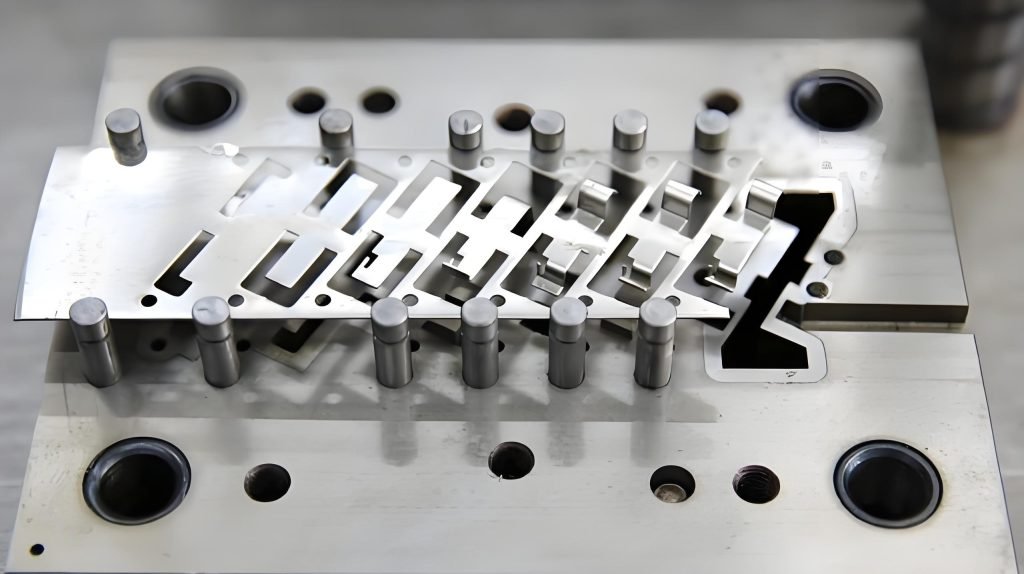

Metal stamping is a crucial process in modern manufacturing, enabling the creation of precise, high-quality components for a wide range of products, from automotive parts to consumer electronics. The backbone of this process is the stamping die, a tool that shapes metal into functional forms. However, the complexity of design requires deep expertise to overcome common challenges that can impact production quality and efficiency.

You need to understand the critical balance between die parameters and production requirements to create robust tooling solutions. This balance is key to delivering consistent quality while minimizing downtime and maintenance costs in your manufacturing operations.

The Critical Role of Stamping Die Design in Manufacturing

Effective stamping die design is the backbone of metal manufacturing processes. As you explore the intricacies of metal stamping, you’ll discover how crucial well-designed dies are for producing high-quality components.

Understanding the Fundamentals of Metal Stamping Processes

Metal stamping enablesthe mass production of precise metal components through controlled deformation of sheet metal materials. The fundamentals involve a series of operations including blanking, piercing, bending, and forming that transform flat sheet metal into three-dimensional components with specific geometrical features.

Modern stamping operations rely on advanced simulation software to predict material behavior, optimize process parameters, and identify potential issues before physical tooling is created. This predictive capability is crucial for achieving the best process, efficiency, and cost for each part, including those stamped from high-yield Dual Phase Steels.

How Effective Die Design Impacts Production Quality and Efficiency

Effective die design directly influences critical production metrics including cycle time, material utilization, part quality, and overall manufacturing efficiency. The relationship between die design and production quality is evident in reduced scrap rates, consistent dimensional accuracy, and improved surface finish of manufactured components.

As manufacturing demands increase for lighter, stronger components, especially in automotive and aerospace industries, die design must evolve to accommodate high-strength materials while maintaining production efficiency. The economic impact of proper die design extends beyond the tooling itself to influence overall production costs, maintenance requirements, and manufacturing flexibility.

5 Common Challenges in Stamping Die Design

Effective stamping die design requires overcoming various hurdles. As you navigate the complexities of metal stamping, you’ll encounter several challenges that can impact production quality and efficiency. Understanding these challenges is crucial for optimizing your die design process.

