Plastic parts made by injection molding often need extra finishing before they are ready to use. There are many surface finish options that change how the parts look, feel, and behave. This finishing is important not just for customers but also for designers and engineers. This is because it affects how the mold is made.

The injection molding surface finish is key to making a good part. It helps the part look nice and work well. A good finish makes the product feel better and seem more valuable and high-quality. Here we will have a complete injection mold surface finish guide to let you understand things better.

Why Use Injection Molding Surface Finishes?

Injection molding surface finish is important to use for multiple reasons. These reasons include:

- Increased Path Aesthetics

Designers and manufacturers use different textures to make parts look nicer. For example, a smooth or matte finish can give the part a clean and polished look. It also hides common problems from injection molding like marks from tools, dents, or lines on the surface. Parts that look good are more attractive to customers and help businesses.

- Improved Functionality of Parts

Surface finishes also help parts work better besides looks.

For example, some designs need a good grip to work properly. Textured finishes on plastic parts make them less slippery and easier to hold. That is why textured surfaces are often used on products where grip is important. Also, textured molds can help trapped gases escape during molding and improving the final part.

Overall, different finishes are used to improve the functionality of different parts.

- Increased Durability

Picking the right finish can protect parts from scratches, wear, and damage from things like sunlight and moisture. This helps the product stay strong and look good for a longer time.

Considerations for Material Selection in Injection Molding

Two important surface features are gloss and matte. These can change depending on the material, ingredients, and how the injection molding process worked.

The type of material matters a lot. For example, parts made with reinforced crystalline resins get shinier and smoother when made at higher melt temperatures. Using a higher mold temperature also makes the surface shinier and smoother for reinforced amorphous resins.

Additives mixed into the plastic also affect the surface. For example, fiberglass makes the surface less shiny. Additives like carbon black or mica can make the surface less rough. This might not be good if you want a certain roughness for how the part works or looks. Adding little particles can make the surface rougher.

Engineers choose the right mix of materials and additives to achieve the required injection molding surface finish for the product.

Available Options for Injection Molding Surface Finishes

There are different types of injection molded parts surface finish options are available out there. Let’s learn the available options for plastic injection molding surface finishes here:

- Grade A: Glossy Finish

Grade A finishes are very smooth and shiny but also the most expensive. Manufacturers use hardened tool steel molds to get this finish and polish with different diamond buffing pastes. This special polishing method creates a surface that doesn’t show clear patterns and reflects light evenly and making it very glossy. These finishes are also popular as Diamond finish, buff finish, or A finish.

Grade “A” finishes are popular to use when you require a smooth and shiny surface for both looks and function.

- Grade B: Semi-Glossy Finish

Semi-gloss finishes help hide marks left by machining, molding, and tools without costing too much. These finishes are made by sanding the surface in straight lines using different grades of sandpaper. This creates a lined pattern.

Semi-gloss finishes look nice and cover up tool marks well. They are often suitable on parts that don’t need to look fancy or be the main focus of the product.

- Grade C: Matte Finish

Grade C finishes are the most affordable and popular. They are polished using fine stone powder. This is why they are sometimes familiar as stone finish. This finish helps parts come out of the mold easily and hides marks from machining. Grade C is also the basic starting point for higher-quality finishes like grades A and B.

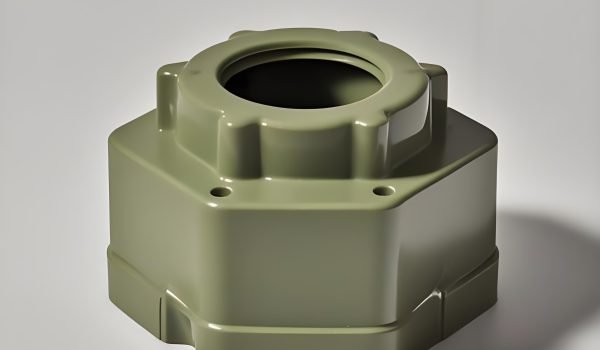

- Grade D: Textured Finish

Grade D finishes are also affordable and common. They start with smoothing the surface using fine stone powder. Then the part is blasted with tiny particles like aluminum oxide or glass beads. This blasting creates a smooth and even finish without any clear patterns.

This textured finish gives a good grip, hides surface flaws, and even hides fingerprints. Grade D finishes are often suitable for industrial thermoset parts and on products that need a dull or satin look.

Key Factors Affecting Injection Molding Surface Finishes

Here are the key factors that can affect injection molding surface finishes:

Material Choice

There are many materials you can use for injection molding. However, not all of them can get the same surface finish. Some plastics are easier to make smooth. While others naturally have a rougher or textured surface.

Things added to the plastic such as fillers or colors can also change how the surface looks and feels. So, picking the right material and additives is important to get the finish you want.

Tooling

The mold used in injection molding is very important for how the surface of part looks. Molds are usually made from metals like steel or aluminum. These metals affect the plastic differently.

Using a hardened tool steel mold is usually the best choice if you want a very smooth and shiny plastic finish. Steel molds help create parts with very low surface roughness. This is ideal for parts that need to look nice.

Functional Reasons

Surface finish can also affect how the part works besides how the part looks.

Some products need a strong grip to work well. Textured finishes help to make the part less slippery and easier to hold. That is why slip-resistant parts often have special textured finishes. Textured surfaces can also make parts stronger and safer to use.

Process Variables

Ways you run the injection molding process can change how the surface looks. For example:

- Injecting the plastic quickly and using a high melt temperature can make the surface shinier and reduce visible weld lines.

- Filling the mold faster also helps hide weld lines which is making the part look better overall.

- Using high mold and melt temperatures together with fast injection gives a smooth and shiny surface finish.

Get Expert Injection Molding and Finishing Support with Fecision!

Injection molding is what Fecision does the best. We work with businesses in many industries to provide reliable molded parts that meet all technical and quality needs. Injection molding is our main service we have been offering for decades. We also help with surface finishing options for your parts as per injection molding surface finish standards.

This means you get strong and accurate injection-molded parts with the choice to add the right surface finish either shiny, matte, semi-gloss, or textured based on what your product needs. We help turn your product ideas into real and finished parts with our skilled team and careful work.