Did you know that nearly 75% of product development costs are determined during the design phase? This is where Finite Element Analysis (FEA) comes into play, allowing engineers to simulate and analyze the behavior of complex structures under various conditions.

As an engineer working with intricate machining parts, you’re likely no stranger to the challenges of optimizing designs without incurring significant costs or time. FEA is a powerful computational technique that breaks down complex systems into smaller, manageable elements to understand their behavior under real-world forces and stresses. By leveraging FEA software, such as SimScale’s cloud-native platform, you can perform structural analysis directly in your web browser, streamlining your design process and reducing the need for physical prototypes.

This technique has revolutionized the engineering design process, enabling the virtual testing of multiple design iterations and saving both time and resources. By adopting FEA, you can bridge the gap between theoretical principles and practical applications, leading to more innovative, efficient, and reliable product development.

Understanding Finite Element Analysis (FEA)

You can leverage Finite Element Analysis (FEA) to predict how products or structures will react under various conditions. This powerful tool has become indispensable in modern engineering, allowing you to simulate and analyze complex systems with a high degree of accuracy.

Definition and Basic Concepts

Finite Element Analysis is a computational method that involves breaking down a complex problem into smaller, more manageable parts called finite elements. By analyzing the behavior of these elements, FEA can simulate the overall behavior of the system, providing valuable insights into stress, strain, and other physical phenomena.

The basic concepts of FEA include the use of nodes, elements, and degrees of freedom to represent the physical system. Understanding these concepts is crucial for applying FEA effectively in engineering design and analysis.

The History and Evolution of FEA

The history of FEA dates back to the work of mathematicians like Euler in the 16th century, with significant mathematical contributions appearing in the 19th and 20th centuries. The practical development of FEA began in the mid-20th century, driven by the need to solve complex structural mechanics problems in aerospace and civil engineering.

Over time, FEA has evolved from a method for solving simple linear static problems to a sophisticated tool capable of handling complex non-linear, dynamic, and multi-physics simulations. This evolution has been driven by advances in computing power and the development of more sophisticated mathematical methods.

What is FEA and Why is it Important?

As engineering challenges grow in complexity, FEA emerges as a critical tool. You can leverage Finite Element Analysis to virtually test and validate your designs, ensuring they meet stringent performance and safety criteria.

The Fundamental Purpose of Finite Element Analysis

The primary purpose of FEA is to enable engineers to simulate and analyze the behavior of complex systems under various conditions. By breaking down these systems into smaller, manageable elements, FEA facilitates a deeper understanding of how different components interact and respond to external forces.

You can utilize FEA software, such as SimScale’s FEA component, to choose the level of accuracy that best fits your needs, ranging from high-fidelity modeling to quick trend predictions.

The Role of FEA in Modern Engineering

FEA has transformed the engineering landscape by becoming an integral part of the design process across virtually all disciplines. It allows you to validate designs against multiple performance criteria, optimize manufacturing processes, and predict material behavior during various operations.

The integration of FEA with CAD systems has streamlined workflows, enabling designers to assess design changes quickly. Moreover, FEA plays a crucial role in reducing time-to-market by identifying potential issues early in the design process.

Modern cloud-based FEA solutions have made powerful analysis tools accessible to even smaller engineering teams, democratizing simulation capabilities without requiring significant hardware investments.

The Science Behind Finite Element Analysis

At its core, FEA is a numerical method that uses mathematical models to analyze complex systems. You will find that understanding the science behind FEA is crucial to appreciating its capabilities and limitations.

Mathematical Foundations: Partial Differential Equations (PDEs)

Finite Element Analysis relies on mathematical models of physical phenomena, such as heat conduction and elastostatics, which are described by partial differential equations (PDEs) with initial and boundary conditions. These PDEs are also known as the Strong Form of the problem.

The Strong Form demands a high degree of smoothness for the solution, meaning the second derivative of the displacement must exist and be continuous. This requirement poses challenges, especially with complex geometries and varying material parameters.

From Strong Form to Weak Form: The Mathematical Transformation

A critical step in the FEA process is transforming the governing differential equations from their “strong form” to a “weak form” that is more amenable to numerical solution. The weak form relaxes the strict requirements of the Strong Form, requiring the solution to satisfy the equation only in an average sense over the domain.