Die Wear and Premature Tool Failure

Die wear and premature tool failure are significant concerns in stamping operations. These issues often arise from improper material selection, inadequate heat treatment, or excessive stress concentration points in the die design. To mitigate these problems, you should focus on optimizing your die material and design.

Material Thinning and Deformation Issues

Material thinning occurs when metal is stretched too thin during the forming process, potentially leading to weak spots or tears in the finished part. You can address this challenge by controlling metal flow during stamping and optimizing your die design to minimize deformation issues.

Part Repeatability and Dimensional Accuracy Problems

Ensuring part repeatability and dimensional accuracy is critical in stamping die design. Inconsistent material properties, die deflection under load, or improper press setup can lead to components that fail to meet tight tolerance requirements. You should monitor these factors closely to maintain high-quality production.

Spring-back Compensation Difficulties

Spring-back, the tendency of metal to partially return to its original shape after forming, presents a significant challenge in stamping die design. When working with high-strength materials, you need to compensate for spring-back in your die design to achieve the desired part geometry.

Complex Geometries and Multi-stage Operations

Complex part geometries often necessitate multi-stage operations, creating challenges in maintaining material flow and preventing wrinkles. You can overcome these challenges by leveraging advanced die design techniques and simulation software to optimize your stamping process.

By understanding and addressing these common challenges, you can significantly improve your stamping die design, leading to enhanced production efficiency, part quality, and reduced tooling costs.

Engineering Solutions for Optimal Stamping Die Performance

Several key engineering solutions can be leveraged to optimize stamping die performance. By implementing these solutions, you can significantly enhance the quality and efficiency of your stamping operations.

Proper Clearance Design and Its Impact on Part Quality

Proper clearance design between punch and die components is fundamental to achieving clean cuts, reducing burr formation, and extending tool life in stamping operations. You can achieve optimal clearance by carefully balancing the punch-to-die clearance, taking into account the material being stamped and the desired edge quality. For instance, a study on clearance design revealed that optimal clearance can reduce tool wear by up to 30%.

