Aluminum dominates modern manufacturing for its lightweight strength, corrosion resistance, and unmatched machinability. When paired with technology, it unlocks precision-engineered components with superior weight-to-strength ratios—ideal for aerospace, automotive, and electronics industries.

This guide dives deep into aluminum CNC machining, revealing best practices for maximizing efficiency, selecting the right alloys (like 6061 vs. 7075), and avoiding common pitfalls. Whether you’re prototyping or scaling production, mastering these techniques ensures high-quality, cost-effective results

What Is Aluminum CNC Machining?

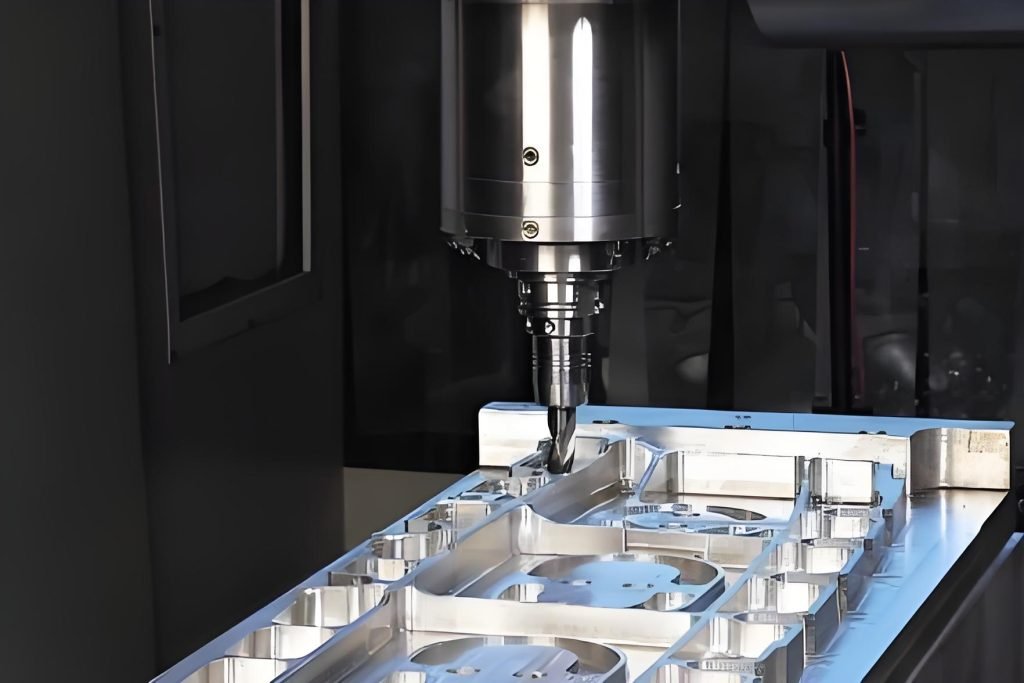

Aluminum CNC machining is the process of precision machining aluminum or aluminum alloy with CNC machine tools. It is an efficient and high-precision processing technology to join automatic control techniques with mechanical processing methods, realizing the combination of various aluminum parts is processed, such as turning, milling, and drilling, or achieve a complex shape and size precision up to fine quality parts, which meet the design requirement.

Aluminum CNC machining is a common method widely used in modern manufacturing. It has superior machinability, allowing manufacturers to create complex shapes via custom aluminum machining, and the accurate size of aluminum parts fully meets production standards.

Benefits of Using Aluminum for CNC Machined Parts

Aluminum is among the leading materials in terms of features, making it ideal for CNC machined aluminum parts due to its attractive combination that enhances production efficiency and part performance. Its main benefits include:

Machinability

Aluminum alloys machine extraordinarily well: they are soft and cut cleanly. CNC tools can cut them quickly and without much power, a fact that greatly reduces costs compared to harder metals like steel. Critically, aluminum does not, to the same extent as many metals when they are being machined on CNC equipment, suffer deformation noticeably greater than any other process stage. This makes it meet very tight tolerances and achieve higher part accuracy.

Strength-to-weight Ratio

With roughly one-third of steel’s density, aluminum is remarkably lightweight. Even though lighter, aluminum is much stronger. The strength of a material, along with its light weight, characterizes this, which we call the material’s strength-to-weight ratio. Thus, aluminum’s high strength-to-weight ratio makes it well-suited for parts needed in a number of industries, including the automotive and aerospace industries.

Corrosion Resistance

Aluminum naturally resists corrosion in standard atmospheric and marine environments by its protective oxide layer. This resistance can be significantly boosted through anodizing. While corrosion tolerance varies between grades, the alloys most frequently CNC machined typically offer excellent inherent protection against rust and degradation.