This transformation is powerful because it reduces the continuity requirements on the solution, allowing for simpler approximation functions. In structural mechanics, the weak form corresponds to the principle of virtual work, which states that for a body in equilibrium, the virtual work of internal forces equals the virtual work of external forces.

The weak form naturally incorporates boundary conditions into the formulation, making it particularly suitable for numerical implementation in finite element analysis.

How Does Finite Element Analysis Work?

At its core, FEA is about simplifying complex problems into a more understandable form through the division of a large system into smaller finite elements. This process allows you to analyze and predict the behavior of complex structures under various conditions.

The FEA Process Step-by-Step

The FEA process involves several key steps. First, you create a finite element model by dividing the geometry into a mesh of small elements. Then, you apply boundary conditions and loads to simulate real-world conditions. The next step is to solve the equations for each element, which gives you the behavior of the individual elements. Finally, you combine these individual results to obtain the overall behavior of the structure.

You need to understand that the accuracy of the FEA results heavily depends on the quality of the mesh. A well-constructed mesh ensures that the results are accurate and reliable. The type of elements used, such as linear or quadratic, and the size of the elements, play a crucial role in determining the accuracy of the results.

Meshing: The Critical Foundation of FEA

Meshing is the process of dividing a continuous geometric model into discrete finite elements. The quality of the mesh is critical to the accuracy of FEA results. A poorly constructed mesh can lead to numerical errors or physically unrealistic results. You must make important decisions about element types, element size, and mesh density, balancing accuracy requirements against computational resources.

Areas with complex geometry or expected high stress gradients typically require a finer mesh to capture the rapid variation in the solution. Modern meshing algorithms can automatically generate meshes with varying element sizes, optimizing computational efficiency. Mesh convergence studies help you determine when the mesh is sufficiently refined to provide accurate results.

Key Components of FEA Simulation

In the realm of Finite Element Analysis (FEA), understanding the key components of a simulation is crucial for accurate results. FEA simulations are complex processes that involve several critical elements to produce reliable and meaningful data.

Elements, Nodes, and Degrees of Freedom

In FEA, the model is discretized into smaller parts called elements, which are connected at nodes. The number of elements and nodes, as well as the degrees of freedom associated with them, play a significant role in determining the accuracy of the analysis. The degrees of freedom refer to the possible movements or displacements that a node can experience.

Boundary Conditions and Loading

Boundary conditions and loading specifications are vital components that define how a model interacts with its environment and the forces it experiences. Boundary conditions constrain the model’s behavior, while loading conditions represent external influences such as forces, pressures, and temperatures. Properly defined boundary conditions are essential to obtain physically meaningful results. Loading conditions can be applied in various forms, including concentrated forces, distributed pressures, and prescribed displacements.

Accurate representation of boundary conditions and loads often requires significant engineering judgment to translate real-world conditions into appropriate mathematical constraints and forces. When solving differential equations, boundary conditions and/or initial conditions need to be provided, and the type of partial differential equation (PDE) will determine the necessary inputs.

Types of Finite Element Analysis

As you explore the capabilities of FEA, you’ll discover several analysis types that cater to diverse engineering needs. Finite Element Analysis is a versatile tool that can be applied in various ways to simulate real-world conditions.

Static Analysis

Static analysis involves evaluating the response of a structure to static loads, providing insights into stress, strain, and deformation. This type of analysis is crucial for understanding how a structure will behave under constant loads, helping engineers ensure that their designs can withstand various forces.

Dynamic Analysis

Dynamic analysis, on the other hand, examines the behavior of structures under time-dependent loads, such as vibrations or impacts. By analyzing how structures respond to dynamic forces, engineers can predict potential failures and optimize their designs for improved performance and safety.

Modal Analysis

Modal analysis is used to determine the natural frequencies and mode shapes of a structure, providing valuable information about its dynamic behavior. This analysis type is essential for avoiding resonance and ensuring that structures can withstand various dynamic loads.

Thermal Analysis

Thermal analysis uses FEA to predict temperature distributions and heat flow within structures subjected to thermal loads. This includes steady-state thermal analysis, which examines equilibrium temperature distributions, and transient thermal analysis, which captures how temperatures change over time. Thermal analysis is crucial for evaluating thermal stresses and designing systems that manage heat effectively.

