Design for Manufacturability) report or mold flow analysis report. Please be aware that further discussions may be needed during the process.

Mold Manufacturing

Upon your confirmation to the mold design, our team will begin making mold components, which will then be sent for inspection and assembly.

Plastic Molding

Once the mold is complete, we will initiate the plastic molding process. A T1 sample will be provided for you to check whether the details align with your specifications. After approval we will continue massive production.

Package & Delivery

Your custom-designed plastic parts undergoes thorough inspection, will be carefully packaged, and delivered to you.

Let's Start!

Together, we can make something remarkable!

Let us turn your vision into reality. Provide us with your project details, and we’ll create a customized proposal designed specifically for you.