Performance at Low Temperatures

Unlike many materials, aluminum does not become brittle under sub-zero conditions. Carbon steel and rubber might all break into pieces when subjected to very cold temperatures—aluminum just keeps on going. This stability at cryogenic temperatures makes it ideal for very demanding low-temperature services.

Electrical Conductivity

Pure aluminum boasts high electrical conductivity (approx. 37.7 MS/m at room temperature). While alloys may conduct less, they still provide sufficient conductivity for many electrical components. However, aluminum would be a poor choice if conductivity isn’t a desired feature in the part.

Recyclability

CNC machining’s subtractive nature generates substantial chips. Aluminum’s high recyclability is key here—reclaimed with low energy and cost. This lets manufacturers recoup expenses, minimize waste, and reduce environmental impact.

Anodisation Potential

Anodizing of aluminum is easy and highly effective. Part of the reason is that this electrochemical process considerably increases surface hardness, wear resistance, and corrosion protection, along with providing an excellent foundation for adding durable, vibrant finishes to machined components (aesthetically pleasing ones, too).

Aluminum CNC Machining Processes

There are various CNC machining techniques employed to shape aluminum alloys, each with distinct characteristics. Here are the three main methods.

CNC Turning

CNC turning involves rotating the workpiece while a single-point cutting tool stays fixed along its axis. To remove material, either the tool or the workpiece moves against the other—this depends on the machine. The raw material spins quickly as the turning center shapes it to the desired form.

CNC Milling

CNC milling, as one of the most extensively utilized methods for aluminum parts machining, employs a multi-point cutting tool that rotates around its axis, with the workpiece held fixed along its axis. Material is gradually removed at a controlled rate, often along multiple axes, allowing for high precision.

CNC Drilling

CNC drilling creates holes in aluminum workpieces. A multi-point rotating tool of specific size moves straight and perpendicular to the material’s surface. This process is great for parts needing assembly or spaces for screws and bolts.

Common Aluminum Grades for CNC Processes

Choosing the right aluminum alloy directly affects the quality of the final processing results. Here are several commonly used aluminum alloys in such machining processes, each with its unique properties and suitable applications:

6061 Aluminum Alloy

Other features, such as its weldability, make 6061 ideal for general machinery construction, consumer goods, aerospace applications, and more. It is heat treatable and medium strength with excellent corrosion resistance. Simple machining makes it easy to use, and when annealed, it works particularly well. It is widely used in all kinds of structural parts for aerospace because of its extensive applications and reliable corrosion resistance.

7075 Aluminum Alloy

7075 is the strongest aluminum alloy and has high fatigue resistance. This makes it suitable for high-stress parts. It is the alloy of choice in aerospace for making complex components with aerospace-grade strength. Its corrosion resistance is not as good as that of some other alloys, but it is still better than that of the 2xxx series ones. It’s mainly used in aerospace machining but is versatile enough for most applications.

6063

6063 is similar in composition to 6061 but has silicon and magnesium added to make it more formable—great for complex shapes. It’s weaker than 6061 but brings better corrosion resistance. 6063 can be heat-treated and anodized well, making it ideal for aesthetic or formed parts (including some aircraft usages).

7050

7050 is a high-tensile alloy; it has good resistance to exfoliation corrosion. It is difficult, abrasion-resistant, and machinable. It contains the strength of zinc, copper, and magnesium, but is not suitable for welding. Utilized in bike parts, rock climbing equipment, and aerospace structures.

2024

A budget-friendly, workable alloy with decent strength from copper and magnesium. It machines easily, is heat-treatable, but has poor corrosion resistance (often clad for protection). Found in auto wheels, aircraft parts, and engine components.

5052

A 5xxx series alloy with 2.2-2.8% magnesium, 5052 relies on cold working for strength (no heat treatment). It has good corrosion resistance, weldability, and formability. It is used in fuel tanks, sheet metal, hardware, and electronics.Best Aluminum Alloy for CNC Machining

6061 and 7075 are the best options for aluminum CNC service processes.

6061—The versatile and easy-to-machine alloy features good workability while offering excellent strength, including reliable corrosion resistance, virtually making it a fit for most applications.

7075, with its exceptional strength and ability to handle complex, high-stress parts, excels in demanding CNC work. This is especially true when strength is not up for debate. Together, they meet the most important and common needs in CNC machining better than other grades.

Challenges in Aluminum Machining

Although advantageous, aluminum machining presents a number of challenges because of its unique characteristics and processing requirements. Here are 10 critical challenges to address:

- Material Adhesion (“Gummy Buildup”): Aluminum’s sticky nature causes welding onto tools, especially at high speeds. Use efficient coolants and specialized coatings (like TiCN) to lessen this.

