In the world of precision machining, a staggering 70% of mechanical components rely on threaded connections for assembly and functionality. One crucial aspect of this process is the creation of threaded holes, also known as tapped holes, where internal threads are carefully cut into a pre-drilled hole. This technique is fundamental to ensuring strong and reliable fastening in various industrial applications.

Understanding the machining process involved in creating these threads is essential for manufacturers and engineers. By grasping the techniques and best practices for tapped holes, you can optimize your manufacturing process and improve the overall quality of your products. Whether you’re working with metals or other materials, the precision of the threaded hole directly impacts the performance and durability of the final product.

Understanding Tapped Holes in Precision Machining

Definition and Basic Concepts

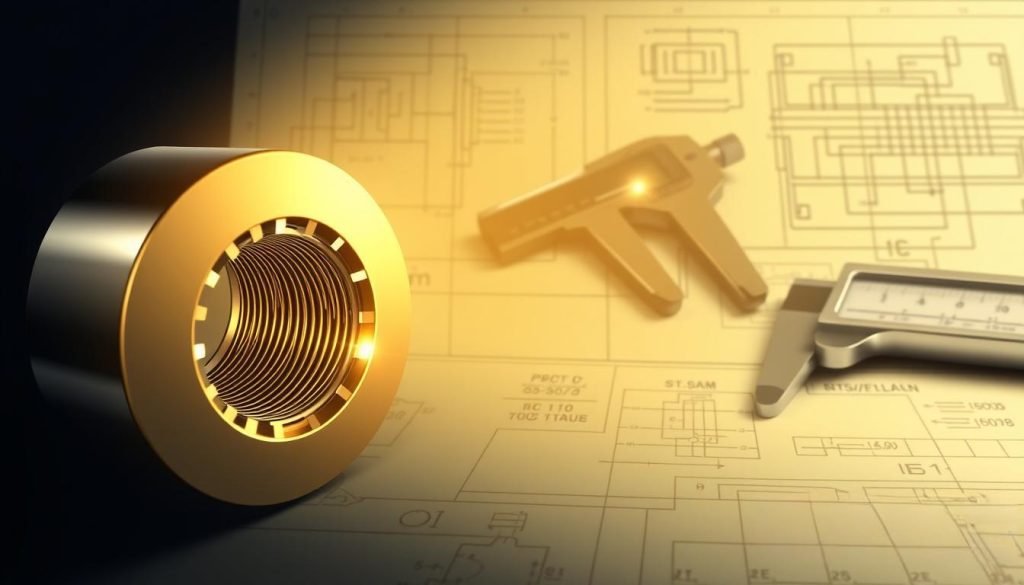

Tapped holes refer to threaded holes that are designed to accommodate fasteners, such as screws or bolts. These holes are created using a tapping process, which involves cutting threads into a pre-drilled hole. The quality of tapped holes directly impacts the overall quality and durability of manufactured products.

The design and creation of tapped holes require careful consideration of factors such as material properties, hole size, and thread type.

The Importance of Tapped Holes in Manufacturing

Tapped holes are fundamental elements in modern manufacturing, serving as the backbone for countless mechanical assemblies. They enable the secure fastening of components, which is essential for product reliability and performance across industries.

The precision-tapped holes contribute to manufacturing efficiency by allowing for repeatable assembly and disassembly operations. Moreover, tapped holes influence product design decisions, enabling engineers to create more compact and efficient mechanical systems.

The quality of tapped holes directly impacts the overall quality and durability of manufactured products. Furthermore, tapped holes facilitate modular design approaches, allowing for easier maintenance, repairs, and upgrades to manufactured products.

Tapped Hole Standards and Specifications

To achieve precision in machining, it’s essential to comprehend the different standards governing tapped holes. These standards ensure that threaded holes are compatible and functional across various applications and industries.

Metric (ISO) Standards

Metric standards, as defined by the International Organization for Standardization (ISO), are widely used globally. These standards specify thread sizes in millimeters, with designations like M6 or M10, indicating the nominal diameter of the thread. The ISO metric thread is characterized by a 60-degree thread angle. This standardization facilitates international trade and cooperation in manufacturing.

Unified Thread Standard (UTS)

The Unified Thread Standard is predominantly used in the United States and Canada. UTS defines thread sizes in inches, with specifications such as 1/4-20 UNC, where 1/4 represents the diameter and 20 represents the threads per inch. The UTS is known for its 60-degree thread angle, similar to ISO standards, but differs in measurement units and thread pitch.

British Standard Whitworth (BSW)

The British Standard Whitworth thread system, one of the oldest standardized thread forms, is still in use today. BSW threads have a distinctive 55-degree thread angle. Sizes like 1/4 BSW (0.250 in or 6.35 mm diameter, 20 threads per inch), 5/16 BSW (0.3125 in or 7.94 mm diameter, 18 threads per inch), and 3/8 BSW (0.375 in or 9.525 mm diameter, 16 threads per inch) are common. BSW threads are significant in legacy equipment and certain industries like railways.

