Titanium Machining Services

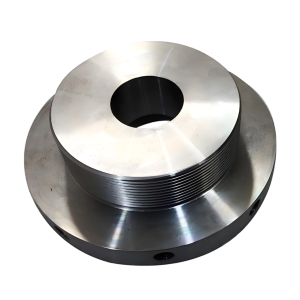

Titanium CNC machining delivers high-precision parts from titanium alloys, known for exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility. Using advanced milling, turning, and drilling, it supports aerospace, medical, automotive, and industrial applications, ensuring tight tolerances, durability, and superior performance in demanding environments.

Various Options

Functionality

Cost-effectiveness

| Specification | Capability | Details |

| Dimensional Tolerance | ±0.001″ – ±0.005″ | Precision varies based on part complexity and size |

| Surface Finish | 16-125 RMS | Customizable based on application requirements |

| Maximum Part Dimensions | Up to 24″ × 16″ × 10″ | Larger parts possible with multi-setup machining |

| Minimum Feature Size | 0.010″ | Dependent on aspect ratio and material grade |

| Maximum Weight | Up to 500 lbs | Specialized fixturing available for heavy components |

| Production Volume | Prototypes to 10,000+ units | Optimized processes for both low and high volumes |

Understanding Titanium in CNC Machining

Titanium has become the material of choice for high-performance applications across multiple industries due to its exceptional properties. However, these same properties present unique challenges in the machining process that require specialized expertise and equipment.

Key Properties of Titanium

- Exceptional strength-to-weight ratio – 40% lighter than steel with comparable strength

- Outstanding corrosion resistance – Naturally forms a protective oxide layer

- Biocompatibility – Non-toxic and not rejected by the human body

- Low thermal conductivity – Retains heat at the cutting zone

- High temperature resistance – Maintains strength at elevated temperatures

- Low modulus of elasticity – More flexible than steel

Expert Titanium Machining for Your Critical Applications

With decades of experience machining titanium components, our team delivers precision parts that meet your exact specifications.