- Thermal Buildup & Dissipation: Its high thermal conductivity concentrates heat at the cutting zone, risking tool fusion, workpiece warping, or melting. Proper coolant application is essential.

- Chip Control Issues: Long, stringy chips can entangle tools, impede evacuation, and cause breakage. Optimize flute design and chip breakers.

- Accelerated Tool Wear: Aluminum’s abrasiveness rapidly dulls tools. Use carbide or diamond-tipped tools and monitor wear consistently.

- Workpiece Softness & Warping: Low rigidity makes aluminum prone to deformation under clamping force or stress. Avoid using too much pressure and use safe, low-distortion fixturing.

- Chatter & Vibration: High spindle speeds combined with aluminum’s low damping capacity induce chatter, harming surface finish. Stabilize setups and optimize cutting parameters.

- Surface Finish Inconsistency: Achieving smooth finishes is difficult due to material softness and built-up edge. Make sure your tools are sharp, use the right feed and speed settings, and keep vibrations under control.

- Holding Tight Tolerances: Dimensional accuracy is challenged by material movement and tool deflection. Robust fixturing, tool rigidity, and process control are key.

- Variable Machinability: Different alloys (e.g., soft/gummy vs. brittle) require precise cutting techniques and tool designs. Familiar with the properties of your alloy.

- Design & Process Complexity: Unnecessary intricate geometries, poor toolpath planning, ignoring tolerances, or sharp internal corners exacerbate other challenges, increasing costs and errors.

Cost remains a factor due to specialized tooling needs and potential scrap from these challenges. Proactive planning addressing adhesion, heat, chip flow, rigidity, and material-specific strategies is crucial for successful aluminum machining. Careful design for manufacturability further optimizes outcomes.

Applications of CNC Machined Aluminum Parts in Industry

The remarkable qualities of aluminum alloys make CNC-machined aluminum parts indispensable in a wide range of industries. The following industries are included.

Aerospace

The aerospace industry is highly dependent on such parts for aircraft fittings, engine components, and wing panels. More than just a weight trimmed from existing parts, these composites are saving mass with strength in order to get them into the air and perform to stringent accuracy requirements for safety and performance.

Automotive Engineering

Electric vehicle parts, suspension systems, and engine components are made from aluminum. Lightweight properties provide weight reduction for the vehicle, and durability promises longevity of performance that needs to withstand daily drivers all the way through high-performance models.

Electronics

Aluminum’s sleek design and usefulness are good for this industry. It makes cases for tablets, smartphones, and laptops that protect the inside parts without adding weight. It also cools down cameras and stops vibrations in high-end audio gear like amplifiers.

Medical Devices

Precision-machined aluminum is used for surgical tools and diagnostic instruments in this field, where accuracy is non-negotiable.

Defense Sector

It counts on aluminum parts for lightweight yet tough components in military vehicles and weapons systems.

Marine Applications

Aluminum is perfect for producing parts for ships and other marine vessels because of its exceptional resistance to corrosion.

Food and Pharmaceutical Industries

They value aluminum’s non-reactivity with organic substances, making it ideal for processing machinery.

3D Printing and Prototyping

Even 3D printing equipment and rapid prototyping rely on aluminum’s easy machinability to create high-precision parts quickly.

Conclusion

Aluminum CNC machining is not only a part of the foundation for modern manufacturing but also a basis for fabricating indispensable parts in different industrial sectors. It does a great job in taking advantage of many unique properties, such as the superior machinability, excellent corrosion resistance, and high strength-to-weight ratio that aluminum has, and maximizes the value these parts provide to their end applications, making this process essential.

At Fecision. We blend extensive material expertise with advanced manufacturing to deliver exactly what you need, including top-tier aluminum CNC machining service:

- All-round Processes: Mastering turning, milling, drilling, turn-milling, and laser cutting.

- Top-grade Materials: Specializing in aluminum alloys like 6061, 6063, 7075, 7050, 2024, and 5052, with 6061 and 7075 as premier choices.

- Quick Lead Time: Prototypes ready in 1-5 business days, with lead times flexibly adjusted based on part complexity, material, machine availability, finishes, and order volume.

- Pinpoint Tolerances: Standard tolerances within ±0.005 inches (±0.127 mm) to ±0.01 inches (±0.254 mm); precision tolerances as tight as ±0.0001 inches (±0.0025 mm). For projects without drawings, follow ISO 2768 medium standards.

- Excellent Finishes: Sharp edges are softened and deburred by default. Surface finishes hit Ra12.5μm to Ra1.6μm for general processes, with additional options to achieve higher precision.

- Versatile Axes: Supporting 2-axis, 3-axis, 4-axis, and 5-axis movement.

Ready to turn your designs into flawless parts? Reach out to Fecision today—let’s craft a tailored solution that gets your project moving faster than ever.