Understanding these standards is crucial for selecting the right fasteners and ensuring compatibility between parts. Each standard has its applications and historical context, influencing their continued use in modern manufacturing.

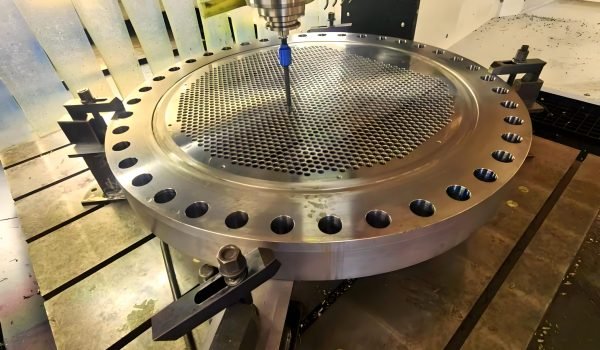

The Process of Creating Tapped Holes

To produce high-quality tapped holes, you must follow a systematic approach that includes preparation and precise tapping. This process is crucial in various manufacturing industries where threaded holes are necessary for assembly or other applications.

Hole Preparation and Sizing

Before tapping, the hole must be properly prepared and sized. This involves drilling a hole of the correct diameter for the tap size you’re using. The hole’s diameter is critical because it affects the tap’s ability to cut threads correctly. Using the right drill bit size ensures that the tap has enough material to work with, resulting in strong, accurate threads.

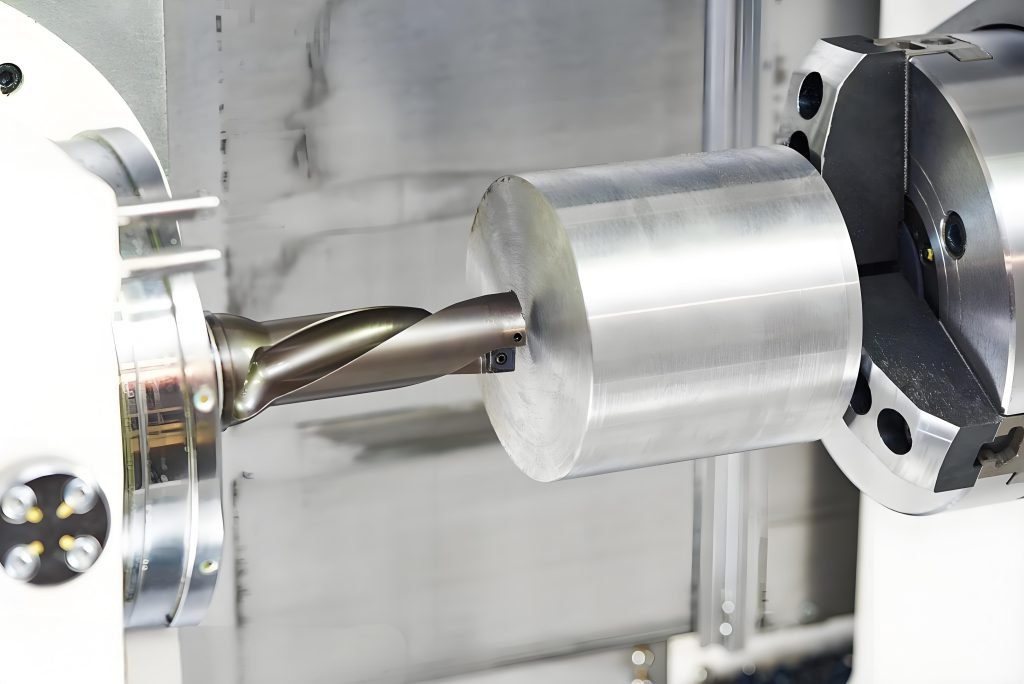

Types of Taps and Their Functions

There are various types of taps, each designed for specific applications. The most common types include hand taps, machine taps, and specialized taps for materials like titanium or stainless steel. Hand taps are used for manual tapping and come in sets that include taper, plug, and bottoming taps. Machine taps are designed for use in machine tools and are typically more robust than hand taps. Understanding the type of tap to use is crucial for the tapping process.

Step-by-Step Tapping Process

The tapping process involves several key steps: lubrication to reduce friction, rotating the tap clockwise to cut threads, removing chips to prevent clogging, checking threads for precision using thread gauges, and further processing the tapped hole by deburring or cleaning. When using tap tools, it’s essential to maintain the correct tapping speed and pressure to achieve optimal thread quality. For blind hole applications, controlling the tap’s depth is critical, whereas through hole tapping requires ensuring the tap doesn’t damage the material on exit.

By following these steps and understanding the nuances of the tapping process, you can achieve high-quality tapped holes that meet your project’s requirements.