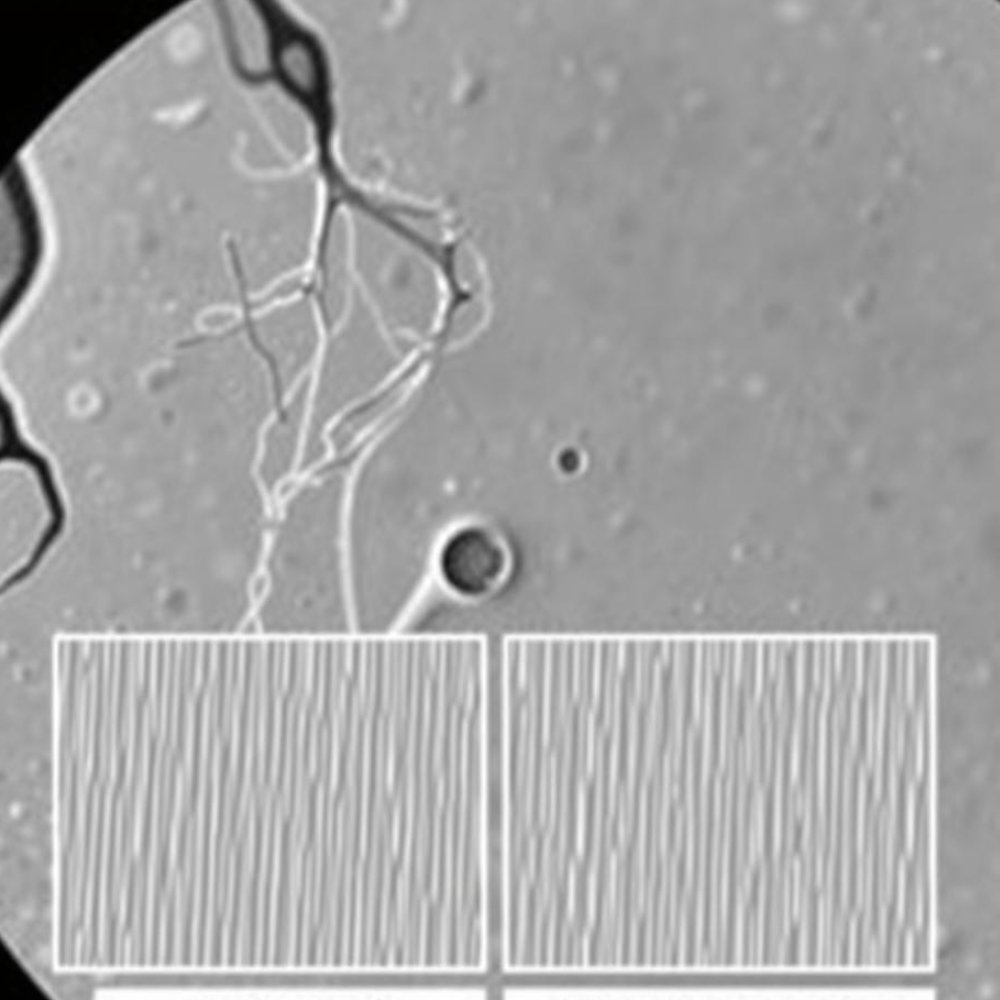

Titanium Machining Challenges & Solutions

Strengths of Titanium

Superior corrosion resistance in harsh environments

Exceptional strength-to-weight ratio for lightweight applications

Biocompatibility for medical implants and devices

Non-magnetic properties for specialized applications

Excellent fatigue resistance for cyclical loading

Machining Challenges

Low thermal conductivity causes heat buildup at cutting edge

Work hardening during machining increases tool wear

Chemical reactivity with cutting tools at high temperatures

Spring-back effect due to elasticity requires special tooling

Higher tooling costs and longer machining times

Our specialized approach includes high-pressure coolant systems, optimized cutting parameters, rigid fixturing, and specialized tooling designed specifically for titanium alloys. This comprehensive strategy ensures consistent quality while maximizing tool life and production efficiency.

Titanium Grades for CNC Machining

Fecision works with all commercially available titanium grades and alloys.

Our expertise allows us to recommend the optimal titanium grade based on your application requirements, balancing performance needs with cost considerations.

TA1

Grade 1

- Characteristics: Low strength, high ductility and corrosion resistance; good formability

- Common Applications: Chemical process, heat exchangers, marine, medical

Tensile Strength (MPa)

Yield Strength (MPa)

Fatigue Strength (MPa)

Hardness (Brinell)

Elongation at Break (%)

Density (g/cm³)

Maximum Temp (°C)

≥345

≥240

≈140–170

≈4.50

≥30

≈4.50

≈300–350

TA2

Grade 2

- Characteristics: Medium strength, good balance of strength/ductility/corrosion

- Common Applications: Chemical, marine, power gen., heat exchangers

Tensile Strength (MPa)

Yield Strength (MPa)

Fatigue Strength (MPa)

Hardness (Brinell)

Elongation at Break (%)

Density (g/cm³)

Maximum Temp (°C)

≥450

≥345

≈170–200

≈130–160

≥25

≈4.50

≈300–350

TA4

Grade 4

- Characteristics: Higher strength than CP Ti; good weldability; limited cold formability

- Common Applications: Structural components, fasteners, filler wire

Tensile Strength (MPa)

Yield Strength (MPa)

Fatigue Strength (MPa)

Hardness (Brinell)

Elongation at Break (%)

Density (g/cm³)

Maximum Temp (°C)

≈550–650

≈450–550

≈200–250

≈150–190

≈15–20

≈4.50

≈400–450

TC4

Ti-6Al-4V

- Characteristics: High strength, good fatigue and fracture toughness; wide use

- Common Applications: Aerospace structures, medical implants, sports goods

Tensile Strength (MPa)

Yield Strength (MPa)

Fatigue Strength (MPa)

Hardness (Brinell)

Elongation at Break (%)

Density (g/cm³)

Maximum Temp (°C)

≥900

≥825

≈300–350

≈220–260

≥10

≈4.51

≈350–400

TC6

Ti-6Al-2Mo-2Cr

- Characteristics: Medium-high strength, good hardenability, wear resistance

- Common Applications: Landing gear, engine components, forgings

Tensile Strength (MPa)

Yield Strength (MPa)

Fatigue Strength (MPa)

Hardness (Brinell)

Elongation at Break (%)

Density (g/cm³)

Maximum Temp (°C)

≈950–1050

≈850–950

≈300–350

≈240–280

≈8–12

≈4.52

≈350–400

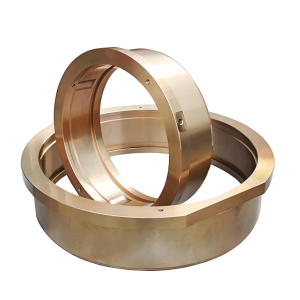

Titanium CNC Machining Surface Finishing Options

Surface finishing plays a crucial role in both the aesthetics and functionality of titanium components.

Fecision offers a comprehensive range of surface finishing options to meet your specific requirements.