By understanding the different types of FEA, you can select the most appropriate analysis method for your engineering project, ensuring that your designs are optimized for performance, safety, and efficiency.

Advanced FEA Methodologies

You can now leverage cutting-edge FEA techniques that have been developed to overcome the limitations of traditional methods. Advanced FEA methodologies are designed to provide more accurate and efficient solutions to complex engineering problems.

Extended Finite Element Method (XFEM)

The Extended Finite Element Method (XFEM) is an advancement of the traditional finite element method, allowing for the simulation of discontinuities and singularities without the need for remeshing. This is particularly useful in fracture mechanics and other applications where traditional FEM may struggle. XFEM enriches the approximation space with discontinuous functions, enabling the modeling of complex geometries and crack propagations.

Generalized Finite Element Method (GFEM)

The Generalized Finite Element Method (GFEM) enhances the traditional FEM by incorporating additional enrichment functions into the finite element space. This allows GFEM to handle problems with high gradients or singularities more effectively. GFEM is particularly useful for problems involving multiple scales or complex material behavior, providing a more flexible and accurate analysis.

Discontinuous Galerkin FEM (DG-FEM)

The Discontinuous Galerkin Finite Element Method (DG-FEM) represents a hybrid approach that combines features of finite element and finite volume methods. Unlike standard FEM, DG-FEM allows for discontinuities at element interfaces, with weak enforcement of continuity through penalty terms or numerical fluxes. This method is particularly well-suited for hyperbolic problems, such as wave propagation, and offers advantages in handling complex geometries and supporting local mesh refinement.

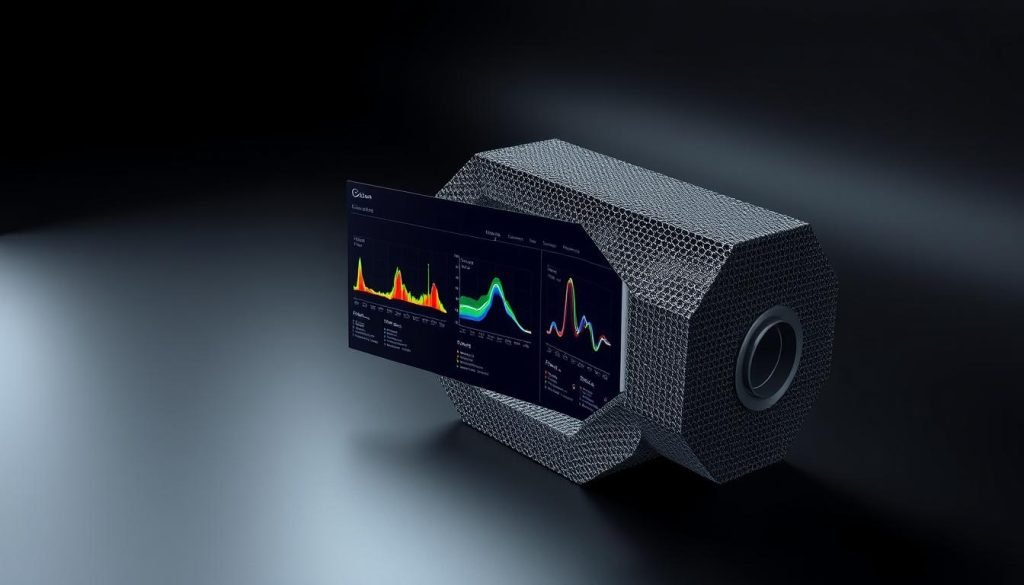

Finite Element Analysis Software Solutions

Finite Element Analysis (FEA) software has become an indispensable tool for engineers, offering a range of solutions for complex simulation tasks. You can choose from various software packages, depending on your specific needs and the type of analysis you want to perform.

Commercial FEA Software Packages

Commercial FEA software packages, such as ANSYS and Abaqus, offer comprehensive solutions for complex simulations. These tools provide advanced features, including robust meshing capabilities, various element types, and sophisticated solver technologies. They are widely used in industries like aerospace, automotive, and civil engineering.

Commercial FEA software often comes with user-friendly interfaces, extensive documentation, and dedicated customer support, making it easier for engineers to get started and resolve issues.