Applications of Tapped Holes in Various Industries

Tapped holes play a crucial role in various industries, providing a reliable means of fastening components together. They are essential for ensuring the stability and durability of parts, particularly in applications where heavyweight or vibration is involved.

Automotive and Aerospace Applications

In the automotive and aerospace industries, tapped holes are used to secure critical components, such as engine parts and aircraft structures. The high precision required in these applications demands accurate tapped hole placement, ensuring that parts fit together seamlessly. This precision is crucial for maintaining the safety and performance of vehicles and aircraft.

Electronics and Consumer Products

Tapped holes are also vital in the electronics and consumer products industries, where they are used to assemble and secure various components, such as circuit boards and mechanical parts. The use of tapped holes enables manufacturers to produce compact, lightweight products with complex internal structures. This has led to the development of innovative products with improved functionality and reliability.

Industrial Machinery and Equipment

In industrial machinery and equipment, tapped holes facilitate the assembly, adjustment, and maintenance of complex systems. They enable the secure attachment of wear components, sensors, and controls, ensuring that machinery operates efficiently and safely. Proper tapped hole design is critical in these applications, as it contributes to equipment longevity and reduced maintenance costs.

Tapped Holes vs. Threaded Holes: Understanding the Differences

The terms ‘tapped holes’ and ‘threaded holes’ are often used interchangeably, but they have distinct meanings in the context of machining. Understanding these differences is crucial for selecting the appropriate method for your specific application.

Terminology Clarification

Tapped holes refer specifically to holes that have been threaded using a tap, a tool designed to cut internal threads. Threaded holes, on the other hand, is a broader term that encompasses any hole with internal threads, regardless of the method used to create them. This distinction is important because it affects both the manufacturing process and the final product’s quality.

Creation Methods and Tools

The process of creating tapped holes involves drilling a pilot hole followed by using a tap to cut the internal threads. The initial setup time is relatively fast with tapping, as it requires finding the right size drill bit and tap. In contrast, threading, which can involve CNC machining for more complex threads, requires not only drilling or machining the pilot hole but also setting up the machine to cut the correct size and pitch, potentially involving CNC programming. This makes threading more versatile but also more time-consuming in terms of setup.

When to Use Each Type

Choosing between tapping and other threading methods depends on several factors, including application requirements, production constraints, and material properties. Tapping is often preferred for prototype development, field repairs, or low-volume production due to its simplicity and speed. Thread milling, on the other hand, becomes advantageous for larger hole sizes, harder materials, or when maximum thread strength is required. Understanding these differences will help you make informed decisions for your machining projects.

Advantages and Limitations of Tapped Holes

Precision machining relies heavily on tapped holes, which offer several advantages but also come with certain constraints. As a fundamental component in various manufacturing processes, tapped holes play a crucial role in determining the overall quality and functionality of the final product.

Strength and Durability Benefits

Tapped holes provide significant strength and durability benefits, particularly in applications where high precision is required. The threading process creates a strong and stable connection, allowing for reliable fastening and reduced risk of damage. In CNC machining, the precision of tapped holes ensures that the threads are accurately formed, resulting in a high-quality finish.

Versatility and Adaptability

The versatility of tapped holes is another significant advantage. They can be used in a wide range of materials, from metals to certain plastics, and can accommodate various thread sizes and types. This adaptability makes tapped holes a preferred choice in many industries, including automotive, aerospace, and electronics. Moreover, tapped holes can be used to create blind holes, which are essential in applications where a flush surface is required.

Common Challenges and Limitations

Despite their advantages, tapped holes also present several challenges and limitations. Tap breakage is a common issue, especially when working with hard materials or small tap sizes. To mitigate this, it’s essential to use the correct tapping technique, such as backing off half a turn to break the chip, and having spare taps on hand. Additionally, material limitations, thread stripping, and alignment issues can affect the performance of tapped holes. Understanding these limitations is crucial for optimizing their use in various applications.

Maintenance, Repair, and Best Practices for Tapped Holes

The lifespan of tapped holes can be significantly extended with appropriate maintenance and repair techniques. To ensure their longevity, it’s crucial to clean the chips out of the hole after tapping using compressed air, while wearing eye protection. Checking your threaded hole with an appropriately sized bolt is also essential; it should thread in smoothly.

You can use a tap to clean or repair damage to existing threaded holes, a process known as “chasing.” Regular inspection for wear, damage, or corrosion, and evaluating when repair or replacement is necessary, is vital. By adopting best practices for tapped hole creation, including proper tool selection and lubrication, you can minimize the need for future repairs.

Proper maintenance strategies, including preventive measures for different environments and troubleshooting common issues like cross-threading or fastener seizure, will ensure optimal performance. By following these guidelines, you’ll be able to maintain tapped holes effectively, extending their lifespan and ensuring continued functionality across various applications.