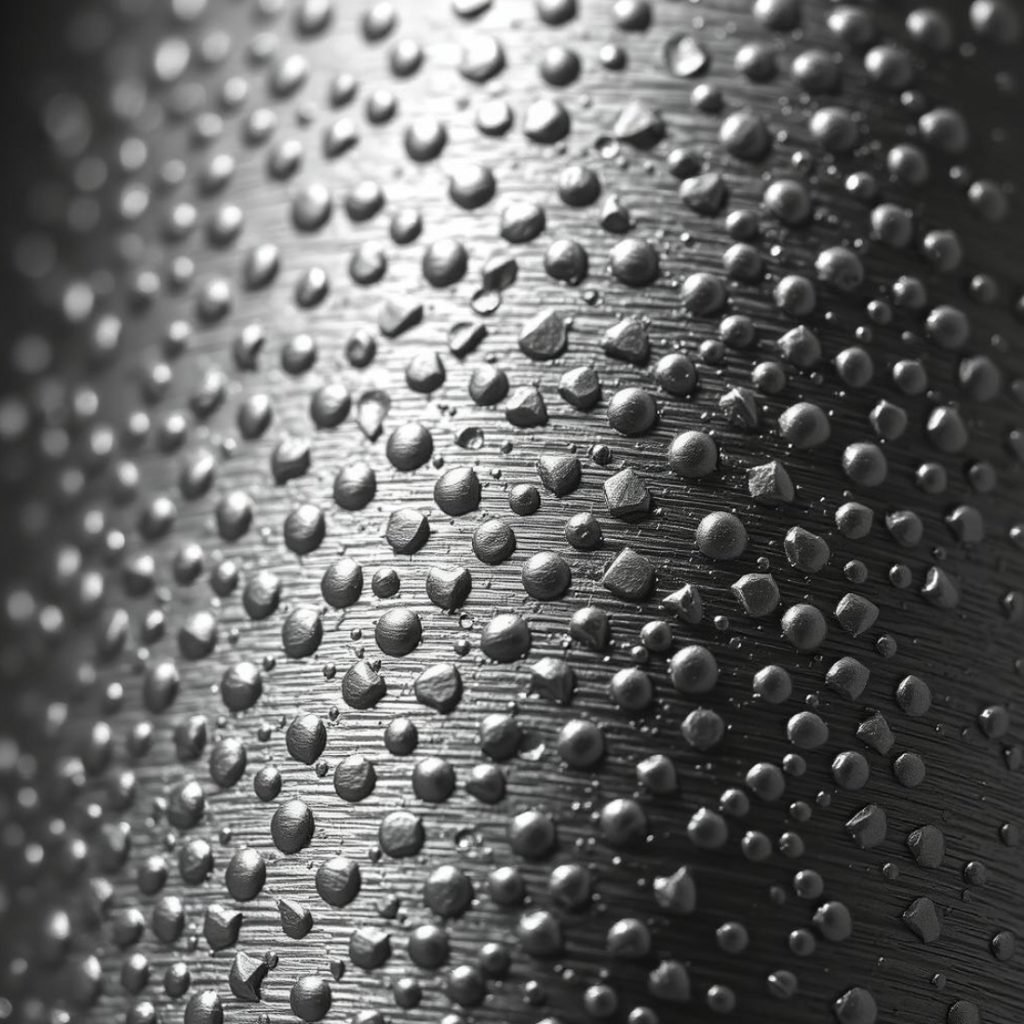

Bead Blasting

Creates a uniform matte finish by propelling fine glass beads at high pressure against the titanium surface. Ideal for removing machining marks and creating a consistent appearance.

Anodizing

Electrochemical process that creates a controlled oxide layer, offering both decorative coloring options and enhanced surface hardness. Available in Type II (thin film) and Type III (thicker, more durable).

Electropolishing

Produces a mirror-like finish by removing a microscopic layer of material through an electrochemical process. Reduces surface roughness and improves corrosion resistance.

Passivation

Chemical process that removes free iron and other contaminants from the surface while enhancing the natural oxide layer. Improves corrosion resistance without dimensional changes.

Mechanical Polishing

Achieves smooth surfaces through progressive abrasive processes. Can range from satin finishes to high mirror polish depending on the application requirements.

Laser Marking

Creates permanent, high-contrast markings without affecting the material properties. Ideal for part identification, serialization, and branding on medical and aerospace components.

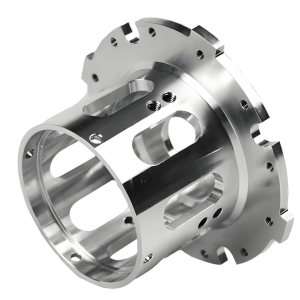

Titanium CNC Machining Application

Industries We Serve

Titanium's unique combination of properties makes it invaluable across numerous industries. At Fecision, we produce precision titanium components for the most demanding applications where performance, weight, and reliability are critical.

Medical & Dental

Prosthetics & surgical instruments

Medical device components

Custom surgical guides

MRI-compatible equipment

Aerospace & Defense

Engine components & turbine blades

Landing gear components

Hydraulic systems

Satellite & spacecraft parts

Automotive & Racing

Connecting rods and fasteners

Exhaust systems

Suspension components

Turbocharger wheels

Industrial & Chemical

Pump components and valves

Offshore and marine equipment

Specialized fasteners

Pressure vessels

Titanium Machining FAQs

Request a Quote for Titanium CNC Machining

Our technical team is available to discuss your titanium CNC machining requirements and provide immediate assistance.

Start Your Titanium Machining Project Today

Contact our titanium machining specialists to discuss your project requirements.