Open-Source FEA Tools

Open-source FEA tools provide accessible alternatives to commercial packages, offering powerful simulation capabilities without licensing costs. Popular options include Code_Aster, Calculix, FEniCS, and Elmer, each with different strengths in terms of supported physics, element types, and solver capabilities.

These tools typically require more technical expertise to implement effectively, as they often lack the polished user interfaces and integrated workflows of commercial packages. However, they are particularly valuable for academic research, startups with limited budgets, and organizations looking to customize or extend simulation capabilities.

Applications and Use Cases of FEA

FEA’s ability to simulate real-world conditions makes it an indispensable method in modern engineering, with applications spanning multiple disciplines. You can leverage FEA to optimize designs, predict material behavior, and streamline manufacturing processes.

Aerospace and Automotive Engineering

In aerospace and automotive engineering, FEA is used to analyze structural integrity, simulate crash tests, and optimize component design. This helps in developing lighter, stronger, and more fuel-efficient vehicles and aircraft.

Civil and Structural Engineering

FEA is applied in civil and structural engineering to assess the stability of buildings, bridges, and other infrastructure under various loads. It aids in designing structures that can withstand natural disasters and last longer.

Biomedical Applications

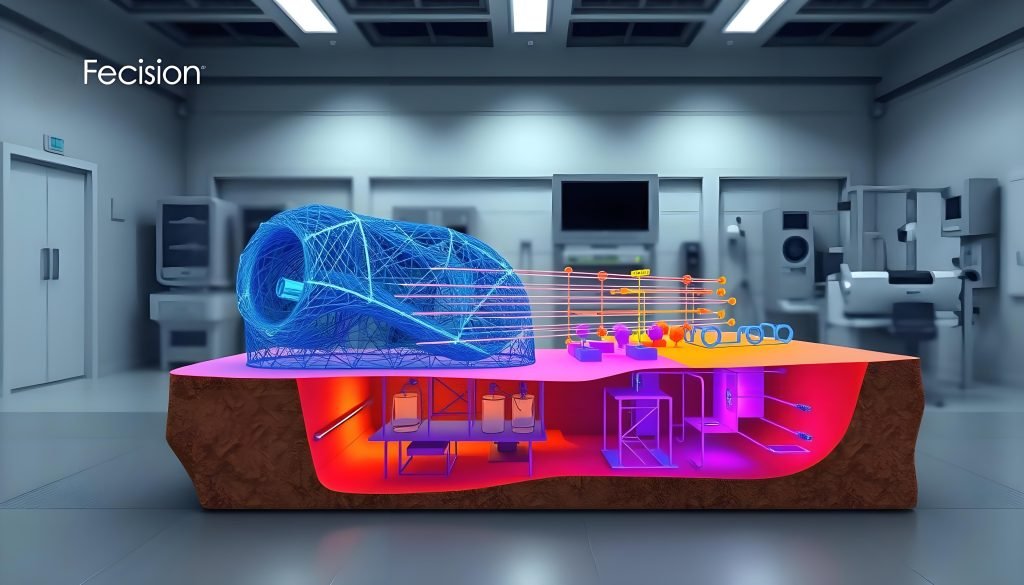

In biomedical engineering, FEA helps in simulating the behavior of medical devices, implants, and biological tissues. This leads to the development of more compatible and effective medical solutions.

Manufacturing and Product Development

You can utilize FEA in manufacturing and product development to simulate production processes, predict potential defects, and optimize product designs. This reduces the need for physical prototypes, saving time and costs. By integrating FEA with design optimization algorithms, you can explore a wide range of design possibilities and identify the most efficient solutions.

Conclusion: The Future of Finite Element Analysis

As we look to the future, Finite Element Analysis is poised to play an increasingly vital role in engineering. Advances in computing power, artificial intelligence, and digital technologies will shape the future of FEA, enabling more complex simulations and expanding the range of solvable problems.

With the integration of AI and machine learning, FEA workflows will become more efficient, from meshing to results interpretation. Digital twins will increasingly incorporate FEA to predict performance and maintenance needs. Multi-scale modeling will continue to evolve, connecting microscale to macroscale simulations.

These developments promise faster design cycles, optimized components, and greater confidence in product performance. As FEA becomes more accessible, its importance for engineers will only continue to grow, making it a critical tool for the industry.