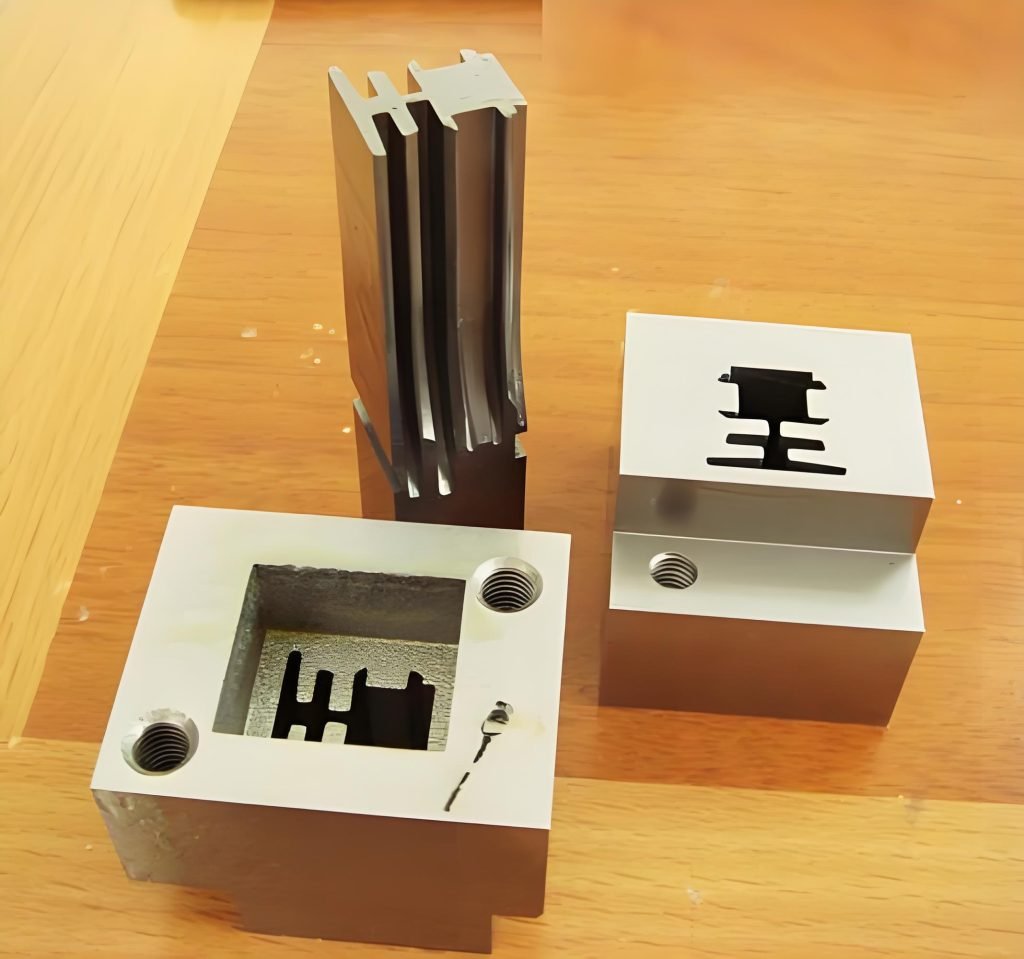

Strategic Material Selection for Dies and Workpieces

Strategic material selection for both dies and workpieces is crucial for optimizing performance and longevity. You should balance hardness, wear resistance, machinability, and cost considerations when choosing materials. For example, using high-strength steel for dies can improve wear resistance, while selecting the right workpiece material can enhance part quality. Simulation software, such as Auto Form, can help determine the feasibility of different materials and designs.

Leveraging Die Simulation Software for Predictive Analysis

Modern die simulation software enables engineers to predict material behavior, identify potential failure points, and optimize die designs before physical tooling is manufactured. By leveraging this technology, you can significantly reduce development time and costs. Simulation is key to the success of tool designs, allowing specialists to determine feasibility, material usage, and required concessions.

Advanced Design Techniques for High-Strength Materials

Advanced design techniques are necessary when working with high-strength materials. You can employ specialized die geometries, optimized draw beads, and strategic blank holder pressure control to manage material flow and prevent defects. Implementing variable clearance designs can also accommodate different material thicknesses and properties within the same die, providing flexibility for multi-material components.

By incorporating these engineering solutions into your stamping die design process, you can achieve optimal performance, improve part quality, and extend tool life. This, in turn, will help you reduce production costs and increase efficiency in your stamping operations.

Maintenance Practices to Extend Stamping Die Lifespan

To maximize the lifespan of your stamping dies, implementing effective maintenance practices is crucial. Regular maintenance not only extends the life of your tooling but also ensures consistent part quality and production efficiency.

Preventive Maintenance Schedules

Implementing structured preventive maintenance schedules tailored to different die types and production volumes is essential. For high-volume production, more frequent maintenance checks are necessary to prevent wear and tear. You should inspect your dies regularly, checking for signs of wear, misalignment, and potential stress points that could lead to premature die failure.

Monitoring and Early Detection

Monitoring systems that track press tonnage, die temperature, and cycle counts provide valuable data for predicting maintenance needs. Early detection of die wear patterns through regular inspection and measurement allows for timely intervention before part quality is compromised.

Refurbishment Strategies

Refurbishment strategies, including regrinding, recoating, and component replacement, can significantly extend die life. At Fecision, we utilize the latest 3D metrology solutions for dimensional analysis and quality control. By adopting these strategies, you can maximize tool life and maintain production continuity.

Conclusion: Achieving Excellence in Stamping Die Design

To optimize your stamping operations, it’s crucial to balance technical requirements with economic considerations. This involves selecting the right die type based on part complexity, production volume, and material properties. By adopting advanced materials, precise CAD/CAM design and simulation analysis, strict quality control, and professional full-lifecycle services, the common challenges abovecan be effectively overcome. Fecision is committed to providing customers with excellent stamping die solutions, helping to stand out in a competitive market and achieve efficient, high-quality production.